High temperature pressure measurement method and sensor for impulse knocking engine based on ion current

A pressure sensor and pulse detonation technology, applied in the field of pressure measurement, can solve the problems of two-pole contact conduction, short probe poles, and short distance between poles, etc., and achieves strong engineering applicability, stable and effective ion current, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

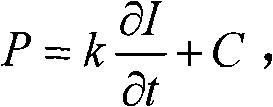

[0032] In order to obtain k and C, with acetylene as fuel and air as oxidant, the chemically proper ratio Bias voltage U=10V, carry out single knock test, select 50 data points in 16 tests for analysis,

[0033] Establish the relationship table between the pressure peak value and the ion current decay speed in Table 1. The decay rate of the ion current is defined as the ratio of the peak value of the ion current to the decay time of the ion current. Due to space limitations, some data are listed here.

[0034] Table 1 Measured value of pressure sensor / peak value of ion current / decay time of ion current

[0035]

[0036] Using the above 50 sets of data, the least square algorithm is used to fit the formula (8) with a straight line, and the result is C=3.005, k=1.254, so as to obtain the relational expression between the pressure in the detonation tube and the decay speed of the ion current

[0037] P = 1.254 + ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com