Aliphatic acid zinc soap rubberlike internal releasing agent

A technology of fatty acid zinc soap and internal release agent, which is applied in the field of rubber additives, can solve the problems of environmental pollution and high cost in the workshop, and achieve the effects of improving the qualified rate of finished products, improving sliding, and improving mold release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

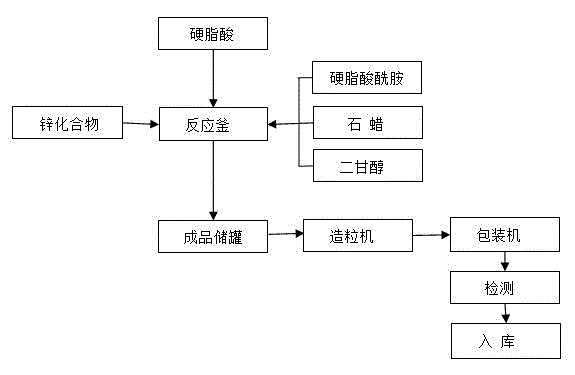

Image

Examples

Embodiment 1

[0022] A kind of fatty acid zinc soap type rubber internal release agent, comprises according to the raw material of quality: stearic acid 450kg, zinc compound 28kg, stearic acid amide 370kg, paraffin 95kg and diethylene glycol ether 8kg; Described stearic acid is stearic acid A mixture of fatty acid 1840, stearic acid 1825 and stearic acid 1810; the zinc compound is a mixture of zinc oxide and zinc hydroxide; the paraffin is a mixture of microcrystalline paraffin, solid paraffin, chlorinated paraffin, polyethylene wax .

[0023] The preparation method of described fatty acid zinc soap type rubber internal release agent, comprises the following steps:

[0024] (1) Put in stearic acid: put 450kg of stearic acid in a 2000L stainless steel reactor, heat it, and start stirring slowly after the stearic acid is partially melted;

[0025] (2) Add zinc compound: when the temperature of stearic acid in the reactor reaches 110°C, add 28kg of zinc compound, and then add water with 4% of...

Embodiment 2

[0031] A kind of fatty acid zinc soap type rubber internal release agent, comprises according to the raw material of quality: stearic acid 550kg, zinc compound 25kg, stearic acid amide 450kg, paraffin 90kg and diethylene glycol ether 8kg; Described stearic acid is stearic acid Fatty acid 1840; the zinc compound is zinc oxide; the paraffin is microcrystalline paraffin.

[0032] The preparation method of described fatty acid zinc soap type rubber internal release agent, comprises the following steps:

[0033] (1) Put in stearic acid: put 550kg of stearic acid in a 2000L stainless steel reactor, heat it, and start stirring slowly after the stearic acid is partially melted;

[0034] (2) Add zinc compound: when the temperature of stearic acid in the reactor reaches 120°C, add 25kg of zinc compound, and then add water with 5% of the total amount of stearic acid, that is, 27.5kg of water, to speed up the reaction and improve production efficiency ;

[0035] (3) Add stearic acid ami...

Embodiment 3

[0040] A kind of fatty acid zinc soap type rubber internal release agent, comprises according to the raw material of quality: stearic acid 650kg, zinc compound 40kg, stearic acid amide 430kg, paraffin 100kg and diethylene glycol ether 12kg; Described stearic acid is stearic acid Fatty acid 1825; the mixture of the zinc compound zinc oxide and zinc hydroxide; the mixture of paraffin wax and polyethylene wax.

[0041] The preparation method of described fatty acid zinc soap type rubber internal release agent, comprises the following steps:

[0042] (1) Put in stearic acid: put 650kg of stearic acid in a 2000L stainless steel reactor, heat it, and start stirring slowly after the stearic acid is partially melted;

[0043] (2) Add zinc compound: when the temperature of stearic acid in the reactor reaches 130°C, add 40kg of zinc compound, and then add water containing 6% of the total amount of stearic acid, that is, 39kg of water, to speed up the reaction and improve production effi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com