Novel composite degradable plastic material for injection molding and preparation method thereof

A degradable plastic and a new technology, applied in the field of new composite degradable plastic materials for injection molding and their preparation, can solve the problems of high intrinsic viscosity, poor degradability of plastic materials, low productivity, etc., and achieve high water resistance and heat resistance, and biodegradation. The effect of good performance and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

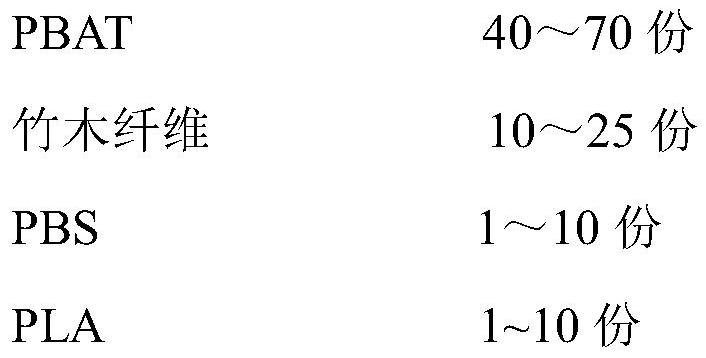

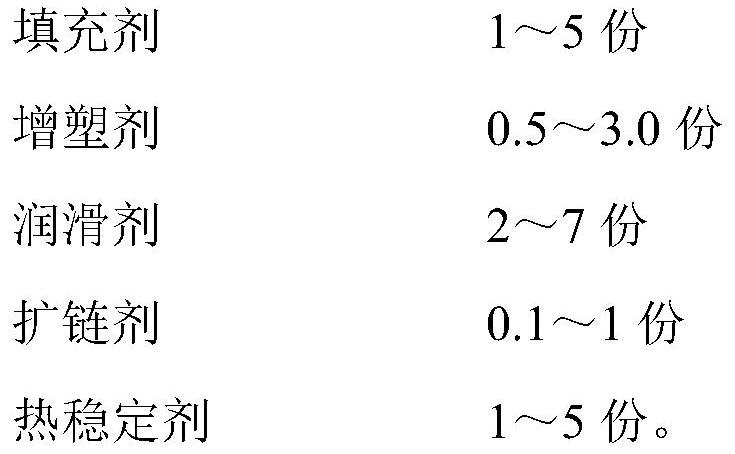

Method used

Image

Examples

Embodiment 1

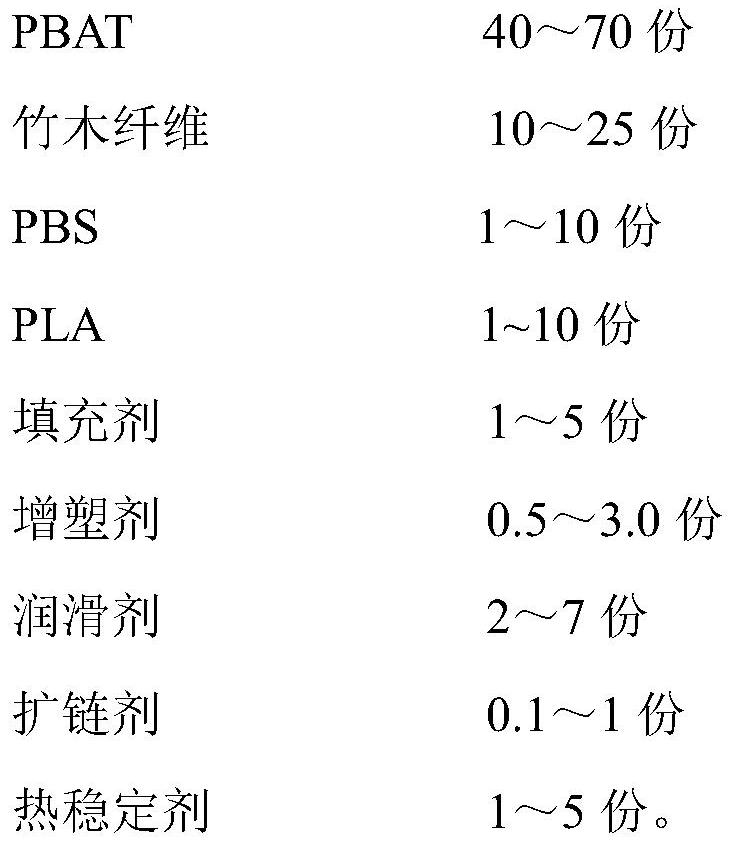

[0034] The novel composite degradable plastic material for injection molding is composed of components in parts by weight of Table 1:

[0035] Table 1 raw material component formula

[0036] type parts by weight / part PBAT 65 PBS 6 PLA 6 bamboo fiber 10 starch 5 glycerin 1.7 stearic acid 3 Isocyanate 0.3 Phenyl diisodecyl phosphite 2

[0037] The preparation method of novel composite degradable plastic material for injection molding comprises the following steps:

[0038] (1) Dry PBAT, PBS, PLA, bamboo and wood fiber at 80°C for 9 hours;

[0039] (2) Bamboo and wood fiber pretreatment: crush the dried bamboo and wood fiber to less than 3mm, mix the bamboo and wood fiber, ammonium sulfate and glycerin according to the mass ratio of 8:1:1, stir and soften at 90°C 20min;

[0040] (3) The pretreated bamboo and wood fiber, PBAT, PBS, PLA, starch, glycerin, stearic acid, isocyanate, phenylene diisodecyl phosphite...

Embodiment 2

[0043] The novel composite degradable plastic material for injection molding is composed of components in parts by weight of Table 2:

[0044] Table 2 raw material component formula

[0045] type parts by weight / part PBAT 60 PBS 7 PLA 7 bamboo fiber 15 talcum powder 4 PEG-400 1.7 white oil 3 Isocyanate 0.3 Phenyl diisodecyl phosphite 2

[0046] The preparation method of novel composite degradable plastic material for injection molding comprises the following steps:

[0047] (1) Dry PBAT, PBS, PLA, bamboo and wood fiber at 80°C for 9 hours;

[0048] (2) Bamboo and wood fiber pretreatment: crush the dried bamboo and wood fiber to less than 3mm, mix the bamboo and wood fiber, ammonium sulfate and glycerin according to the mass ratio of 8:1:1, stir and soften at 90°C 20min;

[0049] (3) Add the pretreated PBAT, PBS, PLA, bamboo wood fiber, talcum powder, PEG-400, white oil, isocyanate, phenylene diisodecyl pho...

Embodiment 3

[0052] The novel composite degradable plastic material for injection molding is composed of components in parts by weight of Table 3:

[0053]Table 3 raw material component formula

[0054] type parts by weight / part PBAT 70 PBS 10 PLA 8 bamboo fiber 20 calcium carbonate 5 Epoxidized soybean oil 2 Oleamide 5 Bisphenol A 1.0 Butylhydrobiphenol 4

[0055] The preparation method of novel composite degradable plastic material for injection molding comprises the following steps:

[0056] (1) Dry PBAT, PBS, PLA, bamboo and wood fiber at 80°C for 9 hours;

[0057] (2) Bamboo and wood fiber pretreatment: crush the dried bamboo and wood fiber to less than 3mm, mix bamboo and wood fiber, ammonium sulfate and glycerin according to the mass ratio of 8:1:1, and stir and soften at 100°C 20min;

[0058] (3) Add pretreated PBAT, PBS, PLA, bamboo wood fiber, calcium carbonate, epoxy soybean oil, oleic acid amide, bisphenol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com