Roller sticking resisting device for inside liner

A technology of anti-sticking rollers and inner linings, applied in the field of rubber machinery, can solve the problems of reducing the return rate of unqualified semi-finished products, achieve the effects of improving the phenomenon of sticking rolls, saving costs, and solving the problem of sticking rolls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

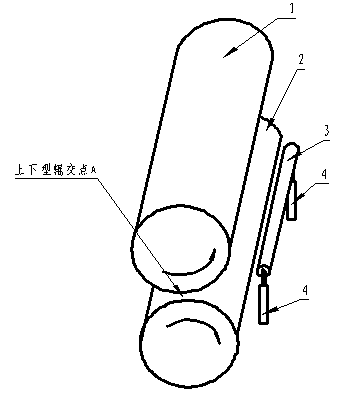

[0011] exist figure 1 Among them, the present invention is provided with parallel upper type roller 1 and lower type roller 2, and one side of upper type roller 1 and lower type roller 2 is provided with a supporting roller 3 in parallel, and the two ends of the rotating shaft of supporting roller 3 are respectively fixed in the vertical setting. On the cylinder rods of the two cylinders 4, the cylinders 4 are perpendicular to the ground, and the idler 3 is connected to the cylinder rods at the top of the cylinder 4, and can move up and down along with the cylinder rods of the cylinders. Assuming that the contact position between the upper type roller 1 and the lower type roller 2 of the inner liner production line is point A, when the cylinder 4 drives the idler roller 3 down to the lowest point, the idler roller 3 is at the same level as point A, and the idler roller 3 is at the same distance from A point 300-400mm.

[0012] When the present invention is in use, the sizing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com