Turnover-falling infrared corncob drying machine

A corn ear and dryer technology, applied in the direction of storing seeds by drying, etc., can solve the problems of inaccurate entry, bursting of corn kernels, high energy consumption, and achieve the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

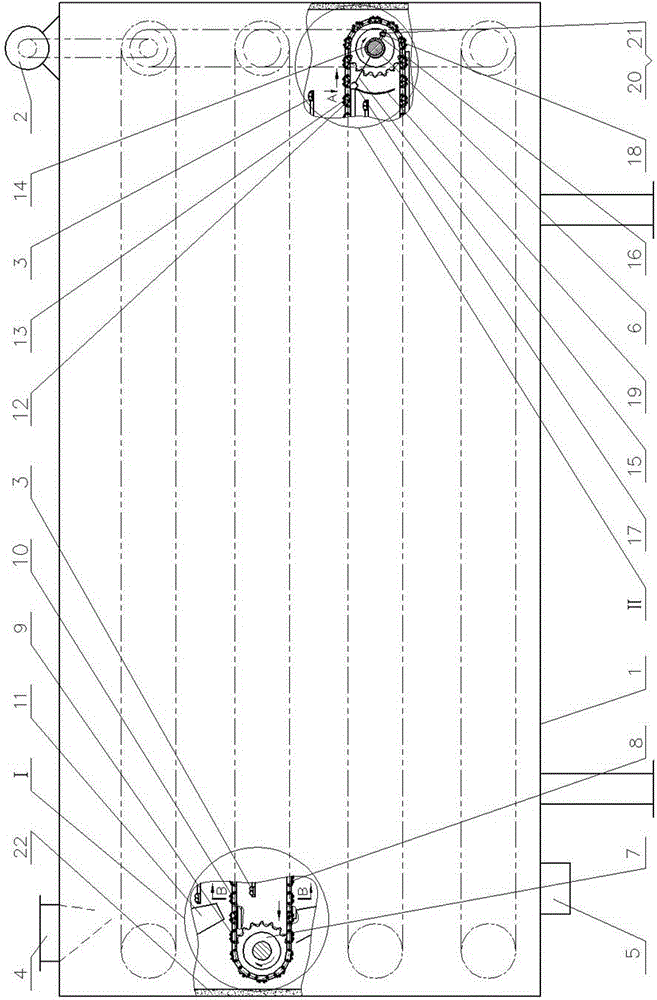

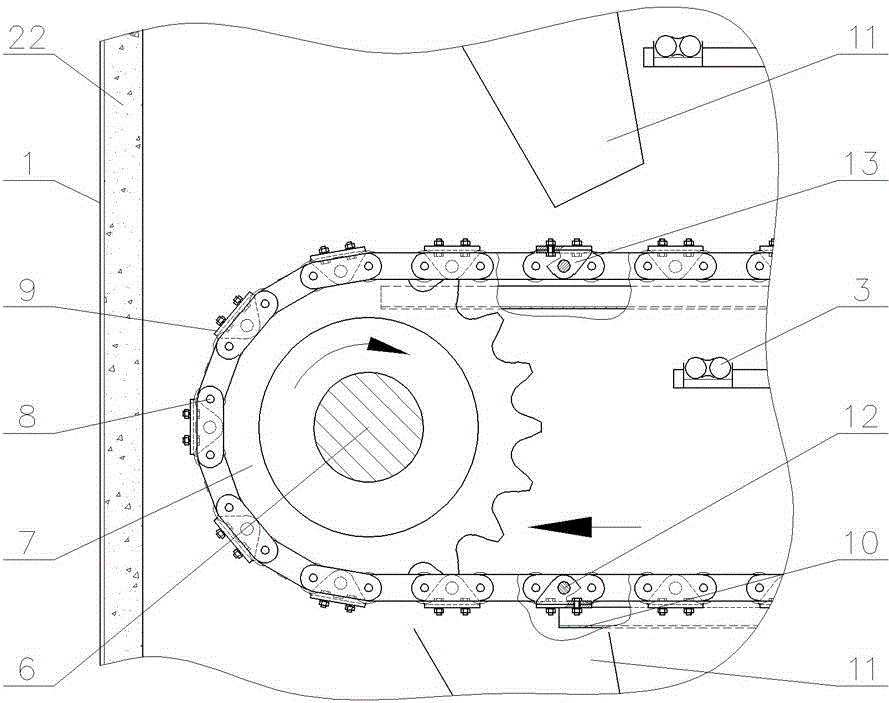

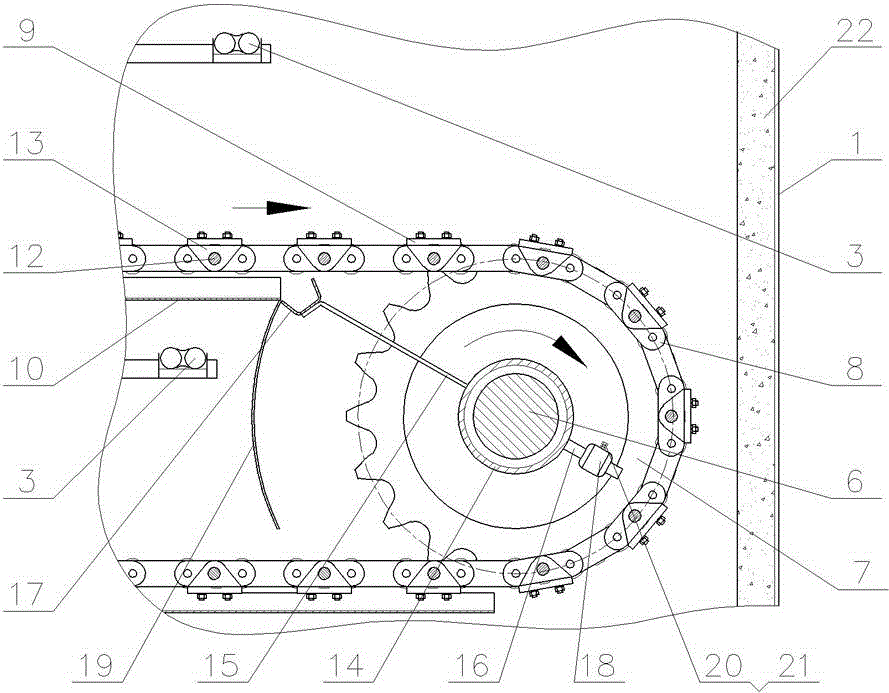

[0019] 1. Box body 2, transmission device 3, radiation device 4, material inlet 5, material outlet 6, shaft 7, sprocket 8, chain 9, bent plate 10, support trough 11, material guide trough 12, straight rod 13. Joint 14, support sleeve 15, support rod 16, adjustment rod 17, material receiving tank 18, adjustment block 19, baffle plate 20, screw 21, nut 22, insulation layer.

[0020] exist Figure 1~5 In the shown embodiment: one end of the top of the rectangular box body 1 is provided with a material inlet 4 , and the same end is provided with a material outlet 5 at the bottom of the box body 1 . There are 4 conveying devices along the length direction in the box 1, two shafts 6 of the same conveying device are arranged horizontally at both ends of the box 1, both ends of the shaft 6 are supported on the side wall of the box 1, and are perpendicular to the box 1 The length direction of the box body 1 is installed on the top of the box body 1 away from the transmission device 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com