Spiral slideway infrared corncob drying machine

A technology of spiral slide and corn ear, which is applied in the field of agricultural engineering, can solve the problems of corn kernels bursting and high energy consumption, and achieve the effects of reducing obstruction, low energy consumption and improving uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

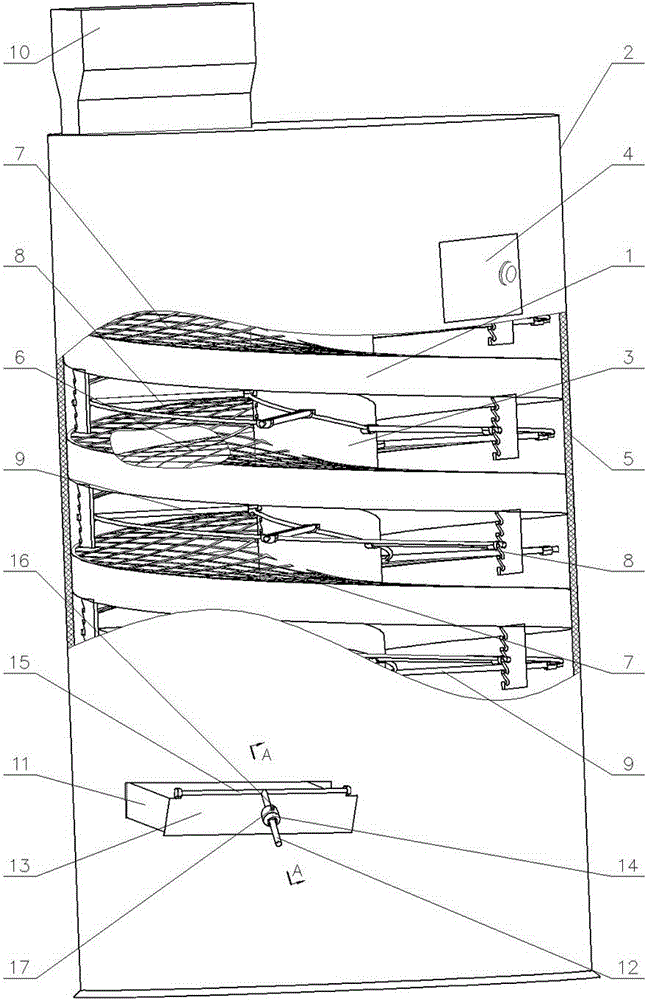

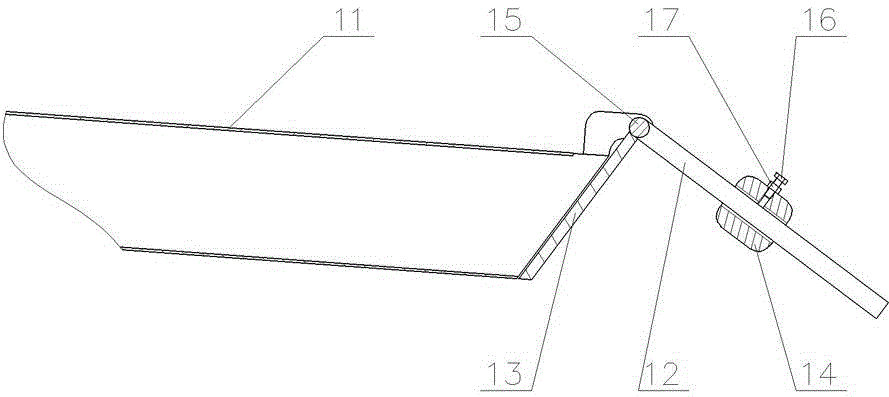

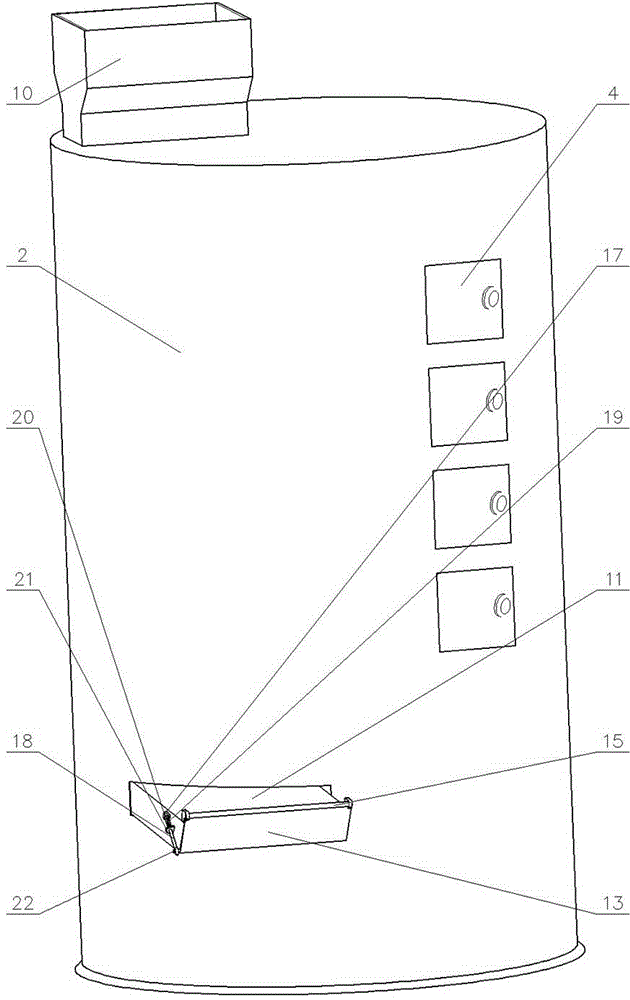

[0016] 1. Spiral slideway 2, box wall 3, central pipe 4, observation door 5, insulation layer 6, pattern 7, shield 8, radiation frame 9, radiation element 10, material inlet 11, material outlet 12, adjustment rod 13. Baffle plate 14, adjustment block 15, pin shaft I 16, screw 17, nut 18, pull rod 19, spring 20, spring seat 21, lug 22, pin shaft II.

[0017] exist Figure 1~2In the shown embodiment: the outer cylindrical surface of the cylindrical box wall 2 with the axis vertically arranged is provided with a plurality of observation doors 4, the inner surface of the box wall 2 is provided with an insulating layer 5, and the inner surface of the box wall 2 is along the axis of the cylinder. A spiral slideway 1 is provided, and the inner edge of the spiral slideway 1 is supported on the central tube 3 whose axis is coaxial with the box wall 2; the radial width of the spiral slideway 1 along the box wall 2 is greater than the maximum length of the ear of corn. The upper surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com