Processing method of high-quality corn seed

A processing method and corn technology, applied in the directions of seed and rhizome treatment, seed coating/seed dressing, furnace type, etc., can solve the problems of reducing seed water content, freezing weather hazards, failing to achieve safe overwintering, etc. The level of development, ensuring food security, and solving the effect of liquid waste and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

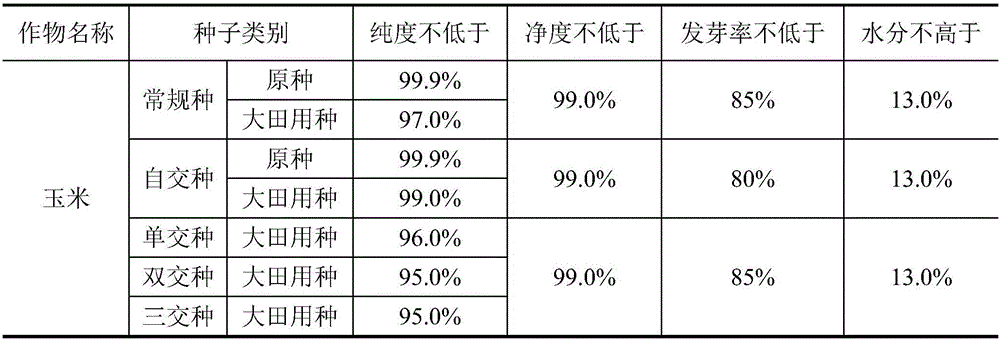

[0020] The present embodiment fine-quality corn seed processing method, carries out according to the following steps:

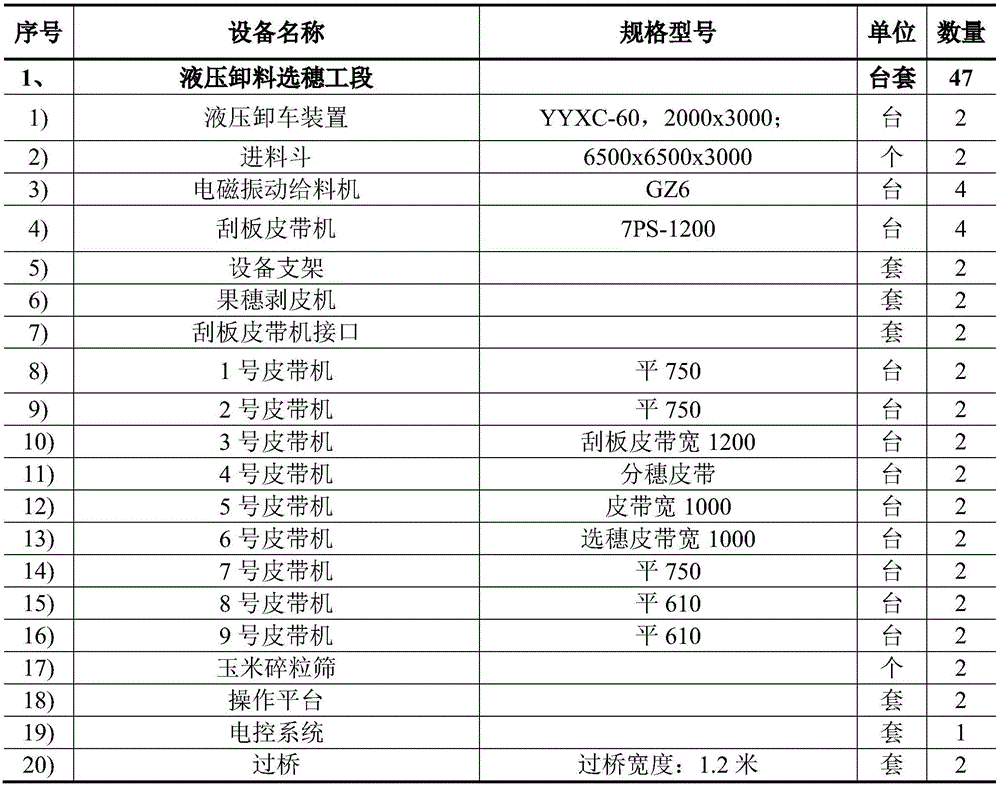

[0021] 1. Ear selection: The wet ear of corn is vibrated by the electromagnetic vibrating feeder, weighed, peeled, and then transported to the ear sorting platform to pick miscellaneous ears and remove seeds, and then transported to the drying workshop by a belt conveyor; The unloading lifting force is 60 tons per strip, and the conveying capacity is greater than 80 tons per hour per strip; the purpose of weighing is to meet the capacity of the drying bin;

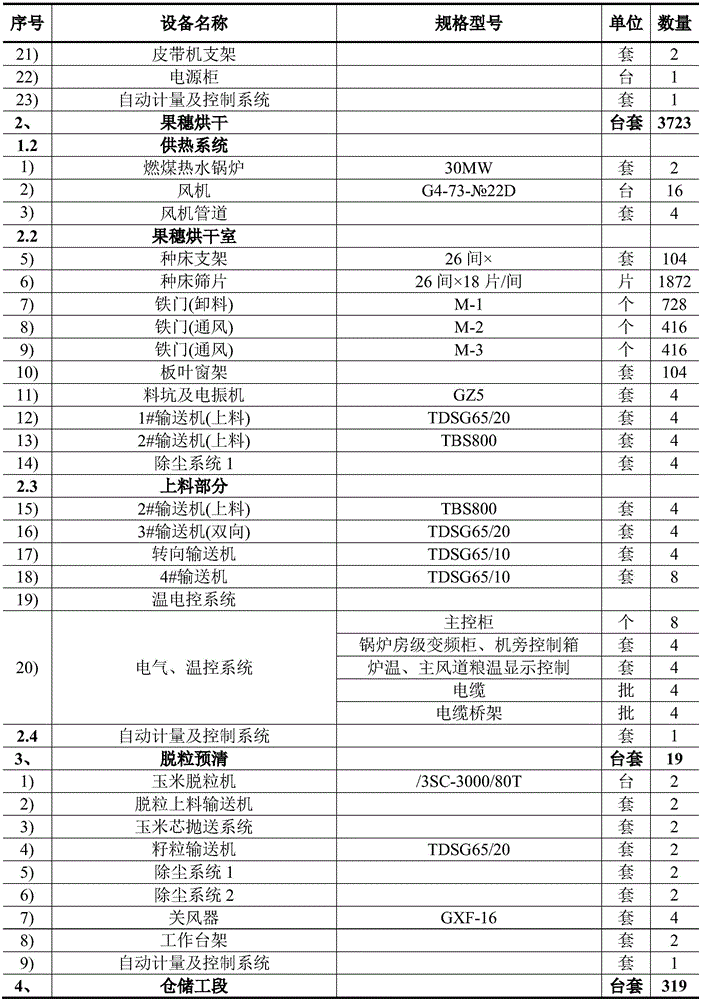

[0022] 2. Fruit ear drying: The wet fruit ears in step 1 are transported to the top of the drying workshop by the belt conveyor, and then sent to the drying warehouse (4 workshops, each workshop has 26 pieces of 60 pieces) through the automatic distributor on the top of the warehouse. tons of drying bin, 1500 tons per batch), drying at a temperature of 36-43°C until the water content of the grains drops b...

Embodiment 2

[0030] The difference between the fine-quality corn seed processing method of this embodiment and Example 1 is that the corn seeds in step 4 are stored before being coated, that is, the corn kernels after threshing and cleaning are stored and temporarily stored (via elevator or conveyor belt) transported to steel silos at all levels for temporary storage).

Embodiment 3

[0032] The difference between the fine-quality corn seed processing method of this embodiment and that of Embodiment 1 is that the corn seed seed coating agent in step 4 is dried and then transported by a belt conveyor to a fully automatic packaging scale for packaging, palletizing, and coding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com