Method and device for effectively reducing breakage rate of lime lump materials

A technology of breakage rate and lime is applied in the field of effectively reducing the breakage rate of lime blocks, which can solve the problems of increased production cost, waste of mine resources, and increased consumption of active lime per ton of steel, so as to reduce the breakage rate and improve production utilization. , The effect of improving the utilization rate of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

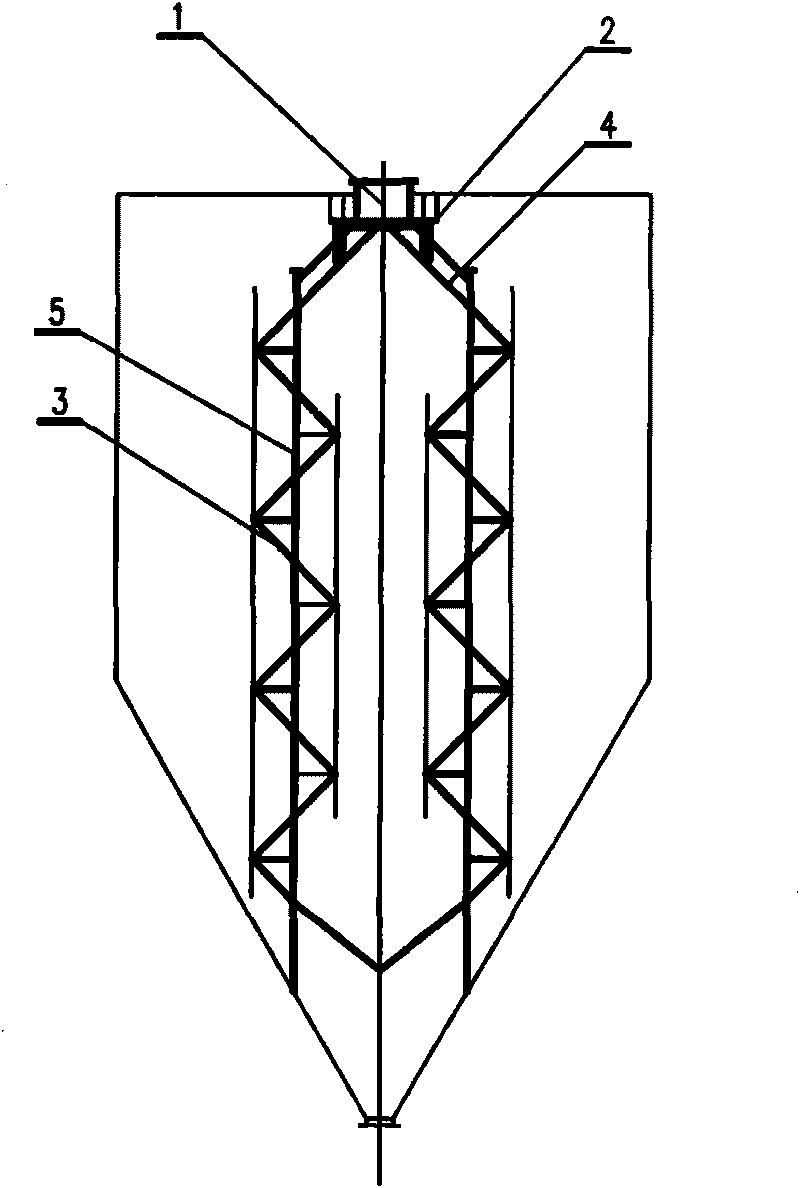

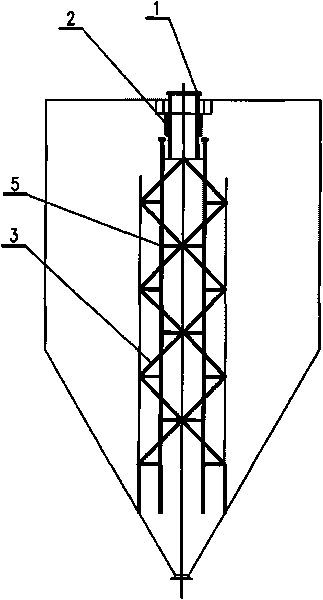

[0021] See figure 1 , figure 2 , image 3 , Figure 4 , a method for effectively reducing the breakage rate of lime block material, the method is realized by setting a lime block material rotating silo device in the silo, and the lime block material into the silo is divided into two paths (multiple The road can also be rotated into the silo through the rotating slide, and the silo is gradually covered. The inclination angle of the rotary slideway is designed to meet the accumulation angle of the lime block and the principle that the lime block cannot impact to the bottom of the bin too quickly, so as to ensure the lowest crushing rate of the block after it enters the bin.

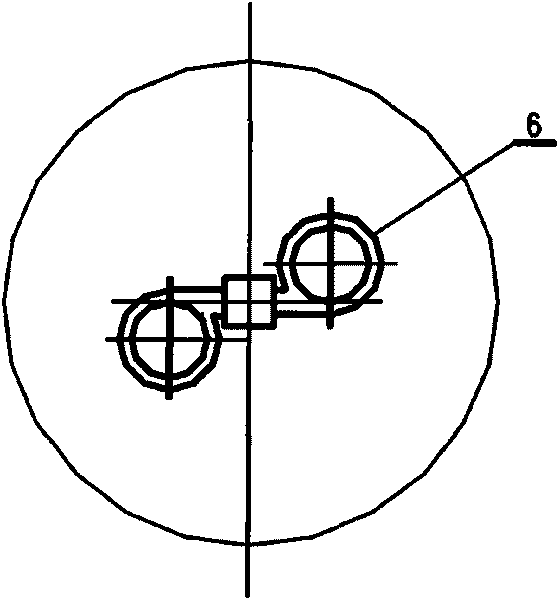

[0022] The device for rotating lime block material into the warehouse includes a bin mouth chute 1, a hanger 2, and a rotating slideway 3, and is installed in the bin of the finished product bin. Rotary slideway comprises distribution chute 4, fixed mount 5, rotary chute 6 ( image 3 , Figure 4 ), t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com