Patents

Literature

45results about How to "Improve production utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electroplating method and device of circuit boards

ActiveCN104862768AReal-time adjustment of working currentRealize seamless switchingCellsPower flowPrinted circuit board

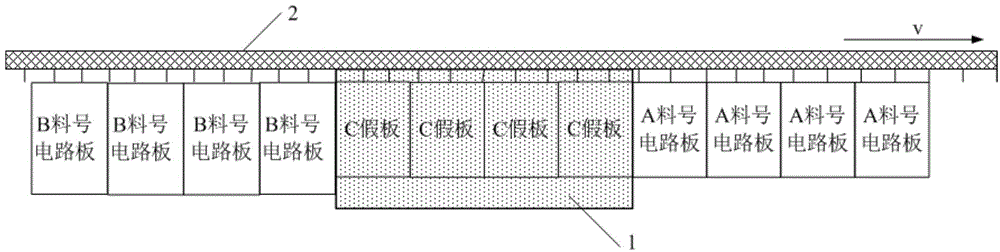

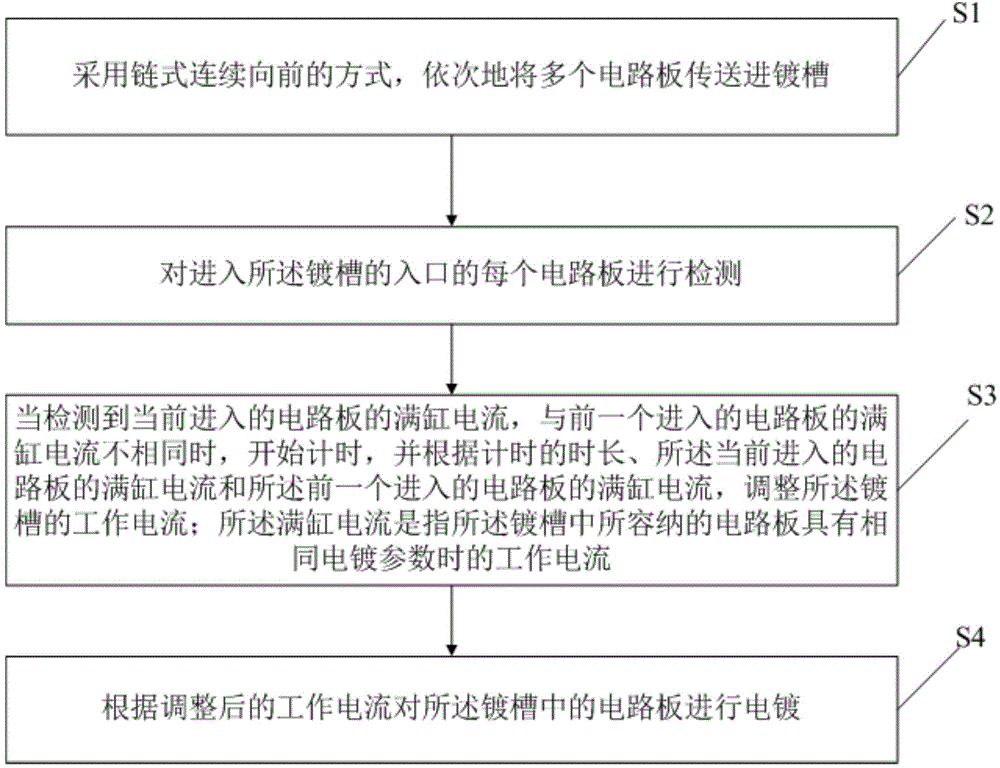

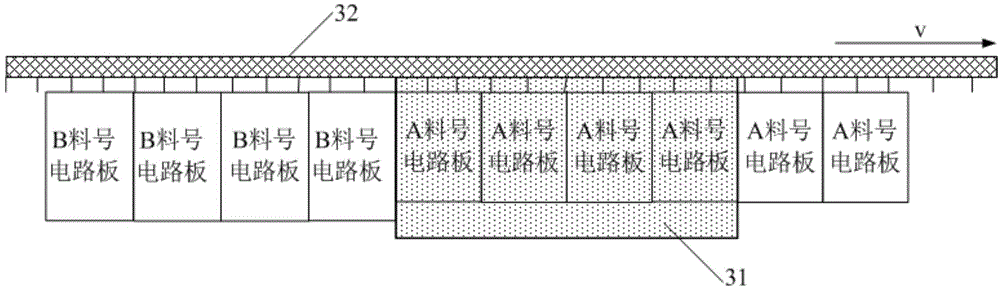

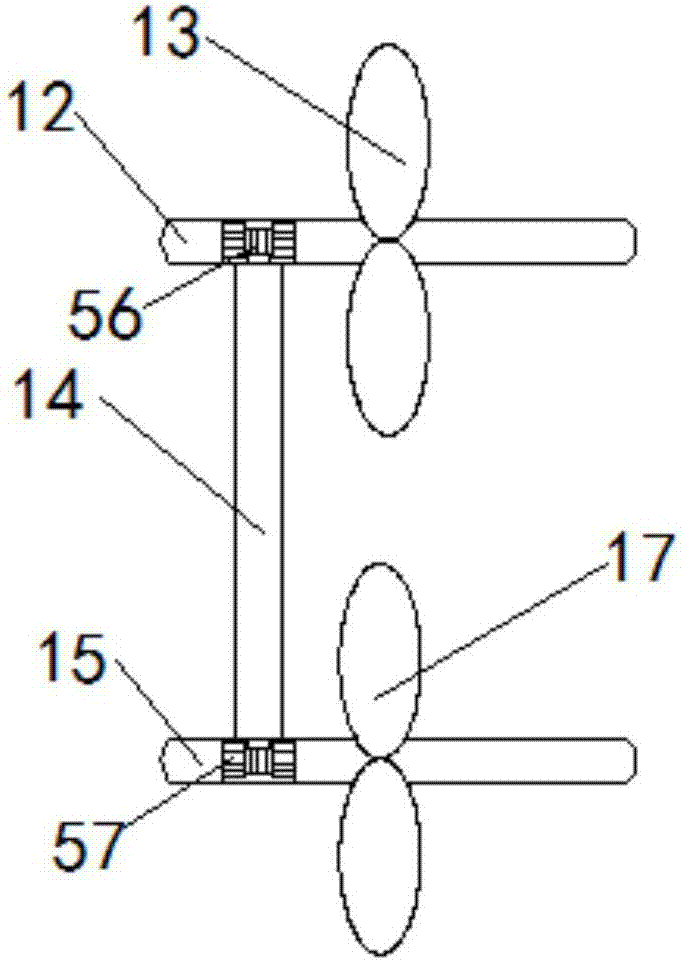

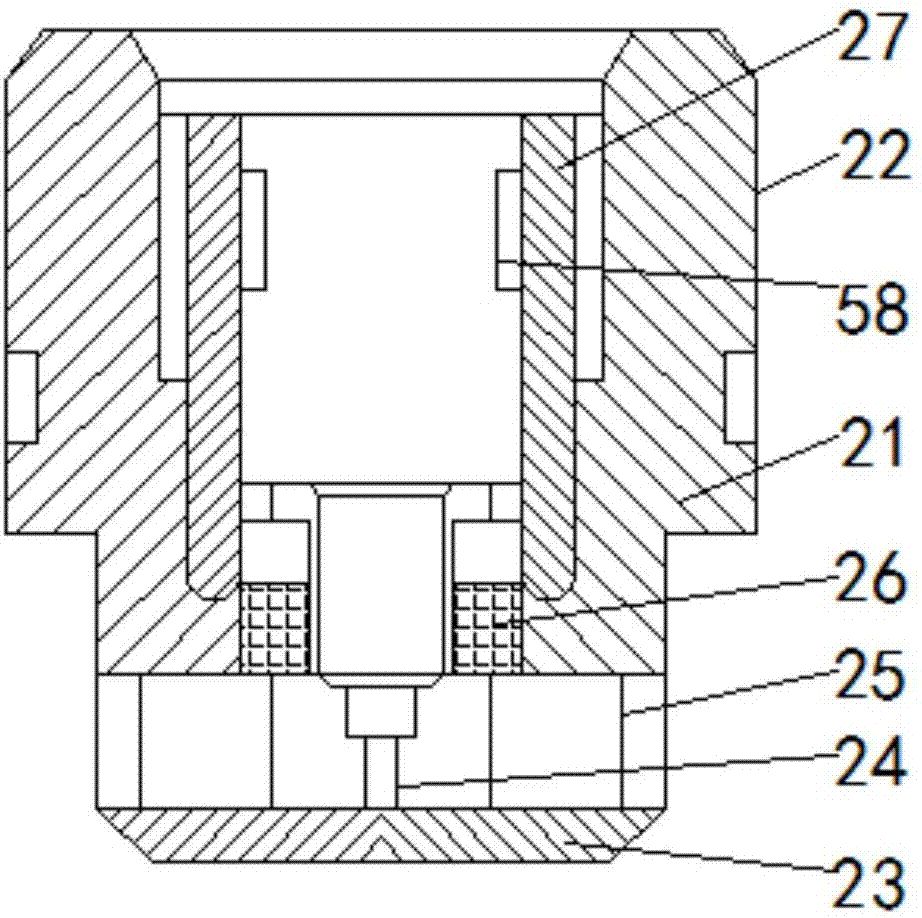

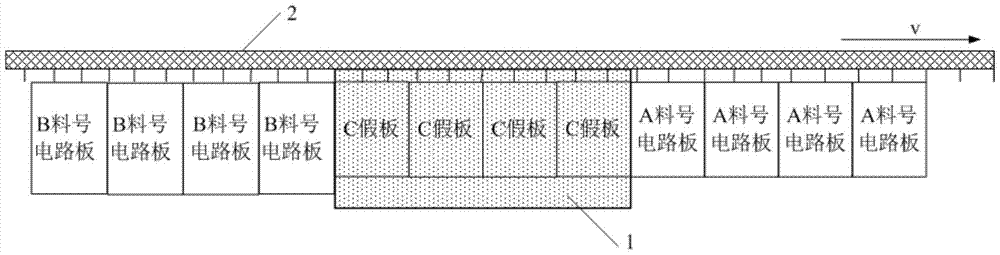

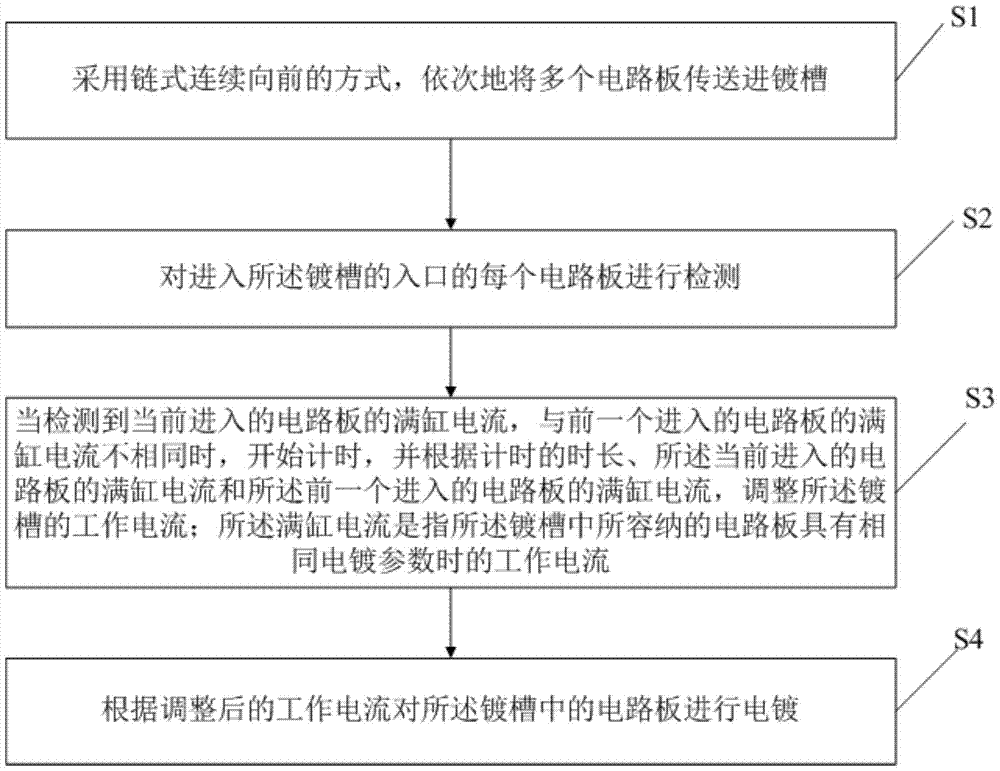

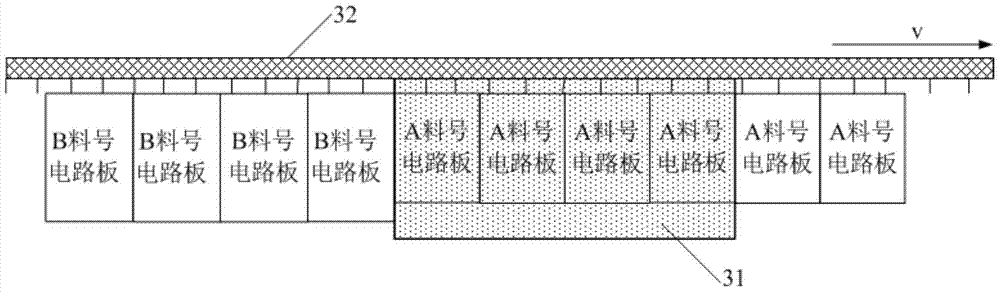

The invention discloses an electroplating method of circuit boards, which comprises the steps of conveying a plurality of circuit boards into a plating tank in sequence in a chain continuous forward manner, detecting each circuit board entering an inlet of the plating tank, starting timing when detecting that full cylinder current of the current circuit board is different from that of the previous circuit board, adjusting working current of the plating tank according to the duration, the full cylinder current of the current circuit board and the full cylinder current of the previous circuit board, and electroplating the circuit boards in the plating tank according to the adjusted working current, wherein the full cylinder current refers to the working current when the circuit boards accommodated in the plating tank have the same electroplating parameter. Correspondingly, the invention further discloses an electroplating device of the circuit boards. With the adoption of the method and the device, seamless switchover of electroplating of different circuit boards can be achieved, and the production and utilization rate of the circuit boards is increased.

Owner:GCI SCI & TECH

Method for hydrolyzing silkworm cocoons through weak base via microwaves

ActiveCN109320595AEfficient manufacturingAvoid damagePeptide preparation methodsEnergy based chemical/physical/physico-chemical processesSodium bicarbonateMicrowave

The invention discloses a method for hydrolyzing silkworm cocoons through a weak base via microwaves. The method comprises the following steps: (1) washing and drying; (2) cutting and separating; (3)carrying out primary hydrolysis and degumming; adding silkworm cocoon sheets and a weak base mixed solution formed by mixing sodium bicarbonate and sodium chloride into a microwave reactor; hydrolyzing for 110 to 130min under normal pressure and at the temperature of 80 DEG C; after hydrolyzing, obtaining a coarse sericin peptide solution and a silk protein fiber solid; pumping out the coarse sericin peptide solution and carrying out ultra-filtration to obtain sericin peptide protein; (4) carrying out secondary hydrolysis to extract silk fibroin peptide protein; then adding the weak base mixedsolution into the microwave reactor again; then hydrolyzing for 110 to 130min under normal pressure and at the temperature of 100 DEG C; carrying out heat insulation for 8 to 11h to completely hydrolyze the silk protein fiber solid into a coarse silk fibroin solution; carrying out ultra-filtration on the coarse silk fibroin solution to obtain silk fibroin protein. The method disclosed by the invention can be used for effectively preparing the sericin peptide protein and the silk fibroin protein in one step and the aim of improving the preparation efficiency and the utilization rate of products is realized.

Owner:YIBIN PINGSHAN HUIRUI OIL CO LTD

Shield excavation slag processing technology

PendingCN109250877AImprove production utilizationTake advantage ofSludge treatment by de-watering/drying/thickeningSolid waste managementBrickSlag

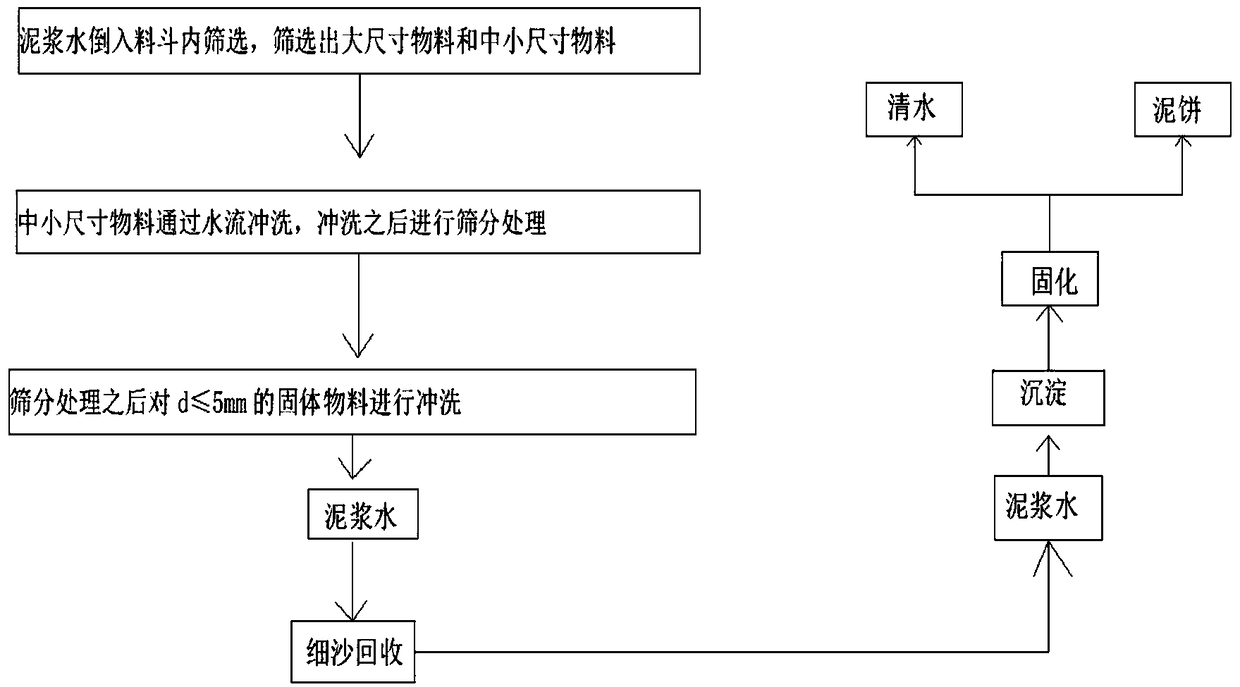

The invention discloses a shield excavation slag processing technology. The shield excavation slag processing technology comprises following steps: muddy water is introduced into a material hopper, and is subjected to sieving using a coarse sieve so as to obtain a large size material and a medium-small size material; the medium-small size material is subjected to flushing with high pressure waterflow, after flushing, the medium-small size material is subjected to sieving, a material obtained through sieving is subjected to flushing, muddy water obtained through flushing is subjected to fine sand recycling processing so as to obtain fine sand, muddy water is subjected to precipitation processing, after precipitation, muddy water is subjected to solidification process, and clear water and mud cake are obtained through solidification process; and the mud cake is subjected to processing. According to the shield excavation slag processing technology, muddy water is subjected to precipitation, and solidification processing, so that full utilization of muddy water is realized; clear water obtained through muddy water processing can be recycled; the obtained mud cake can be processed intoaerated concrete blocks and baking-free bricks, and product utilization rate after muddy water processing is increased.

Owner:深圳市绿锦隆环保科技有限公司

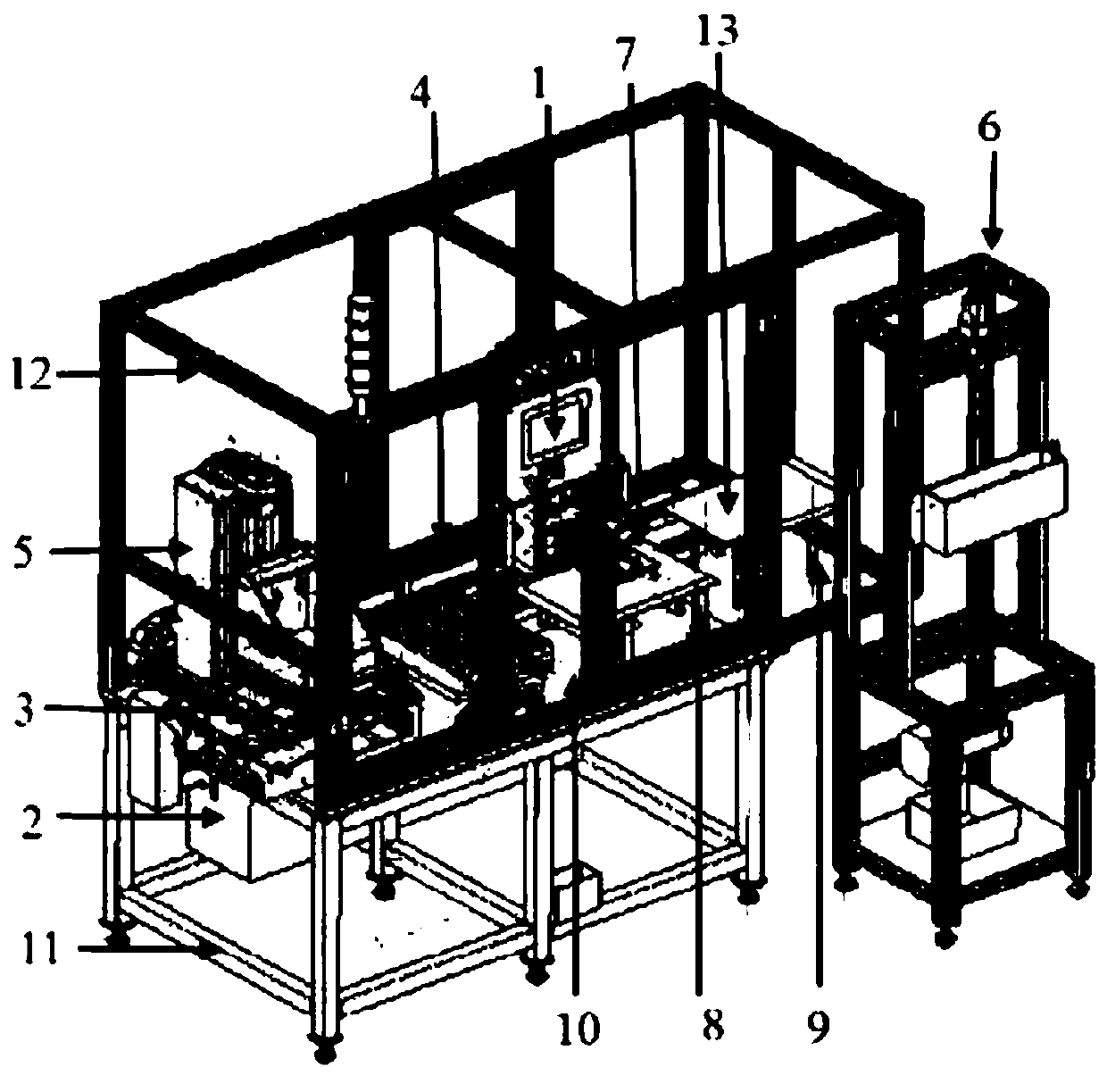

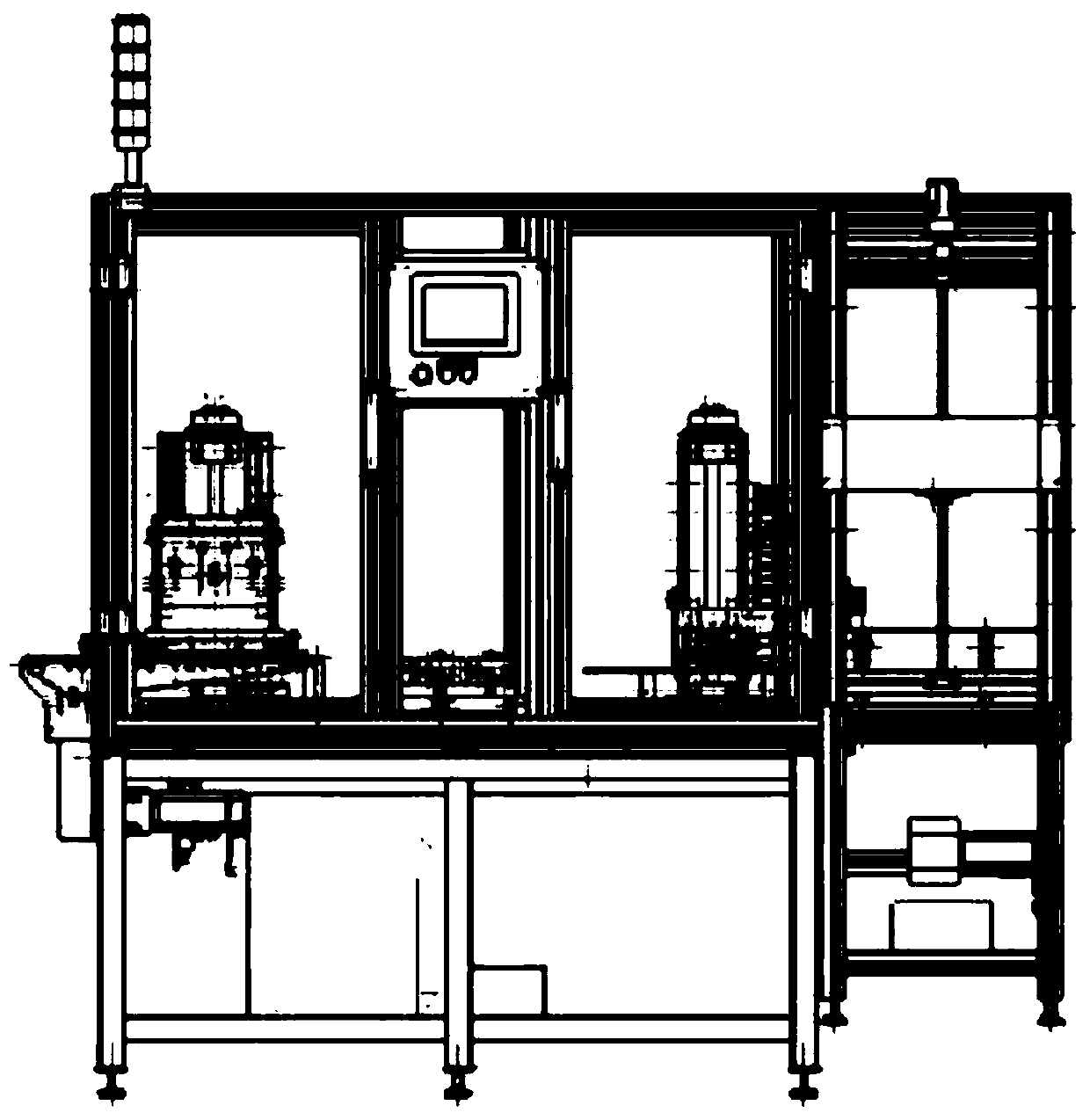

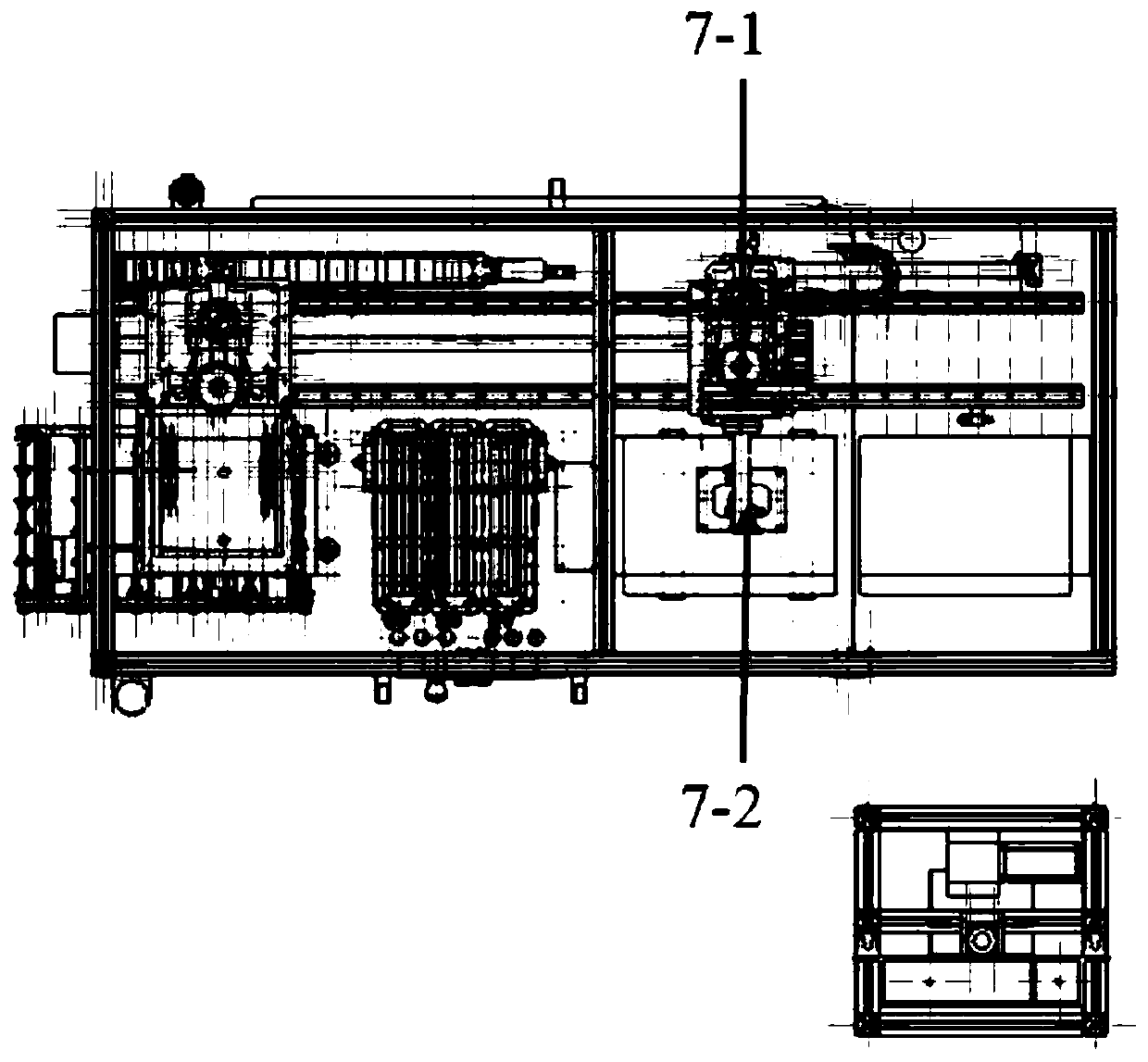

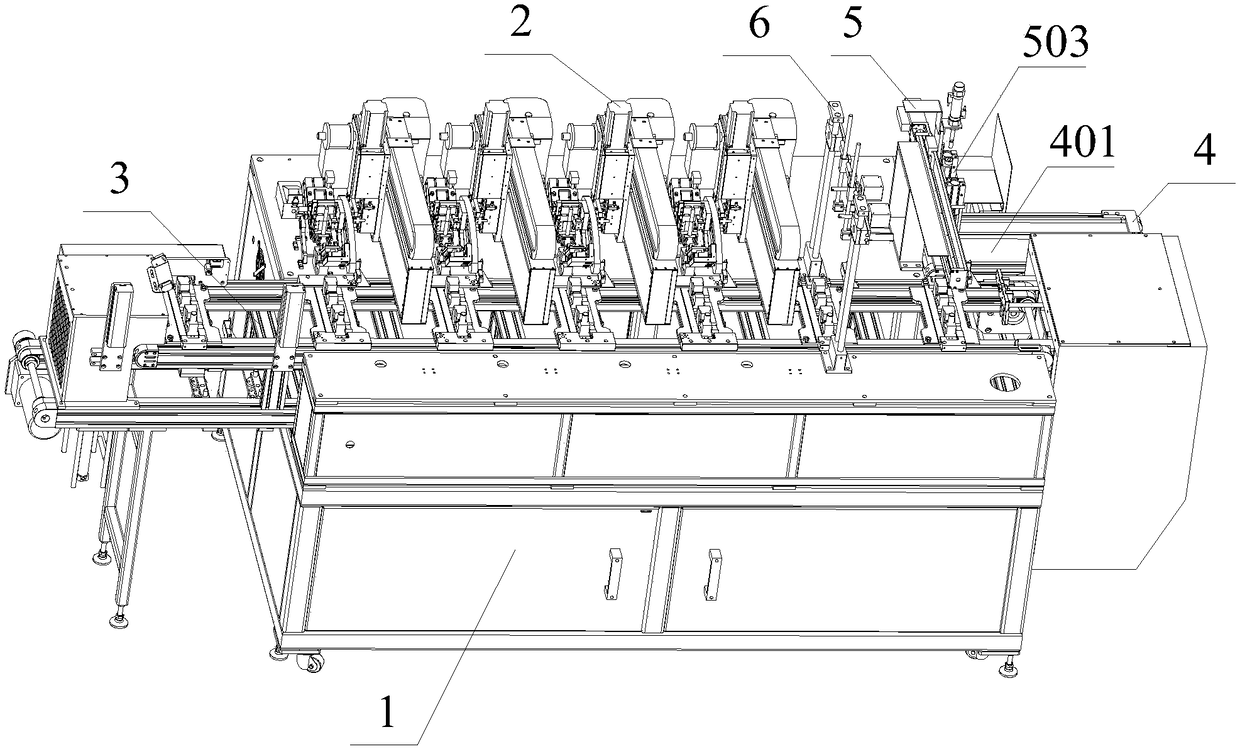

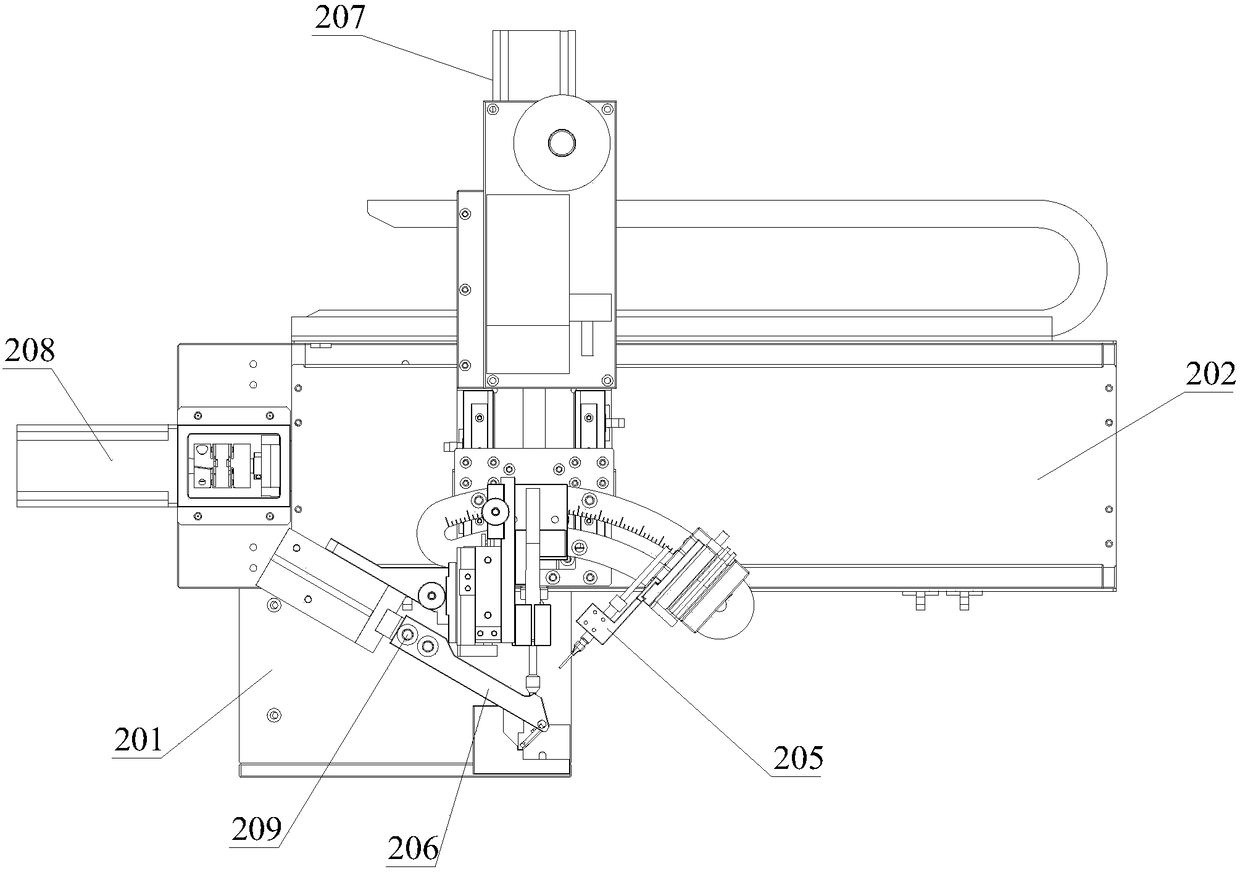

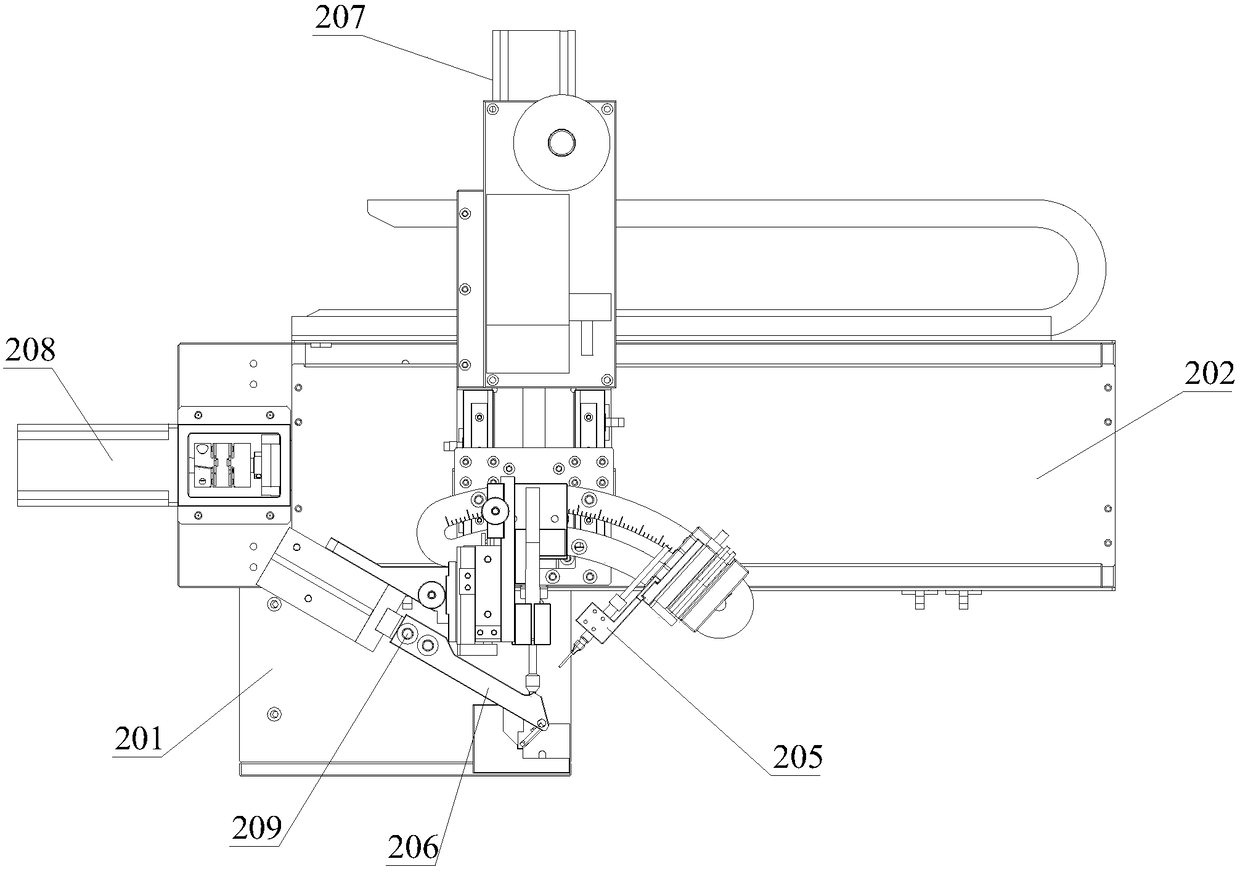

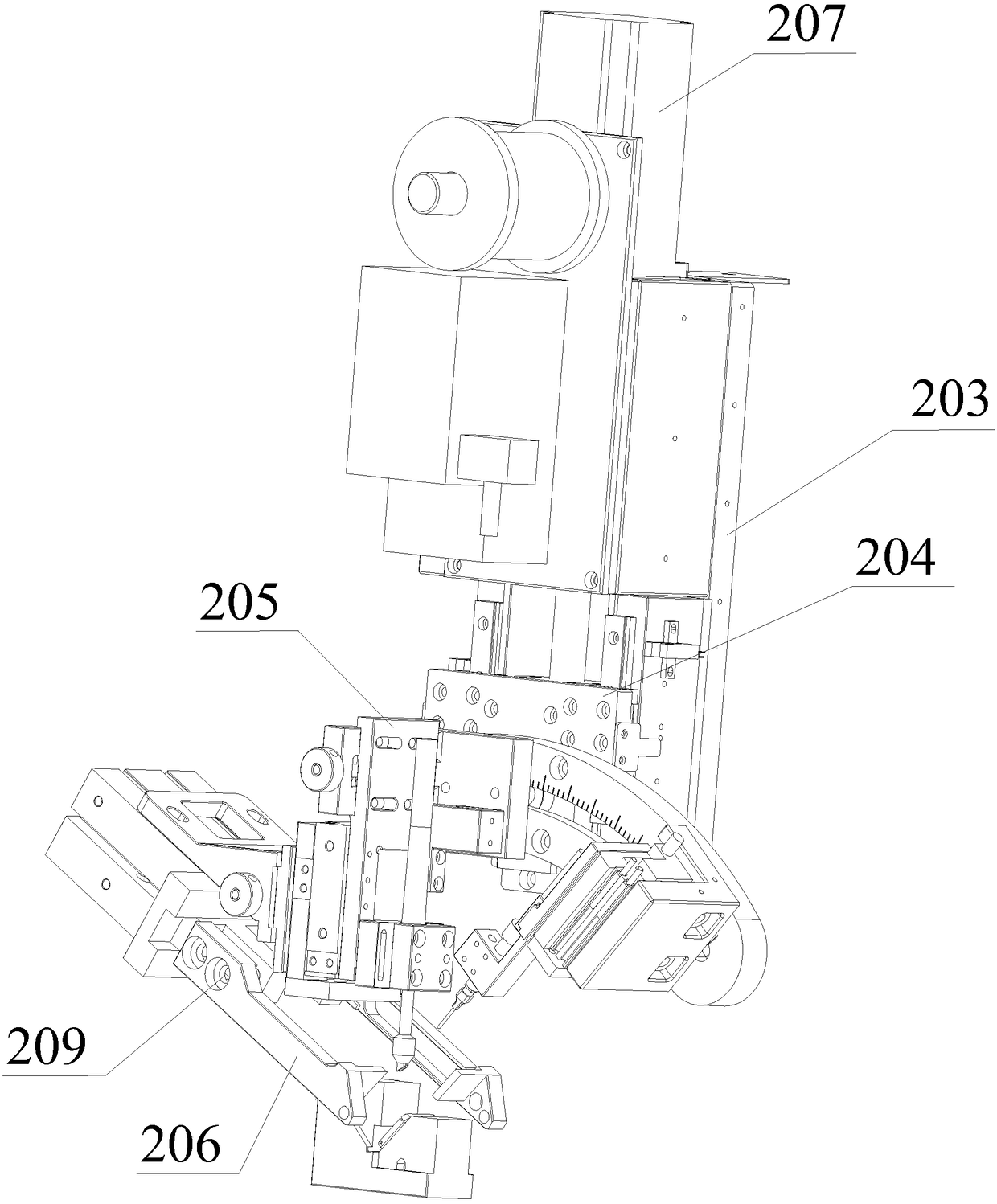

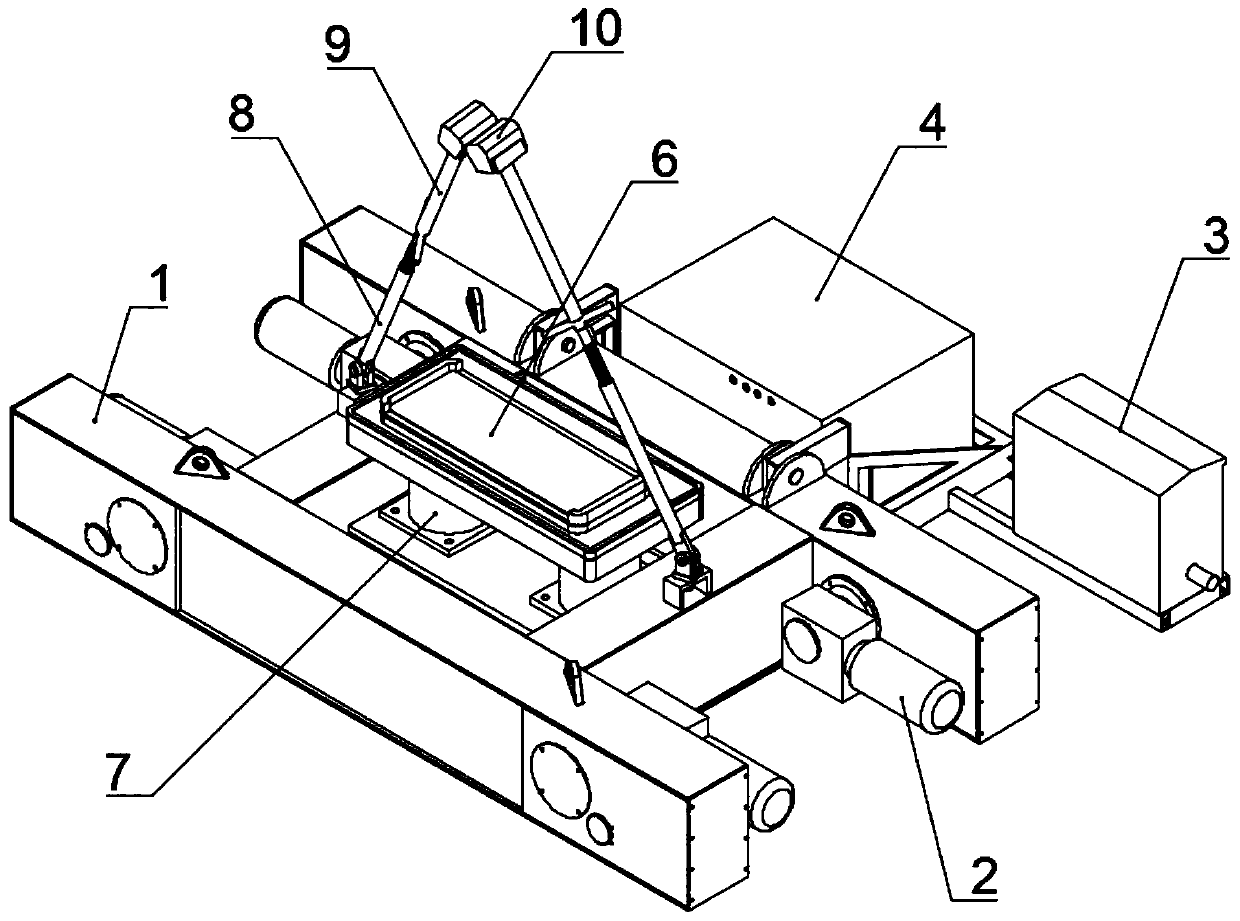

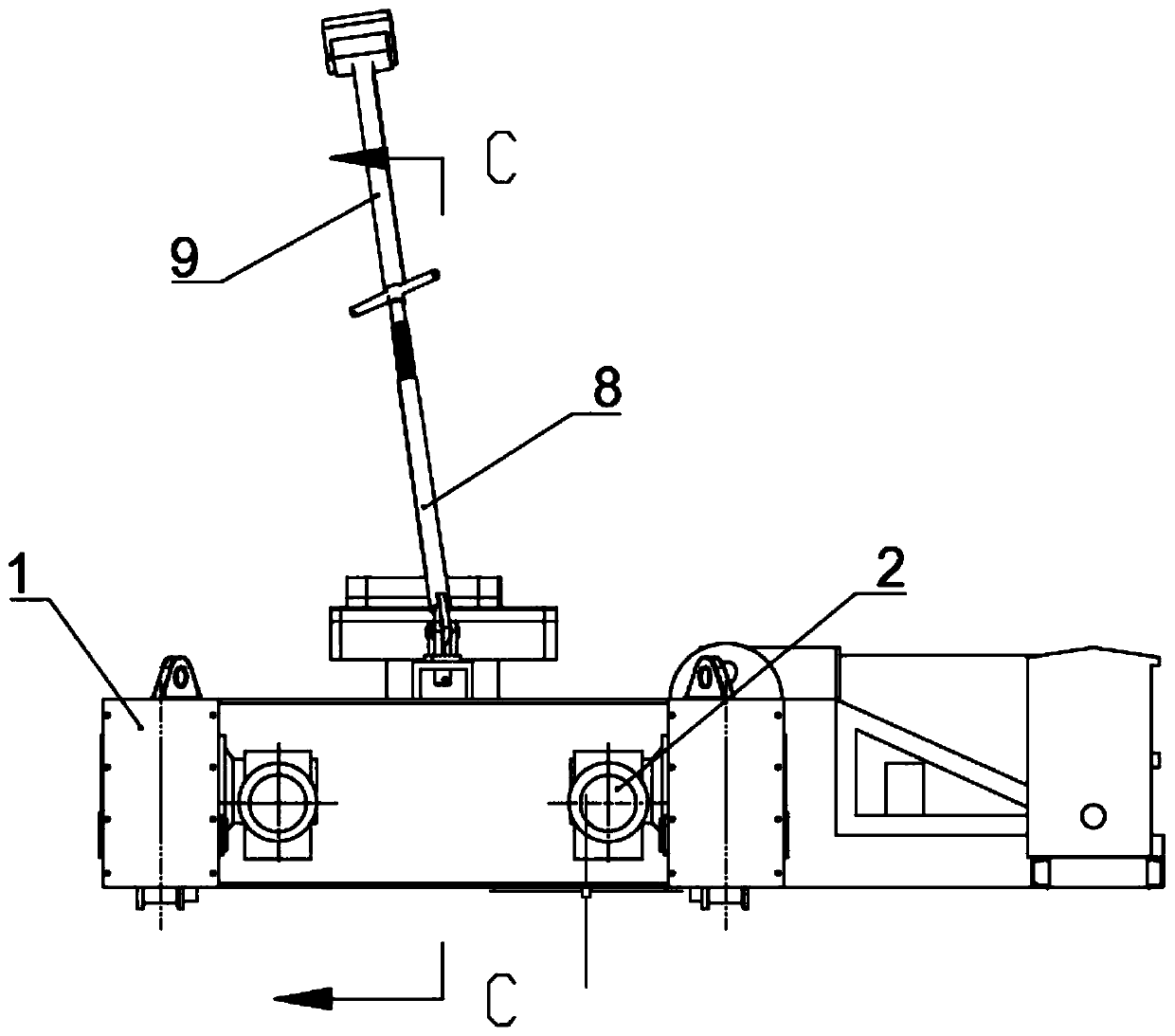

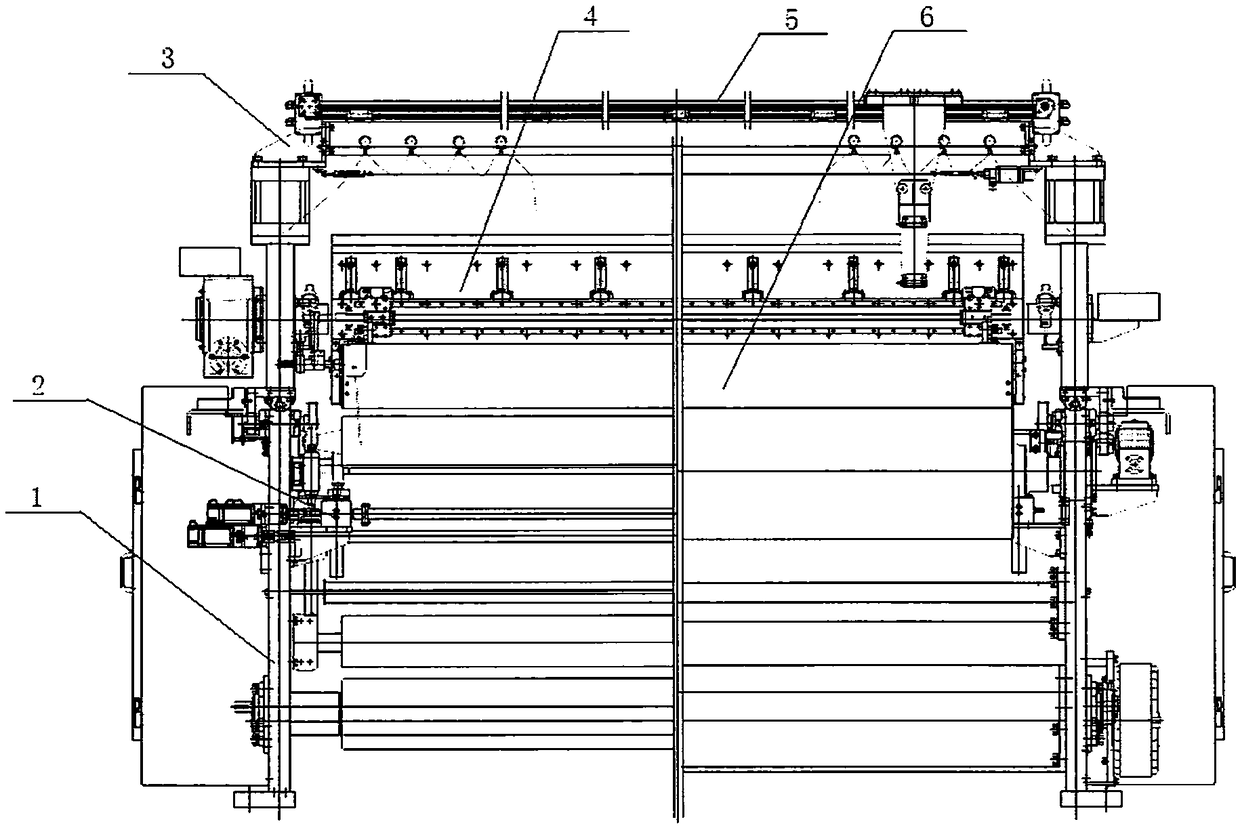

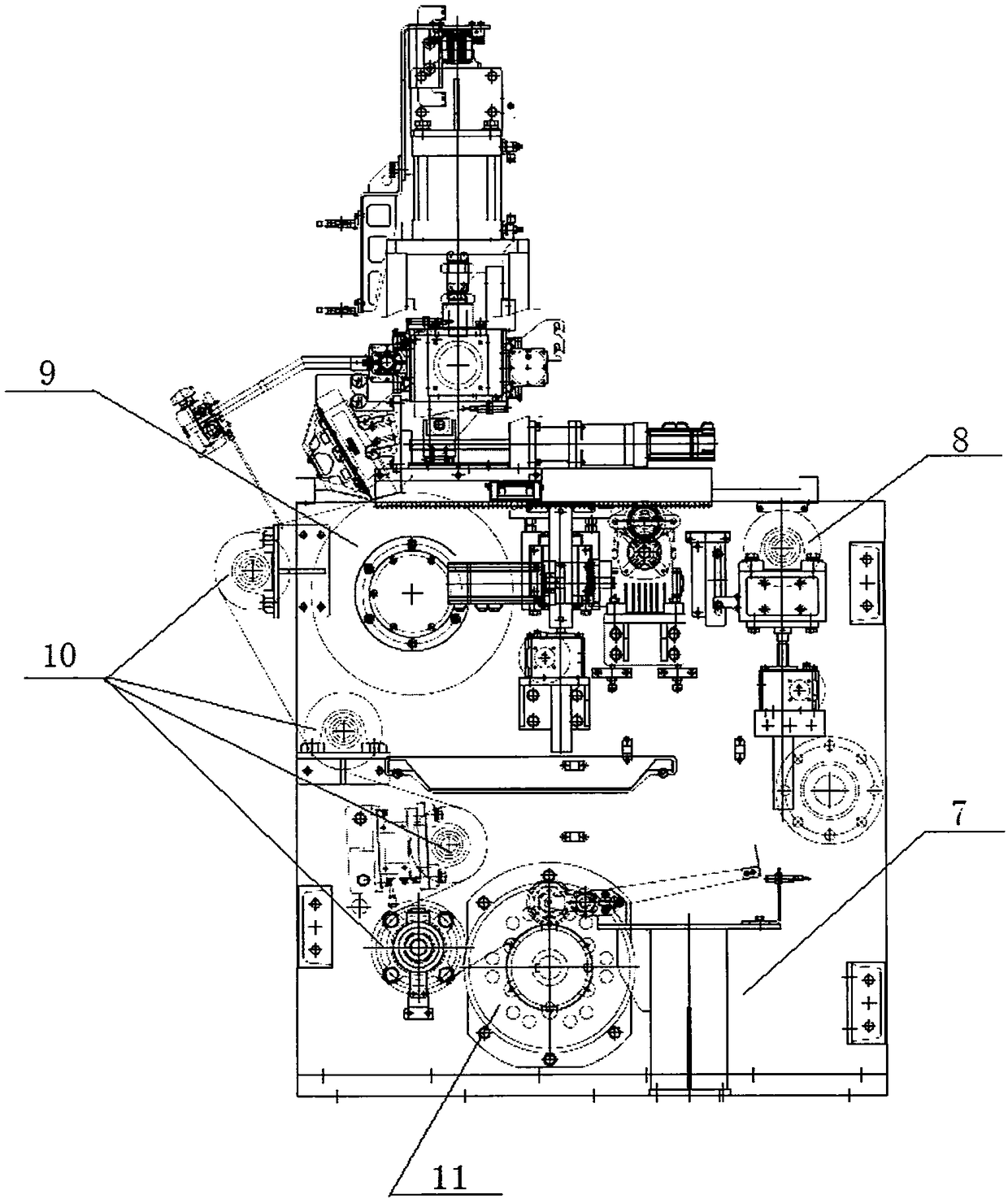

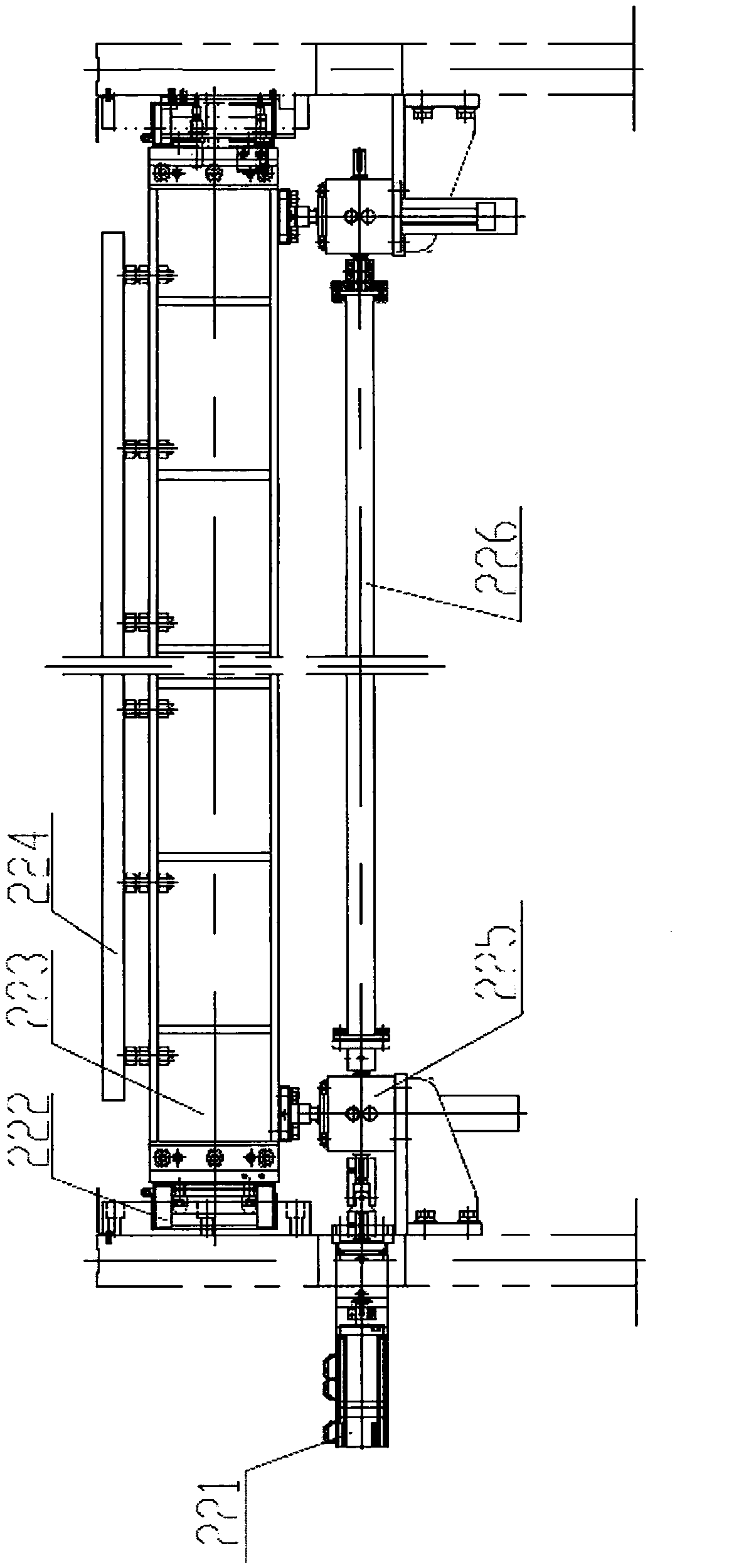

Film-coating equipment for meniscus surface, and suction mechanical arm for film-coating component

PendingCN109821701AIncrease productivityCoating film product quality is highLiquid surface applicatorsCoatingsFilm coatingMeniscus

The invention discloses film-coating equipment for a meniscus surface, and a suction mechanical arm for a film-coating component, and belongs to the field of continuous production for leveled coated films. The coating equipment for the meniscus surface comprises a central control panel (1), a PLC control cabinet (2), a location sheet-loading table (3) for the film-coating component, a linear motordrive guide rail (4), the suction mechanical arm (5) for the film-coating component, a glue supply device (6), an overturning sheet-unloading table (7) for the film-coating component, an overturningtransition frame (8) for the film-coating component, a sheet-unloading placement frame (9) for the film-coating component, an equipment support table (10), an equipment support (11), and an equipmentdustproof cover (12). The equipment is capable of forming a continuous and stable glue solution coating layer for the meniscus surface, has an anti-residual function, and is capable of completing continuous production for high-quality single-sided multilayer film-coated products or double-sided heterogeneous film-coated products.

Owner:宁波甬安光科新材料科技有限公司

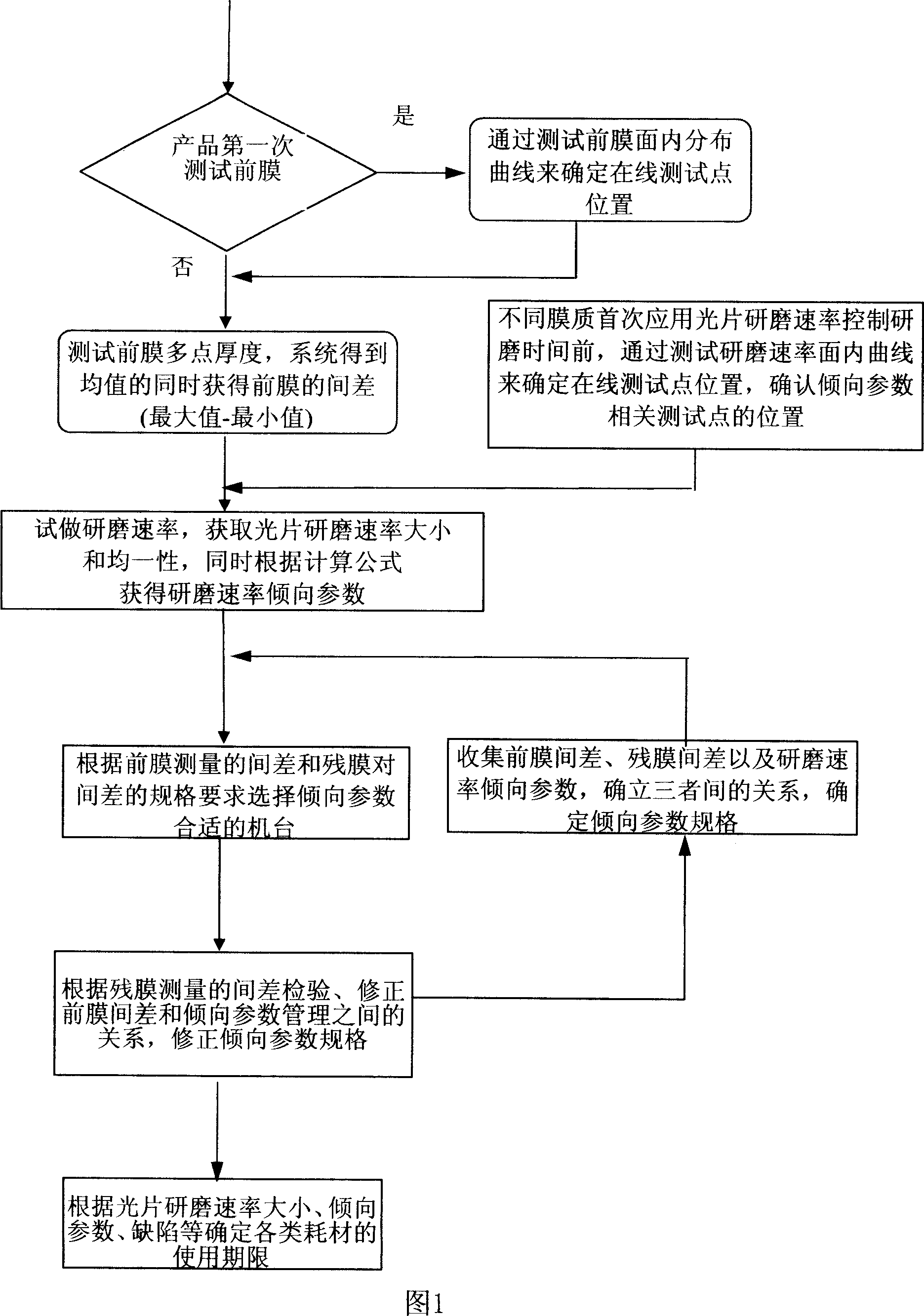

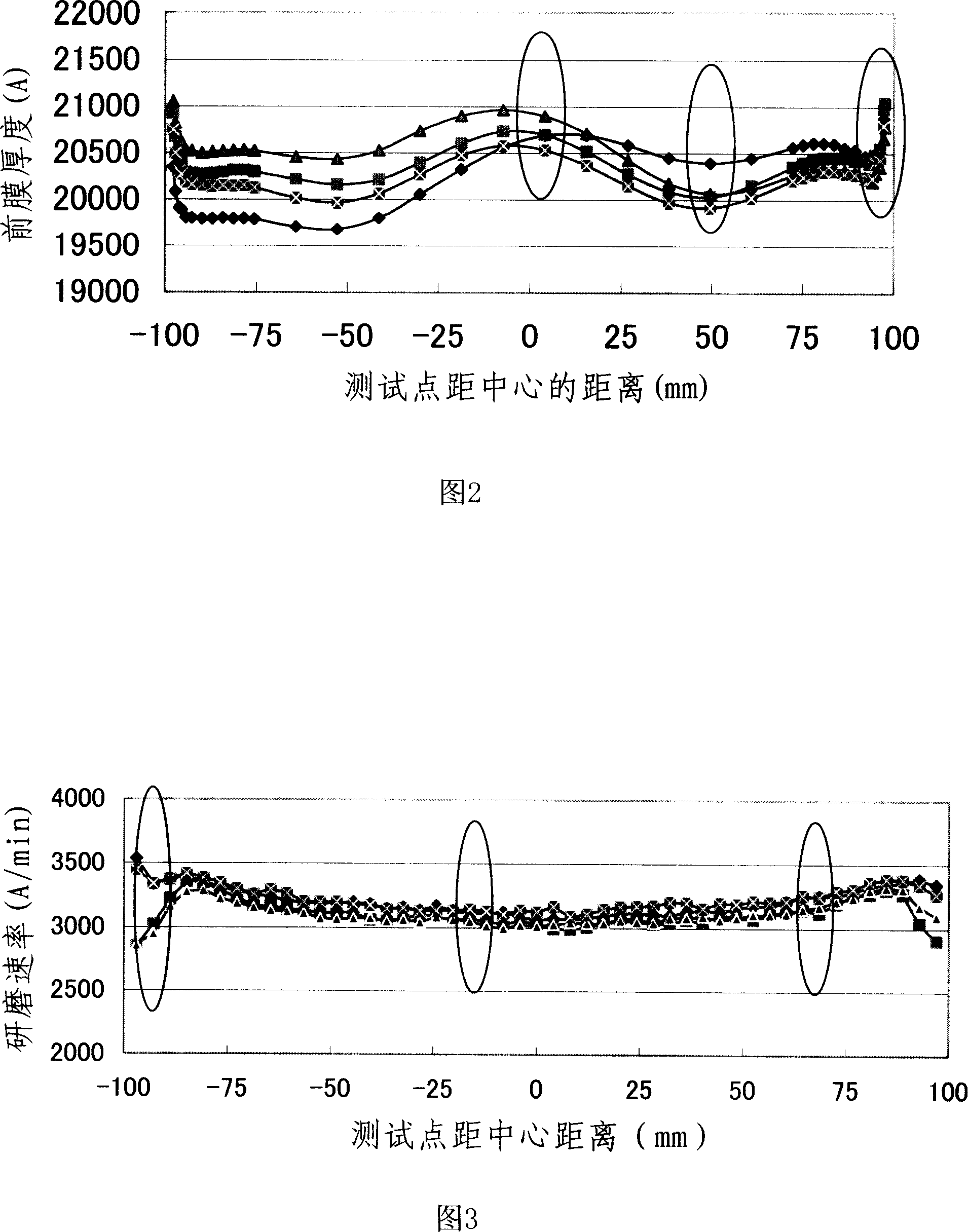

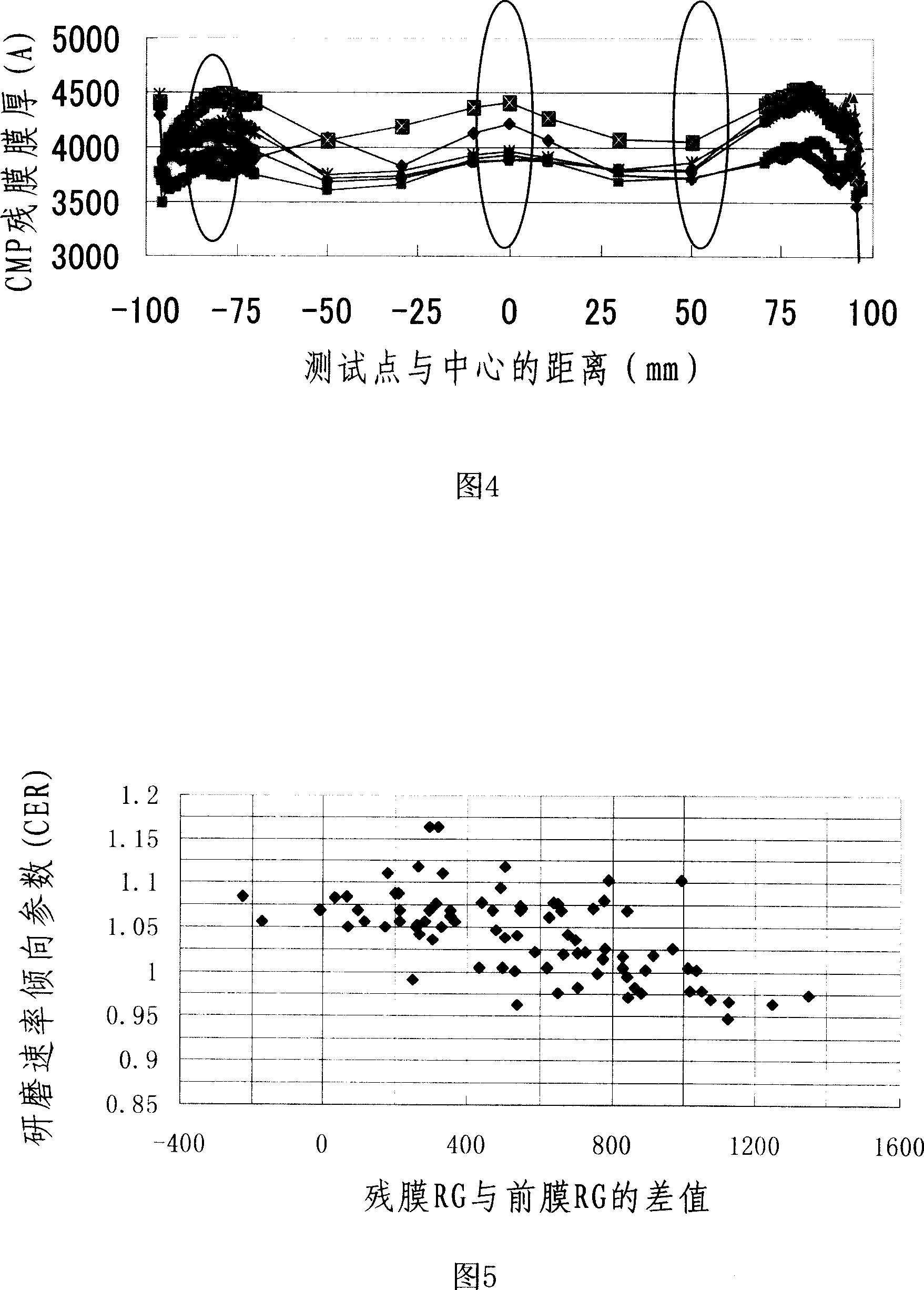

Method for controlling CMP film thickness internal homogeneity

InactiveCN101121240AExtended use timeReduce the burden onPolishing machinesSolid-state devicesEngineeringElectrical and Electronics engineering

The present invention discloses a method for controlling the evenness of the CMP film thick surface; on the basis of control with only optical lens grinding velocity and evenness, the present invention adds the tendency management of the product front film range and optical lens grinding velocity; based on the collected parameters of front film range, grinding velocity tendency and used film range, analyze the relations between the used film range, the front film range and grinding velocity tendency; with these relations, choose the proper machine with parameters similar to the parameter CER according to the front film range and implement CMP exercise. The present invention can effectively control the used film range within specifications.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Dyeing and finishing method suitable for all-cotton embroidery fabric or all-cotton voile

ActiveCN104153193AAvoid breakingGuarantee normal productionVegetal fibresElectricityLiquid temperature

The invention discloses a dyeing and finishing method for all-cotton embroidery fabric or all-cotton voile. The all-cotton embroidery fabric or all-cotton voile is processed through the procedures of white blank singeing, long spinning vehicle scouring and bleaching, mercerizing, dyeing and oiling shaping in sequence, wherein during the long spinning vehicle scouring and bleaching process, 28-32 g / L of tea saponin, 3-5 g / L of OPE (Octylphenol Polyoxyethylene Ether), and 4-6 g / L of N, N-sodium oleoyl di-taurinate into the treating liquid of a long spinning vehicle material groove; the treating liquid temperature is controlled to be 98 DEG C, the vehicle speed is controlled to be 40 meter / minutes, and the piling heat preservation time is controlled to be 40 minutes. According to the invention, only one-time processing is implemented on the long spinning vehicle, the equipment utilization ratio is increased, the damage to gray fabric is reduced, and the water, electricity and steam consumption is reduced by 50%.

Owner:HANGZHOU AOMEI PRINTING & DYEING

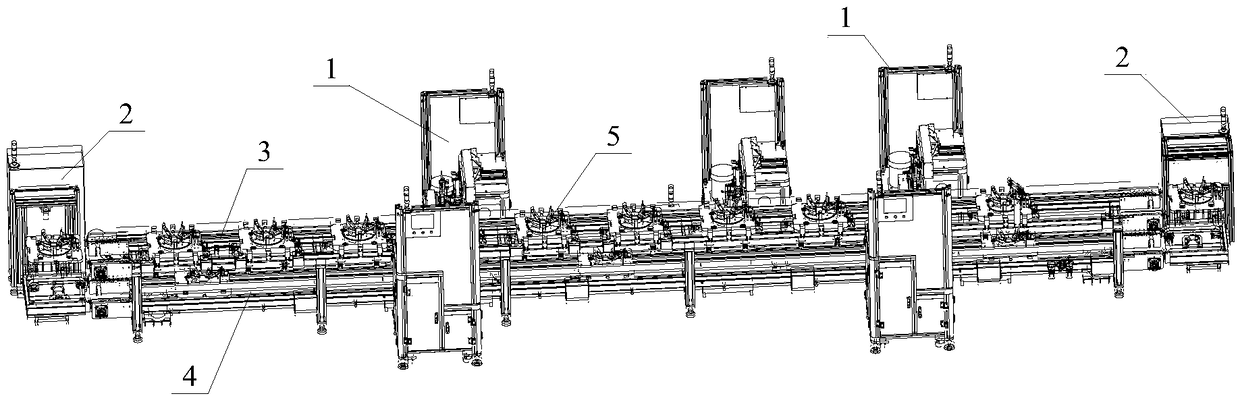

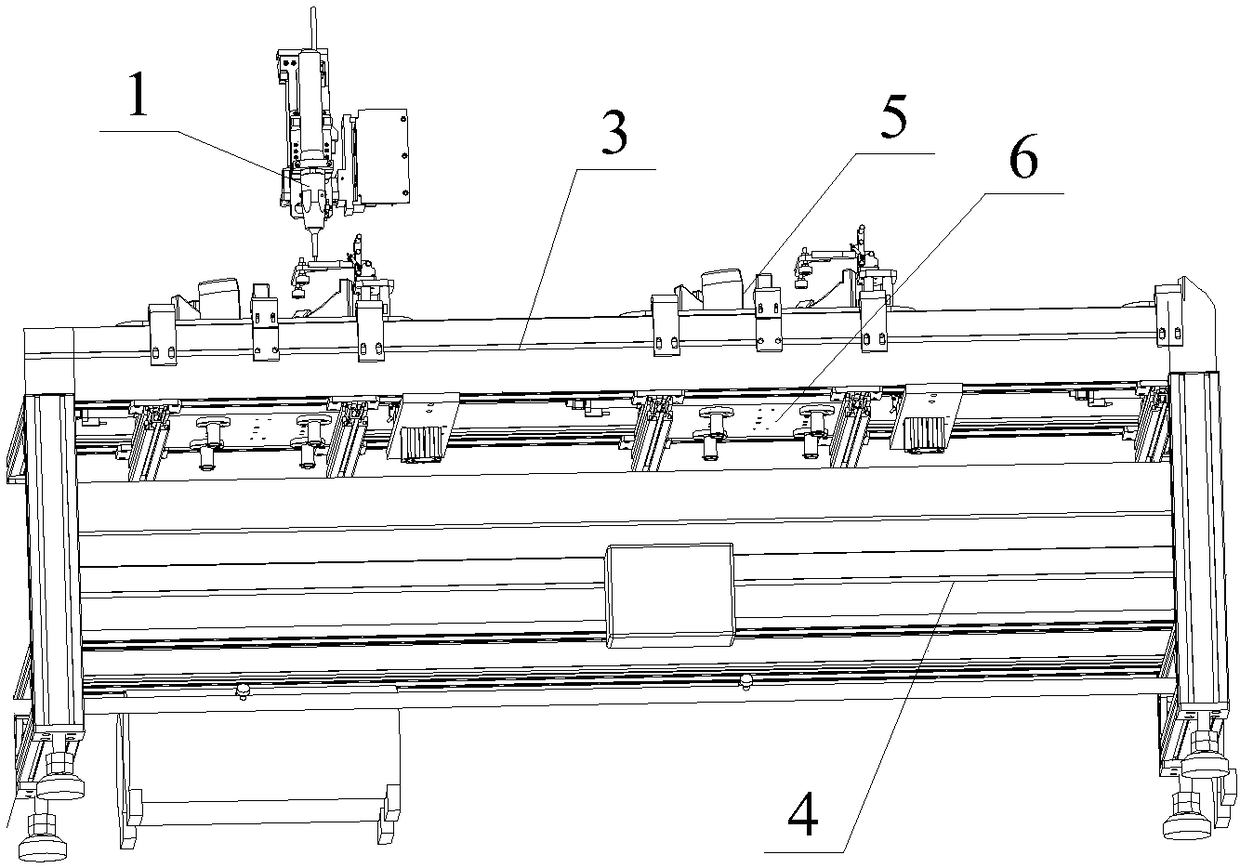

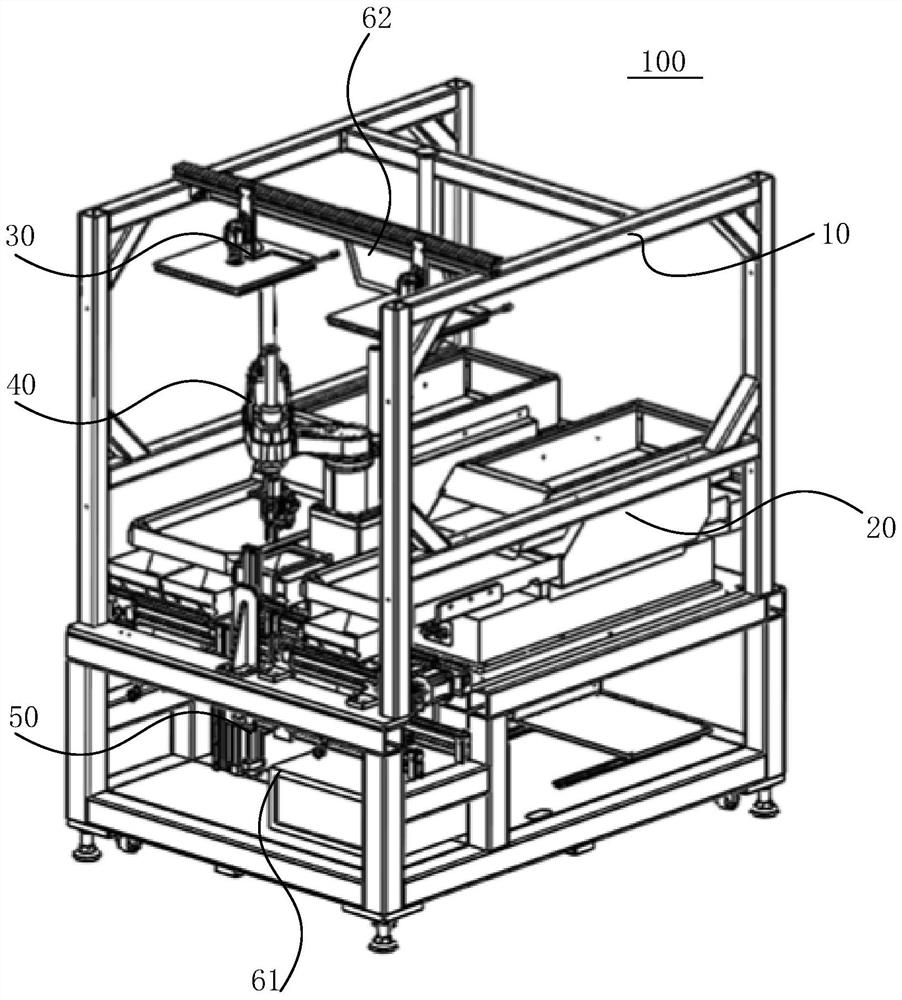

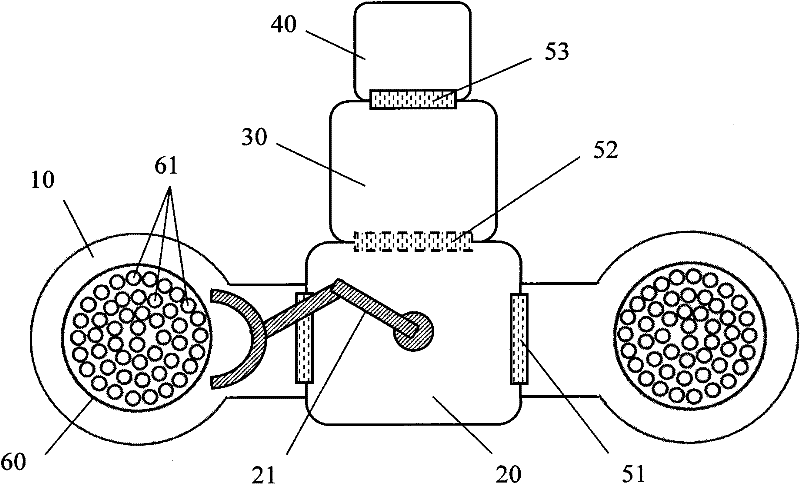

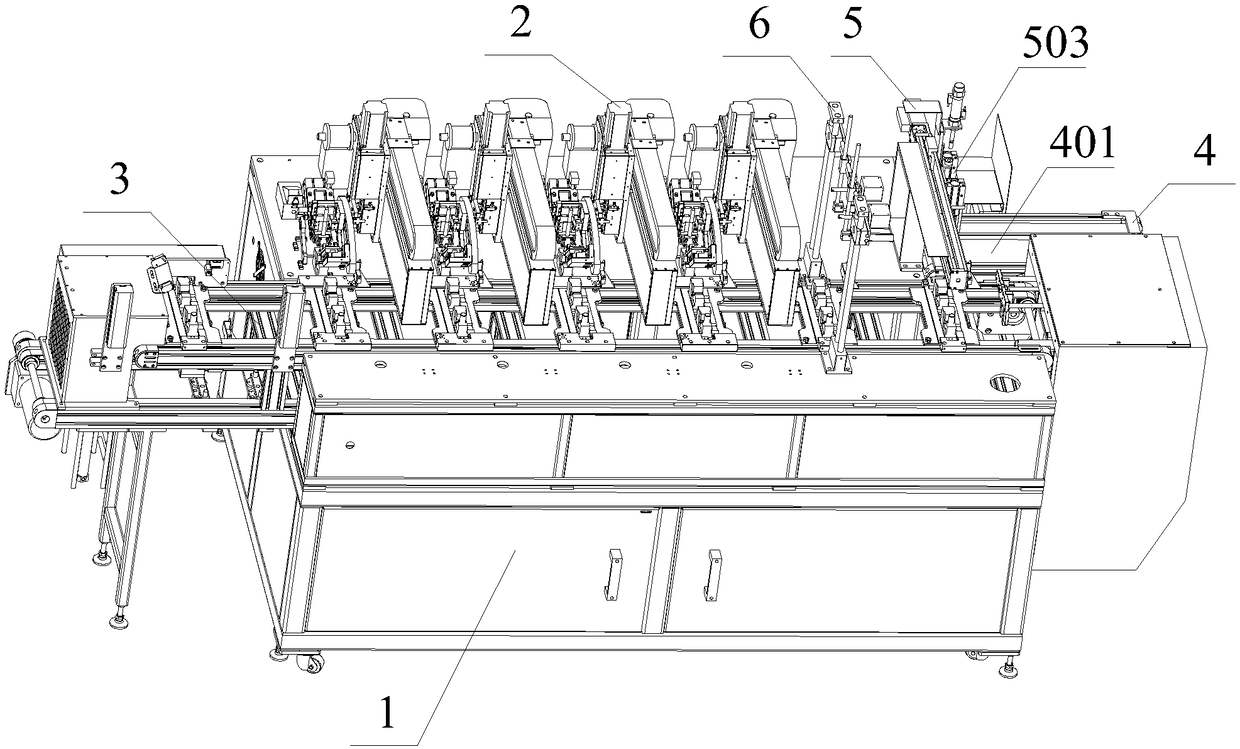

Automatic tin soldering machine assembly

ActiveCN108067699AReduce time consumptionReduce circulation proceduresWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSoldering

The invention provides an automatic tin soldering machine assembly. The automatic tin soldering machine assembly comprises a machine box. The machine box is provided with a plurality of welding cleaning modules which are used for carrying out soldering tin soldering on a workpiece, a conveying module for conveying and transferring the workpiece, a discharging module for discharging the workpiece and a material taking module for transferring the workpiece to the discharging module from the conveying module. The material taking module is arranged between the welding cleaning module and the discharging module. The automatic tin soldering machine assembly is high in automation degree, safety and precision are improved, the whole structure is compact, the space is saved, the tin soldering quality is high, and high-efficiency and high-quality soldering tin soldering work is further achieved while the production cost is reduced.

Owner:石超

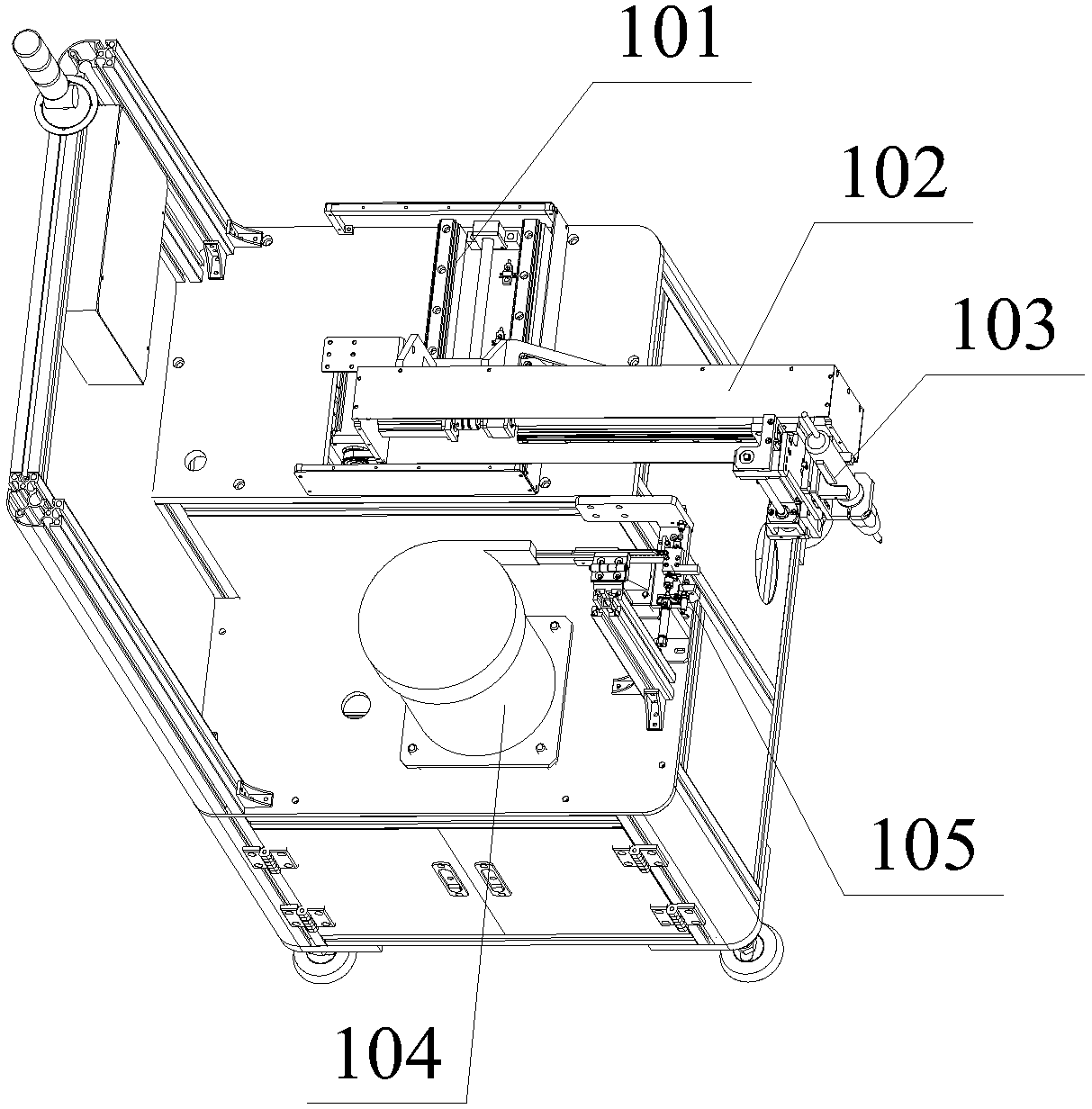

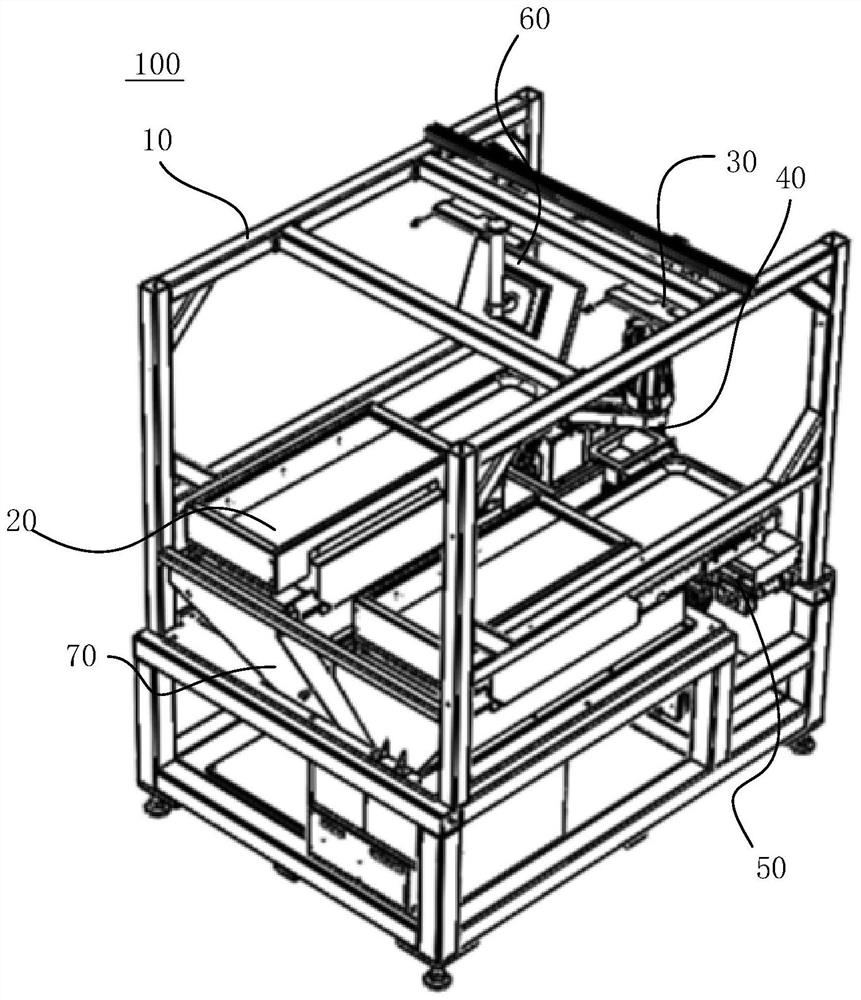

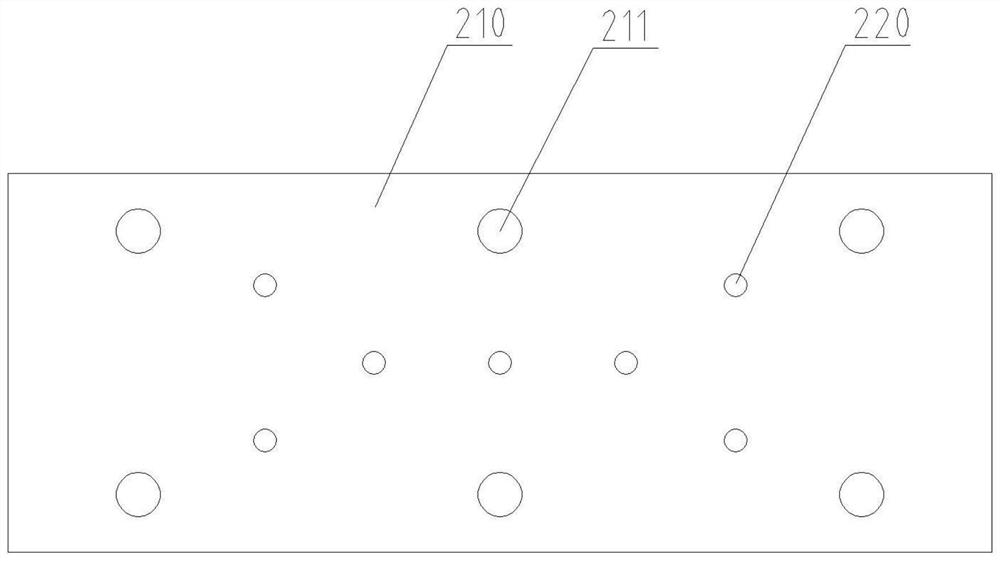

Semi-automatic screw assembling system

ActiveCN108067863AGuaranteed stabilityRealize automatic cycle processingMetal working apparatusSemi automaticAssembly line

The invention provides a semi-automatic screw assembling system. The semi-automatic screw assembling system comprises assembly lines, a plurality of screw tightening mechanisms arranged on the two sides of the assembly lines and lifting positioning mechanisms arranged on the two sides of the assembly lines. The assembly lines include the upper assembly line and the lower assembly line which is arranged corresponding to the upper assembly line. The lower assembly line transfers machined inferior-quality products to the upper assembly line through the lifting positioning mechanisms to be machined again. The semi-automatic screw assembling system is reasonable in function division, automatic circular machining of good products and the inferior-quality products is achieved, in cooperation withautomatic equipment and manual monitoring, automatic assembling of the good products and the interior-quality products is precisely completed, the safety and the accuracy are improved, the whole structure is compact, space is saved, the screw screwing quality can be ensured, and the product reject ratio is greatly reduced.

Owner:重庆桐雨石科技有限公司

Preparation method of fluorescent powder ball mill

InactiveCN105903374AImprove uniformityGood optical performanceTransportation and packagingRotary stirring mixersBall millMaterials science

The invention provides a preparation method of a fluorescent powder ball mill. The preparation method of ball milled powder comprises the steps of, 1 raw material preparation, wherein the fluorescent powder ball mill, a PEO glue solution and an aluminum oxide dispersion solution are prepared independently in advance; 2, powder syrup preparation, wherein the prepared fluorescent powder ball mill is placed into a powder syrup preparation machine, then, the PEO glue solution, the aluminum oxide dispersion solution and recycling powder are added respectively, and sufficient mixing and stirring are performed; 3, powder syrup sampling. The manufacturing method of the fluorescent powder ball mill is improved, on the basis of the proper proportion and sufficient stirring, the fluorescent powder uniformity can be improved, the optical performance can be improved, waste can be recycled, the manufacturing utilization rate can be improved, and the production cost can be lowered.

Owner:ANHUI SHILIN LIGHTING

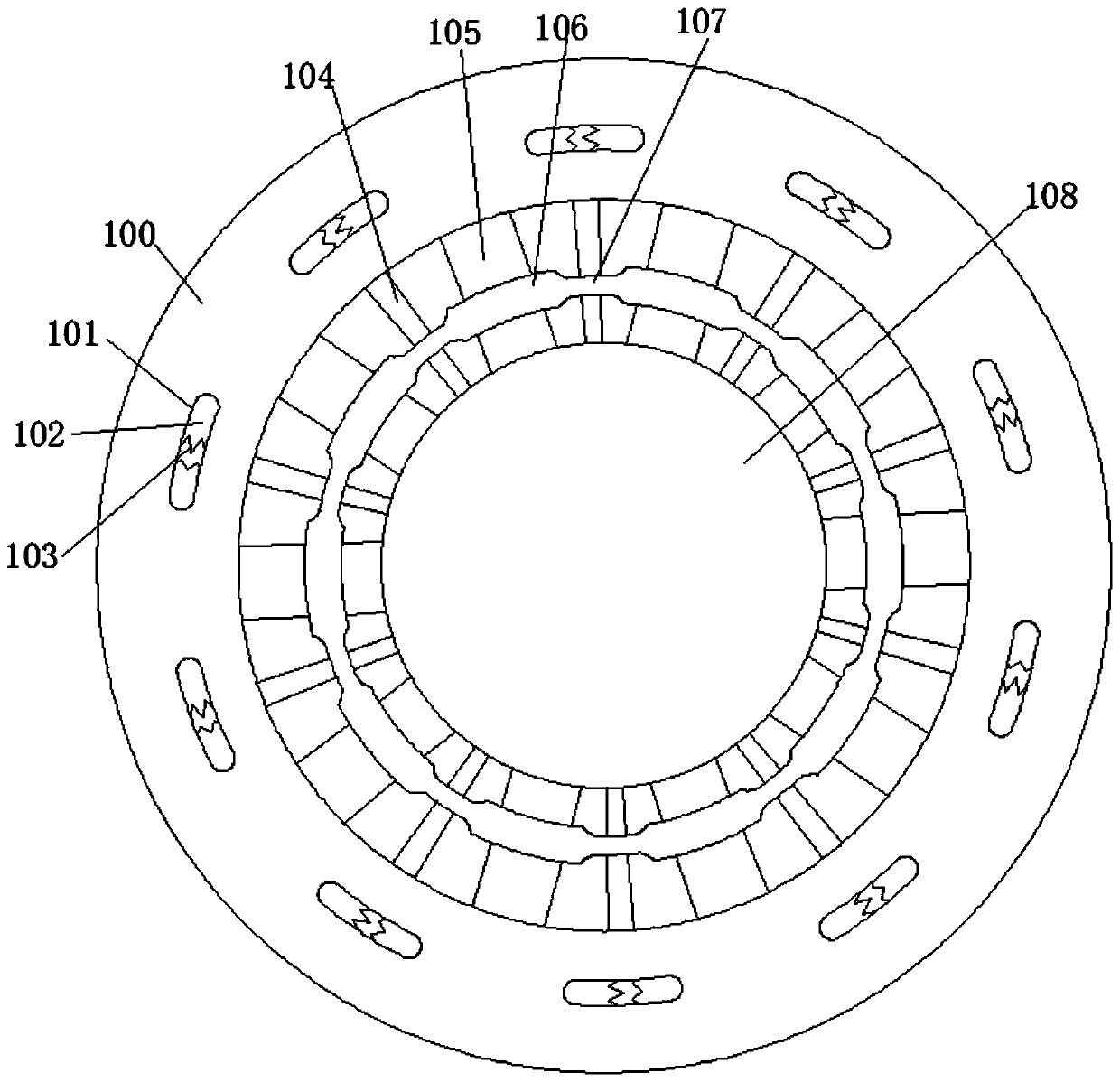

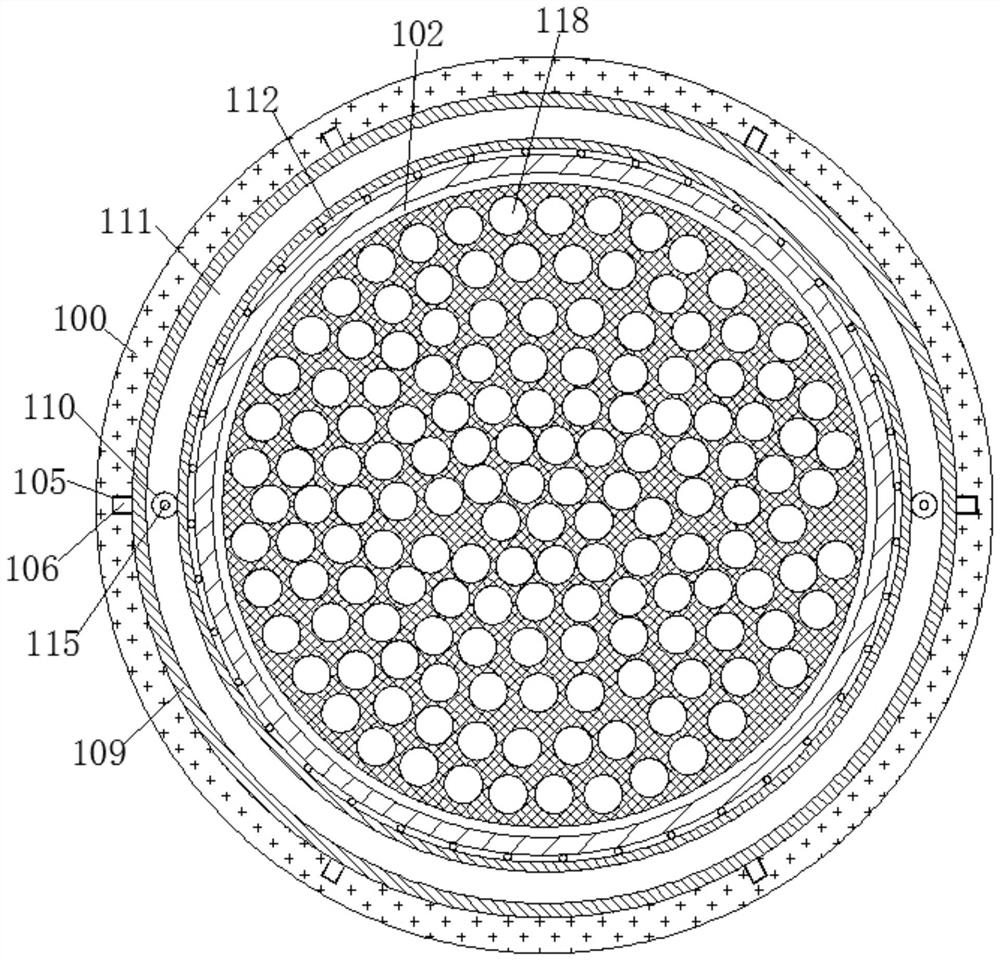

Annular connecting device for connecting of all-casing drilling occlusive piles and structural bottom plate steel bars

The invention discloses an annular connecting device for connecting of all-casing drilling occlusive piles and structural bottom plate steel bars. The annular connecting device comprises an annular shell internally provided with an annular cavity, a plurality of butting holes distributed circumferentially are formed in the annular shell in the mode of penetrating through the annular cavity, double layers of first inserting grooves located between any two adjacent butting holes are formed in the inner wall of the inner circle of the annular shell in a penetrating mode, the annular connecting device further comprises a cylinder shell located at the center of the annular shell and provided with an upwards opening, second inserting grooves corresponding to the first inserting grooves one to one are formed in the inner wall of the side face of the cylinder shell in a penetrating mode, and double layers of fixing rods distributed in the front-back direction are fixedly connected between the end face of the side face of the cylinder shell and the side face of the inner wall of the annular shell, wherein the end face of the side face of the cylinder shell is located between every two adjacent second inserting grooves, and the side face of the inner wall of the annular shell is located between every two adjacent first inserting grooves; and the fixing rods are fixedly connected with stabilizing loops surrounding the cylinder shell, and a stabilizing ring is arranged on the stabilizing loop between every two adjacent fixing rods.

Owner:TENGDA CONSTR GROUP CORP

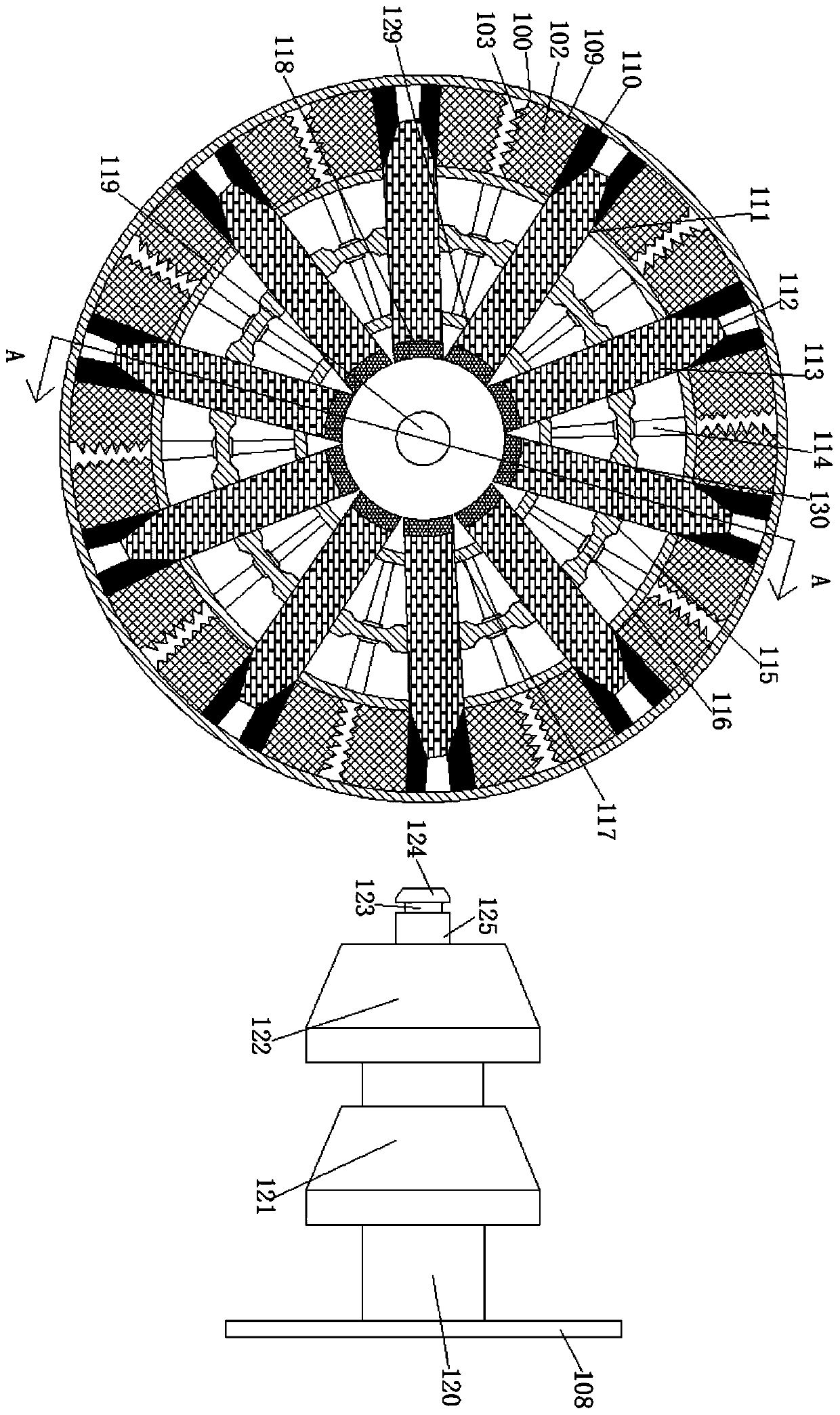

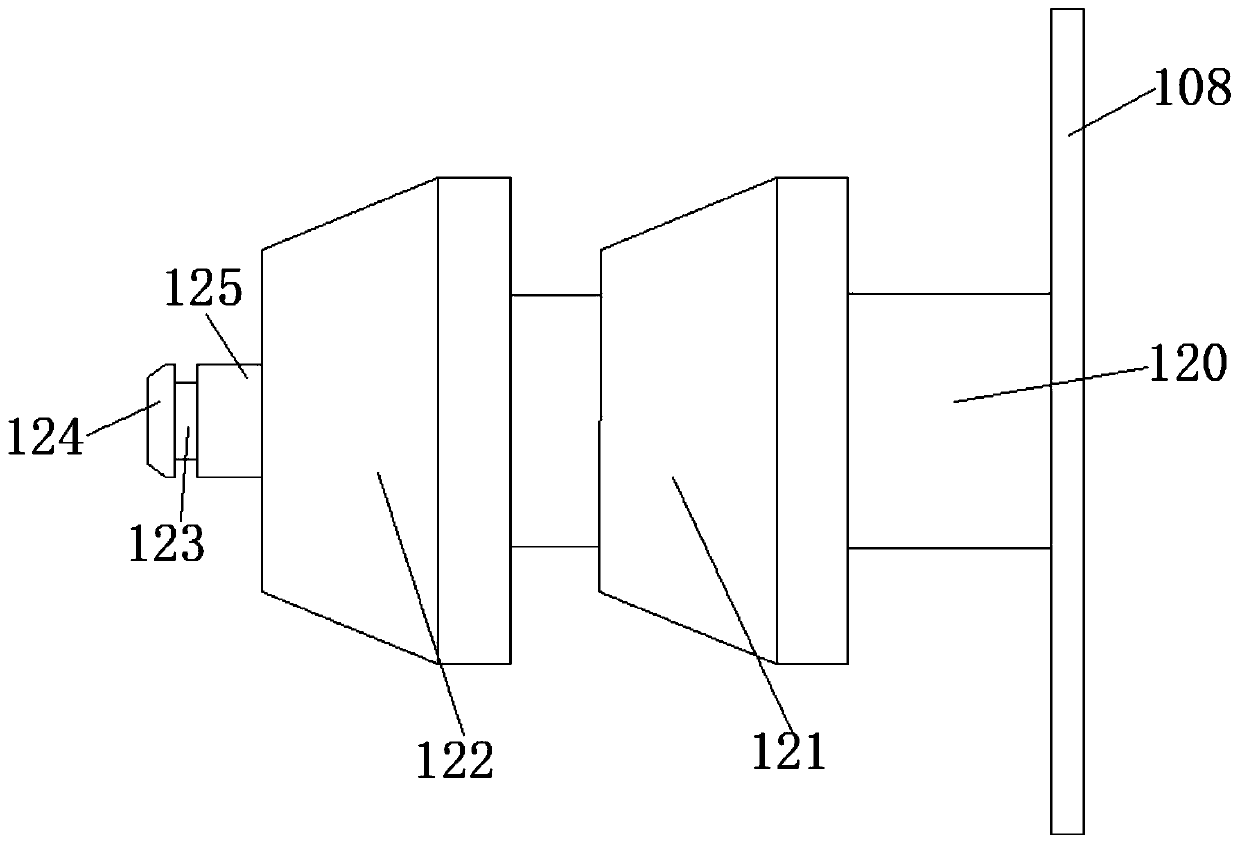

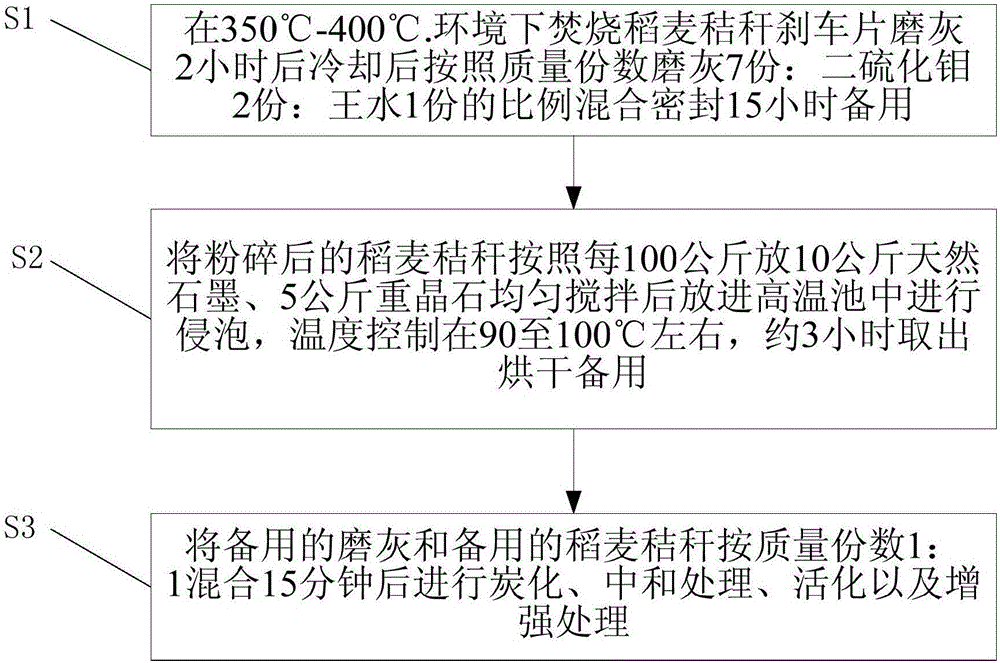

Friction material production process for ground rice and wheat straw brake pad

ActiveCN106118599AReduce pollutionImprove production utilizationOther chemical processesFriction liningCarbonizationEngineering

The invention provides a friction material production process for a ground rice and wheat straw brake pad, comprising the following steps: incinerating rice and wheat straw, grinding for 2 hours at 350-400 DEG C, cooling, mixing 7 parts of ground ash, 2 parts of molybdenum disulfide and 1 part of aqua regia, and sealing for 15 hours for later use; putting 10kg of natural graphite and 5kg of barite in each 100kg of ground rice and wheat straw, uniformly stirring, putting in a high temperature tank for soaking, controlling the temperature at about 90-100 DEG C, taking out after about 3 hours, and baking for later use; and mixing the standby ground ash and the standby rice and wheat straw according to the mass fraction of 1:1 for 15 minutes, and then carrying out carbonization, neutralizing treatment, activation and enhanced treatment. The friction material production process has the advantage of reasonable utilization of waste.

Owner:JIANGSU JINMAISUI NEW ENERGY TECH

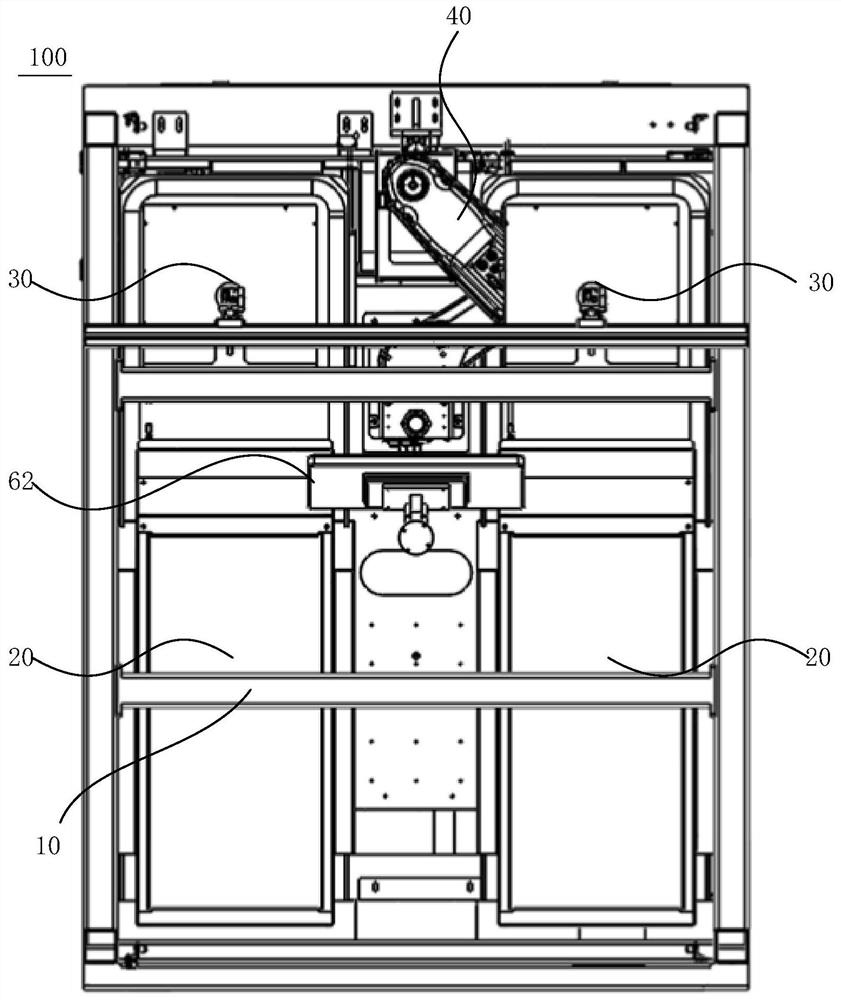

Sorting device and sorting method

PendingCN113262989ARealize sortingRealize the supplySortingProcess engineeringIndustrial engineering

The invention provides a sorting device and a sorting method, and relates to the field of feeding and sorting. The sorting device comprises a feeding mechanism, a recognition mechanism, a picking mechanism, an output mechanism and a control mechanism. The feeding mechanism is used for bearing materials and dispersing the materials, the recognition end of the recognition mechanism faces the feeding mechanism, and the recognition mechanism is used for photographing the materials borne on the feeding mechanism and transmitting photographed image information to the control mechanism. The control mechanism can confirm material information of materials and position information of the materials on the feeding mechanism according to the photographed image information, the picking mechanism is used for picking the materials on the feeding mechanism and placing the materials on the output mechanism, and the output mechanism is used for outputting the materials placed on the output mechanism. According to the sorting device, sorting is carried out without depending on the boundary dimensions of the materials, various different materials can be sorted at the same time, the types of the sorted materials can be rapidly switched according to needs, the production utilization rate is increased, and meanwhile the production land is saved.

Owner:UBTECH ROBOTICS CORP LTD

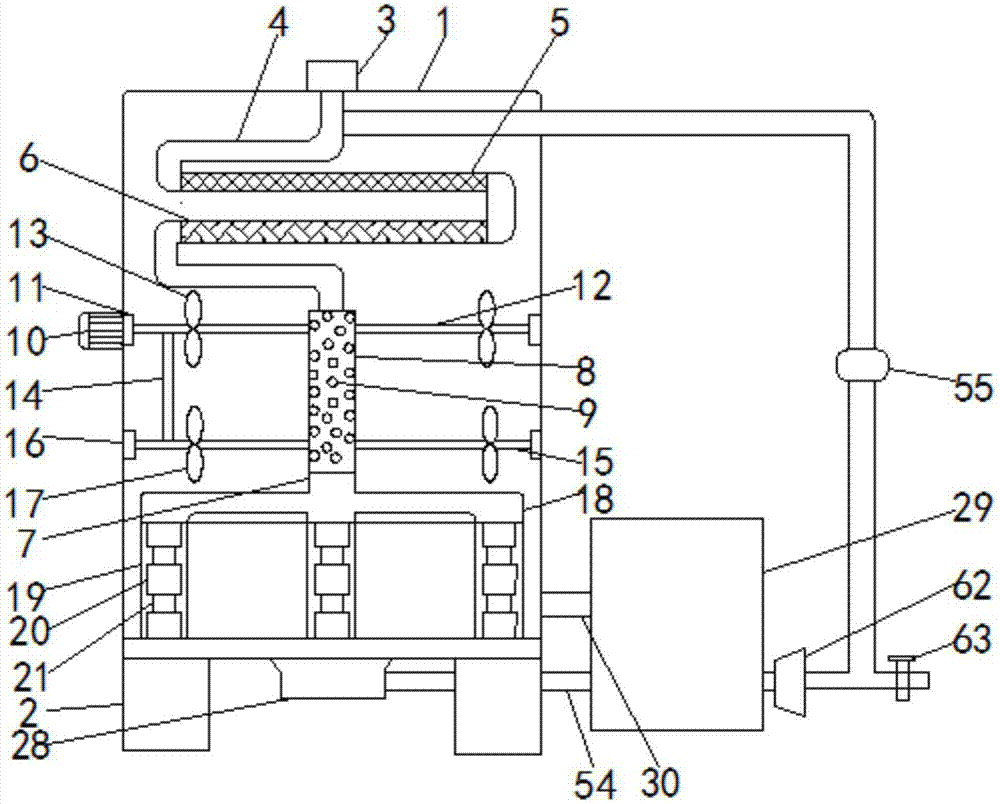

Petroleum recycling and recovery apparatus

InactiveCN107964421AFacilitated DiffusionSpeed up coolingCombination devicesRefining by heating/coolingFan bladePetroleum

The invention discloses a petroleum recycling and recovery apparatus, which includes a shell body. Support feet are installed fixedly on two sides of the bottom of the shell body. An oil inlet is arranged on the center of the top of the shell body. An S-shaped condensing pipe is connected to the bottom of the oil inlet and is arranged on the top of the inner wall of the shell body. An active charcoal adsorption layer and a filtering screen are connected to interior of the S-shaped condensing pipe and are arranged successively from top to bottom. An oil delivery pipe is installed on the bottomof the S-shaped condensing pipe. A protective cover is installed on the oil delivery pipe and is located inside the shell body and a plurality of gas exhausting holes are formed in the protective cover at equal interval. A motor is installed on one side of the outer wall of the shell body. A plurality of first bearings are connected to one end, which is closed to one end of the inner wall of the shell body, of the motor and are symmetric about the center of the shell body. Adjacent first bearings are movably connected with each other through a first transmission rod. First fan blades are installed on the first transmission rod and are located at the two sides of the protective cover. The petroleum recycling and recovery apparatus is convenient to use, ensures that the petroleum can be recycled and waste gas can be recovered completely, is high in work efficiency and is environment-friendly.

Owner:周晓飞

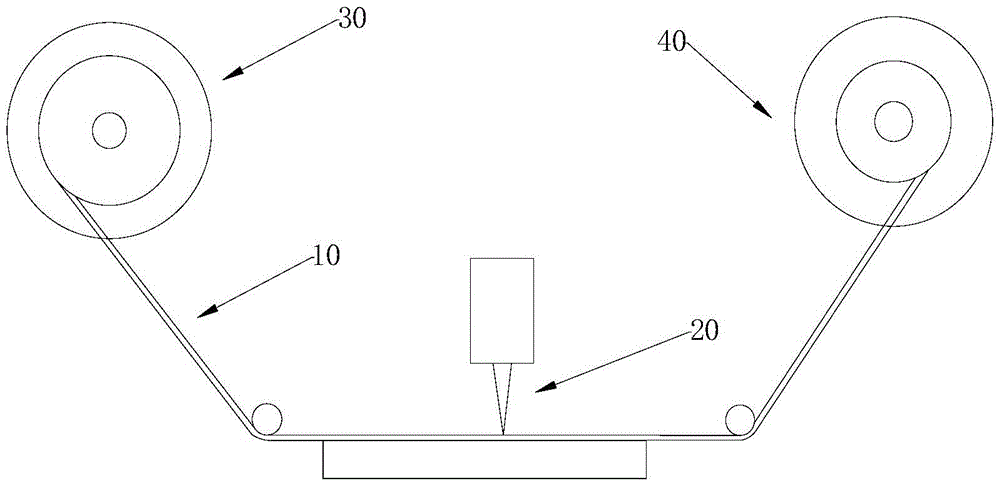

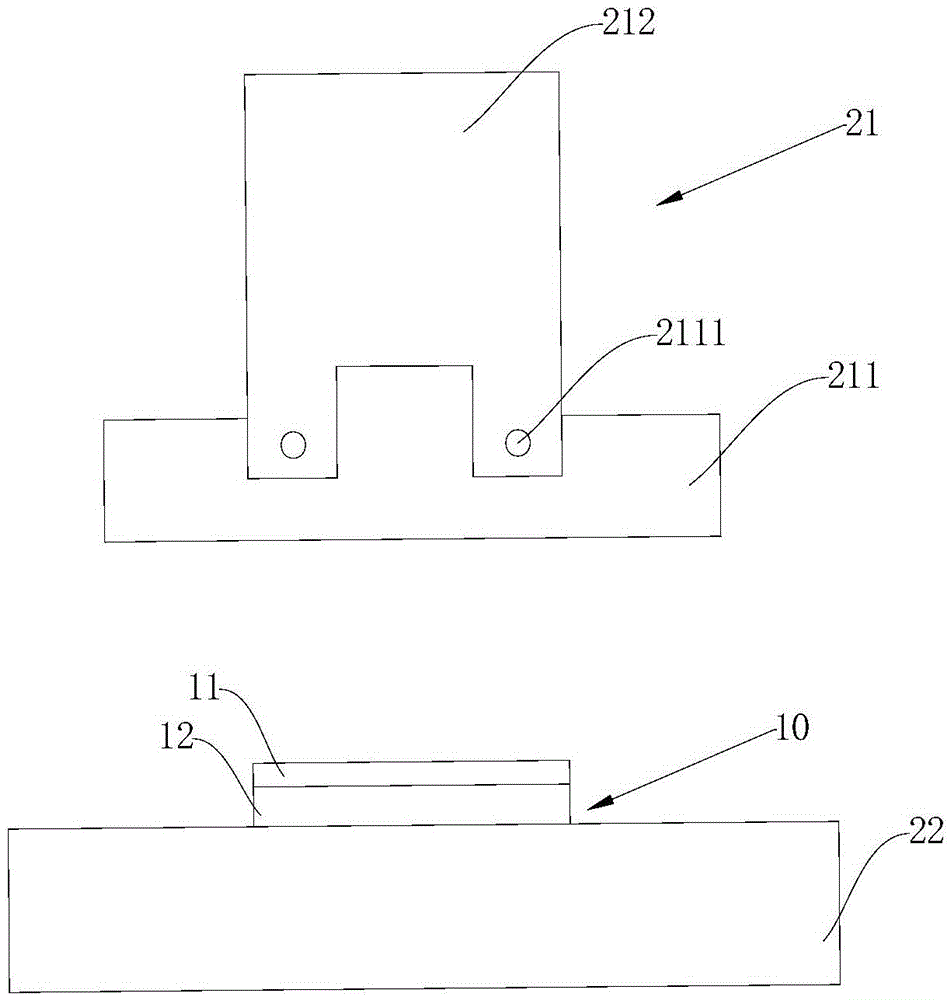

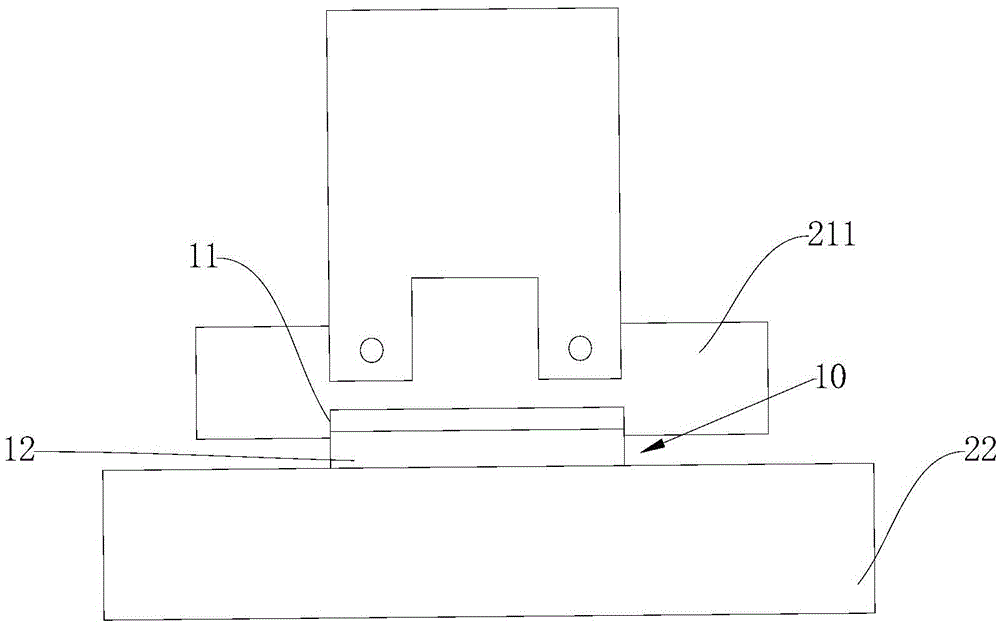

Electroplating method and device for a circuit board

ActiveCN104862768BReal-time adjustment of working currentRealize seamless switchingCellsStart timeEngineering

The invention discloses an electroplating method for a circuit board, which comprises: sequentially transporting a plurality of circuit boards into a plating tank in a chain-type continuous forward manner; detecting each circuit board entering the entrance of the plating tank ; When it is detected that the full tank current of the current entering circuit board is different from the full tank current of the previous entering circuit board, start timing, and according to the length of timing, the full tank current of the currently entering circuit board and The full tank current of the circuit board entering the previous one adjusts the working current of the plating tank; the full tank current refers to the working current when the circuit boards accommodated in the plating tank have the same electroplating parameters; according to the adjustment The final working current is used to electroplate the circuit board in the plating tank. Correspondingly, the invention also discloses a circuit board electroplating device. By adopting the embodiment of the present invention, seamless switching of electroplating of different circuit boards can be realized, and the production utilization rate of circuit boards can be improved.

Owner:GCI SCI & TECH

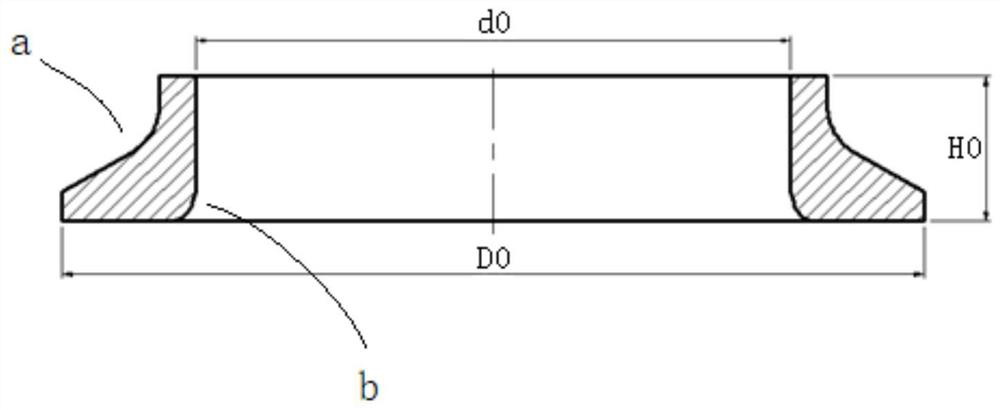

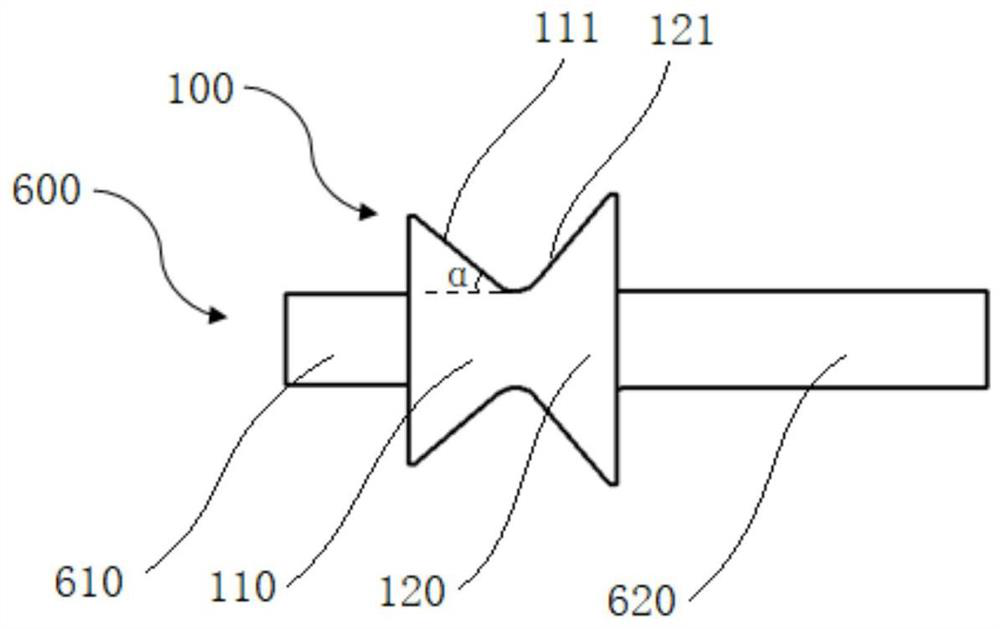

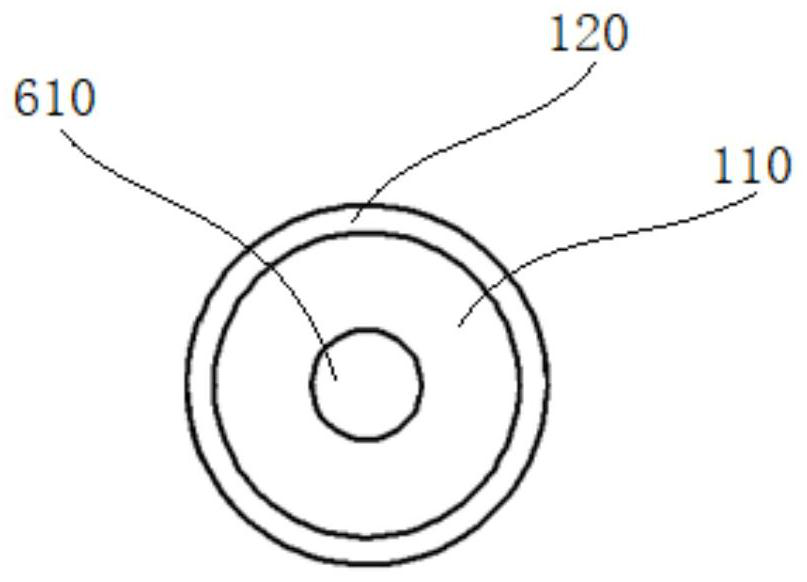

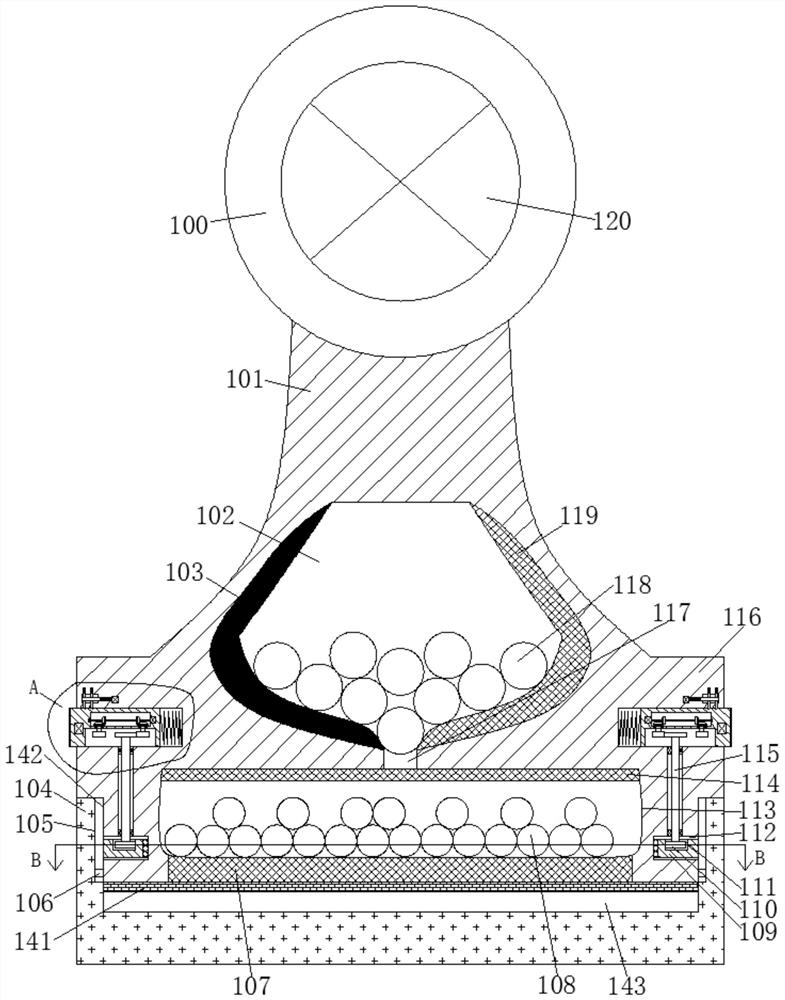

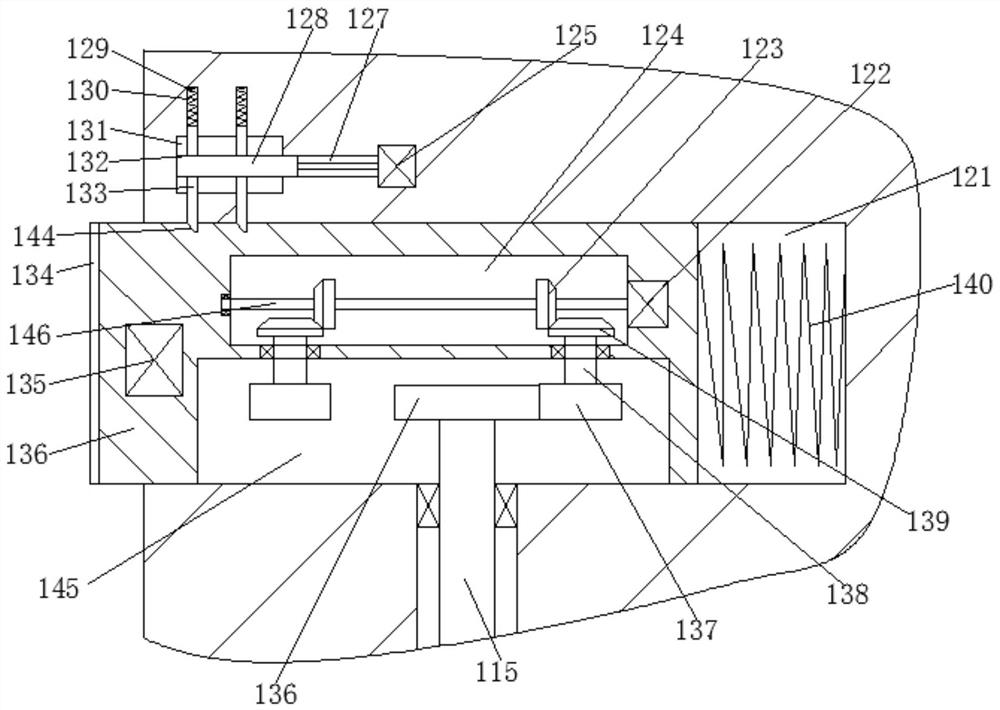

Forming device and forming method for ring forging for offshore engineering

ActiveCN112371887BImprove molding efficiencyImprove production utilizationPiercing pressesForging/hammering/pressing machinesThermodynamicsEngineering

The present invention discloses a type of sea industry for molding device and molding method. This device includes: support blocks, support blocks include support surface one and support surface two, and support surface one and support surface two.Type slot, V -shaped grooves are used to support the part of the workpiece to be processed; the upper anvil, the upper anvil includes a horizontal working face, and the horizontal working surface is used to squeeze the workpiece on the support block of the center line of the V -shaped slot;The upper -type anvil, the upper -type anvil includes the formation surface that matches the outer contour surface of the coastal -to -ring forging. The molding surface is used for horizontal working surface to squeeze and then along the central line of the V -shaped slotextrusion.The present invention has changed the tradition of the tradition of the coastal tolerance to the tradition of the ring forging, avoiding the problem of folding and low imitation of the peeling molding method, and improving the molding efficiency and product utilization of the sea industry for the type of ring forging.

Owner:SHANGHAI ELECTRIC SHMP CASTING & FORGING CO LTD

Full-automatic butting device for reinforcement cage in municipal construction engineering

The invention relates to a full-automatic butting device for a reinforcement cage in municipal construction engineering. The full-automatic butting device comprises an annular shell and a main reinforcement support main body, wherein the annular shell and the main reinforcement support main body are two parts which are completely separated, an annular cavity is formed in the annular shell, the annular shell penetrates through the annular cavity and is provided with a plurality of butting holes distributed in the circumferential direction, and the inner wall of an inner ring of the annular shell is provided with first inserting grooves which are located between any two adjacent butting holes in a penetrating manner. The device further comprises a cylindrical shell with an upward opening located in the center of the annular shell, second inserting grooves which are in one-to-one correspondence with the first inserting grooves are arranged in the inner wall of the side surface of the cylindrical shell in a penetrating manner, and the side surface of the cylindrical shell is located on the end surface between every two adjacent second inserting grooves and is fixedly connected with a double-layer fixing rod which is distributed back and forth between the side surfaces of the inner wall of the annular shell between every two adjacent first inserting grooves.

Owner:吴晓建

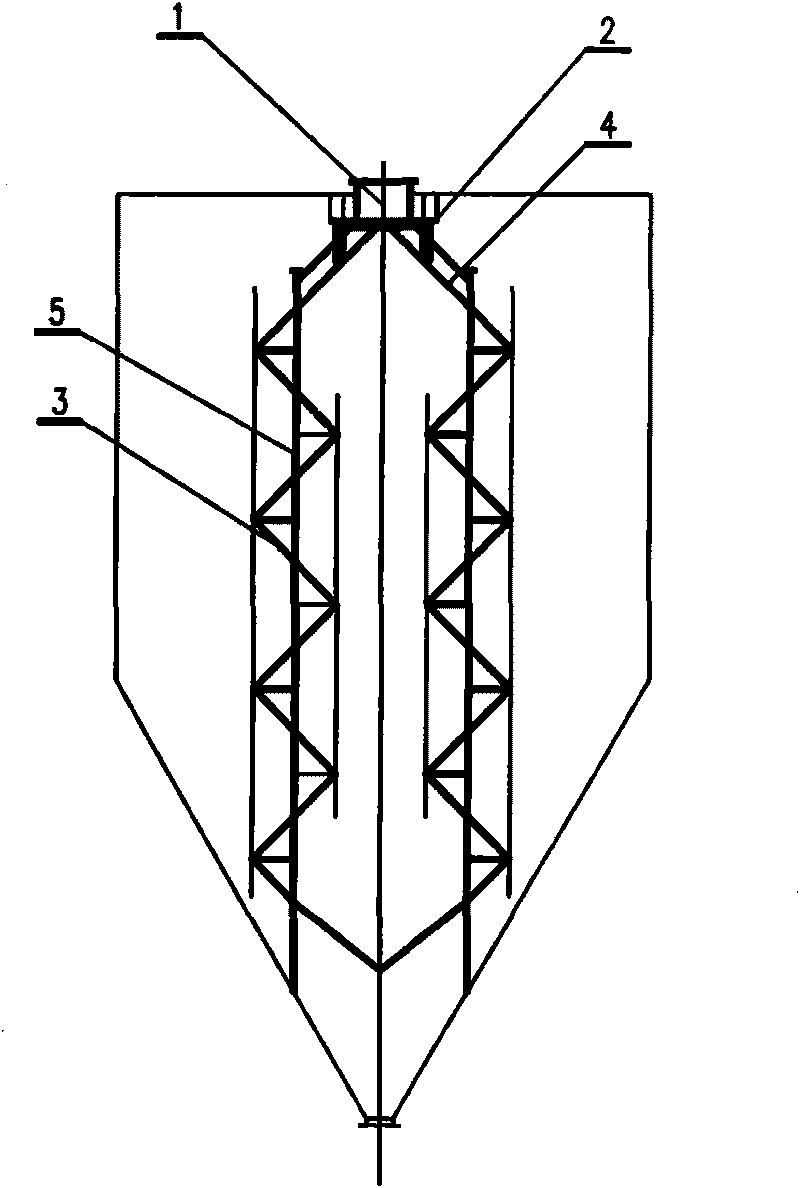

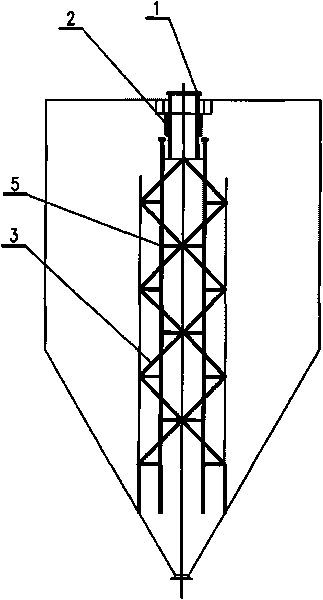

Method and device for effectively reducing breakage rate of lime lump materials

InactiveCN101723188AReduce breakage rateSimple production processLarge containersLoading/unloadingBreakage rateSilo

The invention relates to the technical field of lime production, in particular to a method and a device for effectively reducing breakage rate of lime lump materials. The method is realized by arranging a rotating warehousing device of the lime lump materials in a silo, the lime lump materials to be warehoused are divided into a plurality of paths through the rotating warehousing device of the lime lump materials, then the lime lump materials enter into the silo through a rotating slideway and the lime lump materials are gradually paved in the silo. The device comprises a silo opening chute, a hanger and a rotating slideway, wherein the rotating slideway is connected with an outlet of the silo opening chute, and the other end of the rotating slideway is near to the outlet of the silo; and the hanger is used for suspending the rotating slideway in the silo. The rotating slideway comprises a material distributing chute, a fixed support and a rotating chute, wherein the material distributing chute is arranged at the outlet of the silo opening chute and fixed through the hanger, the rotating chute is connected with the material distributing chute, and the rotating chute is fixed in the silo through the fixed support. The method and the device for effectively reducing the breakage rate of the lime lump materials, and the rotating warehousing device of the lime lump materials is arranged in the silo, thereby effectively reducing the breakage rate of the lime lump materials and improving the finished product utilization rate of the lime lump materials.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC +1

Stone sewage treatment method

InactiveCN108314260AAvoid damagePracticalCeramic shaping plantsMultistage water/sewage treatmentBrickSewage

The invention relates to the field of sewage treatment and especially relates to a stone sewage treatment method which comprises the following steps: the first step, converging and sending dust removing machine absorption sewage, cutting polishing sewage and domestic sewage into a settling pond to be precipitated; the second step, sending precipitated precipitate into a smashing machine to be smashed and then mixing smashed materials and precipitated precipitate and sending into a feeding pump; the third step, utilizing a chemical adding machine to add a flocculant into a chemical adding pump;the fourth step, connecting the feeding pump and the chemical adding pump into a high-speed separating machine to perform water-sewage separation; the fifth step, sending the separated dry mud into astirring machine, adding separated water and cement and stirring; the sixth step, sending the stirred mixture into a brick pressing machine to be pressed and then drying to prepare non-sintered bricks. The stone sewage treatment method solves the technical problems that an existing treating method has a coarse mean and a bad separating effect.

Owner:FUJIAN NANAN WANFU MACHINERY CO LTD

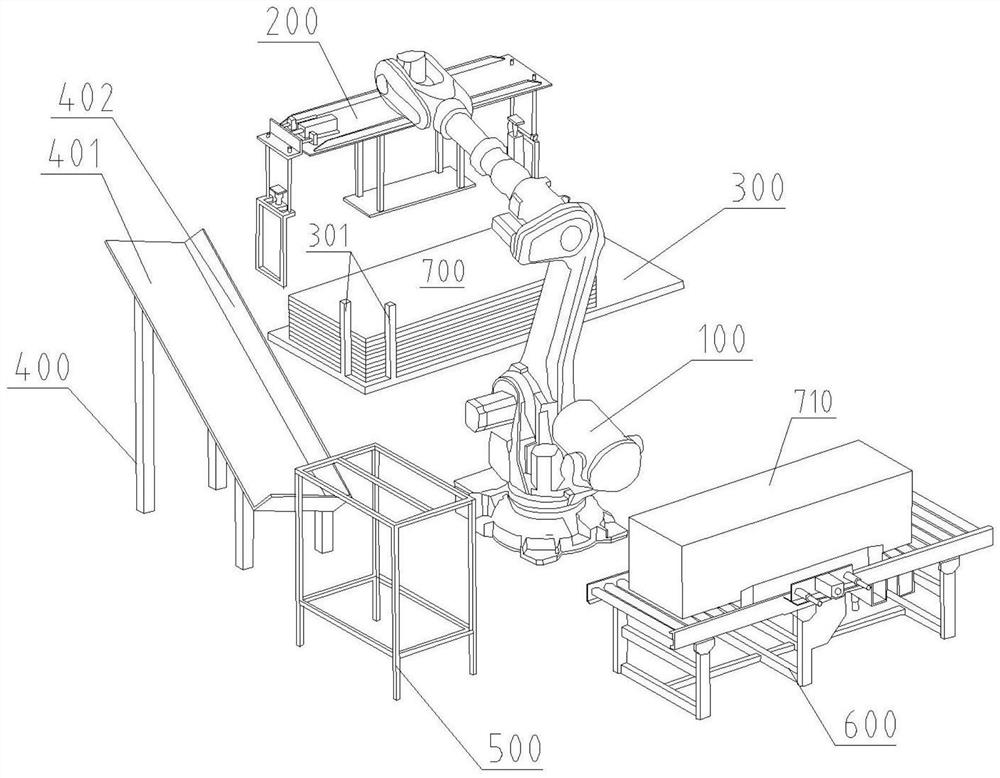

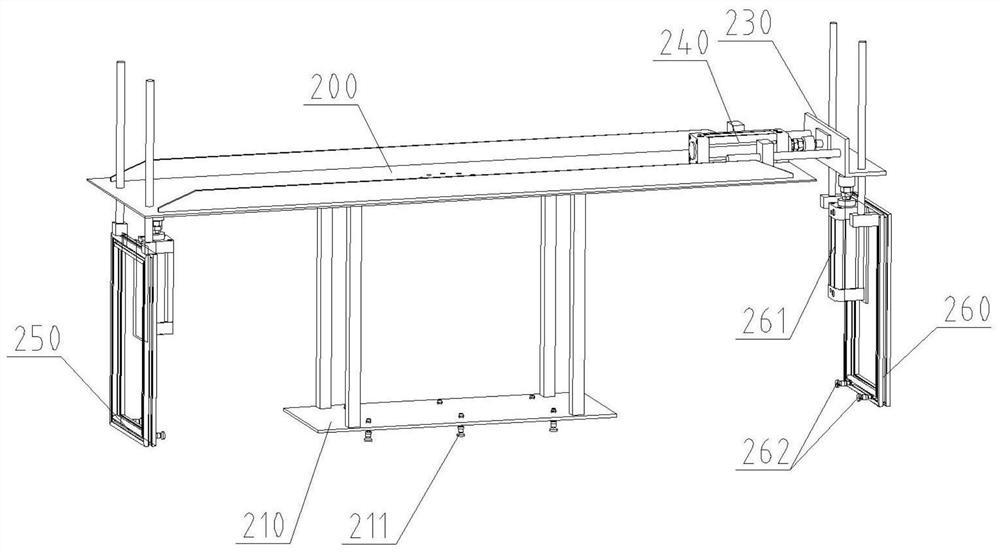

Fan outer packing boxing system and control method thereof

PendingCN112193534AHigh motion positioning accuracyAvoid damagePackaging automatic controlIndividual articlesCartonStructural engineering

The invention relates to the field of fan production equipment, in particular to a fan outer packing boxing system and a control method thereof. The fan outer packing boxing system comprises a robot module, a material frame, an inclined positioning table, a secondary positioning table and a conveying line, wherein the material frame, the inclined positioning table, the secondary positioning tableand the conveying line are arranged around the robot module, the material frame is provided with a positioning structure, and the conveying line is provided with a left centering module and a right centering module. According to the fan outer packing boxing system and the control method thereof, boxing is carried out by a robot, so that the working efficiency is improved, and the labor cost is saved; and the positioning precision of the action of the robot is high, so that the phenomenon that a carton is damaged during manual operation is avoided, and the utilization rate of the carton and thebeauty of the appearance of a fan are guaranteed.

Owner:青岛星华智能装备有限公司

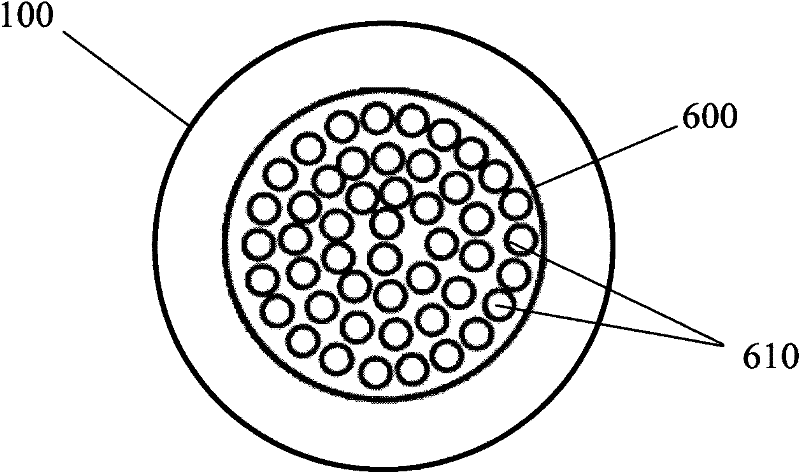

MOCVD (Metal-organic Chemical Vapor Deposition) system with multiple extensional reaction cavities and operation method thereof

ActiveCN102212877BShorten the timeIncrease productionAfter-treatment apparatusSemiconductor/solid-state device manufacturingSystem capacityProcess engineering

The invention discloses an MOCVD (Metal-organic Chemical Vapor Deposition) system with multiple extensional reaction cavities, and the system provided by the invention is used for carrying out extensional reaction on a plurality of substrates arranged on a tray. The MOCVD system comprises a transmission cavity provided with a mechanical arm, a plurality of transit stations and at least two extensional reaction cavities, wherein the plurality of transit stations are connected with the transmission cavity; the substrates can be simultaneously subjected to extensional reaction in the extensionalreaction cavities; and according to mechanical automation operation, the trays in the extensional reaction cavities can be taken out and put in without opening extensional reaction cavity covers, thereby improving the system capacity, saving the time for cooling the extensional reaction cavities and changing trays, and improving the production use ratio of equipment. Because the plurality of extensional reaction cavities share one set of transmission cavity, mechanical arm and the like, one and several other sets of corresponding equipment are saved, the setup cost and operation cost are lowered, and installing sites of the equipment are saved. Because the transit stations have the function of a pre-processing cavity, the tray can be precooled and preheated according to the production requirement so as to further improve the production efficiency.

Owner:JIANGSU ZHONGSHENG SEMICON EQUIP

cutting device

ActiveCN103465294BAvoid cutting failureAvoid Insufficient Cut DepthMetal working apparatusAnisotropic conductive filmEngineering

The cutting device provided by the present invention includes a carrying platform and a cutting unit located above the carrying platform, the cutting unit includes a cutting knife and a knife holder, wherein a connecting portion is provided in the middle of the cutting knife, and the cutting knife passes through the The connecting part is hinged with the knife holder; the cutting device also includes a stopper between the cutter and the carrying platform, and after the cutting knife vertically cuts to the carrying platform, the stopper is used for Keep the blade of the cutting knife parallel to the carrying platform with a gap. The cutting device provided by the invention can be used for cutting the anisotropic conductive film, and can effectively avoid cutting failure of the anisotropic conductive film caused by insufficient cutting depth precision or poor parallelism of the cutter, thereby improving product yield.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

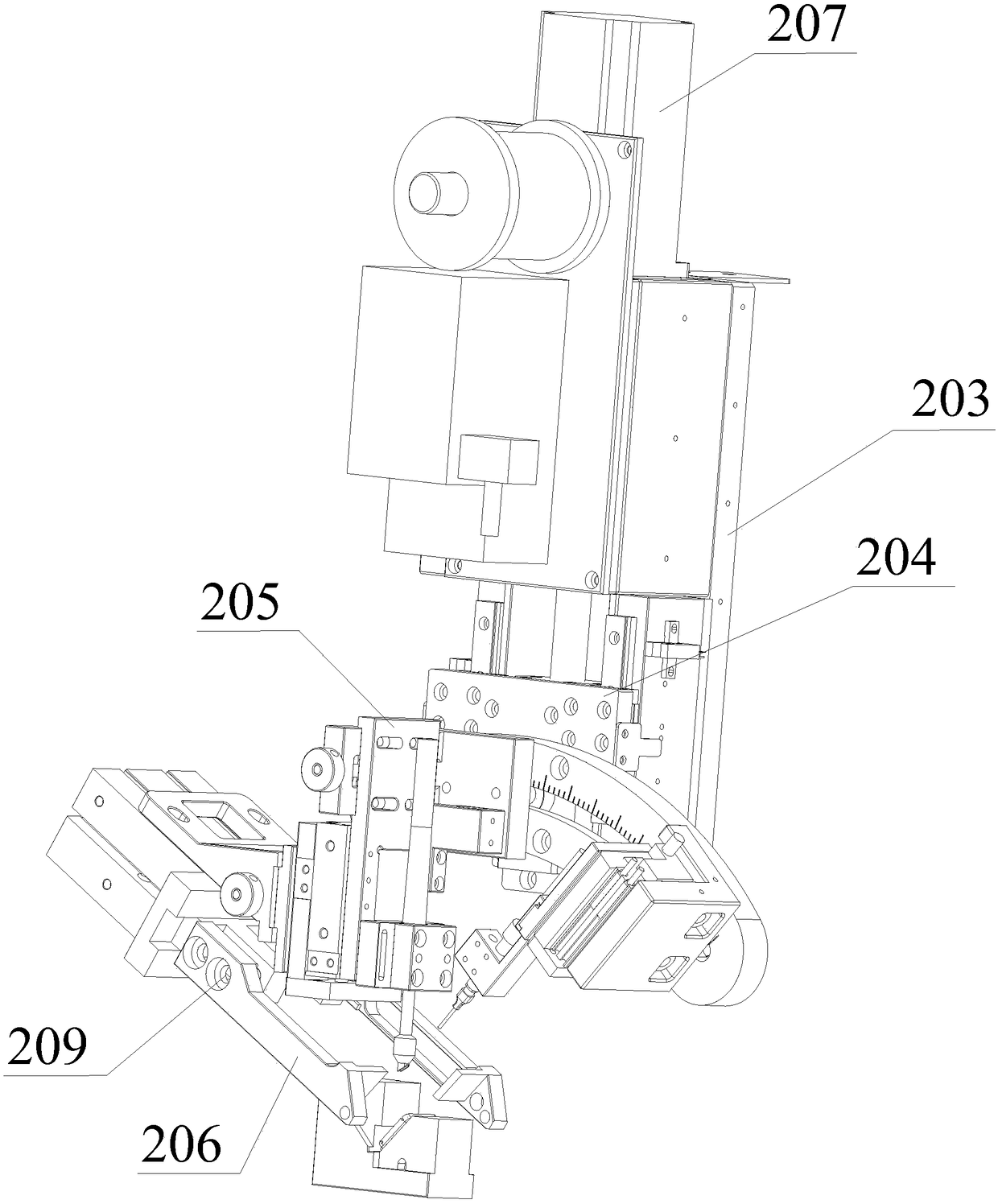

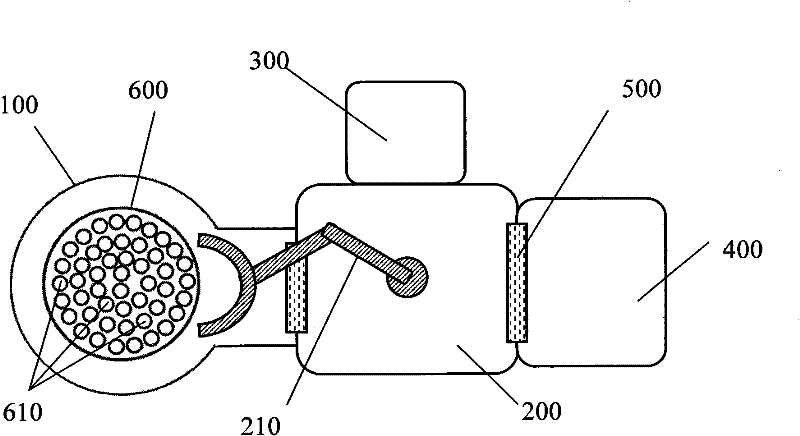

Welding cleaning module applied to soldering tin assembly and soldering tin assembly

ActiveCN108161164AReduce time consumptionReduce circulation proceduresSoldering auxillary devicesEngineeringTin

The invention provides a welding cleaning module applied to a soldering tin assembly and the soldering tin assembly. The welding cleaning module applied to the soldering tin assembly comprises a soldering machine used for conducting soldering tin and welding on workpieces, and a workpiece fine adjusting device used for clamping the workpieces and transferring the workpiece to a preset position andcooperating with the soldering machine for the soldering tin and welding; and the soldering machine comprises a welding head, an electric soldering iron used for conducting soldering tin and weldingcooperating operation on the workpieces and an adjusting frame, wherein the adjusting frame is used for limiting, connecting and cooperating the welding head and the electric soldering iron, and for enabling the welding head and the electric soldering iron to cooperate with each other to form an inclined included angle. The plurality of welding cleaning modules and conveying modules cooperate witheach other so as to finish accurate cooperation between the soldering tin and welding work of the workpieces and the workpiece conveying, the conveying modules can carry out circulating conveying onthe workpieces so as to guarantee the integrity of the tin soldering and welding work, the production efficiency and the product utilization rate are improved, all stations are arranged on the machinebox, and the soldering tin and welding and conveying work of the workpieces are completed in a collaborative mode.

Owner:石超

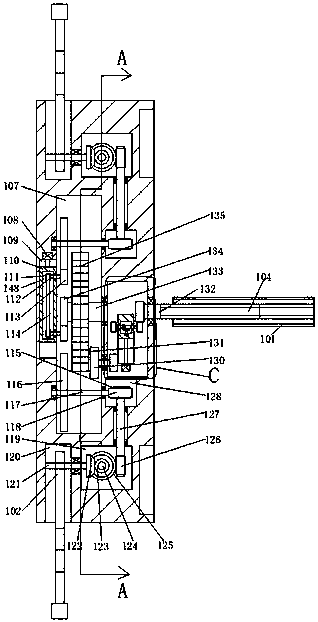

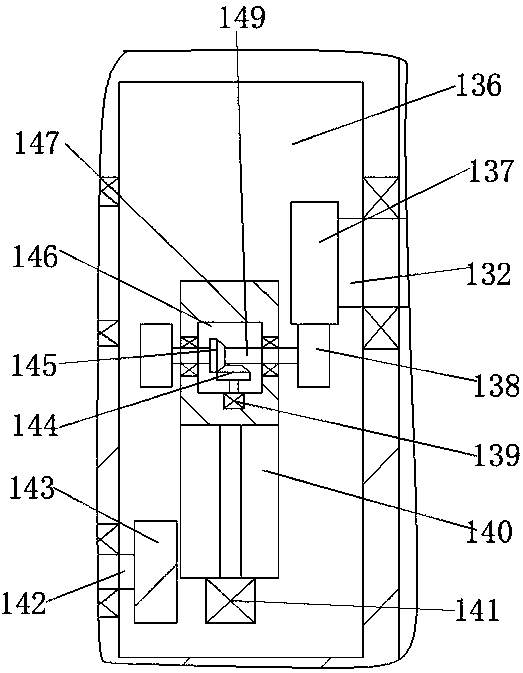

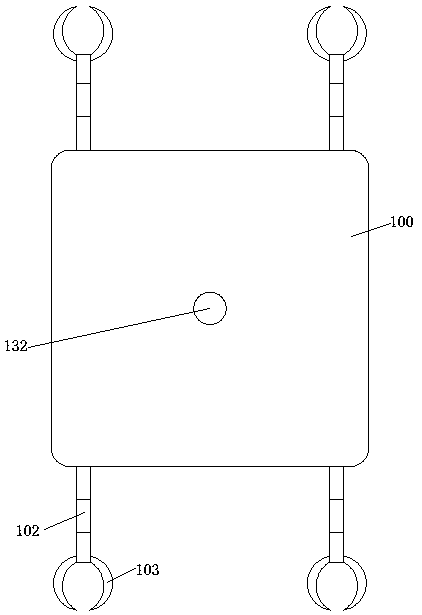

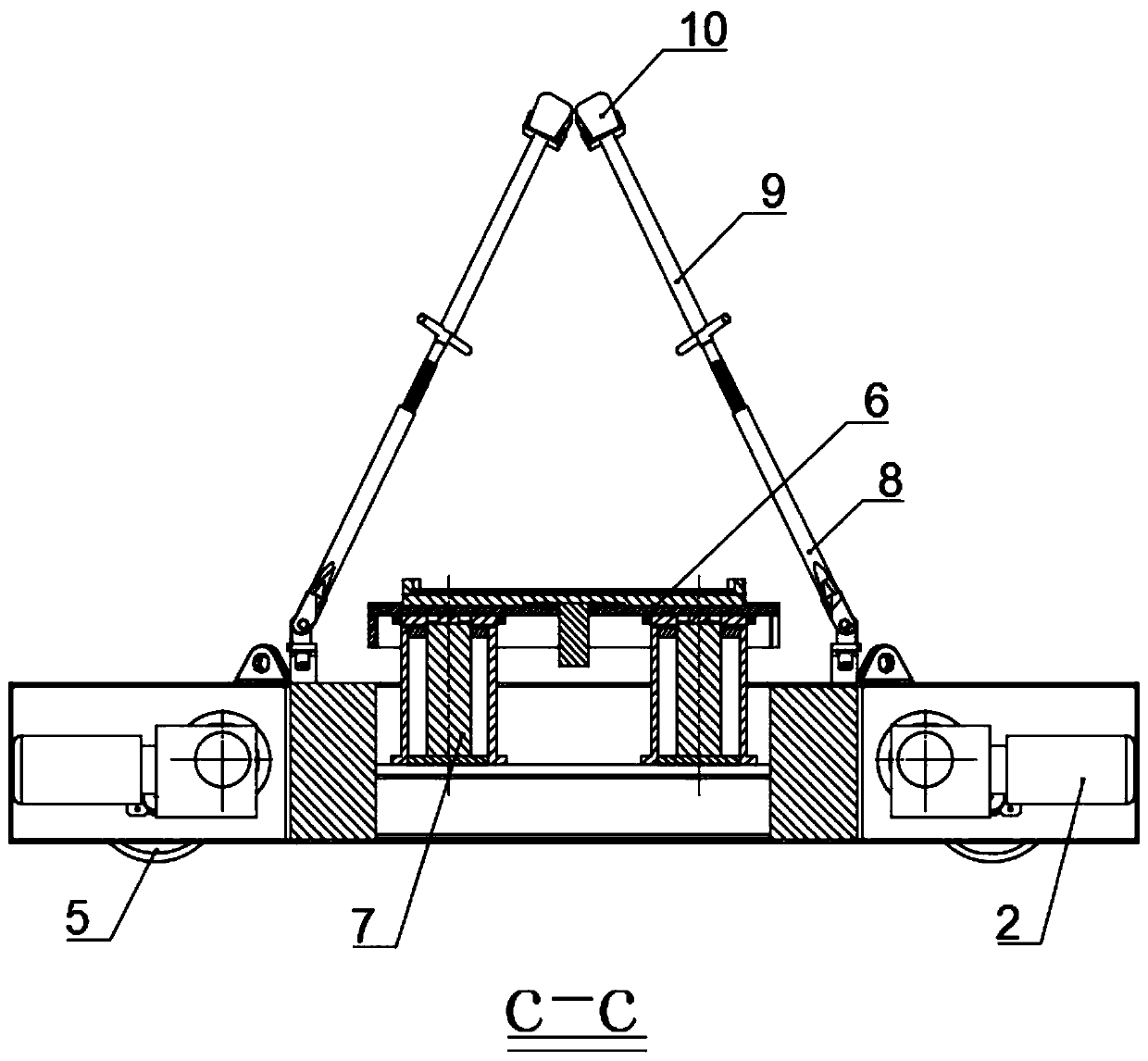

Electric double-platform T-beam transverse moving vehicle

InactiveCN111197284AImprove production utilizationReduce volumeBridge erection/assemblyCarriagesVehicle frameHydraulic pressure

The invention discloses an electric double-platform T-beam transverse moving vehicle and belongs to the technical field of bridge construction equipment. The vehicle comprises a beam moving vehicle frame; a walking mechanism is arranged on the beam moving vehicle frame; and the beam moving vehicle frame is driven by the walking mechanism to move on a walking track; the electric double-platform T-beam transverse moving vehicle further comprises a supporting beam plate; the supporting beam plate is provided with a hydraulic mechanism for driving the supporting beam plate to vertically lift relative to the beam moving frame; the electric double-platform T-beam transverse moving vehicle also comprises a control part electrically connected with the walking mechanism and the hydraulic mechanism;and the control part is provided with a remote controller in remote communication with the control part. The electric double-platform T-beam transverse moving vehicle has the advantages of small size, light weight, convenience in transportation and low use cost.

Owner:中铁八局集团第七工程有限公司 +1

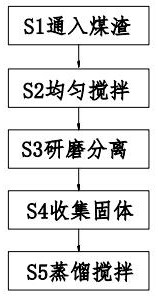

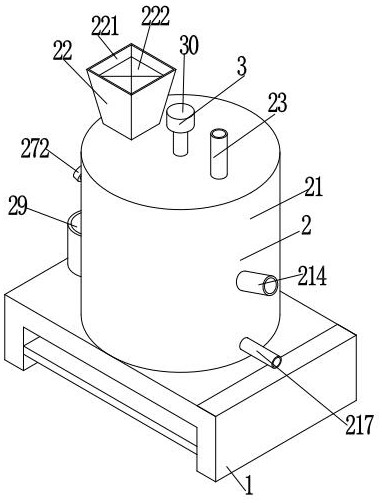

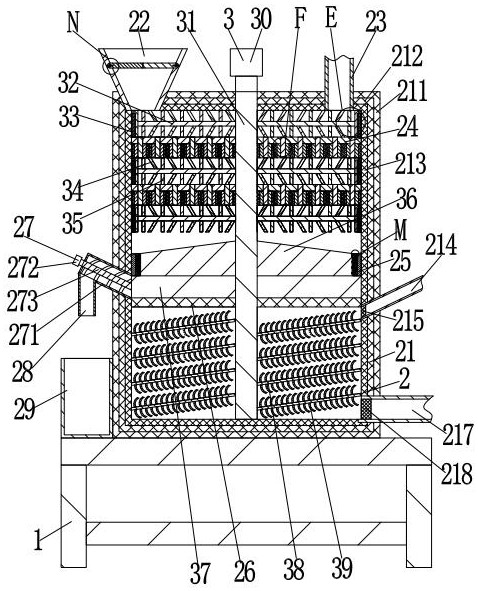

A kind of coal tar pitch preparation and processing method

ActiveCN113025361BFully heatedImprove production utilizationWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by chemical meansThermodynamicsSlag

The invention relates to a method for preparing and processing coal tar pitch, comprising a workbench, a heating device and a stirring device. A heating device is fixedly installed on the upper end of the workbench, and a stirring device is fixedly installed in the middle of the heating device. The heating device includes a heating tank, Feed funnel, feed pipe, heat conduction rod, grinding frame 1, filter plate, discharge pipe, drop pipe and collection tank, the present invention cooperates with heating device and stirring device, coal slag is broken and ground, thereby make coal slag and The extraction liquid is fully contacted to improve the production utilization rate of the cinder, and at the same time accelerate the speed of solid-liquid separation and reduce the time spent on production. Reduced in order to fully heat the cinder.

Owner:辽宁东颢化工有限公司

High-precision numerical control coating head device

ActiveCN108754917ALabor savingAccurate detectionInspecting textilesTextile treatment machine arrangementsNumerical controlControl system

The invention relates to a high-precision numerical control coating head device, and belongs to the technical field of printing and dyeing. The high-precision numerical control coating head device comprises a machine frame, an ascending and descending coating table mechanism, an automatic coating cutter position regulating mechanism, a moving material application mechanism and roller shafts, wherein the ascending and descending coating table mechanism is arranged in the machine fame; the automatic coating cutter position regulating mechanism is arranged above the ascending and descending coating table mechanism; a support frame is fixed above the automatic coating cutter position regulating mechanism; the moving material application mechanism in horizontal arrangement is arranged on the support frame; a plurality of roller shafts are arranged in the machine frame positioned under the ascending and descending coating table mechanism. The high-precision numerical control coating head device provided by the invention has the advantages that the cutter frame, the coting table, the material application frame, the material blocking plate and the like can realize the automatic operation through a control mechanism; meanwhile, the seam head can be accurately detected; the cutter head can avoid the seam head of the cloth. The device has the advantages that the operation is convenient; the labor is saved; the precision is high; errors are avoided; the quality and the work efficiency of the cloth sizing are greatly improved.

Owner:江苏日新印染机械有限公司

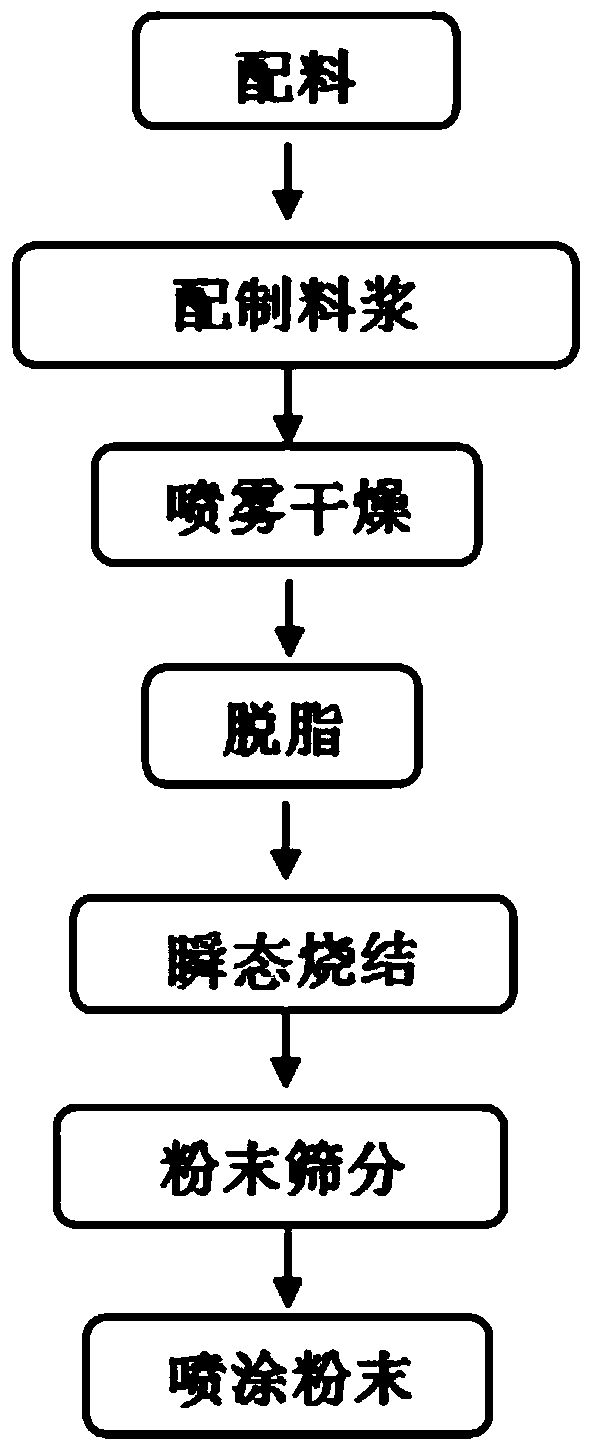

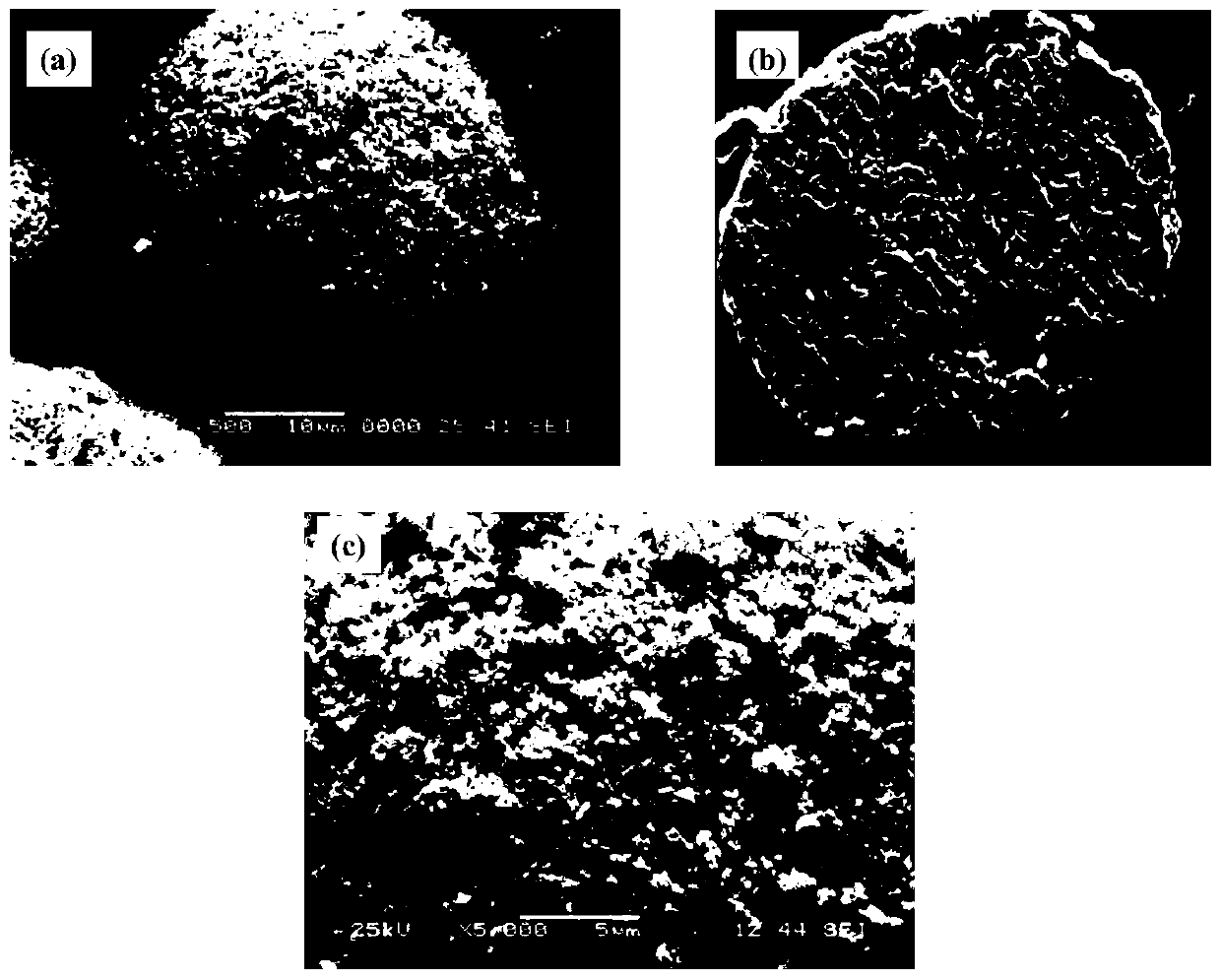

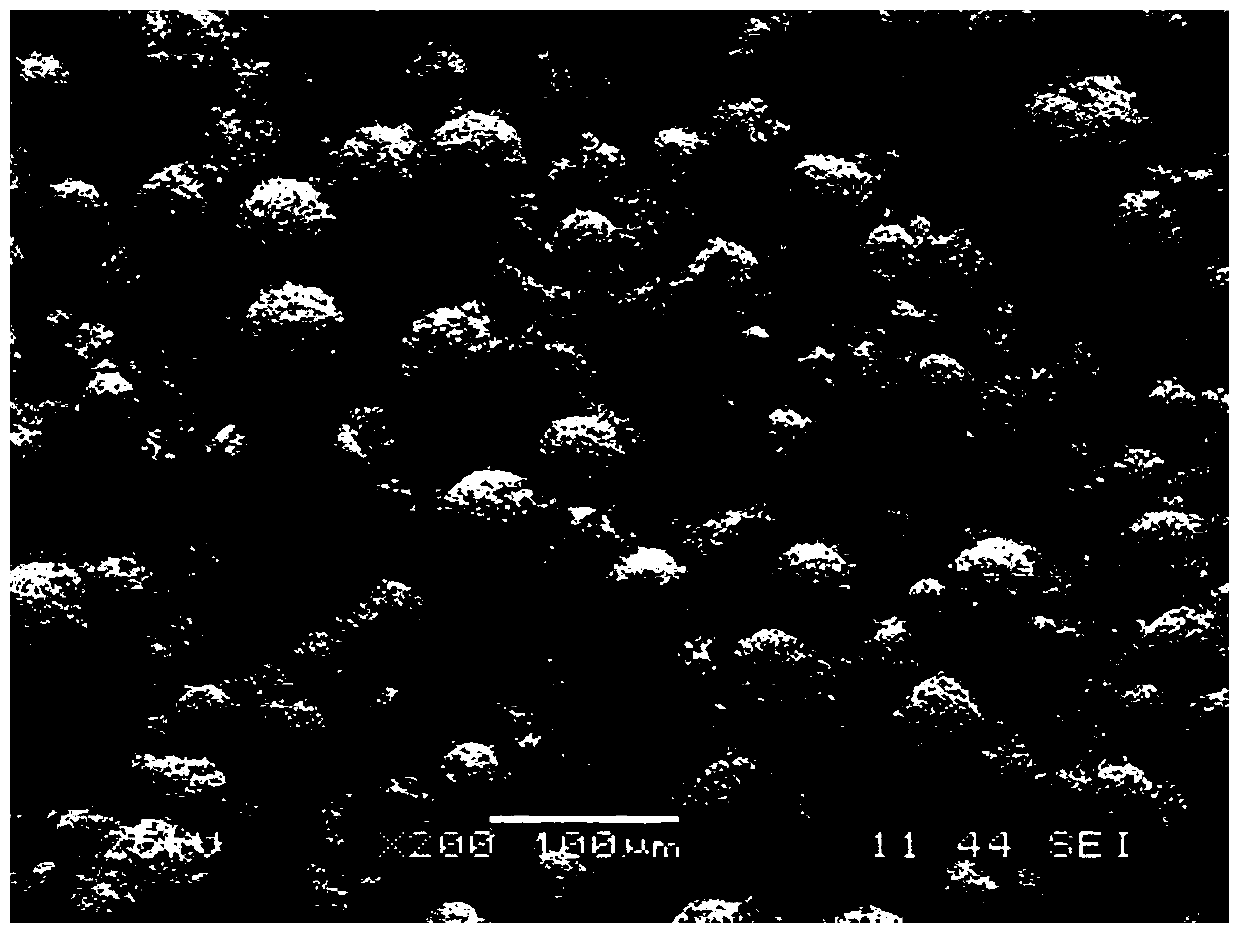

A preparation method of ultrafine tungsten carbide-based spherical thermal spray powder

ActiveCN104988451BInhibit growthAvoid stickingMolten spray coatingMaterials preparationSpray Granulation

The invention relates to a preparation method of ultrafine tungsten carbide-based spherical thermal spray powder, belonging to the technical field of preparation of special materials. The present invention distributes the raw material powder according to the design group, and the raw material powder is sprayed and granulated after wet ball milling; the semi-finished product with a particle size of 5-150 μm is obtained; After flowing into the vertical sintering furnace with the protective gas, the transient sintering is completed in the high temperature zone of the vertical sintering furnace; cooling and grading to obtain the ultrafine tungsten carbide-based spherical thermal spray powder; the temperature of the transient sintering is 1000 ‑1500℃, when transient sintering, the average sintering time of a single degreased powder is 1‑10s. The preparation process of the invention is simple, the obtained product has excellent performance, and is convenient for industrialized production.

Owner:CENT SOUTH UNIV

A new type of stamping tool with efficient use of ink pads

InactiveCN110143071BEasy to play stamping effectSolve problems that are often used indiscriminatelyStampingEngineeringSteel ball

The invention discloses a novel stamp tool capable of efficiently utilizing red ink paste. The stamp tool comprises a main body, a stamp neck body, a holding sphere and a protective cover; the top part of the main body is fixedly connected with the stamp neck body; the top part of the stamp neck body is fixedly connected with the holding sphere; a red ink paste milling cavity penetrating through the stamp neck body and the main body is arranged in the stamp neck body and the main body; a stirring cavity is arranged in the main body; an ink outlet is arranged between the stirring cavity and thered ink paste milling cavity in a communicating manner; a plurality of dipping steel balls are arranged in the red ink paste milling cavity; the top part of the stirring cavity is fixedly connected with a first soaking sponge communicating with the ink outlet; a second soaking sponge is paved at the bottom part of the stirring cavity in a through manner; transmission assemblies which are used forcontrolling the protective cover to be opened and closed and are symmetrical are arranged between the left inner wall and the right inner wall of a first ring slot; and the end face of the left end of the main body is provided with a fingerprint recognition and switchover starting power assembly used for driving the transmission assemblies; and the fingerprint recognition and switchover startingpower assembly comprises a fingerprint lock assembly and a switchover power assembly used for controlling a switchover driving force by the fingerprint lock assembly to turn.

Owner:ZHENGZHOU INST OF TECH

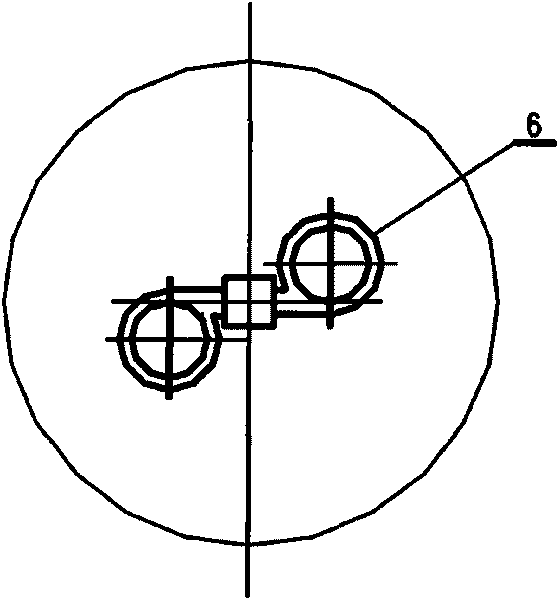

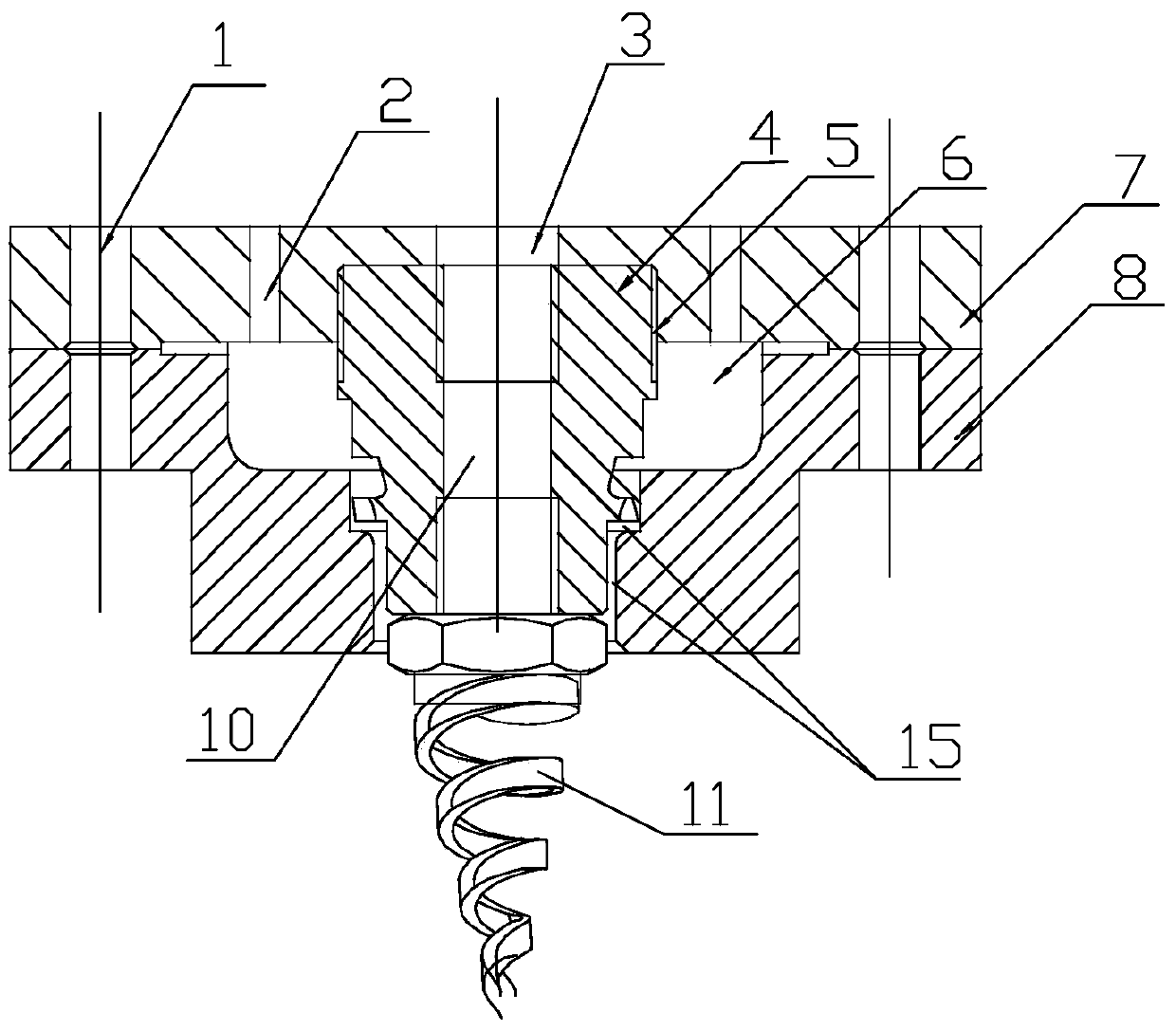

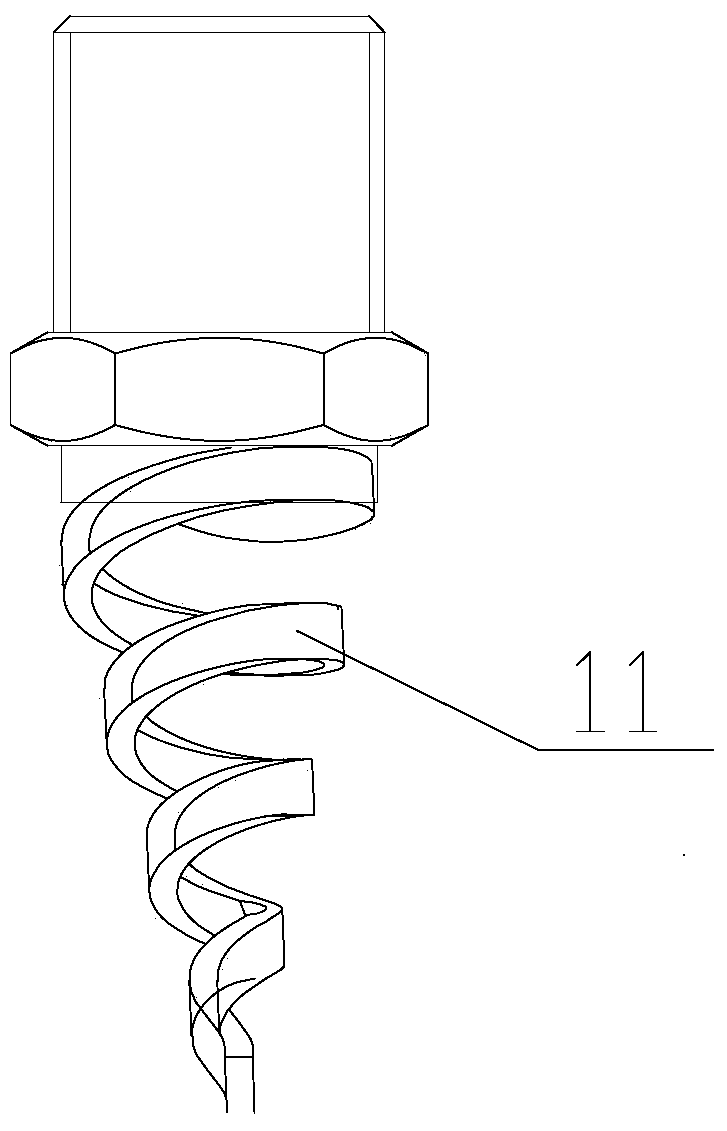

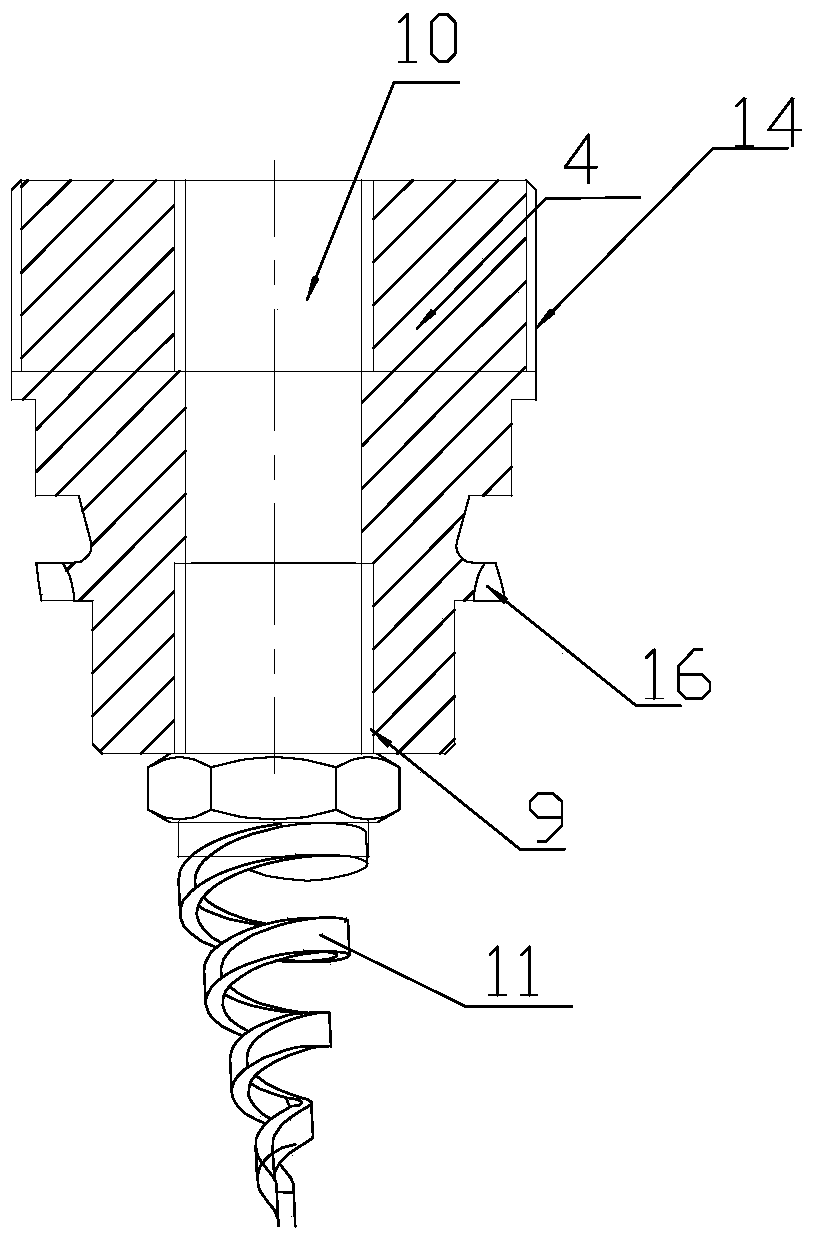

spiral nozzle device

The invention provides a spiral nozzle device. The spiral nozzle device comprises an outer flow atomizing nozzle, a fixing flange, an inner flow atomizing nozzle and a spiral nozzle, wherein the lower end of the fixing flange is connected with the upper end of the outer flow atomizing nozzle, a cooling water hole is formed in the central part of the upper section of the fixing flange, a threaded hole is formed in the central part of the lower section of the fixing flange, and a through hole is formed in the central part of the outer flow atomizing nozzle; the threaded hole communicates with the through hole; the upper section of the inner flow atomizing nozzle is arranged in the threaded hole, the lower section of the inner flow atomizing nozzle is arranged in the through hole, a guide hole is formed in the central part of the inner flow atomizing nozzle, and the guide hole penetrates through the top end and the bottom end of the inner flow atomizing nozzle; the cooling water hole communicates with the guide hole; and the spiral nozzle is connected at the bottom end of the inner flow atomizing nozzle. The water atomizing effect of the spiral nozzle device provided by the invention is great.

Owner:SHANDONG IRON & STEEL CO LTD

Method for hydrolyzing silkworm cocoons with weak alkali microwave

ActiveCN109320595BEfficient manufacturingAvoid damagePeptide preparation methodsEnergy based chemical/physical/physico-chemical processesSodium bicarbonatePolymer science

The invention discloses a method for hydrolyzing silkworm cocoons with a weak base microwave, which comprises the following steps: (1) cleaning and drying; (2) cutting and separating; Add the mixed weak alkali mixture into a microwave reactor, hydrolyze it for 110-130min at 80°C under normal pressure, and obtain a crude sericin peptide solution and silk protein fiber solid after hydrolysis, extract the crude sericin peptide solution and perform ultrafiltration Filtrate to obtain sericin peptide protein; (4) Extract silk fibroin peptide protein by secondary hydrolysis, add weak alkali mixed solution into microwave reactor again, then hydrolyze at 100°C under normal pressure for 110-130min, and keep warm for 8- At 11 hours, the silk fibroin fiber solid is completely hydrolyzed into a thick silk fibroin solution, and the thick silk fibroin solution is subjected to ultrafiltration to obtain silk fibroin peptide protein. The invention can effectively prepare sericin peptide protein and silk fibroin peptide protein at one time, and achieves the purpose of improving preparation efficiency and product utilization rate.

Owner:YIBIN PINGSHAN HUIRUI OIL CO LTD

Equipment safety monitoring system and method

ActiveCN108062075AAvoid hysteresisEfficient and safeTotal factory controlProgramme total factory controlHysteresisMonitoring system

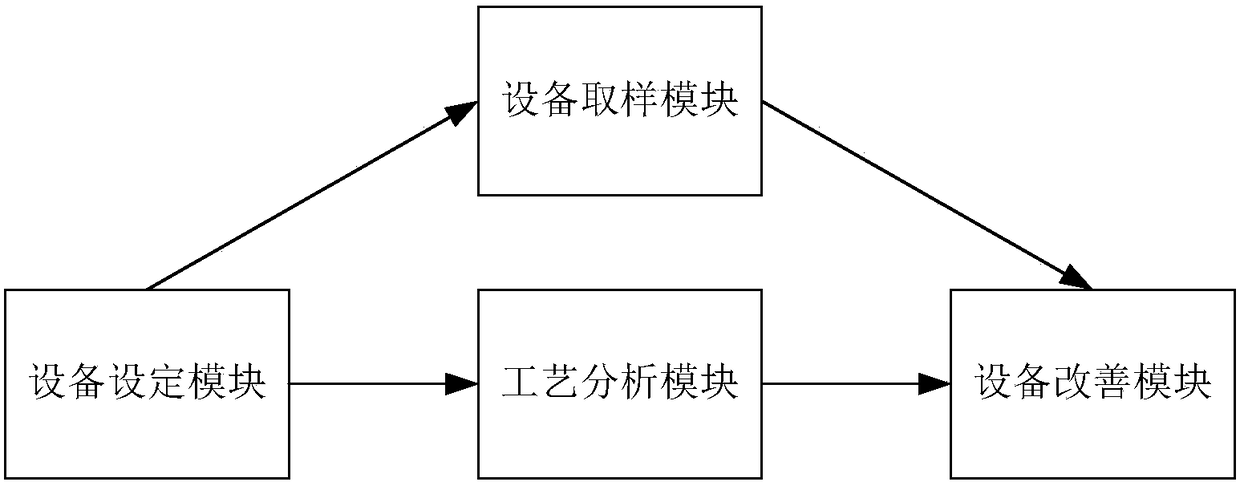

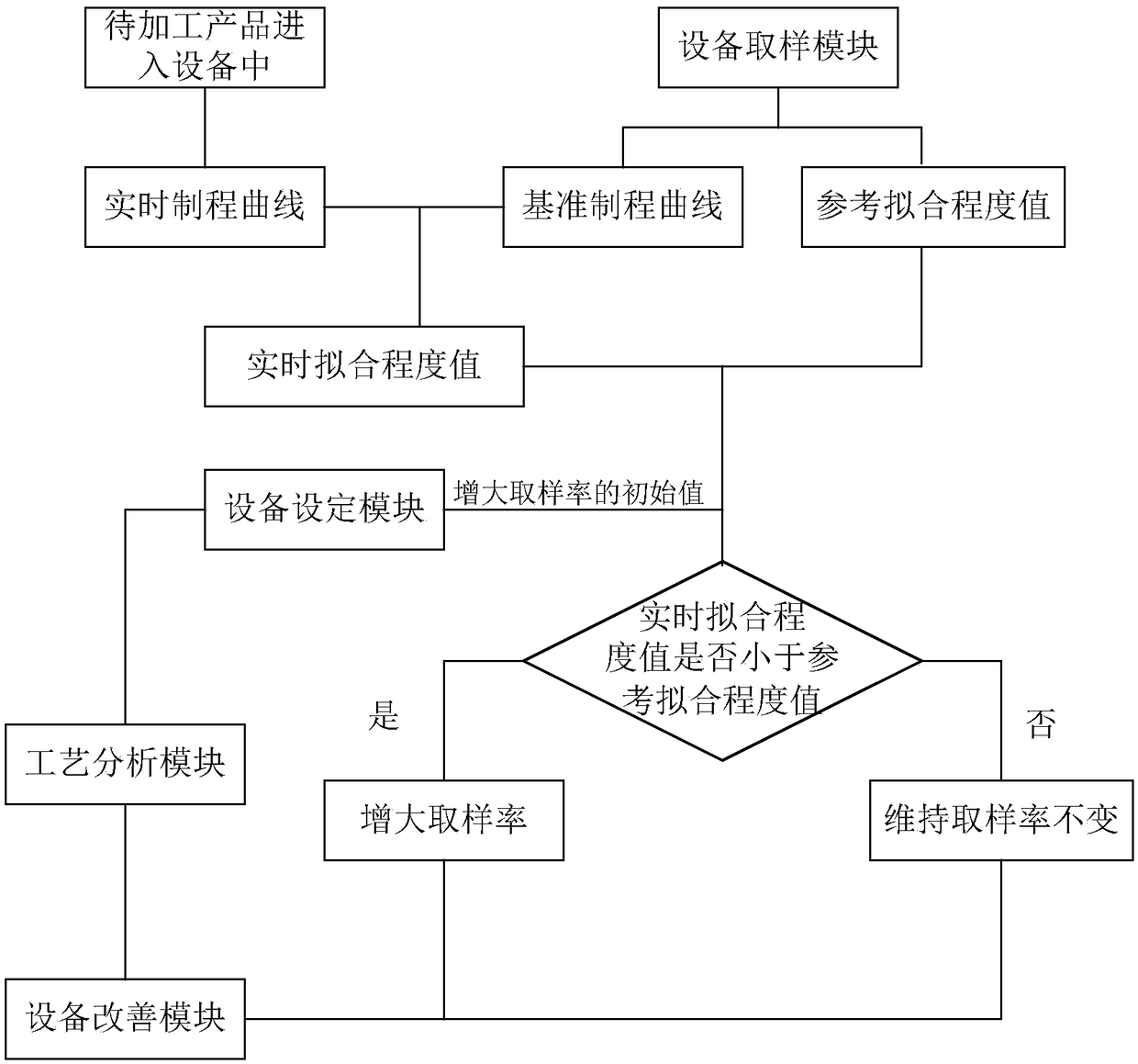

The invention reveals an equipment safety monitoring system and method. The system provided by the invention comprises an equipment setting module which is used for monitoring the abnormal motion of equipment; an equipment sampling module which is used for outputting a reference processing curve and a reference fitting degree value of the equipment, wherein the reference processing curve is combined with a real-time processing curve so as to obtain a real-time fitting degree value; executing the dynamic sampling operation according to the sizes of the reference fitting degree value and the real-time fitting degree value and an abnormal motion; a technological analysis module which is used for analyzing the abnormal motion of the equipment and providing an improved motion; and an equipmentimproving module which is used for combining with the improved motion to maintain the equipment according to the change of the dynamic sampling. Through the cooperation of the four parts, the system achieves the real-time feedback of information, avoids the hysteresis of the discovery of a fault of the equipment, and improves the utilization rate of the equipment.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com