Electric double-platform T-beam transverse moving vehicle

A dual-platform, electric technology, used in bridges, passenger vehicles, bridge construction, etc., can solve the problems of few products and unstable equipment reliability, achieve low cost of use, large use and promotion value, and improve production utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

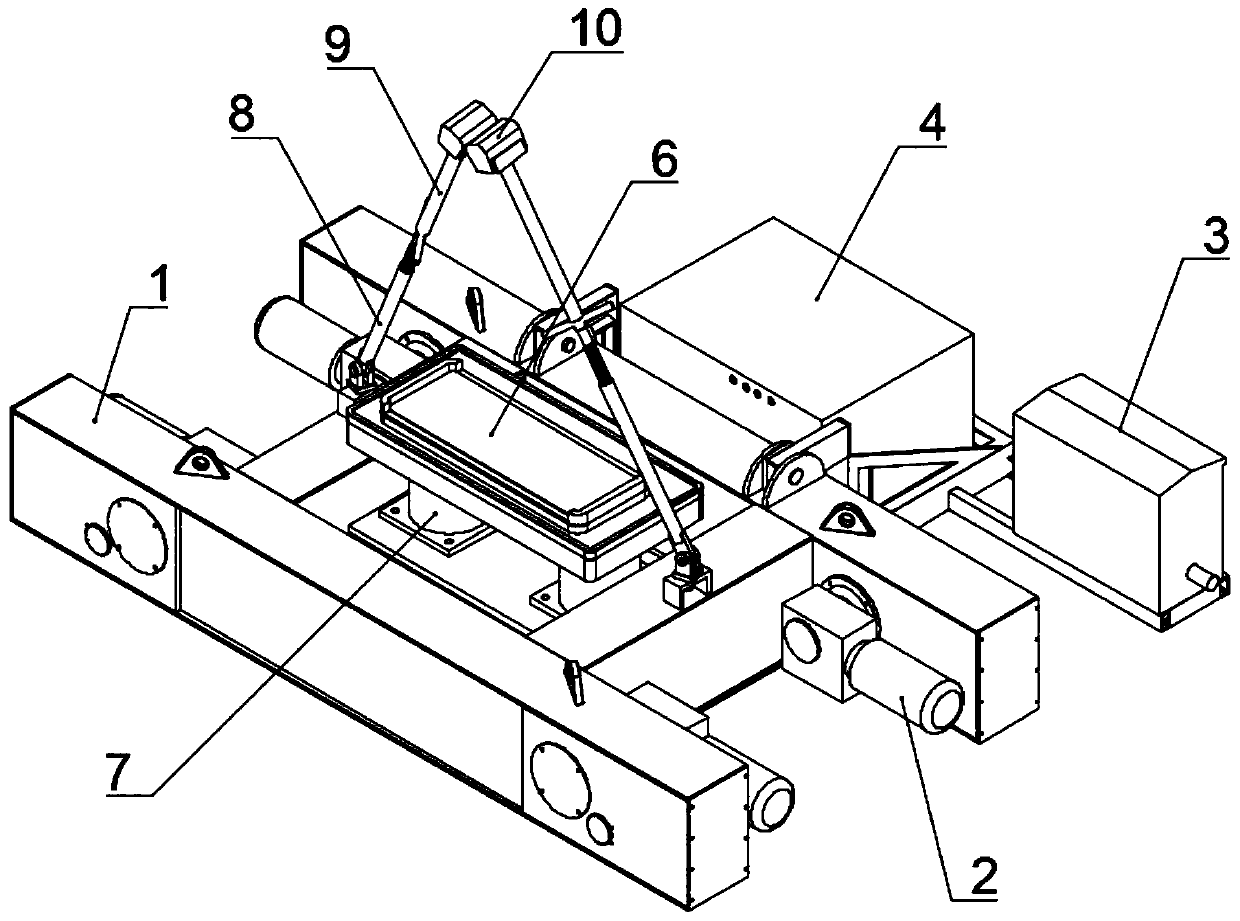

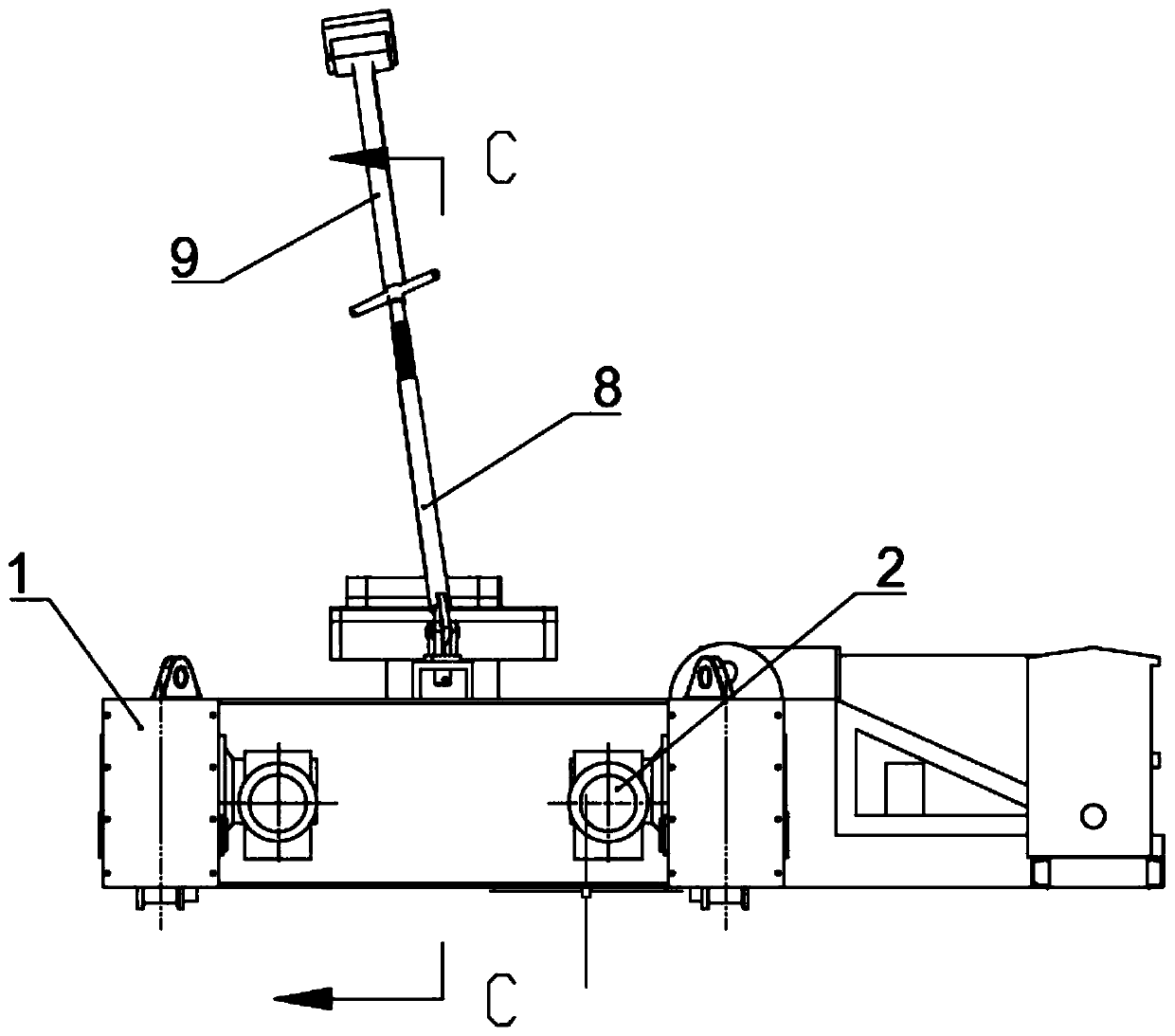

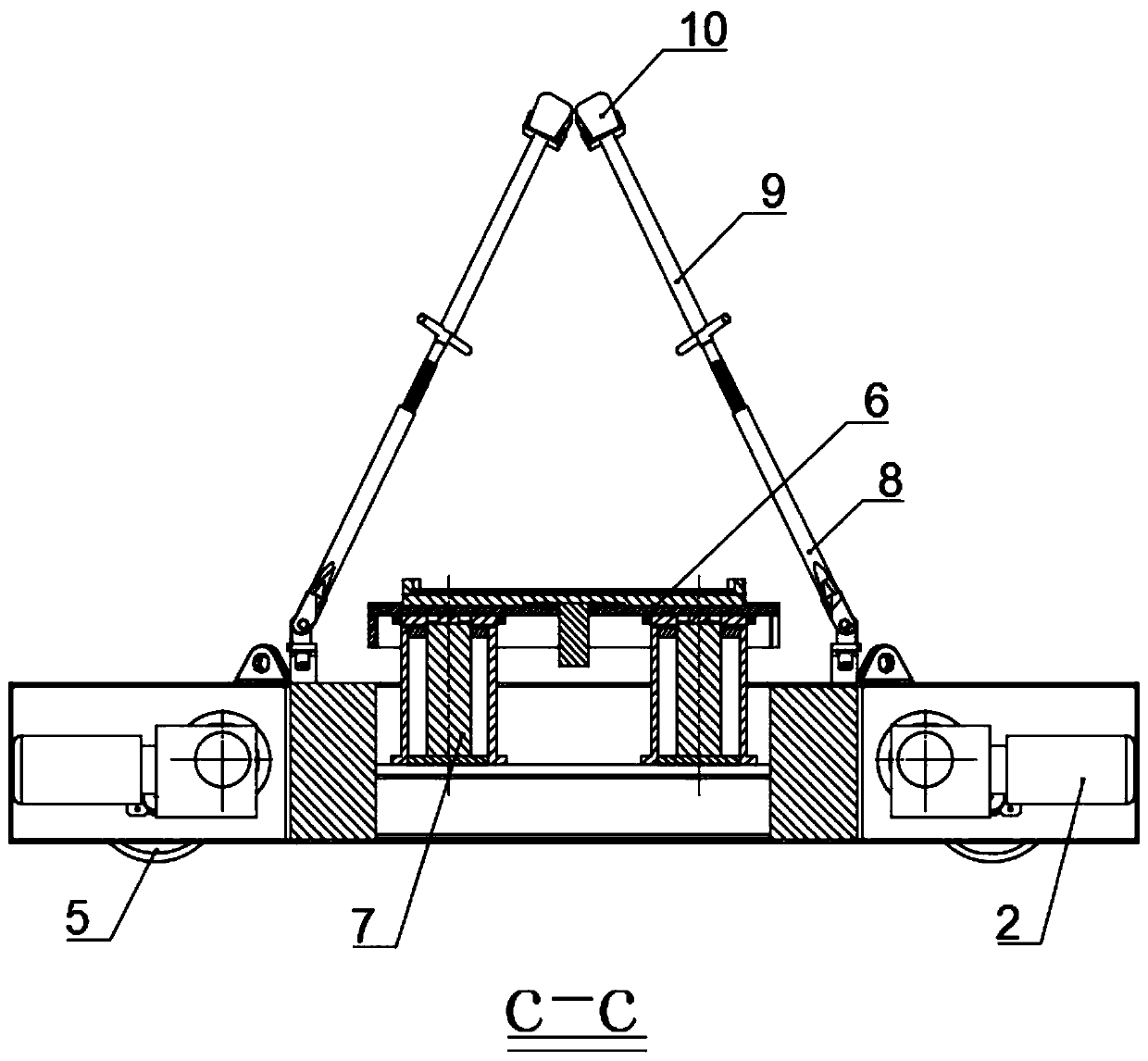

[0030] Such as Figure 1-Figure 4 As shown, in this embodiment, an electric double-platform T-beam transverse beam-moving vehicle is specifically provided, including a beam-moving frame 1, and the mobile frame is used as the main load-bearing part of the beam-moving vehicle. In this embodiment, , make it similar to an "H" shape. A running mechanism is provided on the beam-moving frame 1 and the beam-moving frame 1 is driven to move on the running track through the running mechanism, and the running mechanism matches the running track; preferably, the running mechanism is provided with four and symmetrical Arranged on the beam-moving frame 1, the four running mechanisms are respectively arranged at the four end positions of the "H" shape. Of course, the number of running mechanisms can also be less than four, and the other parts are equipped with running wheels 5 that is Yes, it is also possible to realize the displacement movement of the beam-moving vehicle frame 1 under the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com