A preparation method of ultrafine tungsten carbide-based spherical thermal spray powder

A thermal spraying powder, tungsten carbide-based technology, applied in the direction of coating, molten spraying, metal material coating process, etc., can solve the problems of tungsten carbide grain growth, low product utilization rate, complex process, etc., to achieve sintering The effect of short time, reduced sintering time, and shortened production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

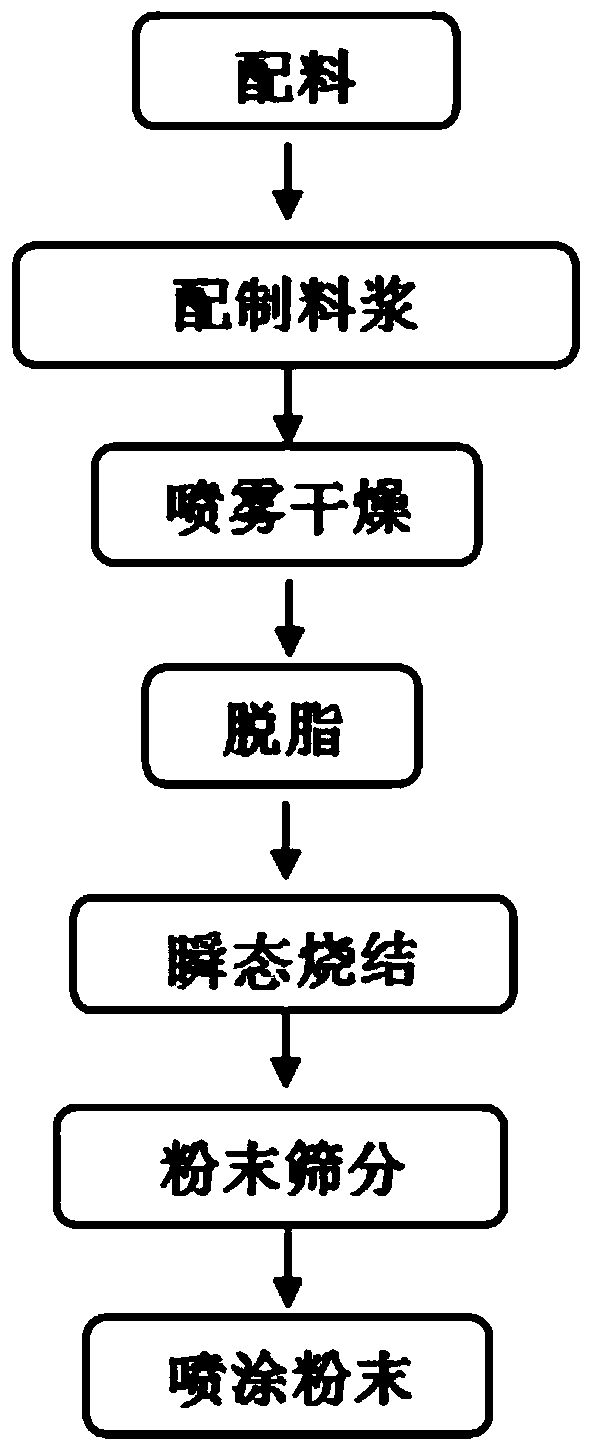

Method used

Image

Examples

Embodiment 1

[0083] Embodiment 1: ultrafine WC-17Co thermal spray powder

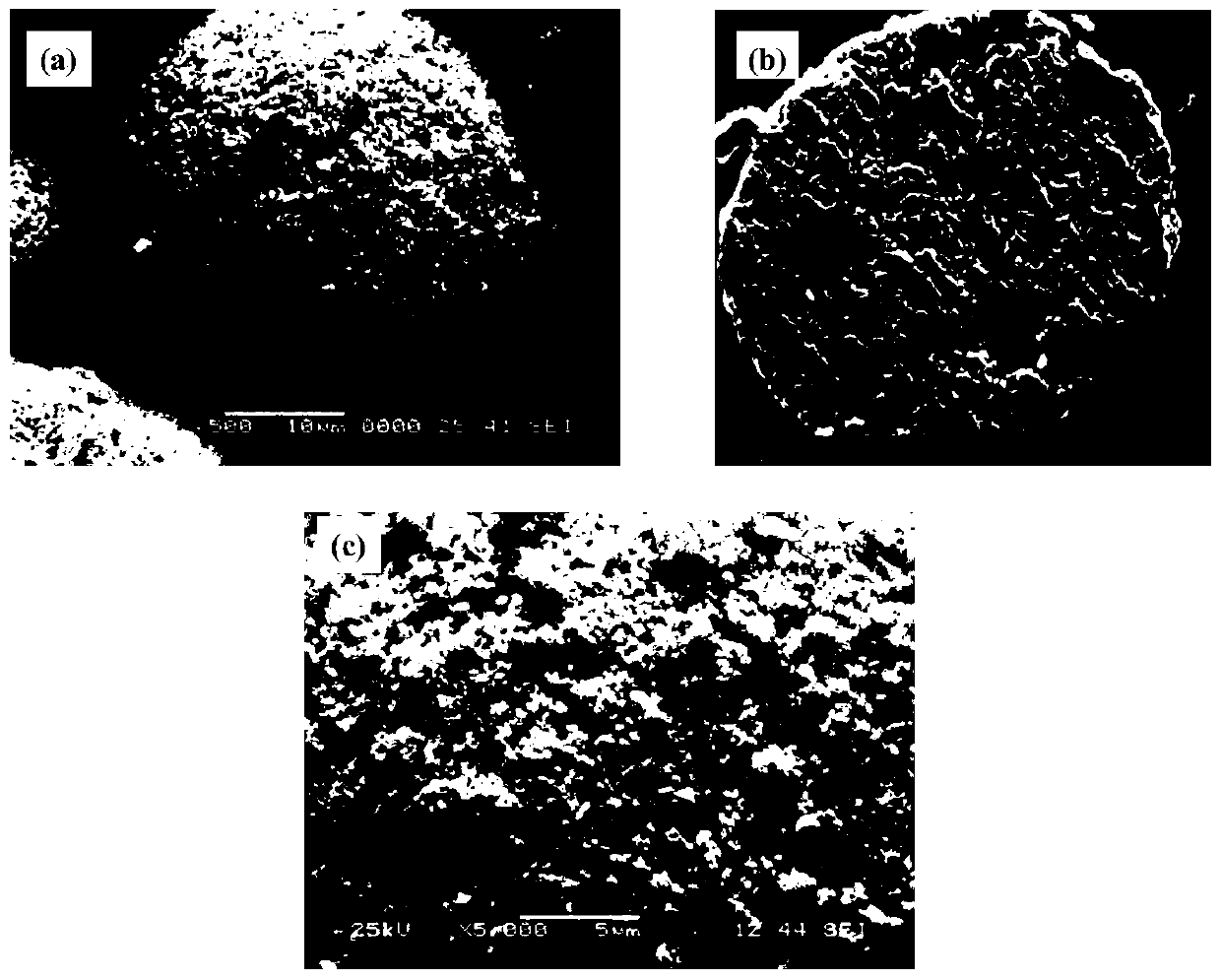

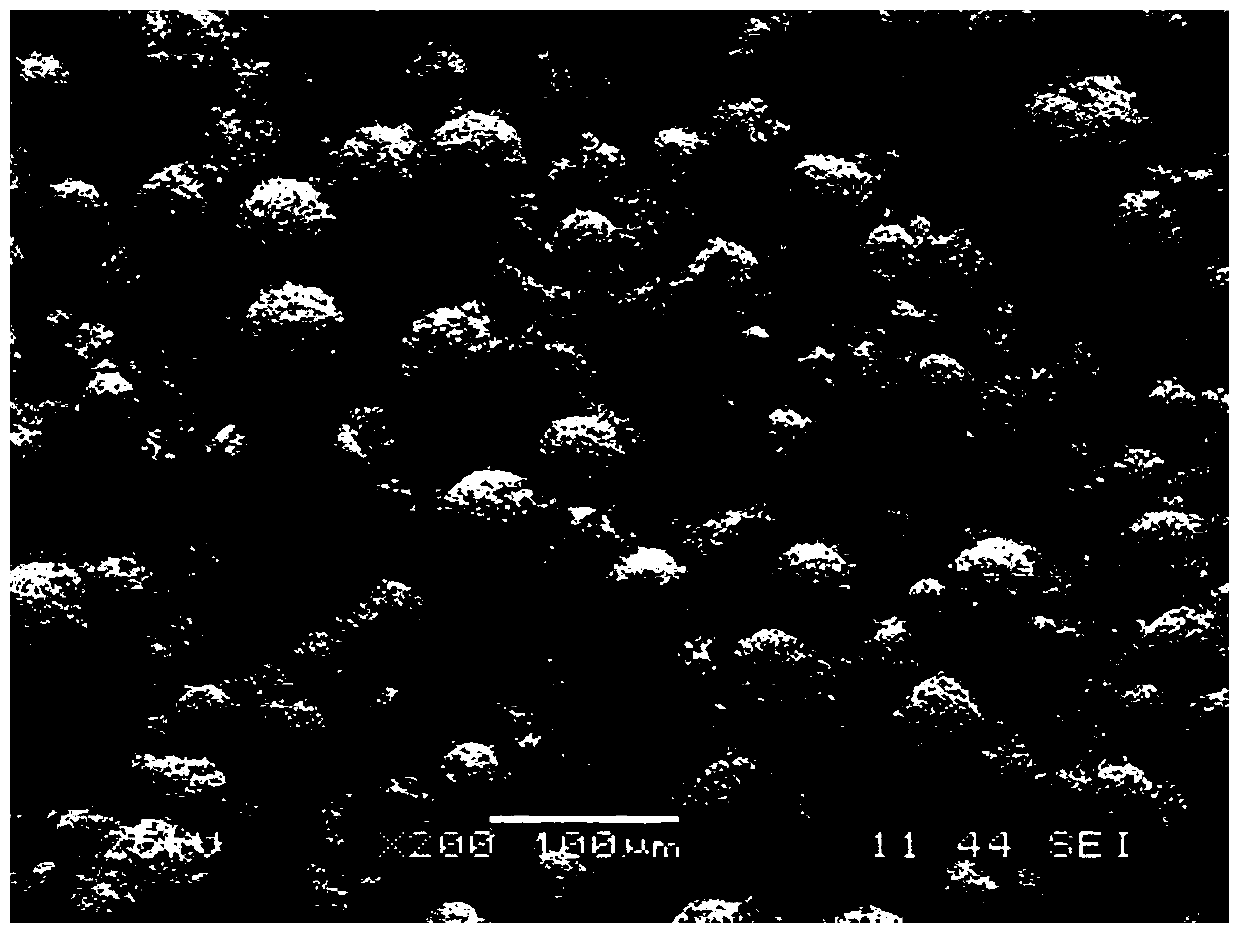

[0084]First, 83wt% tungsten carbide powder (particle size 100-300nm) and 17wt% cobalt powder (particle size 1-2μm) are added to the ball mill, and absolute ethanol is added at the same time. Alloy grinding balls, the ball-to-material ratio is 4:1, the ball milling speed is 50r / min, and the ball milling time is 12h; after wet milling, add polyethylene glycol accounting for 2% of the mixed powder mass fraction, stir for 2h, and place in a closed spray drying tower Carry out granulation to obtain granulated powder, the inlet temperature is controlled at 240°C, the outlet temperature is controlled at 120°C, the atomizer speed is 18000r / min, the drying and protective atmosphere is nitrogen, and the tower pressure is 2KPa; the granulated powder is placed in a tube The degreasing treatment was carried out in a vertical furnace at a temperature of 800°C for 12 hours; the degreasing powder was transiently sintered in a verti...

Embodiment 2

[0090] Example 2: Ultrafine WC-10Co-4Cr 3 C 2 thermal spray powder

[0091] First, add 86wt% tungsten carbide powder (particle size 100-300nm), 10wt% cobalt powder (particle size 1-2μm) and 4wt% chromium carbide powder (particle size 100-300nm) into the ball mill, and add anhydrous For ethanol, two sizes of Ф16mm and Ф6mm YG6 cemented carbide grinding balls are used for the grinding balls, the ball-to-material ratio is 3:1, the ball milling speed is 35r / min, and the ball milling time is 10h; Diol, after stirring for 2 hours, granulate in a closed spray drying tower to obtain granulated powder, the inlet temperature is controlled at 220°C, the outlet temperature is controlled at 105°C, the atomizer speed is 14000r / min, drying and protective atmosphere It is nitrogen, and the tower pressure is 1.5KPa; the granulated powder is degreased in a tube furnace at a temperature of 550°C for 9 hours; (carrier gas flow rate is 85ml / min) under the action of acceleration and continuous u...

Embodiment 3

[0097] Example 3: Ultrafine WC-10Co-4Cr 3 C 2 thermal spray powder

[0098] First, add 86wt% tungsten carbide powder (particle size 100-300nm), 10wt% cobalt powder (particle size 1-2μm) and 4wt% chromium carbide powder (particle size 100-300nm) into the ball mill, and add anhydrous For ethanol, two sizes of Ф16mm and Ф6mm YG6 cemented carbide grinding balls are used for the grinding balls, the ball-to-material ratio is 2:1, the ball milling speed is 20r / min, and the ball milling time is 8h; Diol, after stirring for 2 hours, granulate in a closed spray drying tower to obtain granulated powder, the inlet temperature is controlled at 200°C, the outlet temperature is controlled at 90°C, the atomizer speed is 10000r / min, drying and protective atmosphere Nitrogen, the tower pressure is 1KPa; degrease the granulated powder in a tube furnace at a temperature of 300°C for 6 hours; transiently sinter the degreased powder in a vertical sintering furnace, and the powder is carried out i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com