Film-coating equipment for meniscus surface, and suction mechanical arm for film-coating component

A robotic arm and meniscus technology, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of reducing the utilization rate of coating components, high energy consumption, and continuous production limitations, and achieves a high level of improvement. Coating film quality and product utilization rate, high film coating product quality, and the effect of preventing residual liquid from returning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 meniscus film coating equipment and its operation process

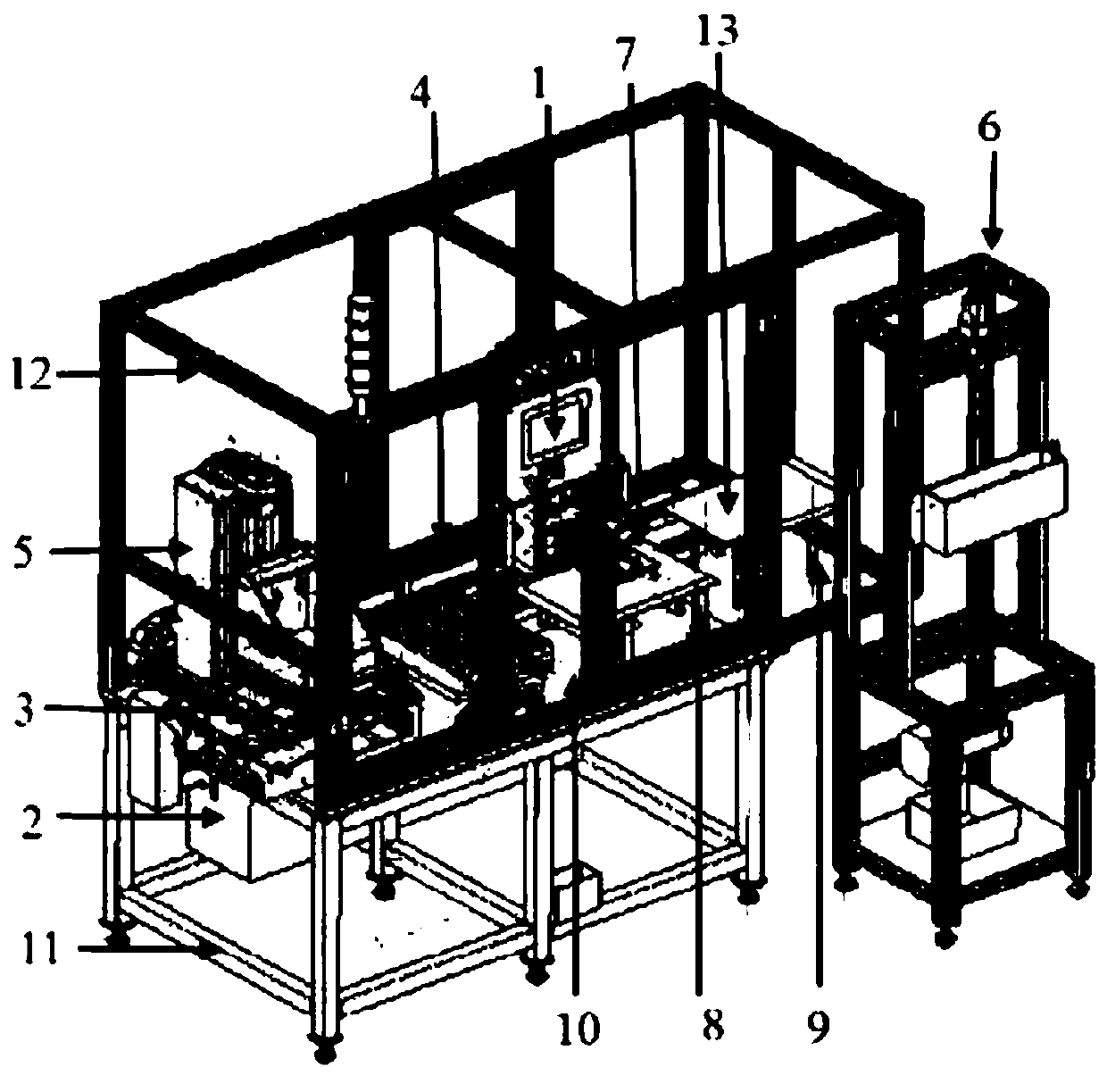

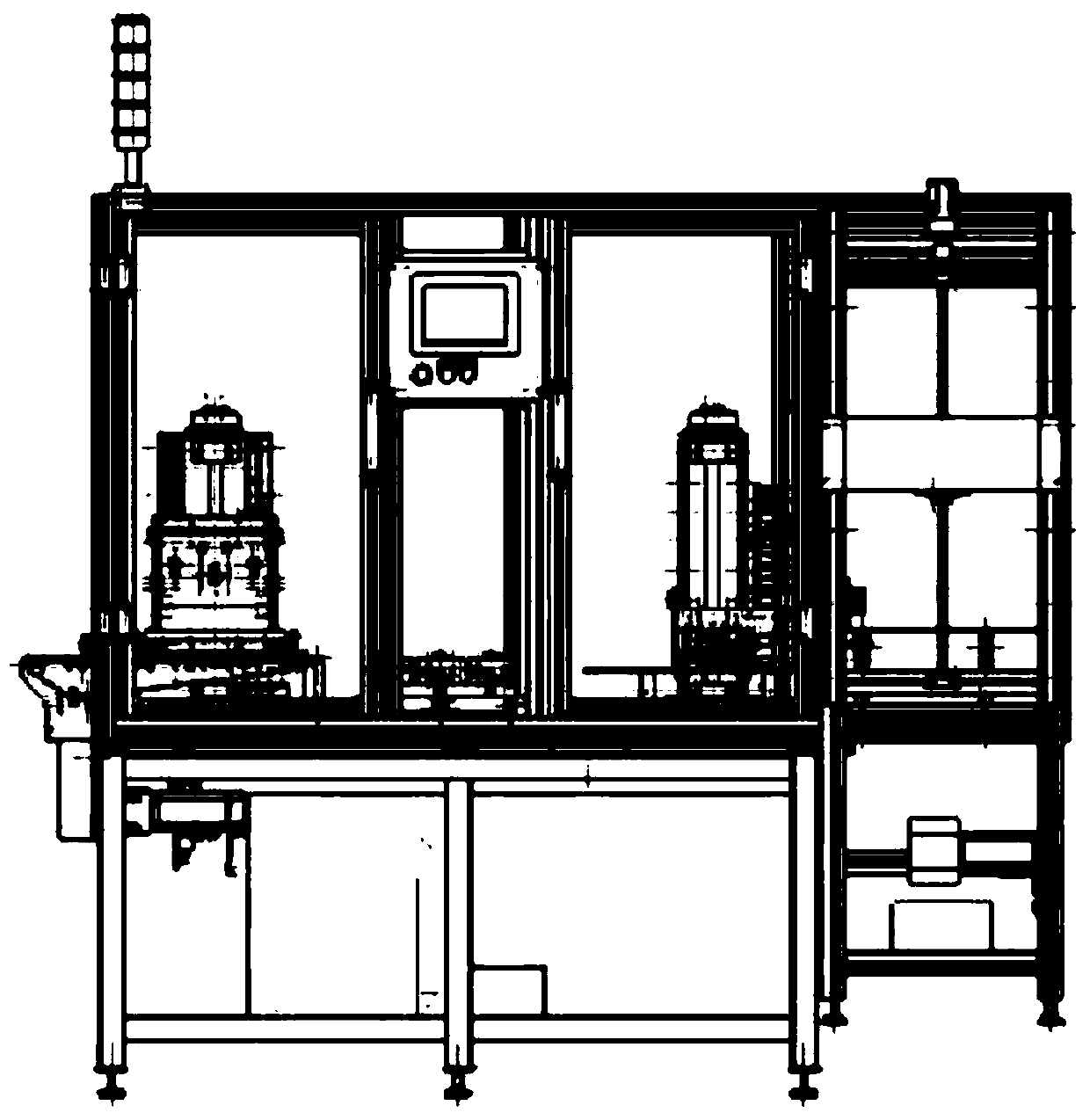

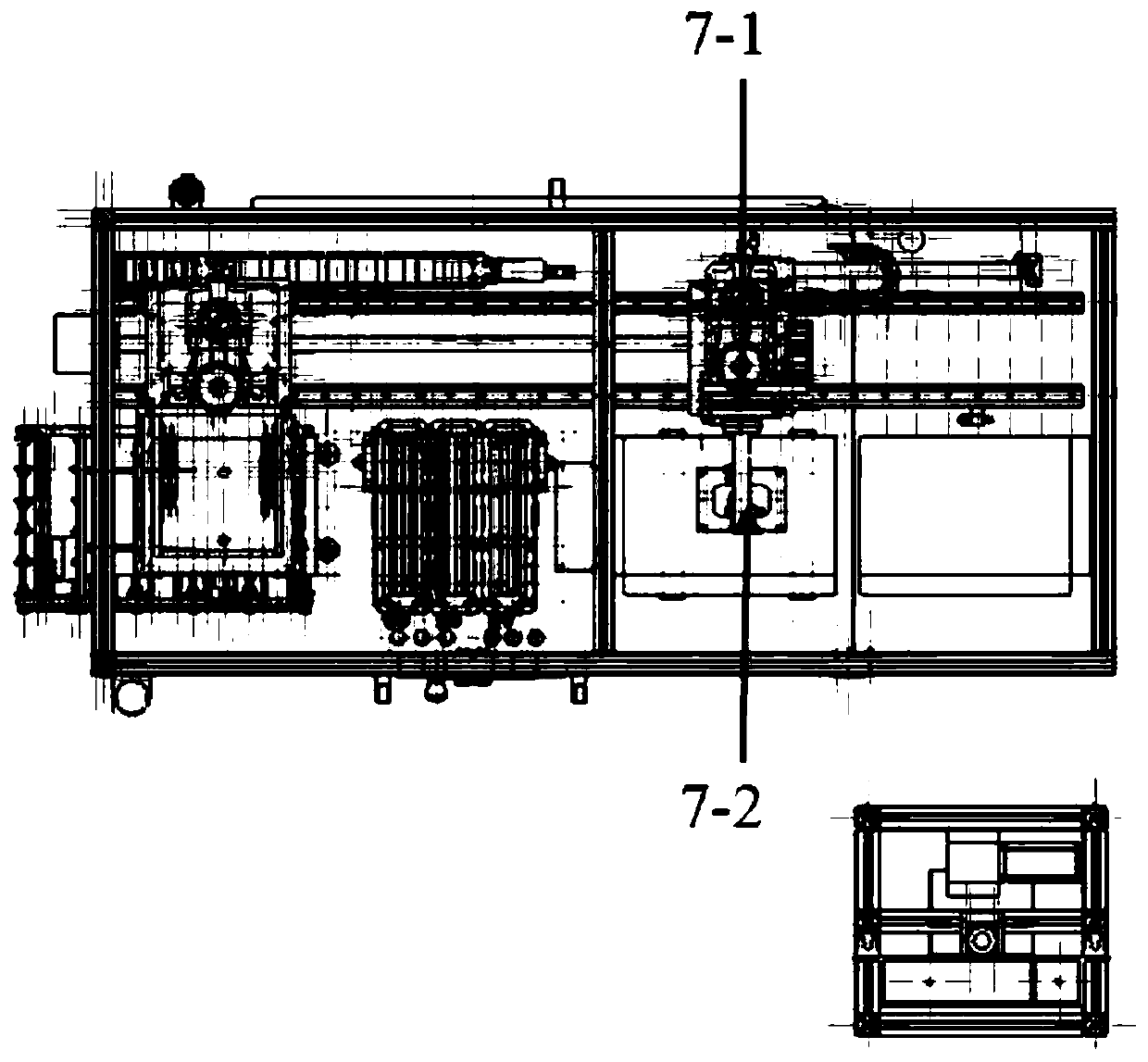

[0040] The three-dimensional structure of the meniscus gluing equipment of the present invention is as follows: figure 1 As shown, the front schematic diagram is shown in figure 2 As shown, the top view is as image 3 As shown, it can be understood from the figure that the main components of the meniscus film coating equipment of the present invention, Figure 4 It is the operation principle diagram of the meniscus film coating equipment, from which the film coating operation process of the meniscus film coating equipment of the present invention can be clearly understood.

[0041] The above-mentioned meniscus film coating equipment includes a central control panel (1), a PCL control cabinet (2), a coating film component positioning loading table (3), a linear motor drive guide rail (4), a coating film component suction mechanical arm (5 ), Glue supply device (6), film-coating element overturni...

Embodiment 2

[0053] Embodiment 2 Coating element suction mechanical arm with anti-swinging edge effect

[0054] The three-dimensional schematic diagram, the front schematic diagram and the top view of the coating element absorbing mechanical arm with the anti-shake effect of the present invention are respectively as follows Figure 5-7 As shown, it mainly includes the following important components: film coating element walking robot arm (5-2), drainage elastic clip (5-2-2), suction cup (5-2-1).

[0055] Such as Figure 6As shown, the elastic clip (5-2-2) at the tail end of the coating element and the contact part of the coating element (13) have a concave structure, and only the bottom edge coincides with the coating surface of the coating element, while the coating element The upper surface does not touch any parts, so the residual liquid on the coating surface of the coating element will not flow back to the upper surface of the coating element to affect the effect and quality of the c...

Embodiment 3

[0057] Example 3 Glue spraying device with leveling function [HJ1]

[0058] The structure of the glue spraying device with leveling effect of the meniscus glue coating equipment of the present invention is as follows: Figure 8 shown.

[0059] The leveling device (6-2-5) includes an adjustment wheel (6-2-5-1), a leveling piece (6-2-5-2) and a support base (6-2-5-3). Wherein the connection between each component of the leveling device and the glue spraying device can be clearly reflected, the leveling device not only has the main leveling function, but also is the main supporting part for fixing the glue spraying device, the spraying glue The glue device is fixed on the equipment support plate by means of the support base of the leveling component and the support base of the rotating shaft of the leveling component. The leveling member mainly relies on the relative movement between the leveling wheel and the leveling member to realize the leveling of the glue spraying device....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com