Shield excavation slag processing technology

A slag treatment and process technology, applied in the field of shield slag treatment technology, can solve the problems of low product utilization rate, long treatment time, and inability to completely separate mud and water, and achieve the effect of improving economic benefits and improving product utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

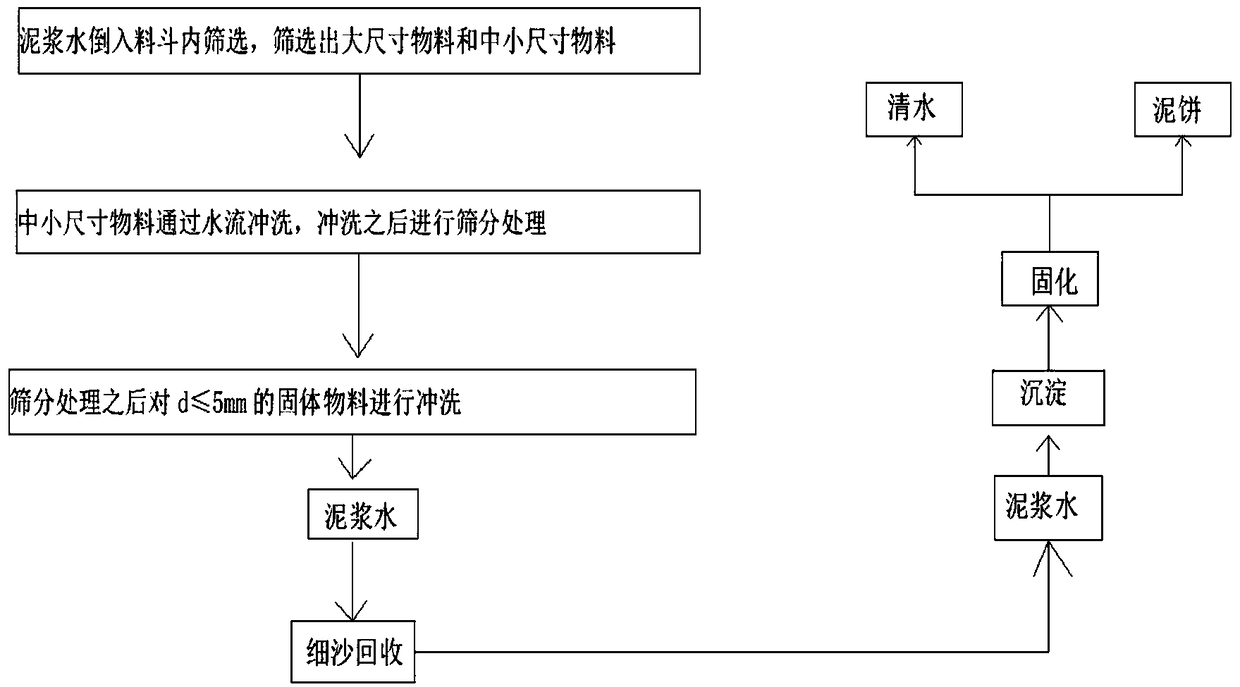

[0034] A shield slag treatment process, comprising the following steps:

[0035] 1) The muddy water is poured into the hopper, and then screened through a coarse sieve to screen out large-sized materials and small and medium-sized materials. During the screening process, heavy-duty vibrating screens are used, and heavy-duty vibrating screens use polyurethane screens. Polyurethane screens are more efficient than other types of screens The screen has a longer service life and is not easy to block holes. The large materials screened out can be stacked together and then crushed to make building aggregates. After screening out large-sized materials, it is conducive to the screening of small and medium-sized materials. The screening time is only 3 -5 seconds, the screening speed is fast, thereby increasing the subsequent sand forming time;

[0036] 2) Small and medium-sized materials are washed by high-pressure water flow. After washing, small and medium-sized materials are screened...

Embodiment 2

[0043] In the present invention, the slurry water is first poured into the hopper, and then screened with a coarse sieve to screen out large-sized materials and medium-sized and small-sized materials. For construction aggregates, the diameter of small and medium-sized materials is ≤100mm. Small and medium-sized materials are washed with high-pressure water. After washing, four sizes of materials are obtained. Materials with a size of 30mm≤d≤100mm are re-crushed, and 10mm<d<30mm, 5mm The material <d<10mm is collected as finished sand, and the material with d≤5mm is washed again. After cleaning by the double-screw sand washing machine, some muddy water flows out, and the muddy water flows into the layer sand recovery machine, and the layer sand is recovered. The machine recycles it to form fine sand, and the remaining muddy water enters the first-level sedimentation tank, the second-level sedimentation tank, and the third-level sedimentation tank for sedimentation, and settles th...

Embodiment 3

[0045] During the solidification process, a centrifugal mud compactor is used to process the mud water. The mud at the outlet of the three-stage sedimentation enters the mud compactor from the inlet of the mud compactor, and the mud is sent into the drum of the mud compactor by the hollow shaft. It consists of reloading and a screw conveyor with a hollow shaft. The mud is sent into the drum by the hollow shaft. Under the centrifugal force generated by high-speed rotation, it is immediately thrown into the drum cavity. Due to the different specific gravity, solid-liquid separation is formed. Driven by the conveyor, the conical end of the drum is continuously discharged from the first outlet; the liquid in the liquid ring layer is continuously overflowed from the weir to the outside of the drum and discharged by gravity. The pressure of the mud compactor on the mud It is 0.8MPa, and the action time is 5 minutes. The mud cake solid with a moisture content of <30% is discharged fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com