cutting device

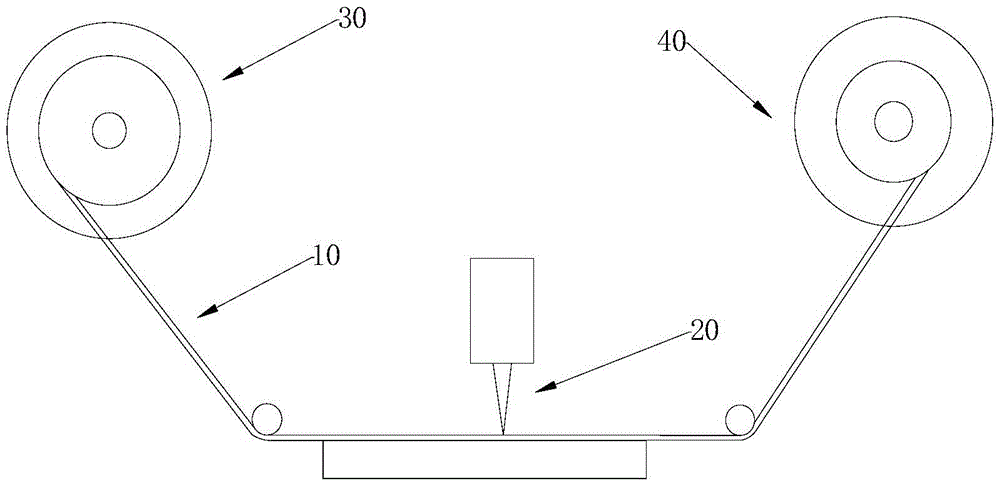

A technology of cutting device and cutting unit, which is applied in the direction of metal processing, etc., can solve the problems of complex disassembly and installation of cutters, difficulty in precise control of cutting depth, and difficult adjustment of parallelism, so as to improve equipment production utilization and avoid cutting depth Not enough, save the effect of correction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

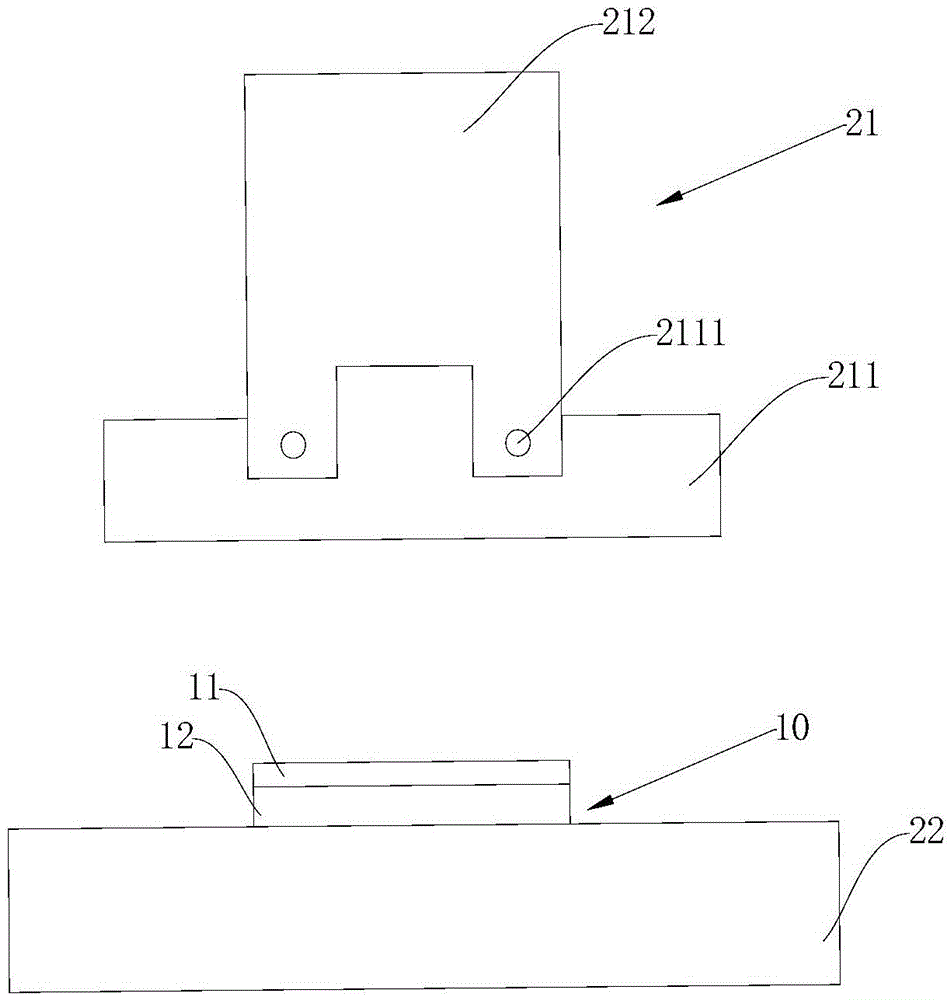

[0033] refer to Figures 3a-3e ,Such as Figure 3aAs shown, the cutting device provided in this embodiment includes a carrying platform 22 and a cutting unit 21 located above the carrying platform 22 , wherein the cutting unit 21 includes a cutting knife 211 and a knife holder 212 . The cutting device also includes a first stopper 231 and a second stopper 232 fixedly connected to the carrying platform 22 ; wherein, the upper ends of the first stopper 231 and the second stopper 232 are flush and parallel to the carrying platform 22 . When the cutter 211 is perpendicular to the carrying platform 22, the first stop 231 and the second stop 232 are used to keep a certain distance between the cutting edge of the cutting knife 211 and the carrying platform 22, so that the cutting depth of the cutting knife 211 can be precisely controlled. The middle part of the cutting knife 211 of the cutting device in this embodiment is provided with a connecting portion 2111, and the cutting knif...

Embodiment 2

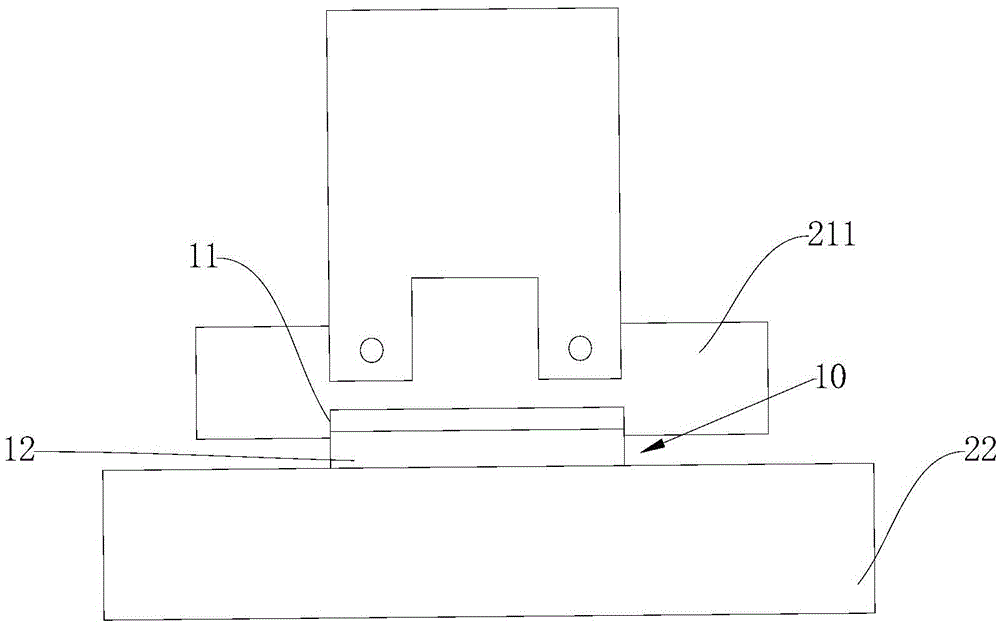

[0037] refer to Figures 4a-4c , the cutting device provided in this embodiment is as Figure 4a As shown, the same as in Embodiment 1, the cutting device includes a carrying platform 22 and a cutting unit 21 positioned above the carrying platform 22, wherein the cutting unit 21 includes a cutting knife 211 and a knife holder 212. Unlike Embodiment 1, in In this embodiment, the stopper is fixedly connected with the cutter 211 instead of being connected with the carrying platform 22 . Wherein, the stopper includes a third stopper 233 and a fourth stopper 234 , the bottom ends of the third stopper 233 and the fourth stopper 234 are flush and parallel to the cutting edge of the cutting knife 211 . The middle part of the cutting knife 211 of the cutting device in this embodiment is provided with a connecting portion 2111, and the cutting knife 211 is hinged with the knife rest 212 through the connecting portion 2111, so that the cutting knife 211 can freely swing around the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com