A thermal insulation pipe skin cutting device

A cutting device and outer skin technology, applied in metal processing and other directions, can solve the problems of difficulty in controlling the cutting force and drop, and achieve the effects of simplifying the operation process, reducing fatigue, and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

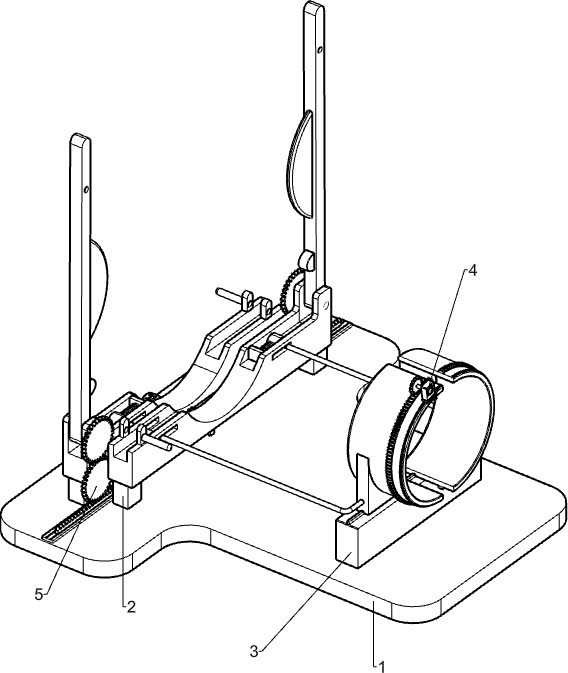

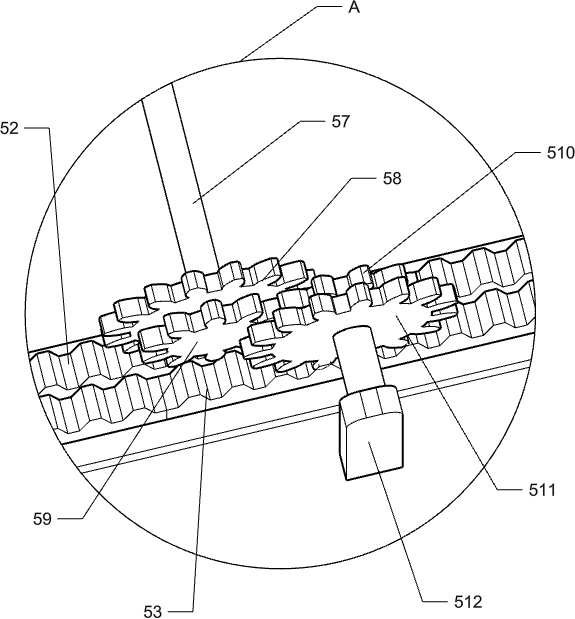

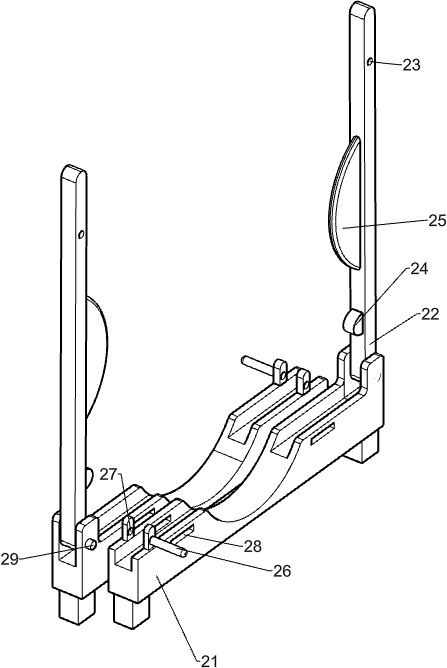

[0042] A kind of thermal insulation pipe outer skin cutting device, such as figure 1 As shown, it includes a base 1, a flattening mechanism 2, a clamping mechanism 3, a cutting mechanism 4 and a rotating mechanism 5. The left side of the top of the base 1 is connected to the flattening mechanism 2, and the right side of the top of the base 1 is connected to the clamping mechanism 3. When the staff needs to cut the outer skin of the heat preservation pipe, the outer skin of the heat preservation pipe can be placed between the flattening mechanism 2 and the clamping mechanism 3, and then the flattening mechanism 2 is rotated downward, so that the flattening mechanism 2 Press the outer skin of the heat preservation pipe, and the flattening mechanism 2 rotates downward to drive the relative movement of the clamping mechanism 3. At this time, the clamping mechanism 3 can clamp the outer skin of the heat preservation pipe, and the outer side of the front part of the clamping mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com