A semiconductor wafer precision cutting device

A cutting device and semiconductor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as heat generation, reduced output, and circuit rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

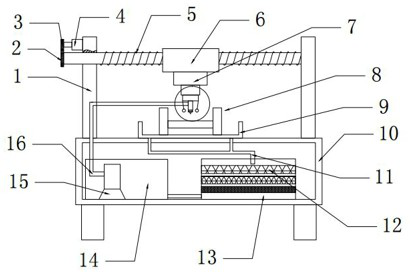

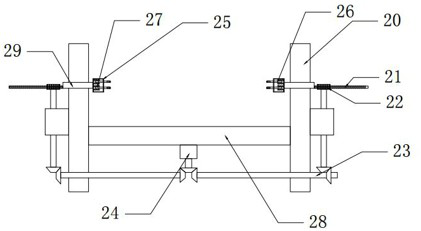

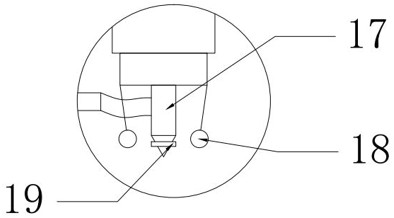

[0024] see Figure 1~3 , in an embodiment of the present invention, a semiconductor wafer precision cutting device includes a support rod 1, a fixing device 8, a fixing seat 10 and a cutter head 17, and the support rod 1 is provided on both sides of the top of the fixing seat 10, and the left side supports A first motor 4 is provided on the left side of the top of the rod 1, and the first motor 4 is bolted to the support rod 1, and the left output end of the first motor 4 is connected to the second gear 3, and the lower side of the second gear 3 A screw 5 bearing-connected to the support rod 1 is provided, the left end of the screw 5 is provided with a first gear 2, and the first gear 2 is meshed with the second gear 3, and the screw 5 is located between the two support rods 1 The outer side of the middle part is provided with a first fixed block 6, and the first fixed block 6 is threadedly connected with the screw mandrel 5, and the bottom of the first fixed block 6 is provid...

Embodiment 2

[0028] A cutting device includes the precise semiconductor wafer cutting device described in Embodiment 1.

[0029] The semiconductor wafer precision cutting device can effectively remove the impurities generated after cutting by setting multi-layer filters, thereby ensuring the cleanness and recycling of the cutting fluid, avoiding the secondary pollution of the semiconductor wafer, and reducing the cutting fluid. The use cost also protects the environment. By setting the fixing device 8, the wafer can be effectively fixed, avoiding the cutting failure caused by the side slip of the wafer during the cutting process, and improving the cutting accuracy. The adjustment of the light source 18 The angle ranges from 0 to 90 degrees, so that the light source 18 can be completely and accurately aligned on the semiconductor wafer. By setting the light source sensor 19, the precision of cutting can be effectively improved and the cutting quality can be improved.

[0030] The working pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com