Friction material production process for ground rice and wheat straw brake pad

A technology of rice straw and friction materials, applied in the direction of friction linings, other chemical processes, chemical instruments and methods, etc., to reduce pollution and improve production utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

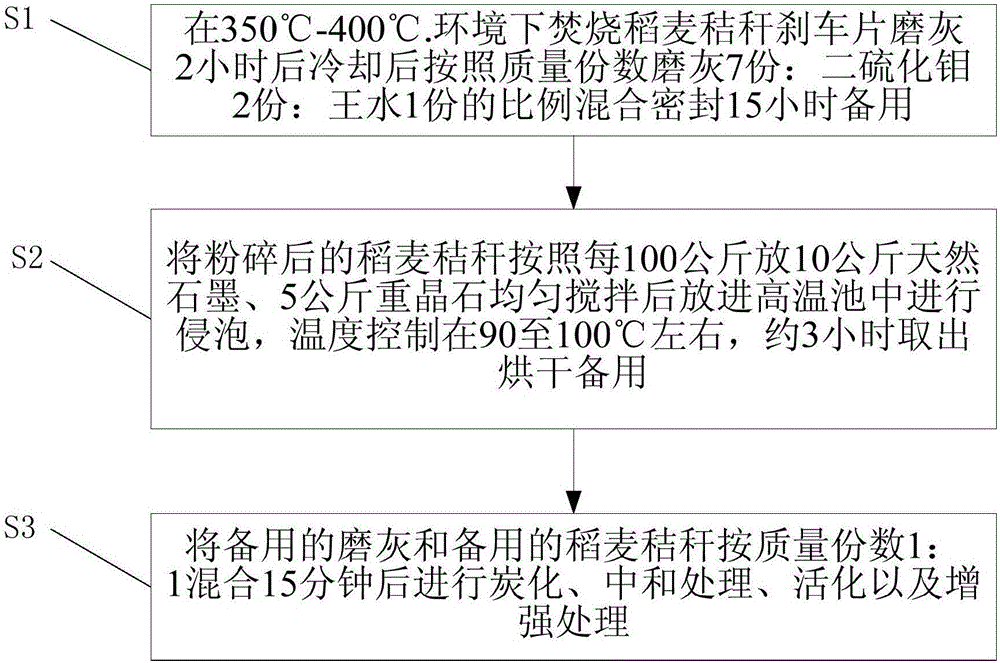

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0013] see figure 1 . The friction material production process of the rice-wheat straw brake pad ash-grinding brake pad in the preferred embodiment of the present invention includes steps:

[0014] S1: Incinerate rice and wheat straw in the environment of 350°C-400°C. After grinding for 2 hours, the brake pads are cooled and ground according to the mass parts. 7 parts of molybdenum disulfide: 1 part of aqua regia are mixed and sealed for 15 hours for later use. ;

[0015] S2: Add 10 kg of natural graphite and 5 kg of barite for every 100 kg of crushed rice and wheat straw, stir evenly, put it into a high-temperature pool for soaking, control the temperature at about 90 to 100°C, take it out and bake it for about 3 hours dry standby;

[0016] S3: The spare ground ash and the spare rice and wheat straw were mixed according to the mass ratio o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com