Full-automatic butting device for reinforcement cage in municipal construction engineering

A fully automatic technology for construction engineering and cages, applied in the field of construction engineering, can solve the problems of time-consuming and laborious, poor standardization, etc., and achieve the effects of various types of applications, reduced workload, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

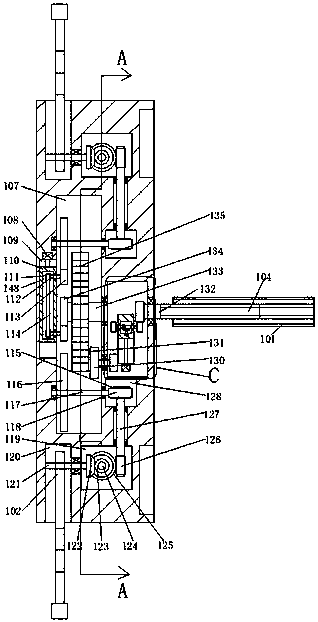

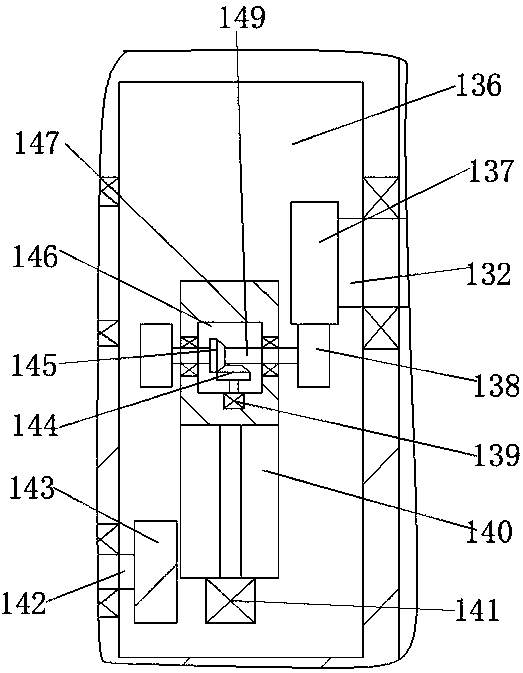

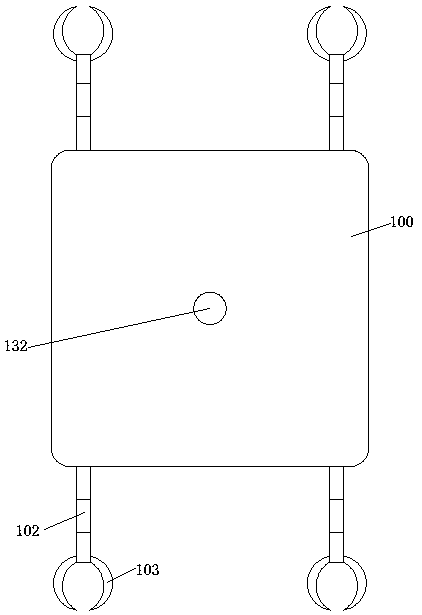

[0028] see Figure 1-9 , a fully automatic tie-joining device for reinforcement cages in municipal construction projects, which includes an annular housing 150 and a main reinforcement supporting body 100, the annular housing 150 and the main reinforcement supporting body 100 are two completely separated parts, and the annular housing 150 is provided with An annular cavity 159, the annular housing 150 is provided with a plurality of butt holes 151 distributed in the circumferential direction through the annular cavity 159, and the inner wall of the inner ring of the annular housing 150 is provided with a hole between any two adjacent butt holes 151. The double-layer first slot 161, the device also includes a cylindrical shell 167 located at the center of the annular housing 150 with an upward opening, and the inner wall of the side of the cylindrical shell 167 is provided with a second slot corresponding to the first slot 161 one-to-one. 179, the side surface of the shell 167 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com