Continuous corncob dryer

A drying machine and corn cob technology, applied in the direction of drying machine, seed preservation through drying, drying, etc., can solve the problems of not being able to meet the production needs and the high rate of grain breakage, so as to solve the problem of high grain breakage rate and ensure normal The effect of running and improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

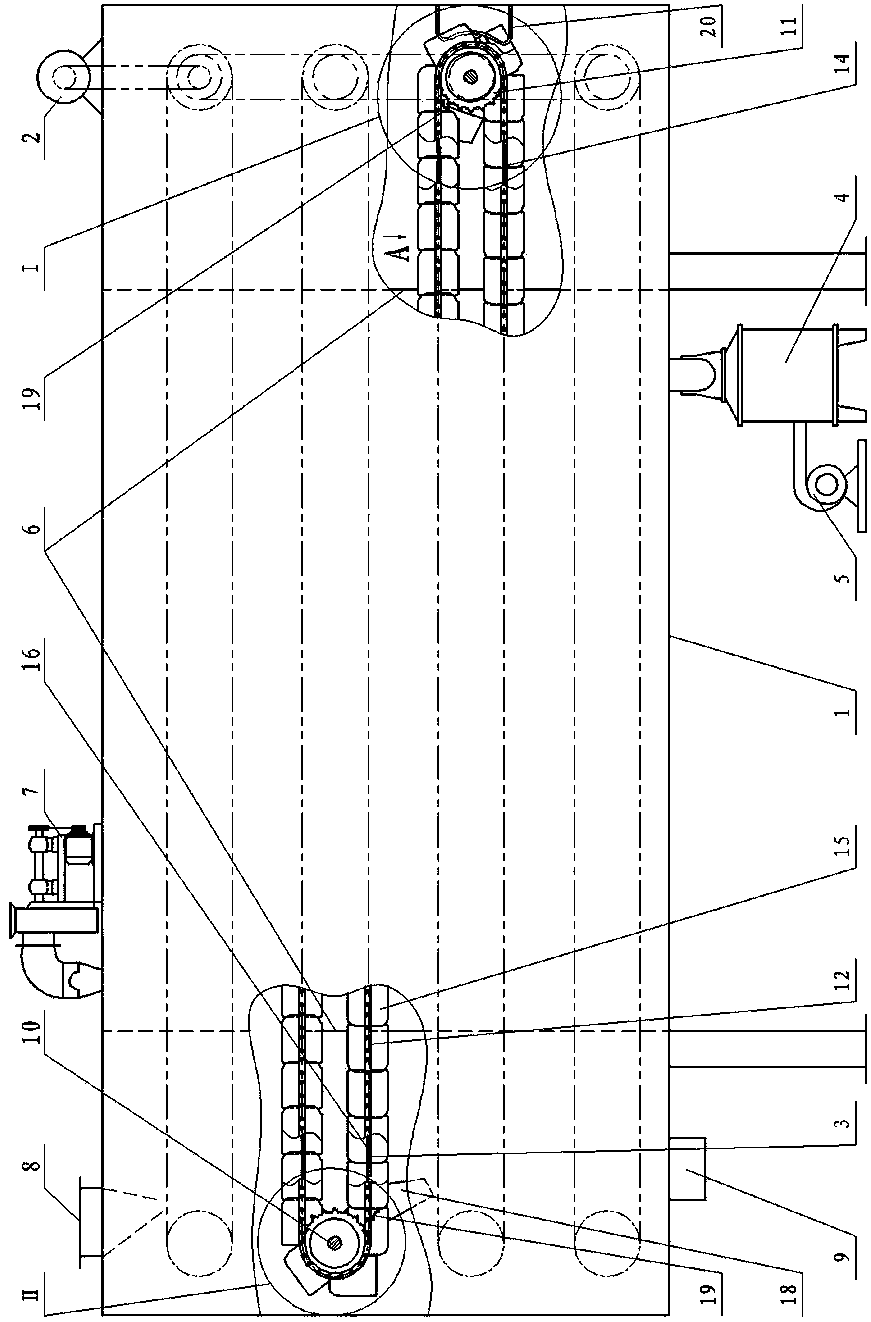

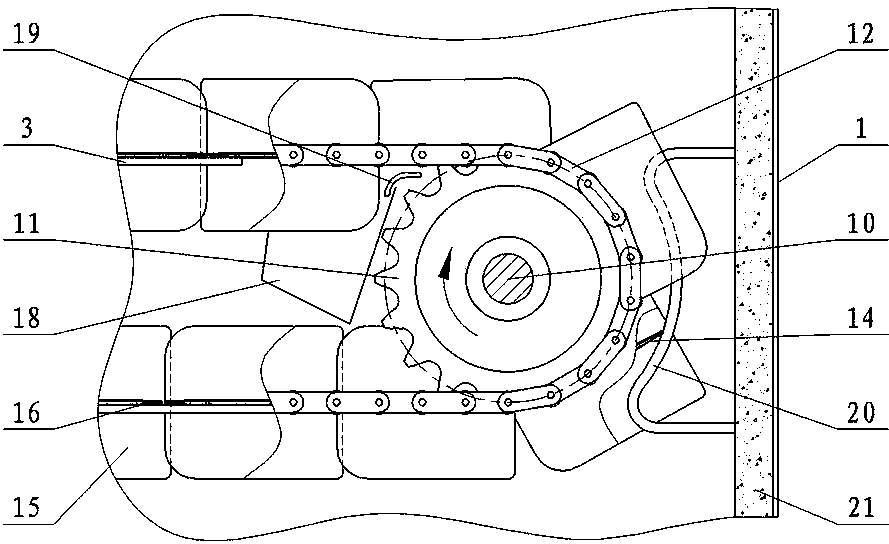

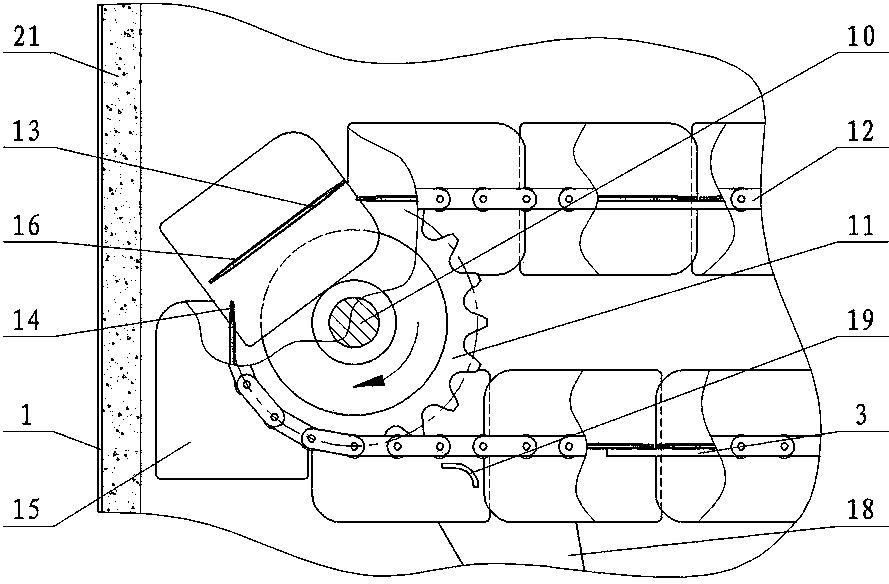

[0021] 1. Box body 2, transmission device 3, guide rail 4, air heater 5, blower 6, clapboard 7, induced draft fan 8, material inlet 9, material outlet 10, shaft 11, conveying sprocket 12, conveying chain 13 , bearing pin 14, forming panel 15, baffle plate 16, ventilation hole 17, hanging hole 18, material guide groove 19, guide rod 20, limit rod 21, insulation layer.

[0022] exist Figure 1~7 In the shown embodiment: the present invention adopts 18 vertical partitions 6 to intermittently divide the interior of the rectangular box 1 into three parts: left, middle and right along the length direction; the bottom of the middle part of the box 1 is close to the partition 6 An air heater 4 is installed, and the air blower 5 blows normal-temperature air into the air heater 4 for heating and then enters the middle part of the box body 1. An induced draft fan 7 is installed at the top of the box body 1 near the partition plate 6 on the other side; One end of the fan 7 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com