Isostatic pressing forming method and forming mold for ceramic roller bars

A technology of isostatic pressing and ceramic rollers, used in ceramic molding machines, ceramic molding cores, molds, etc., can solve the problems of uneven stress, affect product quality, and uneven overall compactness, and avoid fillers. The effect of equalizing, reducing the gas content, and filling the balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

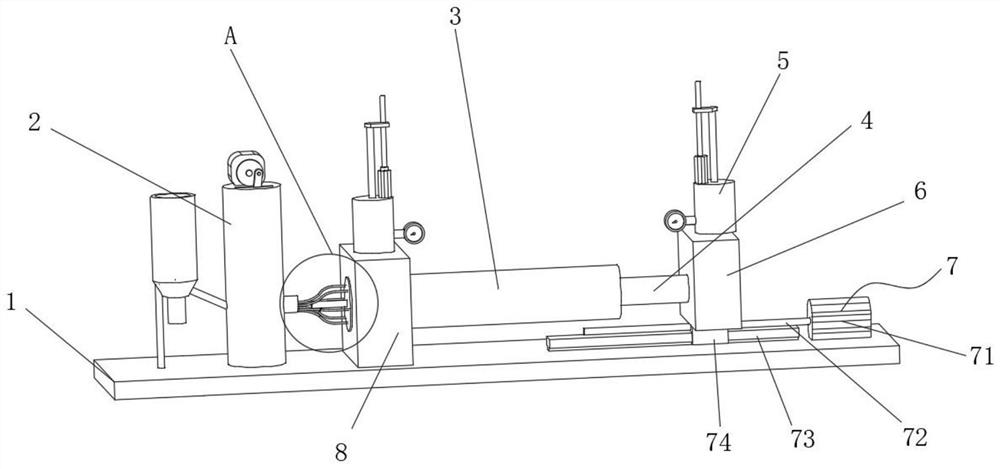

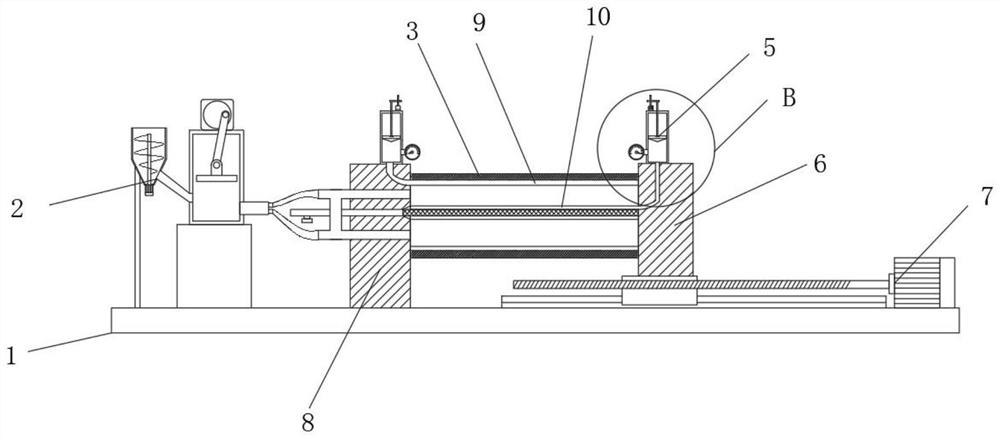

[0040] As an embodiment of the present invention, the push assembly 7 includes a push motor 71, a push screw 72, a slide rail 73, and a slide buckle 74. Buckle 74, push motor 71 is installed on the top side of base plate 1 through bolt cooperation, and push screw rod 72 is installed on the rotating shaft of push motor 71, and push screw rod 72 is worn in the slide buckle 74 through thread rolling bearing, and slide buckle 74 The top side is welded with movable block 6.

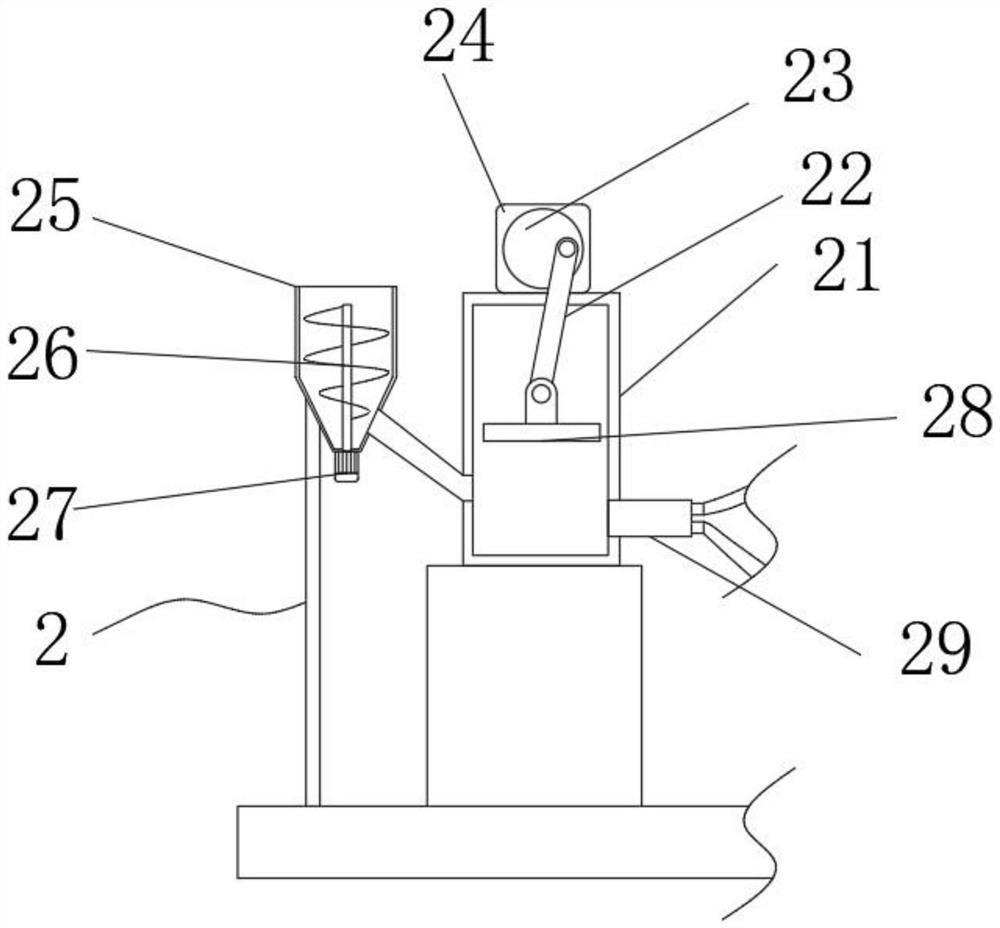

[0041] As an embodiment of the present invention, the feeding assembly 2 includes a feeding cylinder 21, a linkage rod 22, a rotating disk 23, a rotating motor 24, a material hopper 25, a mixing screw 26, a conveying motor 27, a piston disc 28 and a discharge Tube 29 and feeding cylinder 21 are erected on the top side of base plate 1, piston disc 28 is installed inside feeding cylinder 21, rotating motor 24 is installed on the top of feeding cylinder 21 by bolts, rotating disk 23 is installed on rotating motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com