Patents

Literature

119results about How to "Achieve padding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing high-tenacity composite material with heat conducting function

ActiveCN103435998AHigh thermal conductivityHigh thermal conductivity systemHeat-exchange elementsMelt blendingHeat conducting

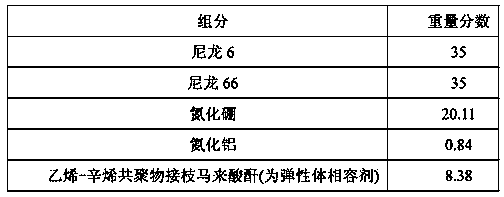

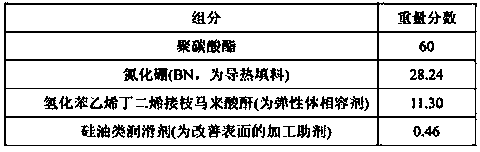

The invention relates to a method for preparing a high-tenacity composite material with a heat conducting function. The method for preparing the high-tenacity composite material with the heat conducting function adopts the basic principle that a core-shell structure can enhance tenacity, heat conducting filler is designed into a core, and an elastomer is designed into a shell, so that high filling is realized while the tenacity enhancing effect of the elastomer is fully played. The method for preparing the high-tenacity composite material with the heat conducting function comprises the following concrete steps: firstly preparing master batch of a heat conducting composite material from the heat conducting filler, an elastomer compatilizer and a processing aid, and then carrying out melt blending on the master batch of the heat conducting composite material with engineering plastic in a certain ratio. The high-tenacity composite material with the heat conducting function, prepared by adopting the preparation method, has the functions of high tenacity, high heat conductivity coefficient, good processing fluidity and the like, can be applied to moulding processing such as extrusion and injection, has a good application prospect, is simple in production process, easy to operate and control, stable in quality and high in production efficiency and has broad industrialization and market prospects.

Owner:SICHUAN UNIV

Method for preparing ceramic composite wood

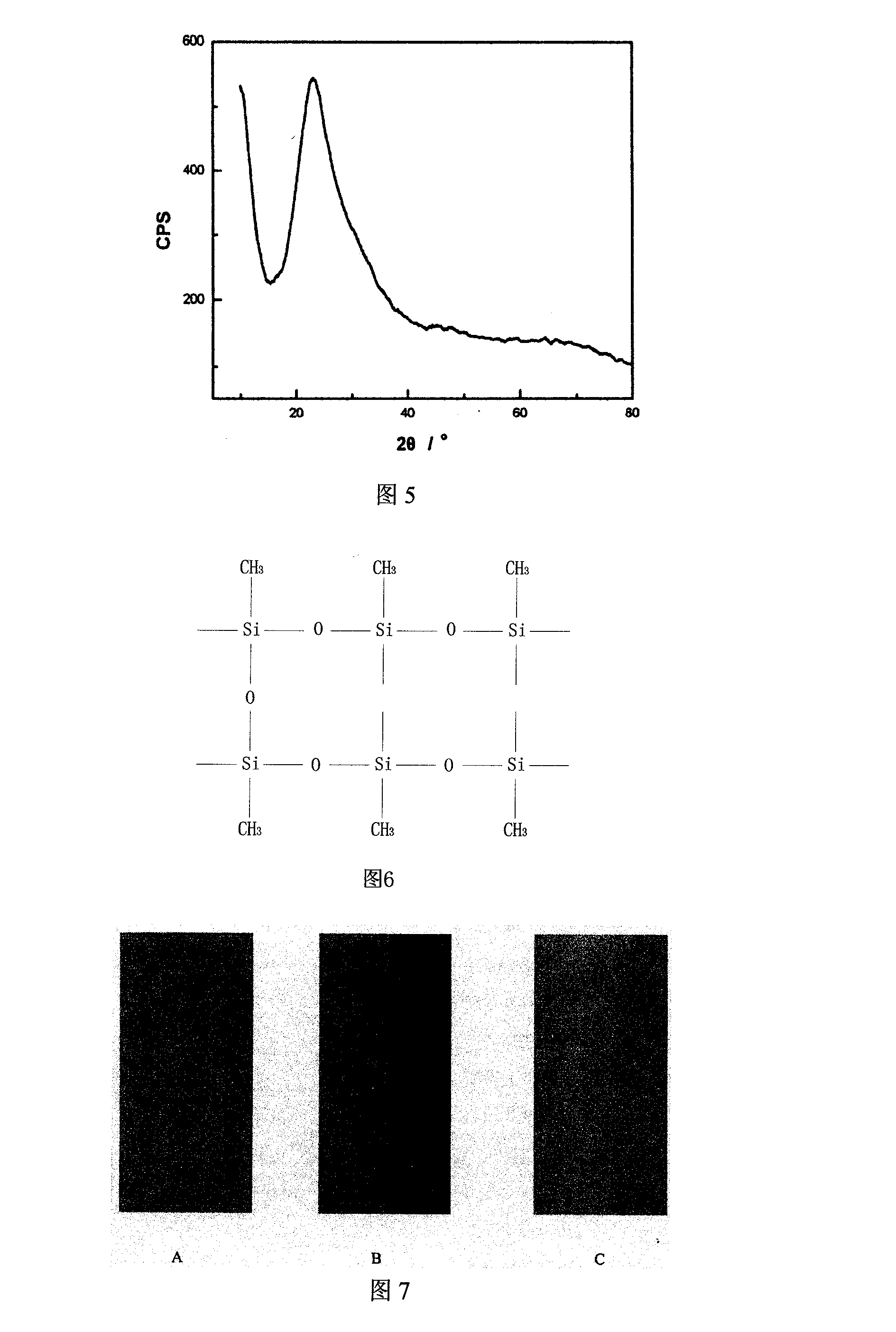

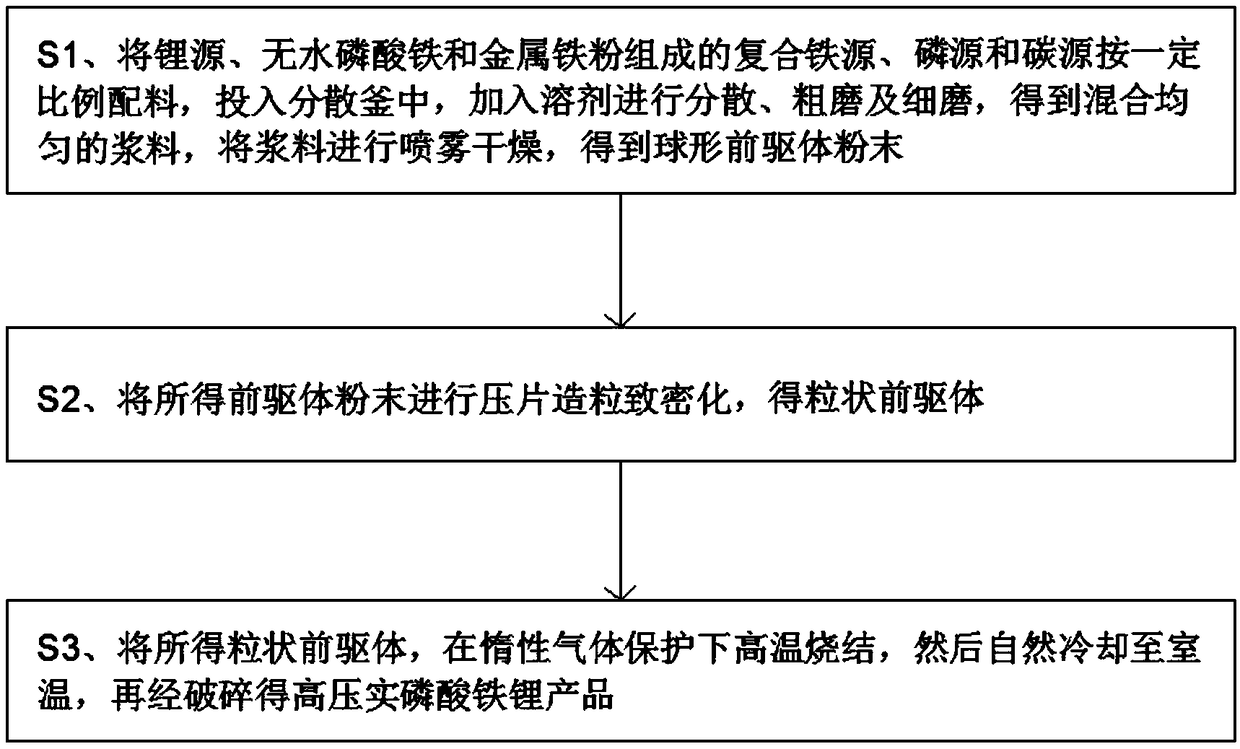

InactiveCN101164744AIncrease profitOvercome the shortcoming of serious volatile lossWood treatment detailsPolymerisation impregnationCeramic compositePositive pressure

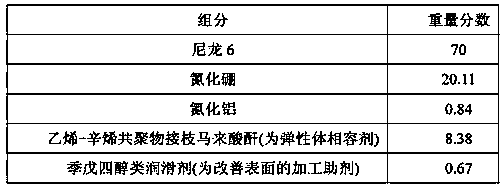

The present invention discloses a preparation method of vitrified composite wood material. Said preparation method includes the following steps: (1), preparing MTES-TEOS sol; (2), making the wood material to be treated undergo the process of negative pressure and positive pressure treatment in a treatment tank and impregnating the wood material to be treated with the sol prepared in step 1 in the process of negative pressure treatment; and (3), making the above-mentioned wood material undergo the process of ageing treatment in the room, then making gel treatment in the drying oven so as to obtain the invented vitrified composite wood material.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

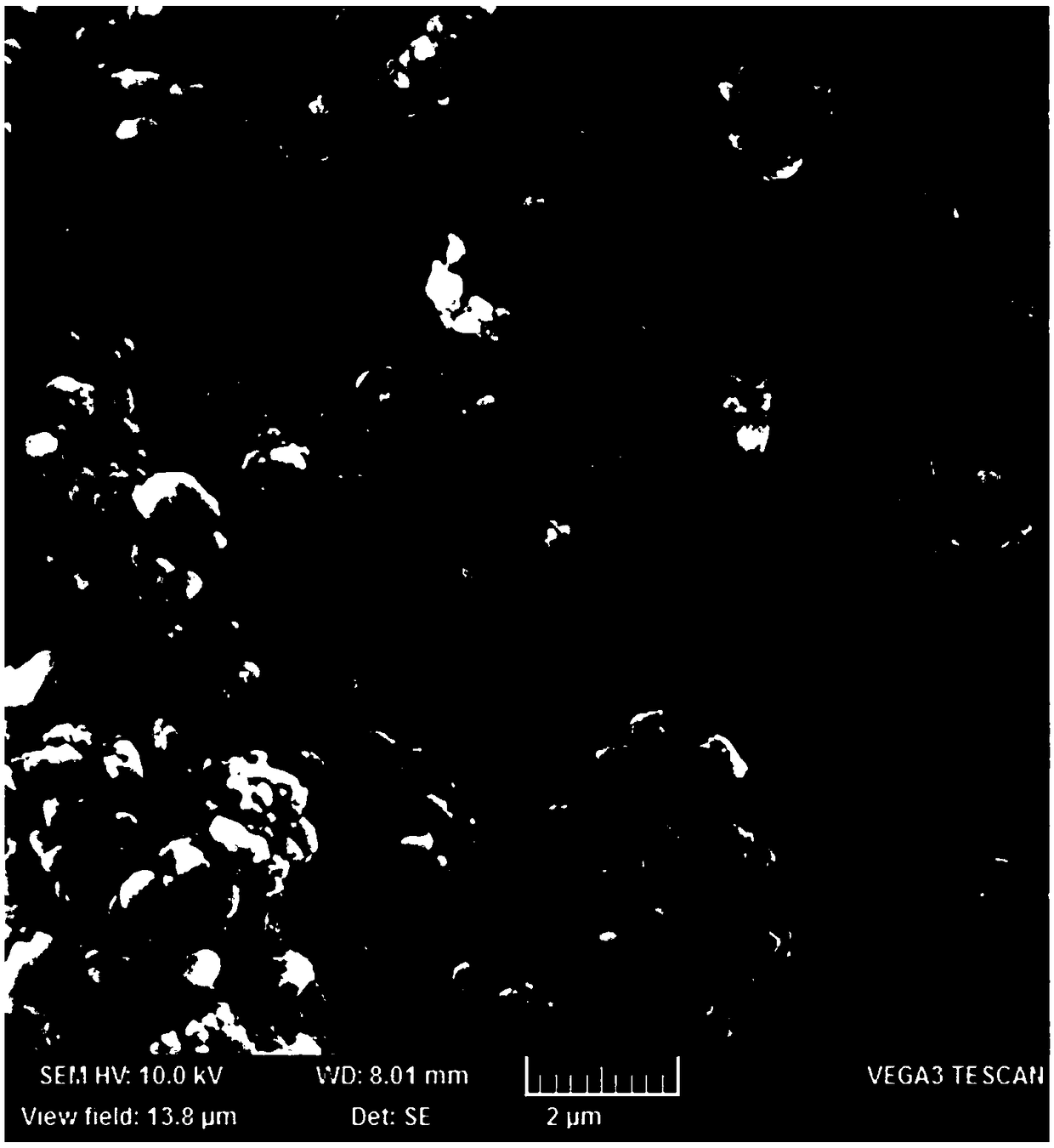

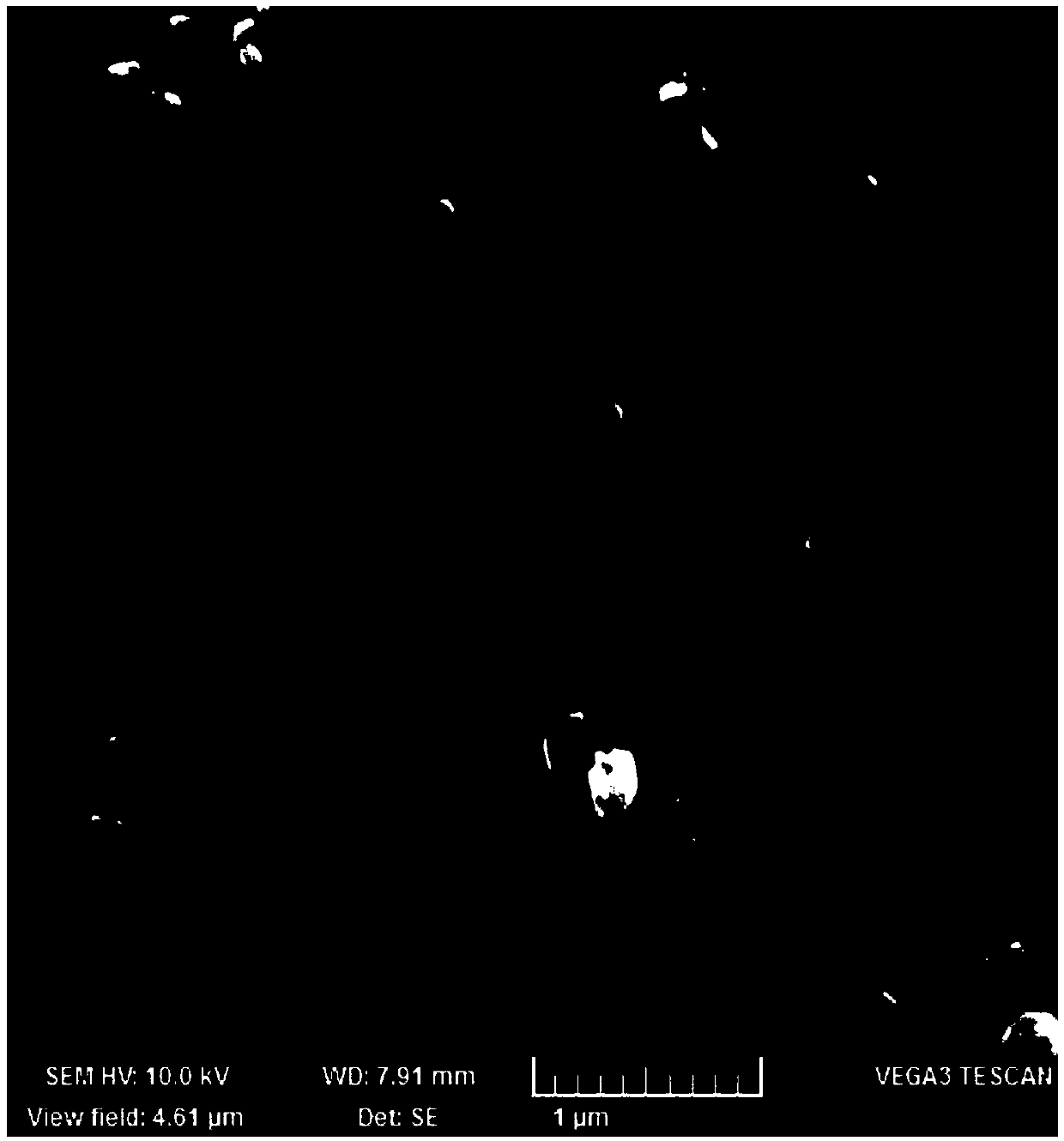

Preparation method of positive electrode material lithium iron phosphate for high-compaction lithium ion battery

The invention provides a preparation method of a positive electrode material lithium iron phosphate for a high-compaction lithium ion battery. The preparation method comprises the following steps thatS1, a lithium source, a composite iron source composed of ferric pyrophosphate and metal iron powder, a phosphorus source and a carbon source are prepared according to a certain proportion and put into a dispersion kettle, a solvent is added for dispersion, coarse grinding and fine grinding to obtain uniformly-mixed slurry, and the slurry is subjected to mist spraying and drying to obtain spherical precursor powder; S2, the obtained precursor powder is tableted, granulated and densified to obtain a granular precursor; S3, the obtained granular precursor is sintered at a high temperature underthe protection of inert gas, and then naturally cooled to the room temperature and pulverized to obtain a high-compaction lithium iron phosphate product. According to the preparation method, the composite iron source is adopted, the density of the metal iron powder is high, and in cooperation of nanoscale ferric pyrophosphate, synthesized lithium iron phosphate has excellent electrochemical performance and higher tap density; the precursor powder obtained by mist spraying and drying is tableted, granulated and densified, and therefore the sintering production efficiency and the density of thelithium iron phosphate material are improved.

Owner:江西省金锂科技股份有限公司

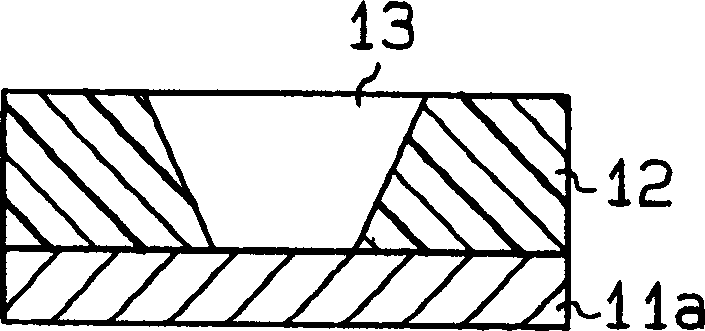

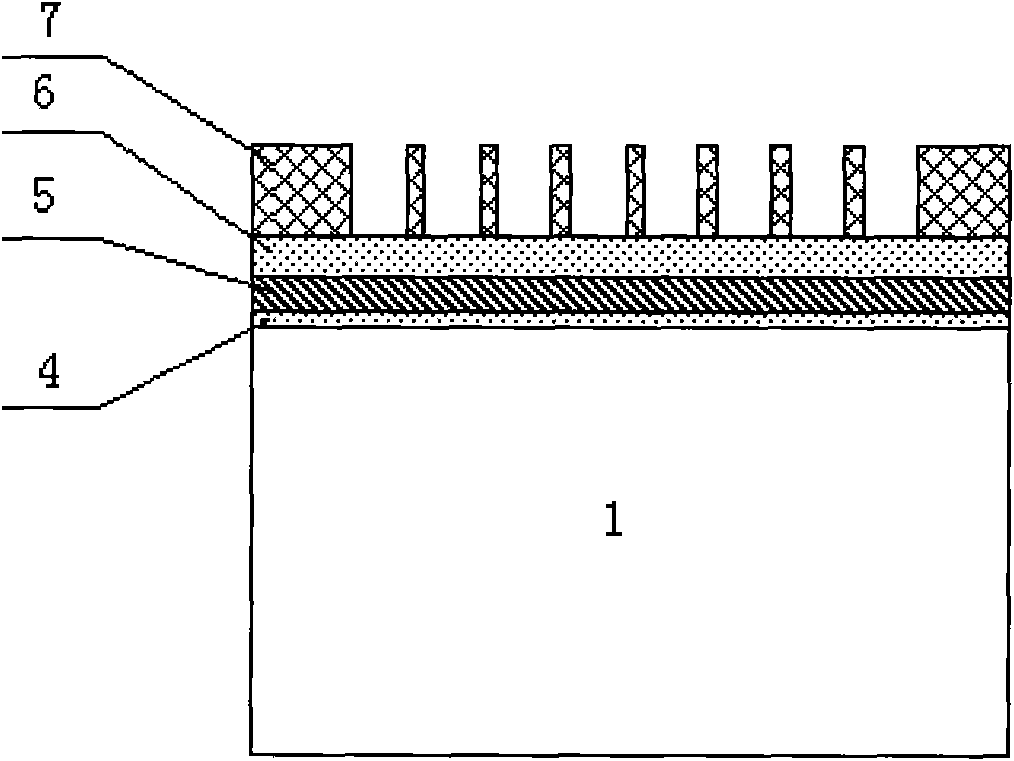

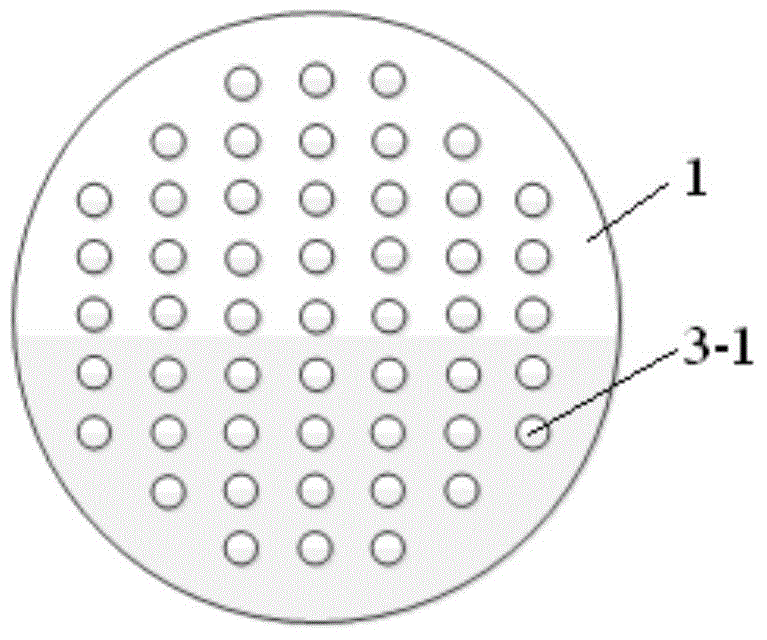

Method for manufacturing vertically interconnecting carbon nanotube bundle

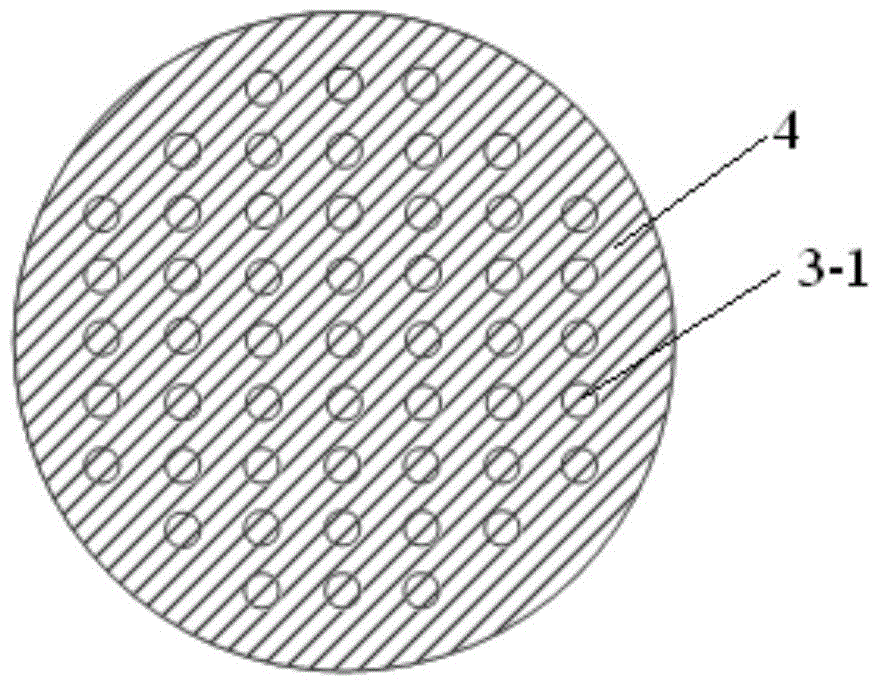

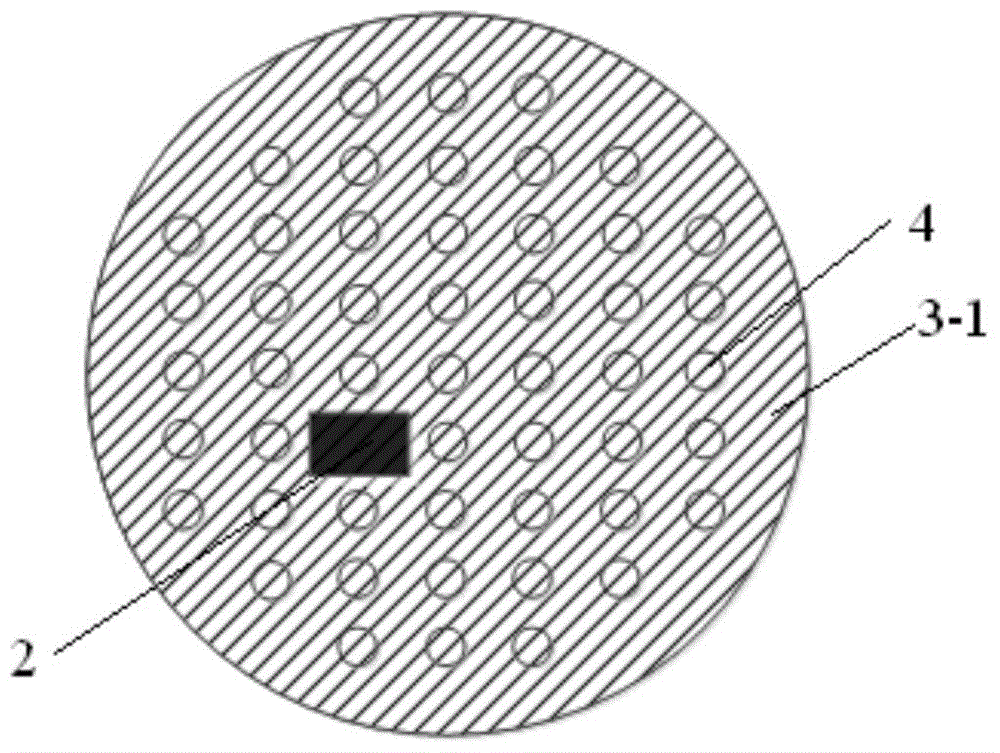

ActiveCN102569181AAchieve paddingHigh densitySemiconductor/solid-state device manufacturingMetal catalystCarbon nanotube

The invention discloses a method for manufacturing a vertically interconnecting carbon nanotube bundle with high interconnecting reliability and high performance. The method is compatible with a through silicon via (TSV) process and is mature and easy to implement. The method comprises the following steps of: forming a hole, and depositing a metal catalyst film at the bottom of the TSV only, so that the carbon nanotube bundle vertically grows at the bottom of the TSV from bottom to top so as to fill the TSV. Meanwhile, gas between carbon nanotubes is exhausted through densification operation so as to improve the density of the carbon nanotube bundle; and an interconnecting structure of the metal-coated carbon nanotube bundle is manufactured, and the interconnecting reliability and the performance of the carbon nanotube bundle can be effectively improved by taking the interconnecting structure as an interconnecting material. The invention has the advantages that: the method is compatible with the TSV process and is mature and easy to implement, and the interconnecting reliability and the performance can be greatly improved.

Owner:NAT CENT FOR ADVANCED PACKAGING

High-rate high-safety long-life lithium iron phosphate battery and preparation method thereof

ActiveCN109687013AHigh magnificationRaise the ratioFinal product manufactureElectrode carriers/collectorsHigh rateCeramic coating

The invention discloses a high-rate high-safety long-life lithium iron phosphate battery and a preparation method thereof, and relates to the field of lithium batteries. Anode slurry of the battery uses lithium iron phosphate, conductive carbon black, carbon nanotube, polyvinylidene fluoride and N-methylpyrrolidone; an anode current collector adopts a carbon coated aluminum foil; cathode slurry uses artificial graphite composite material, conductive carbon black, thickener CMC and binder SBR; a cathode current collector uses a microporous copper foil; an electrolyte adopts a lithium hexafluorophosphate organic solvent electrolyte with the liquid injection amount of 6.0-6.2 g; a diaphragm adopts a ceramic coating diaphragm. The lithium iron phosphate battery has the advantages of high rateperformance, high use safety and long service life.

Owner:江西省汇亿新能源有限公司

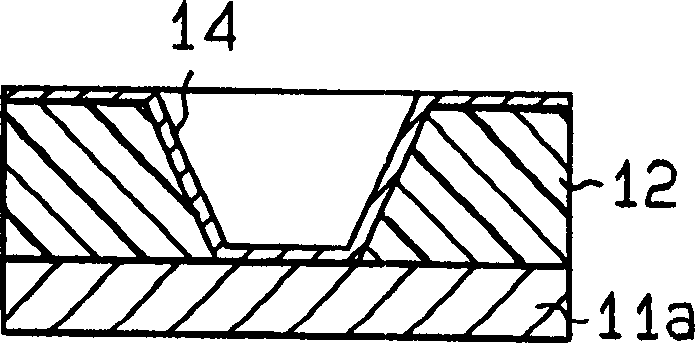

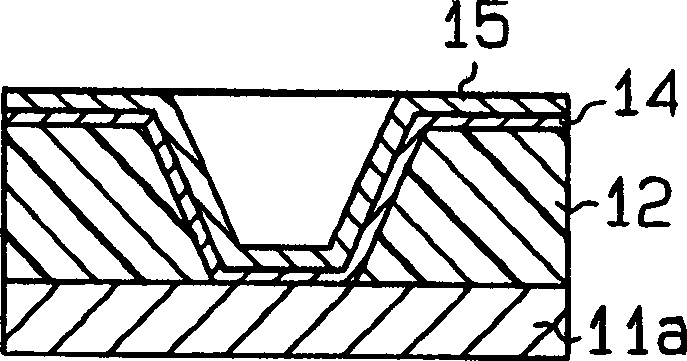

Method for plating via hole with copper

InactiveCN1402608AAchieve paddingPrinted circuit aspectsSemiconductor/solid-state device manufacturingCopper platingSecondary stage

A copper plating method for a via hole formed on a multi-layer substrate is provided. The via hole interconnects conductive layers of the multi-layer substrate. The method includes performing chemical copper plating on an inner wall of the via hole and performing electrolytic copper plating on the inner wall of the via hole, on which the chemical copper plating has been performed. The electrolytic copper plating includes a first stage and second stage. The first stage is performed with a current density equal to or less than 1.5 A / dm2 to deposit copper film having a thickness of 1 mum or more. The second stage is performed at a current density higher than that in the first stage.

Owner:TOYOTA IND CORP

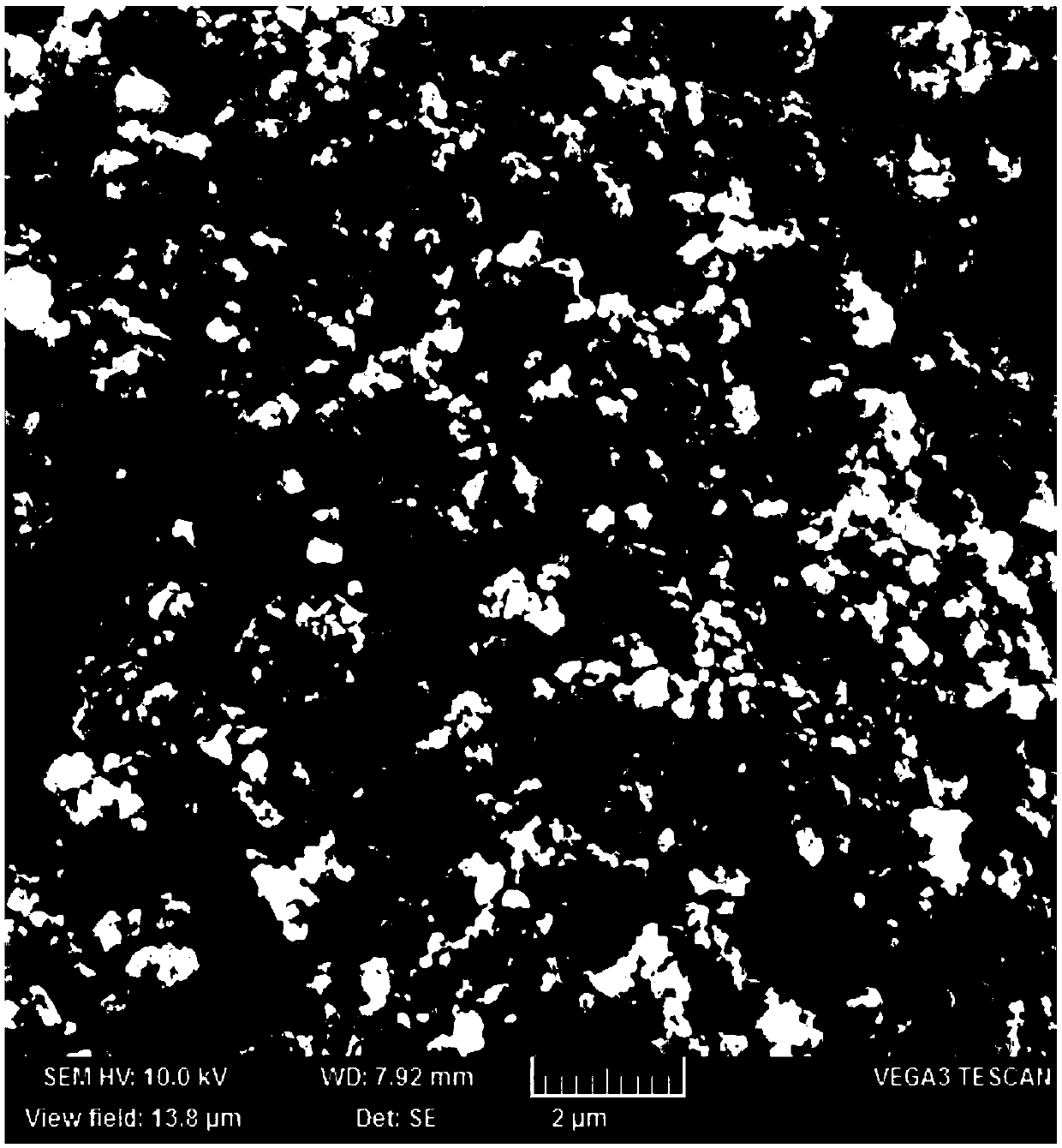

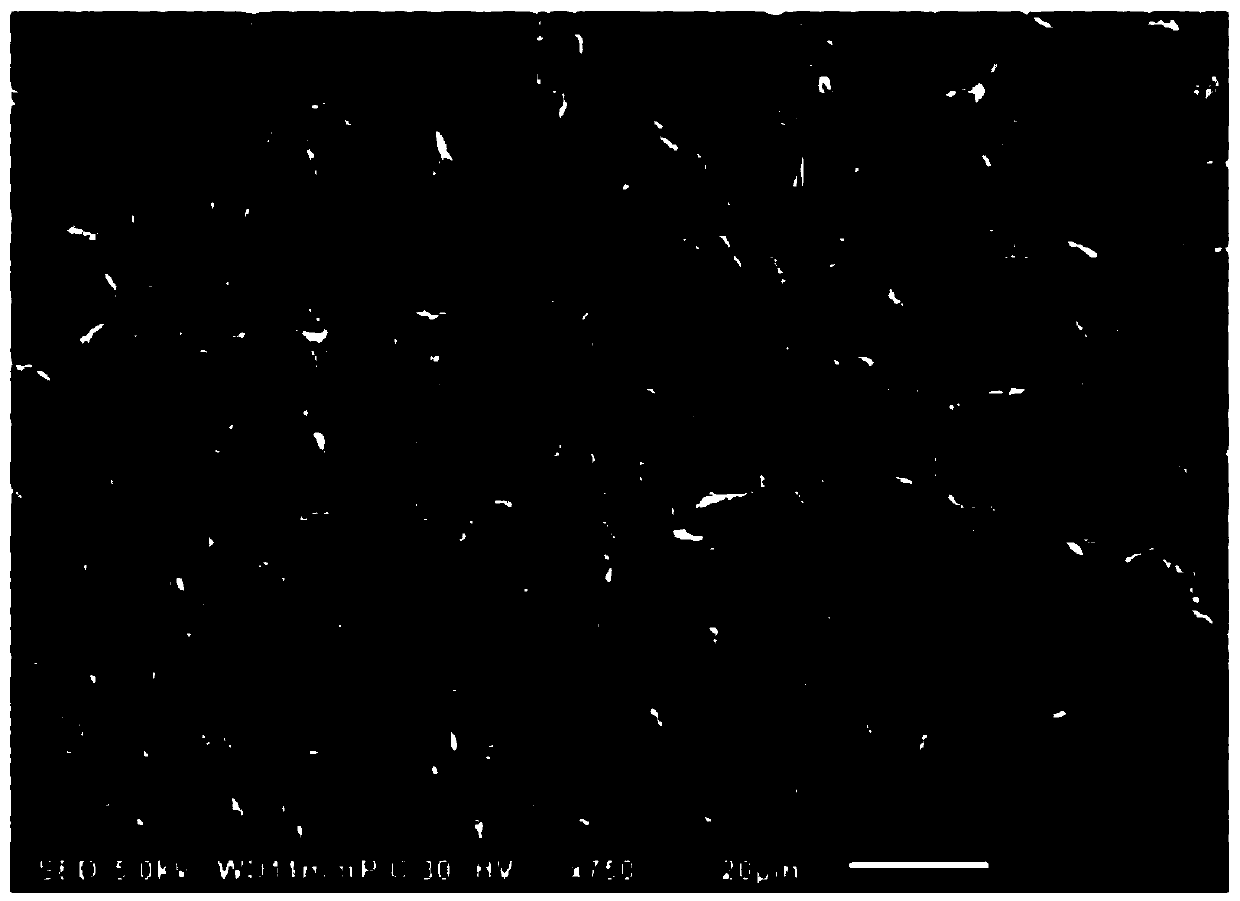

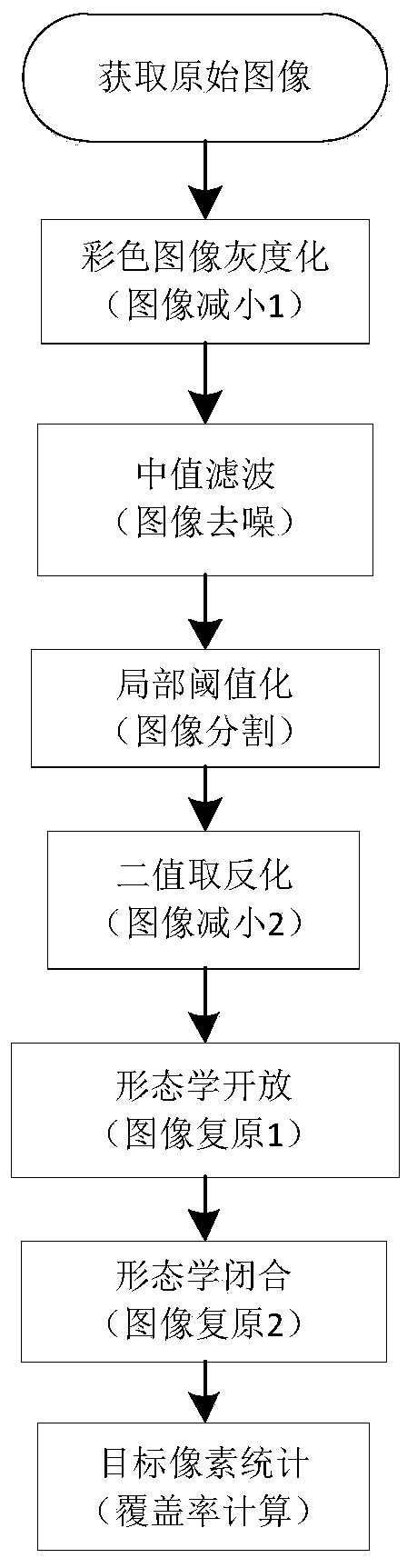

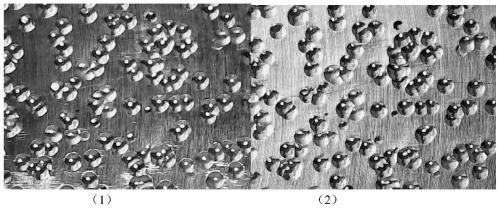

Digital shot blasting coverage rate measurement method based on computer vision technology

InactiveCN111192273AReduce laborShort timeImage enhancementImage analysisVisual technologyImaging processing

The invention discloses a digital shot blasting coverage rate measurement method based on a computer vision technology, and belongs to the technical field of digital image processing. The method comprises the steps of image acquisition, gray scale conversion, noise elimination, region segmentation, binarization processing, filling, pseudo connection elimination and statistics, and image processingfor surface dents after shot blasting of a plate. A computer program is adopted for shot blasting image processing, the consistency of multiple times of measurement is guaranteed, the measurement error is controlled within 5%, the measurement and calculation speed is high, the method does not depend on personal experience, the compatibility with other computer-aided manufacturing equipment is good, the portability is good, and possibility is brought to detection feedback link work in automatic shot blasting control circulation.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

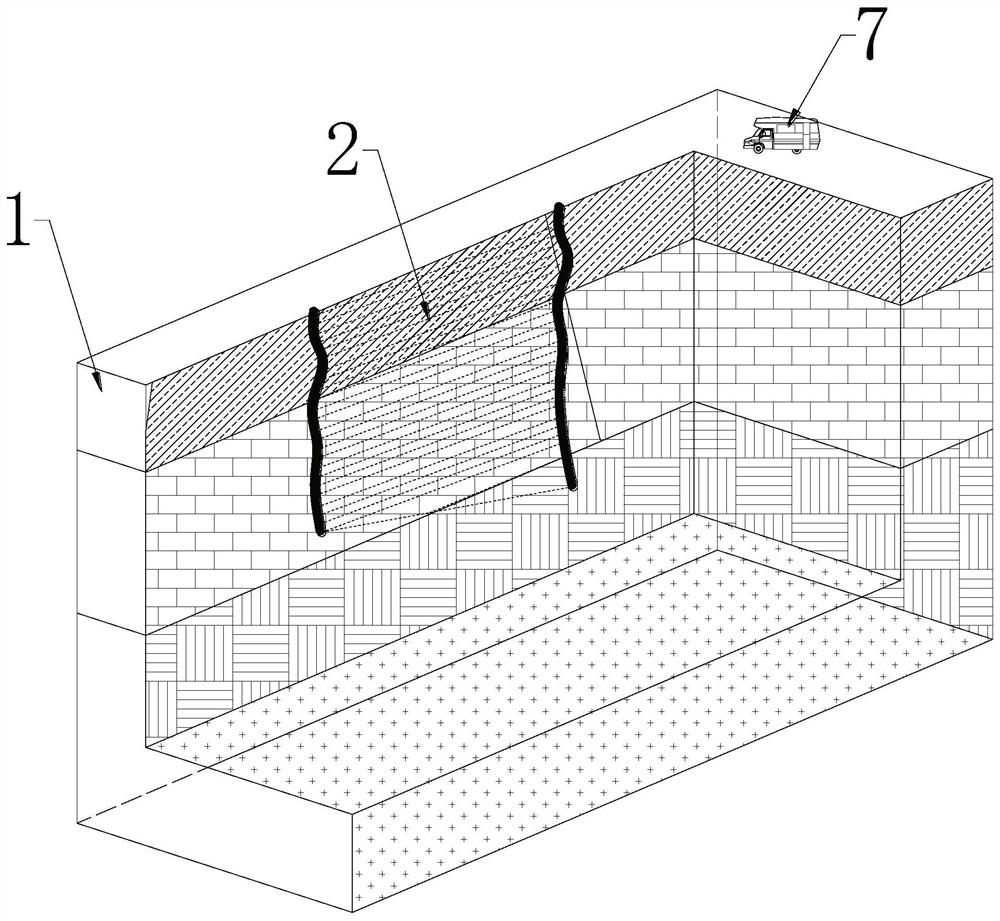

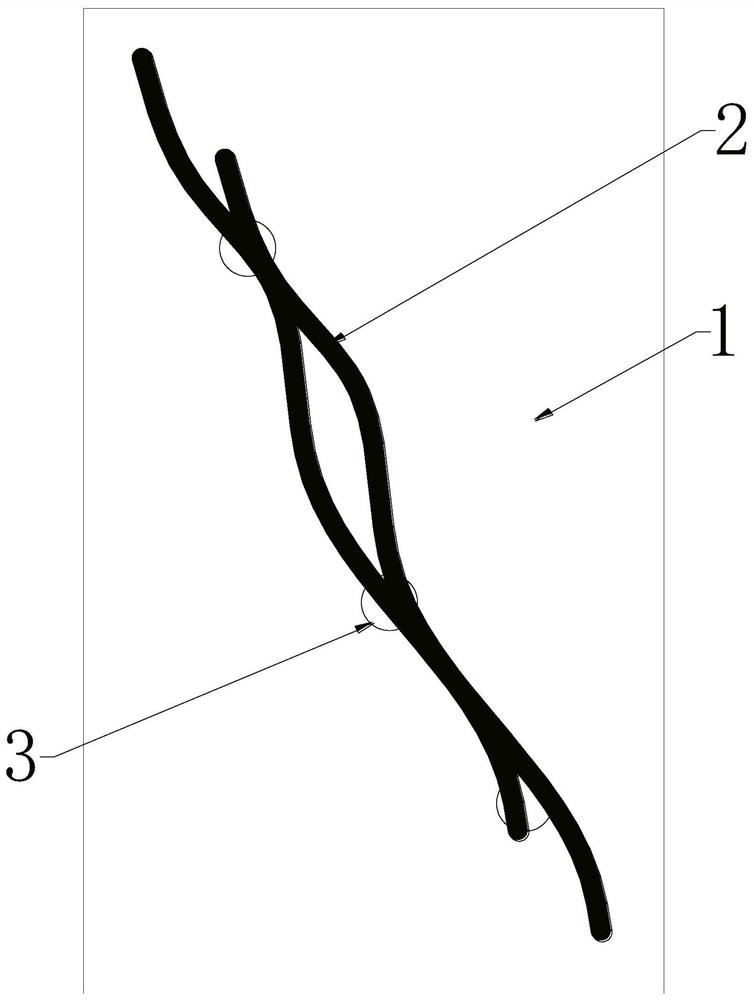

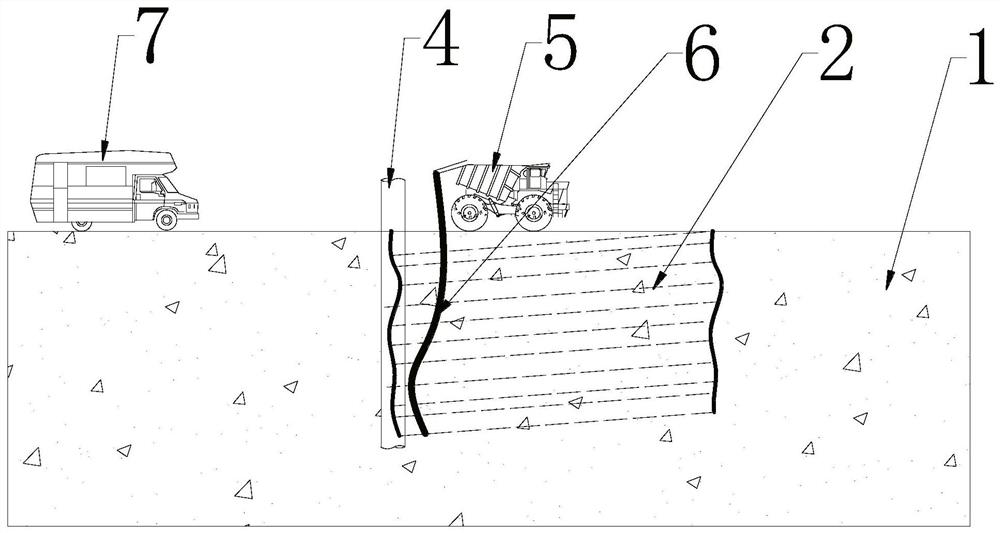

Construction method for disposing road cracks by using waterborne polyurethane

PendingCN112609553AFully grasp the traitsFully grasp the parametersRoads maintainenceEngineeringStructural engineering

The invention discloses a construction method for disposing road cracks by using waterborne polyurethane. The method comprises the following steps: carrying out nondestructive testing on road cracks, drawing a crack distribution diagram, cutting and slotting cracks with the width of less than 3mm as required, drilling grouting holes at intervals along the trend of the cracks, installing grouting pipes, injecting water into the cracks; and then injecting a waterborne polyurethane grouting material, enabling the slurry to react with water in the cracks to generate gel to fill the cracks, sealing the grouting holes after grouting is completed, and finally performing rechecking to confirm that repairing is completed. The method has the advantages that visual detection of road cracks can be achieved, follow-up grouting repair is effectively guided, the characteristics that the waterborne polyurethane material is high in water reaction speed and short in gelation time are ingeniously utilized, roadbed and pavement cracks can be rapidly and comprehensively repaired, the material cannot generate a corrosion effect. And the road crack disease is effectively solved, and wide applicability is achieved.

Owner:ZHENGZHOU RAILWAY VOCATIONAL & TECH COLLEGE

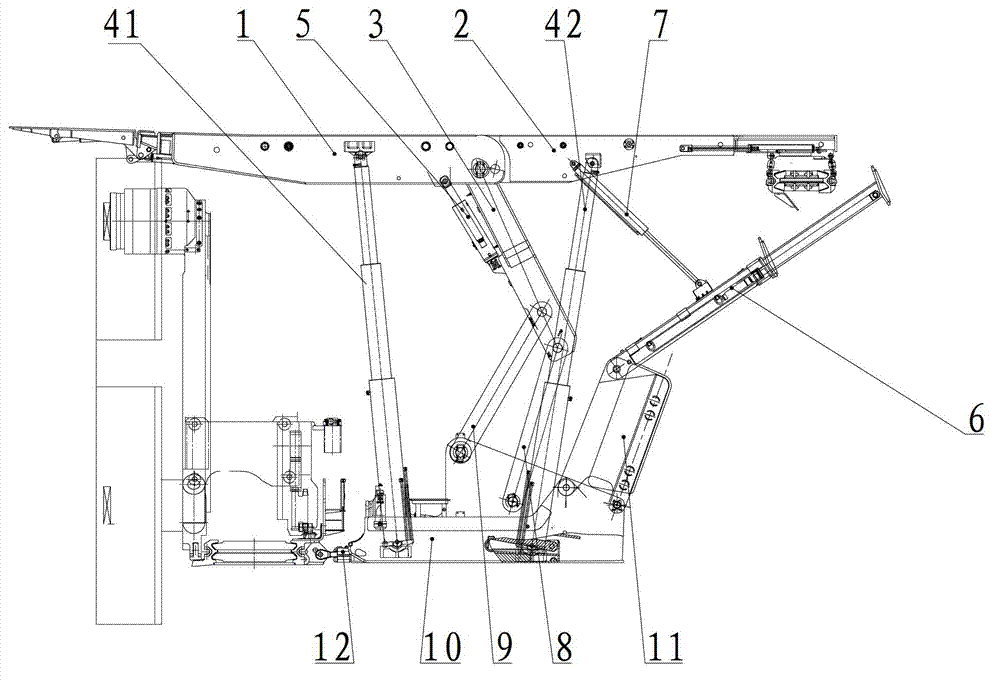

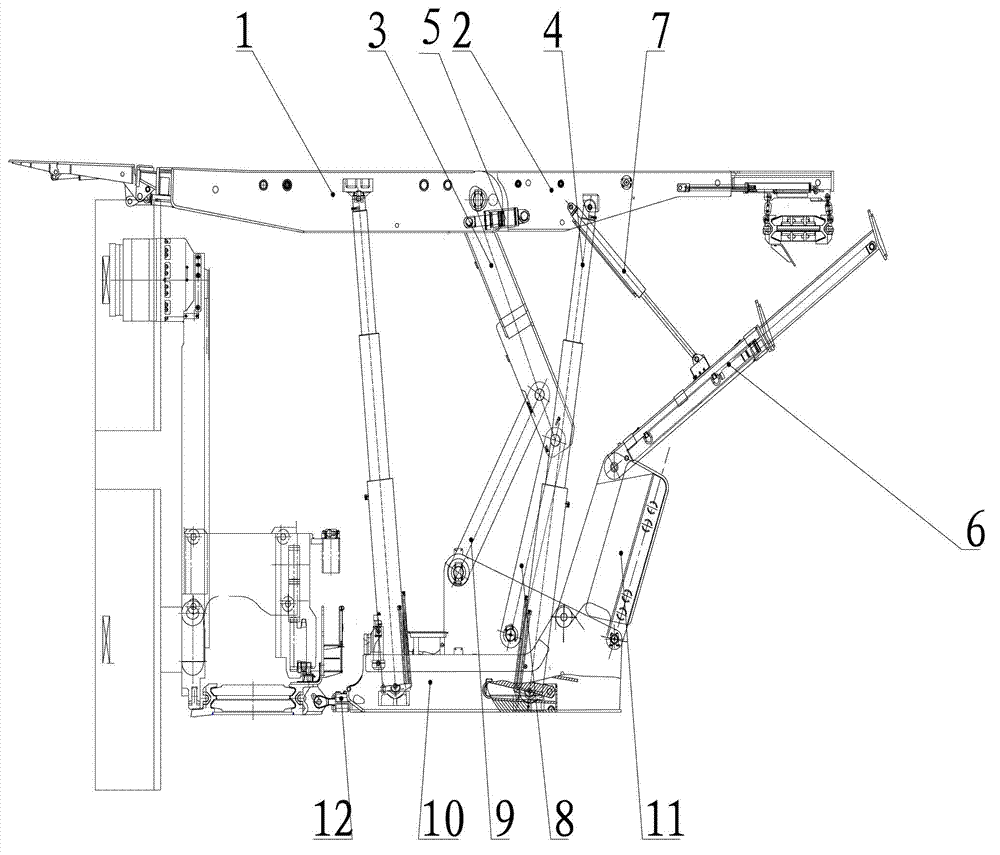

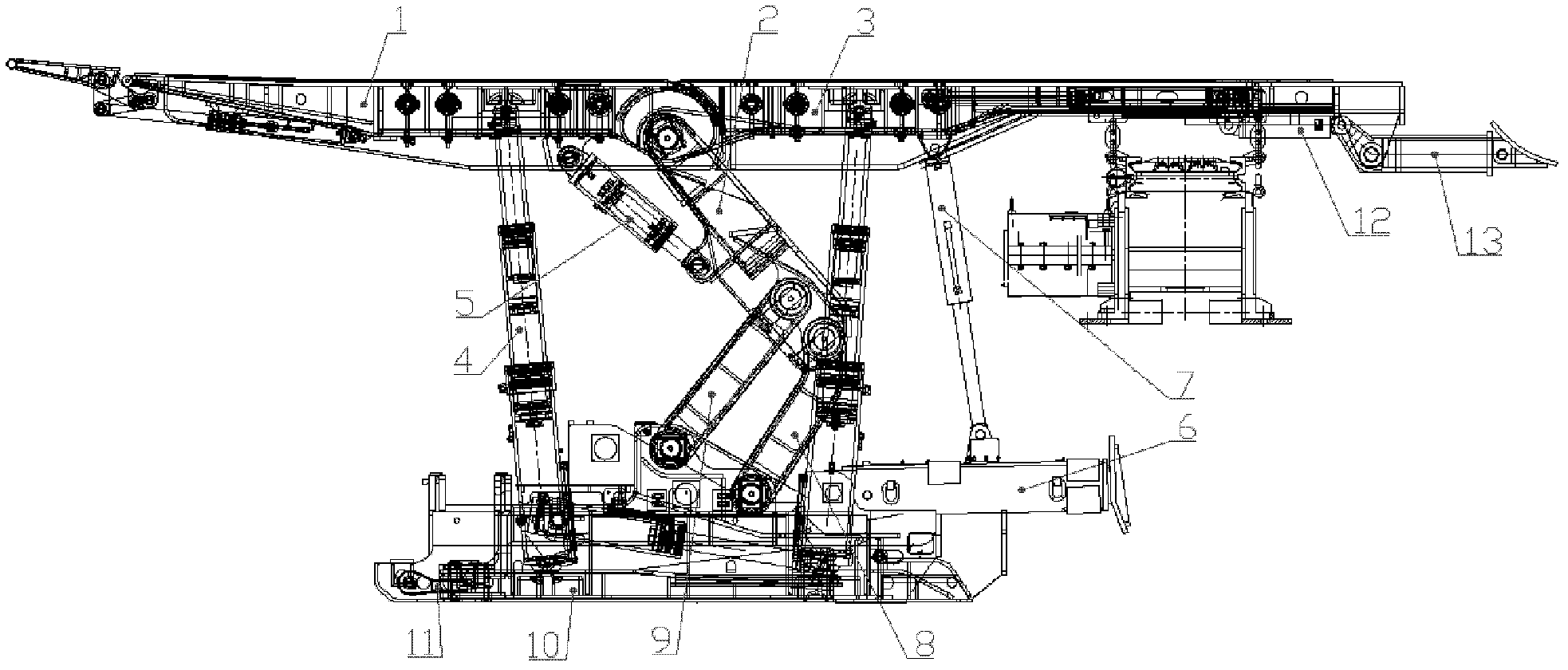

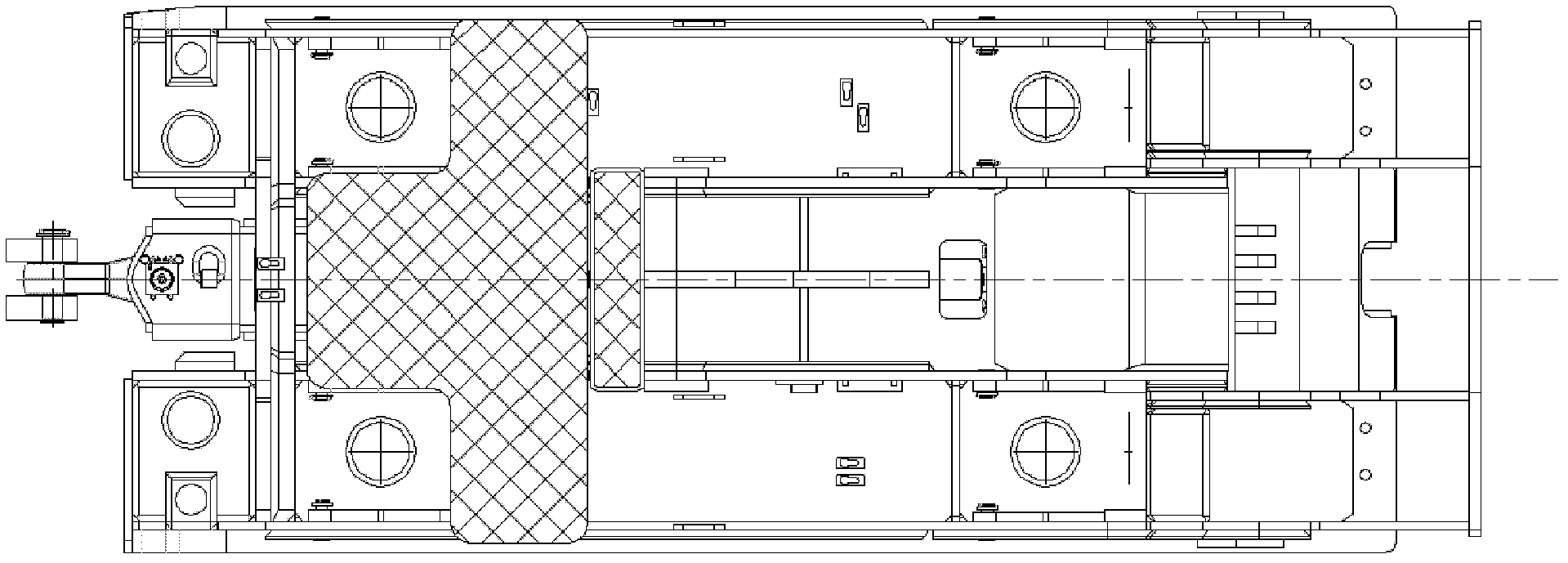

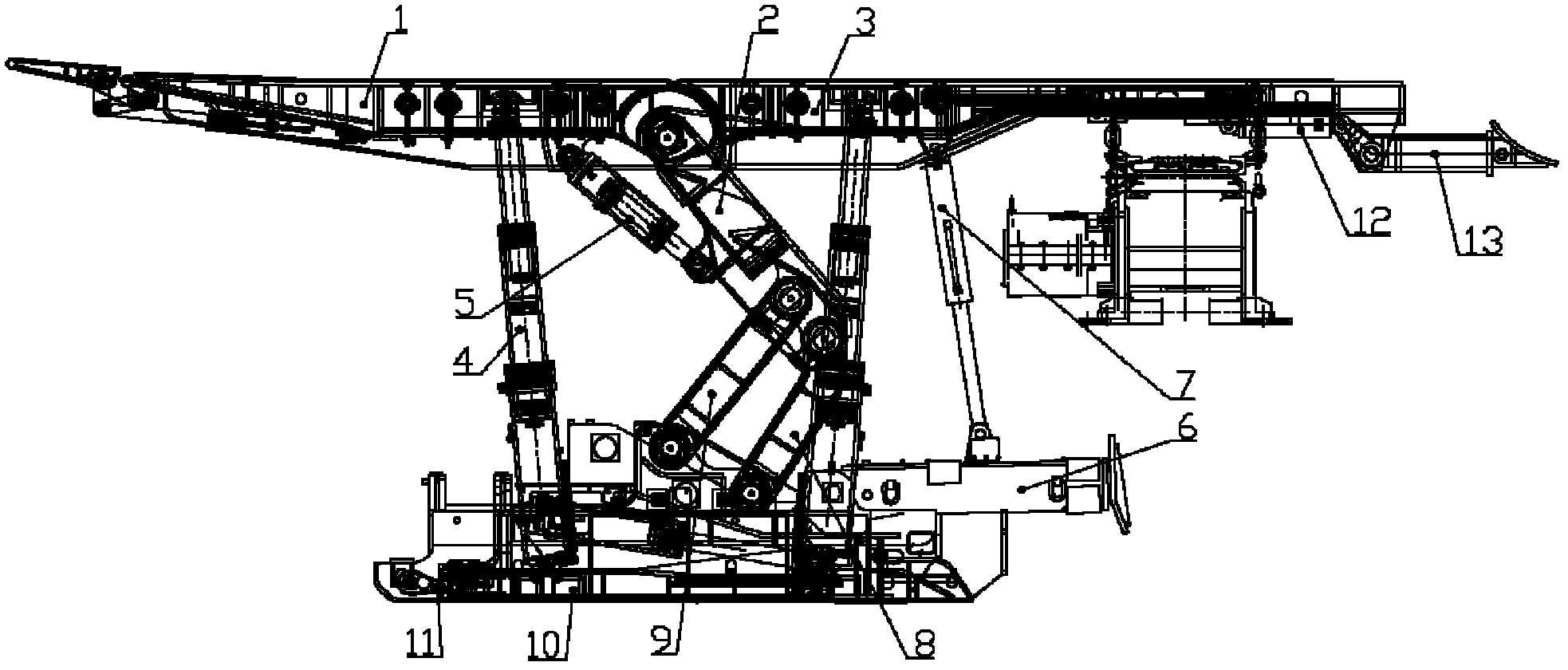

Four-column suspension swinging beam type gangue filling hydraulic support

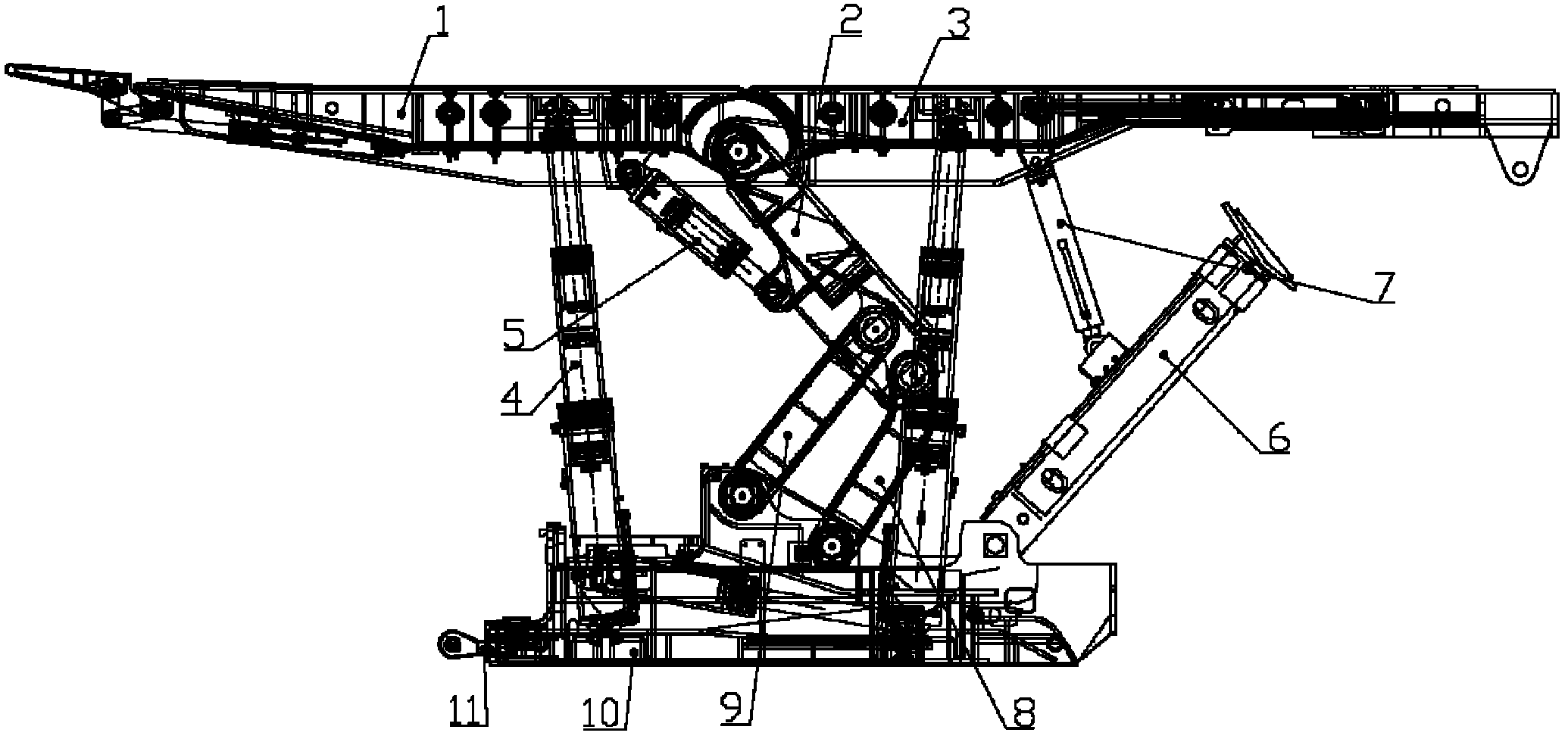

InactiveCN102562112AEasy to fillSupportMaterial fill-upMine roof supportsStructural engineeringCoal mining

The invention relates to a four-column suspension swinging beam type gangue filling hydraulic support. The four-column suspension swinging beam type gangue filling hydraulic support comprises a front top beam, an Y-shaped upper connection rod, and a rear top beam, a stand column, a balance jack, a swinging beam, a swinging beam jack, a rear connection rod, a front connection rod, a foundation, a pushing frame, and a pushing jack which are connected with the front top beam; the stand column is supported between the front and rear top beams and the foundation; the upper end of the Y-shaped upper connection rod is connected with a connection point of the front and rear top beams; the Y-shaped upper connection rod, the front connection rod, the rear connection rod, and the foundation are connected two by two to form a four-connection-rod structure; the swinging beam is positioned at the rear end of the foundation, the upper part of the swinging beam is connected with the swinging beam jack which is arranged on the rear top beam, and the swinging beam can swing in a vertical direction under the action of the swinging beam jack; and the upper and lower parts of the swinging beam jack are connected with the rear top beam and the swinging beam respectively, and the swinging beam is adjusted in a vertical direction under the action of the swinging beam jack. The four-column suspension swinging beam type gangue filling hydraulic support can support a top plate during coal mining, can fill a gob, and integrates support and filling.

Owner:CATERPILLAR ZHENGZHOU

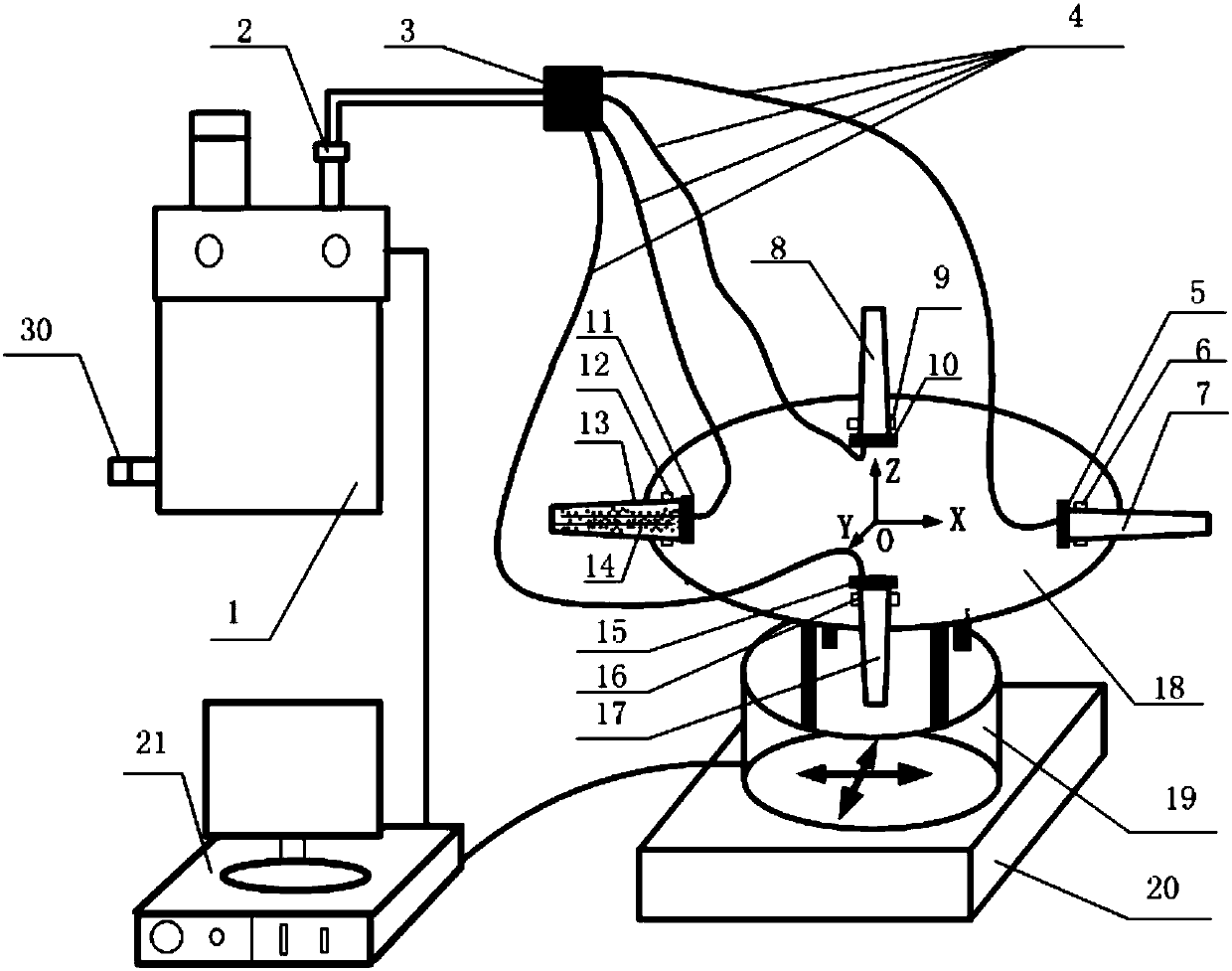

Laser processing drilling method of workpiece with complex cavity and auxiliary filling system

PendingCN108044243AEvenly filledFilled tightlyLaser beam welding apparatusParticulatesLaser processing

The invention relates to a laser processing drilling method, in particular to a laser processing drilling method of a workpiece with a complex cavity and an auxiliary filling system. The laser processing drilling method of the workpiece with the complex cavity comprises the following steps of firstly, by adopting gas as a carrier of powder particles, after uniformly mixing the powder particles andthe gas, blowing a mixture into a workpiece cavity which is to be filled and has a complex cavity; controlling the workpiece cavity to be filled to vibrate in the blowing process, and ensuring the powder particles to be densely filled in an inner cavity of the workpiece to be filled; then performing laser processing drilling on the filled workpiece; adopting a high-pressure air flow to clean theinner cavity of the workpiece to be cleaned at multiple angles for a part which is processed in the step two; and in the cleaning process, controlling the workpiece to be cleaned to vibrate at the same time. By adopting the laser processing drilling method and the auxiliary filling system, the problem that a wall opposite to film holes is easily damaged when the film holes are processed by utilizing laser light is solved.

Owner:XIAN MICROMACH TECH CO LTD

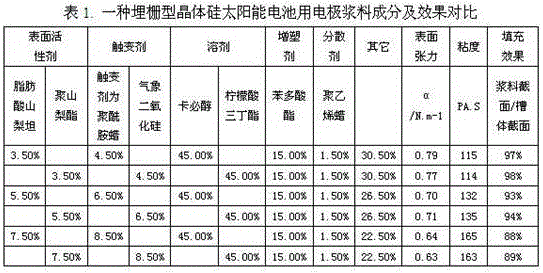

Electrode paste for buried-gate type crystalline silicon solar cell

InactiveCN106847374ALow viscosityReduce surface tensionNon-conductive material with dispersed conductive materialPhotovoltaic energy generationScreen printingCrystalline silicon

The invention relates to the technical field of solar paste, in particular to electrode paste for a buried-gate type crystalline silicon solar cell. The paste is prepared from, by weight, 80-92% of silver powder, 1-4% of glass powder, 0.1-5% of additives and 3-12% of an organic carrier. According to the electrode paste for the buried-gate type crystalline silicon solar cell, for the defect that existing paste cannot be applicable to grooved buried-gate electrodes, by adjusting components and proportioning of the paste, the viscosity and surface tension of the paste are effectively lowered, and filling of an electrode tank can be achieved in a screen printing mode.

Owner:北京市合众创能光电技术有限公司

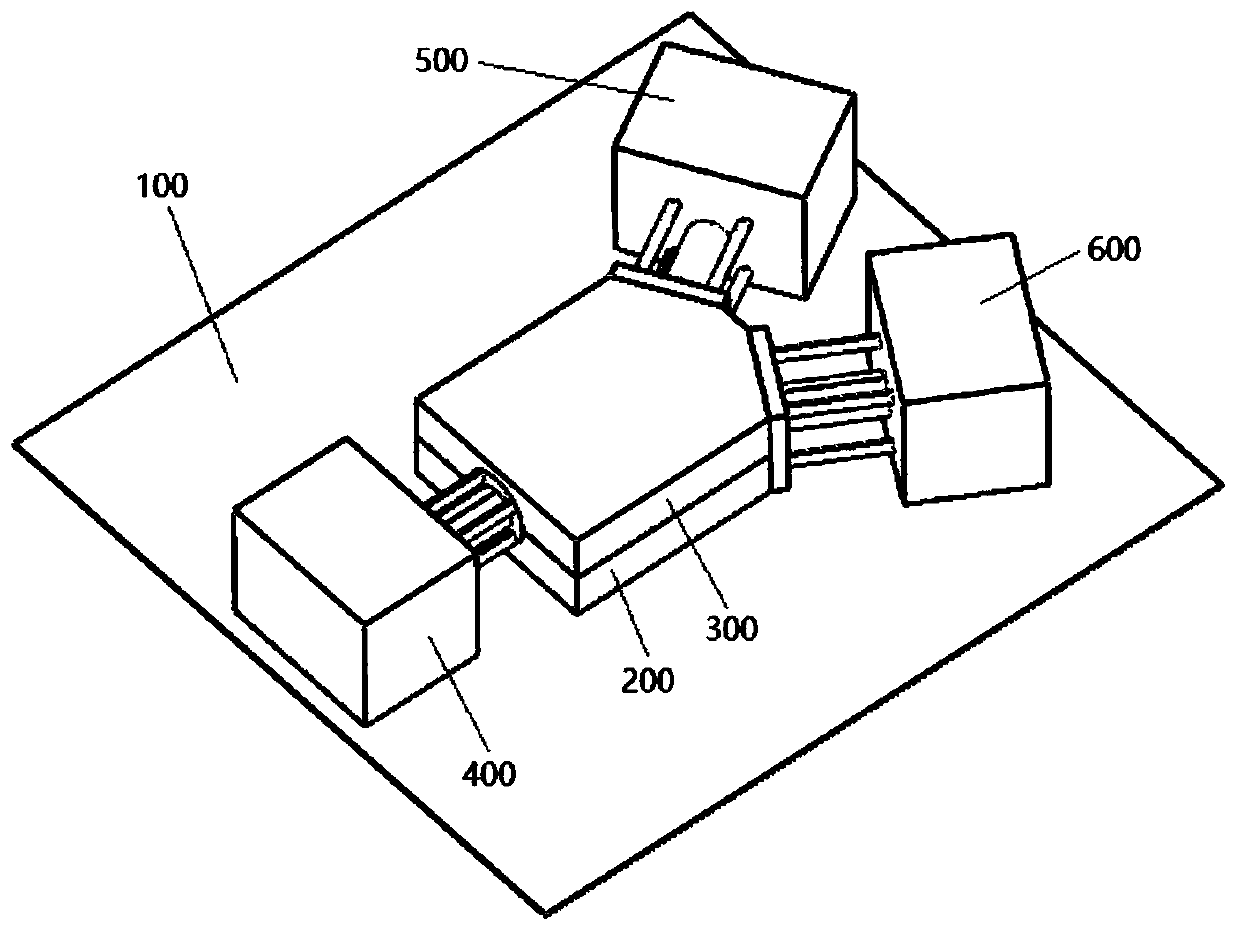

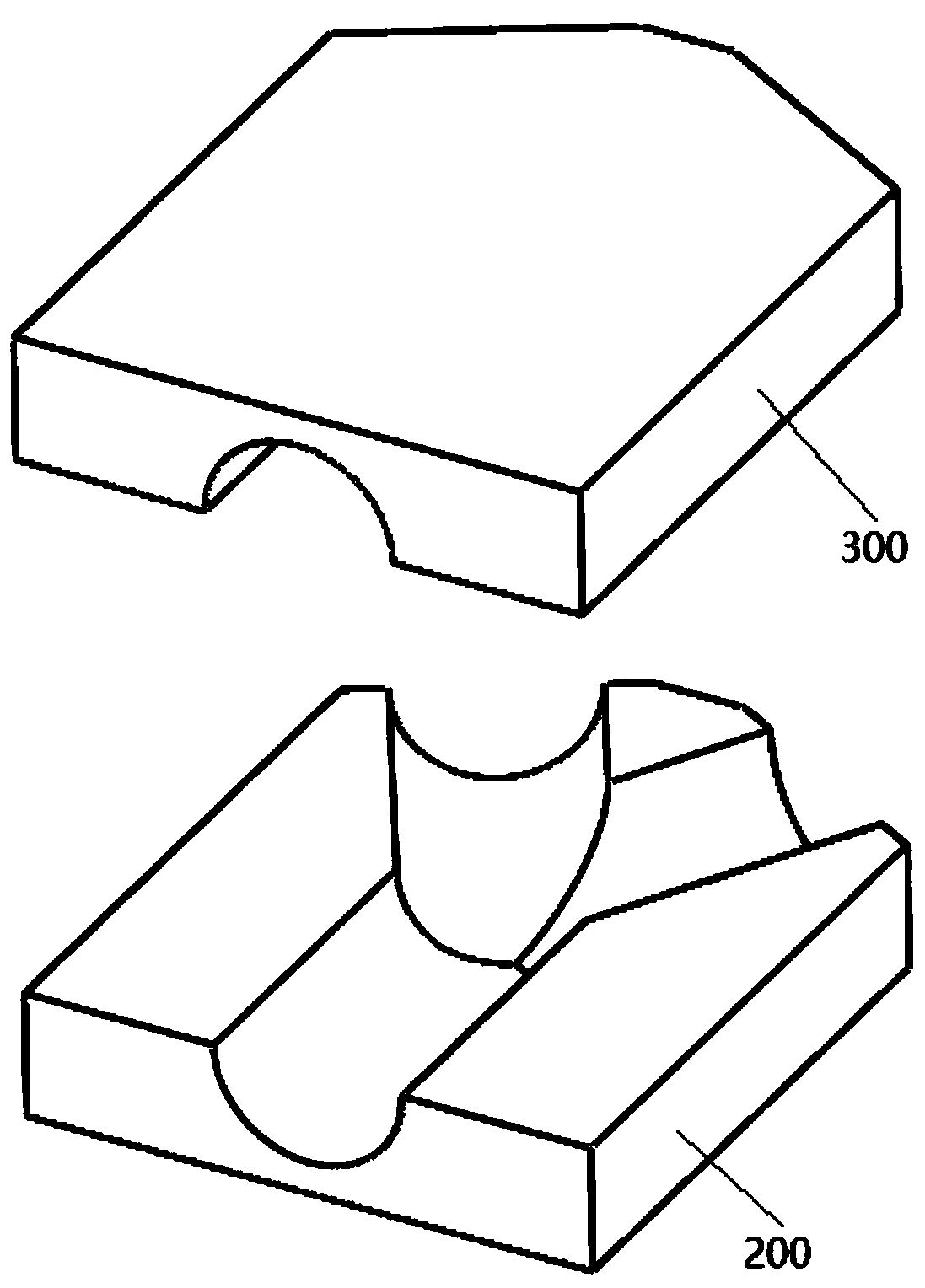

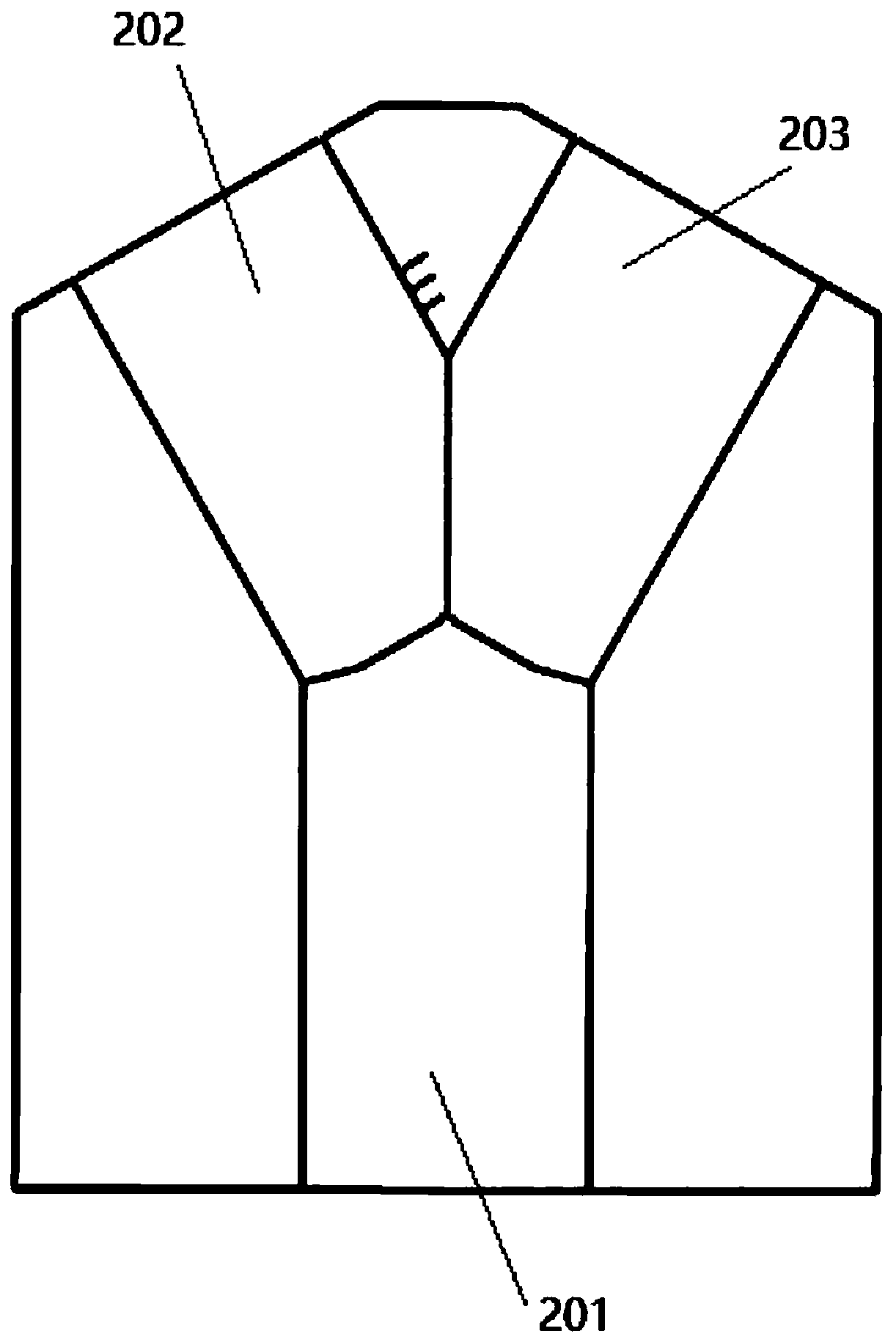

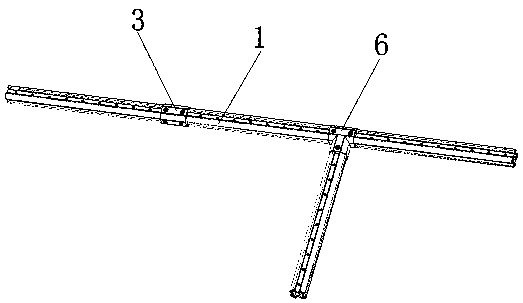

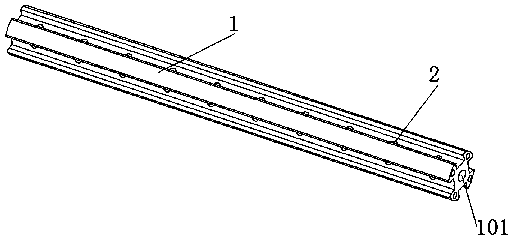

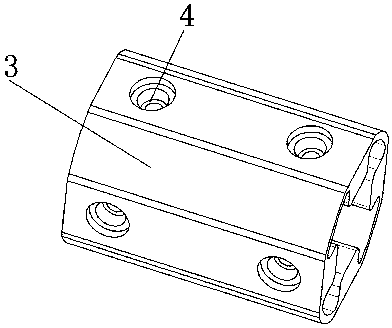

Large three-way joint die forging device for power station equipment and die forging method thereof

InactiveCN111570695AReduce the amount of processingLow running costForging/hammering/pressing machinesForging press detailsPower stationEngineering

The invention discloses a large three-way joint die forging device for power station equipment and a die forging method thereof. The key point of the technical scheme is as follows: the large three-way joint die forging device for power station equipment comprises a bottom plate, a lower die and an upper die wherein the lower die comprises a main cavity, a first branch cavity and a second branch cavity, the main cavity, the first branch cavity and the second branch cavity are semi-cylindrical, the upper die corresponds to the lower die in structure, and the lower die and the upper die are encircled to form a chamber for forming a large Y-shaped three-way joint; the bottom plate is connected to a trunk propelling device, a first branch blocking device and a second branch blocking device, and the first branch blocking device and the second branch blocking device are consistent in structure and correspond to the first branch cavity and the second branch cavity, separately. The large three-way joint die forging device improves the percent of pass of forged large Y-shaped three-way joints, shortens the production period while improving the reliability, lowers the operation cost of the equipment and improves the enterprise benefit and competitiveness.

Owner:SHANGHAI DIANJI UNIV

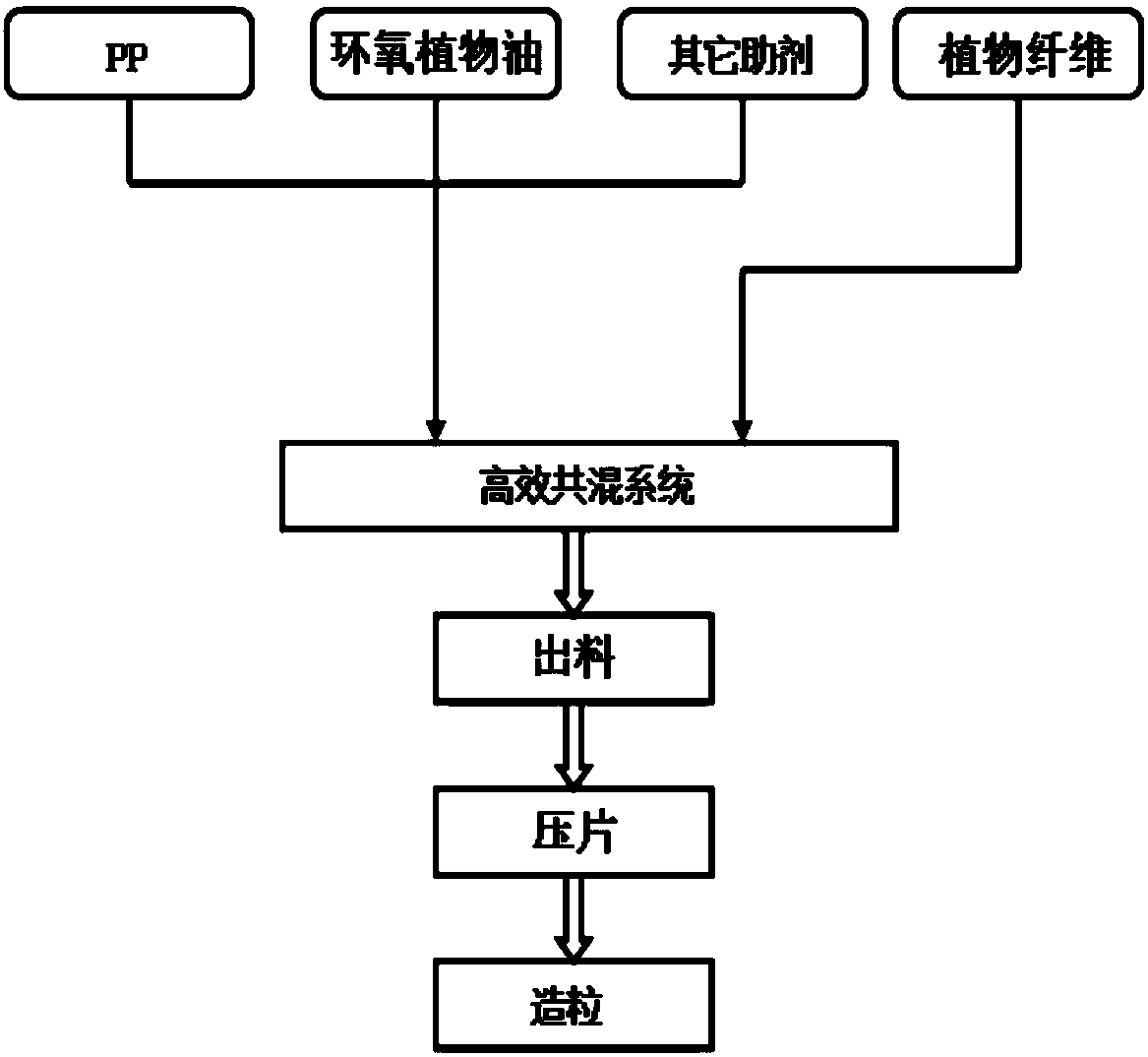

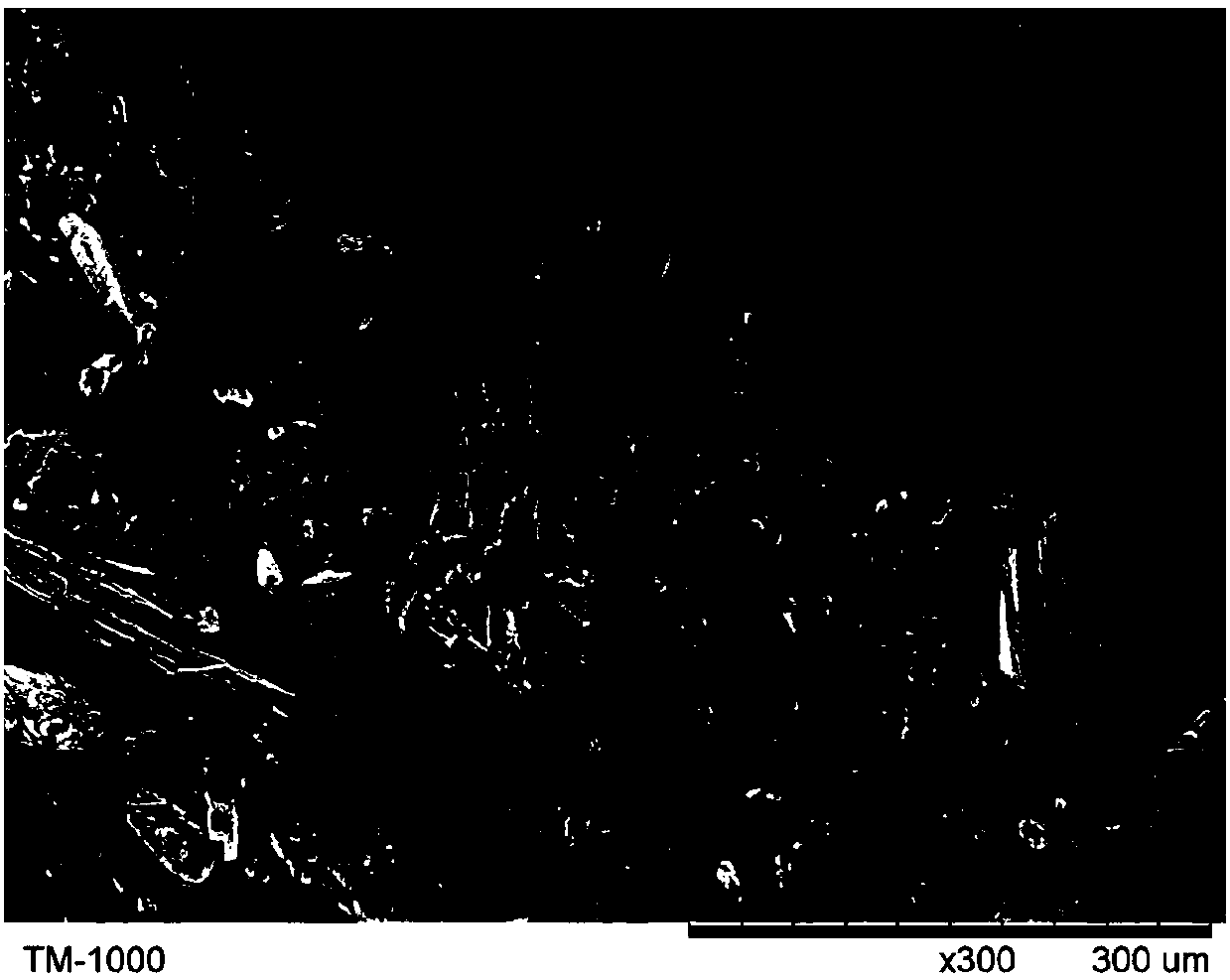

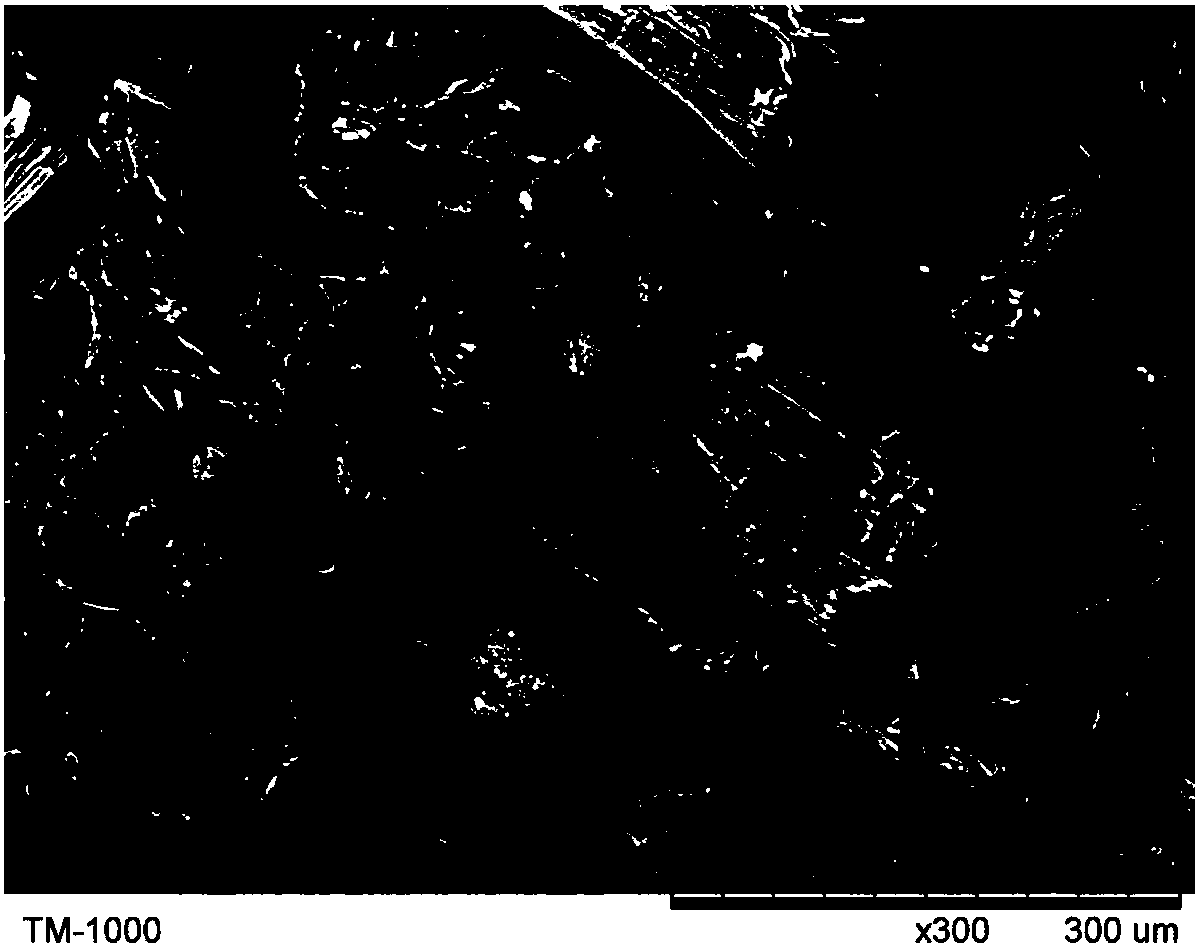

Long plant fiber-reinforced polypropylene composite material and preparation method thereof

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

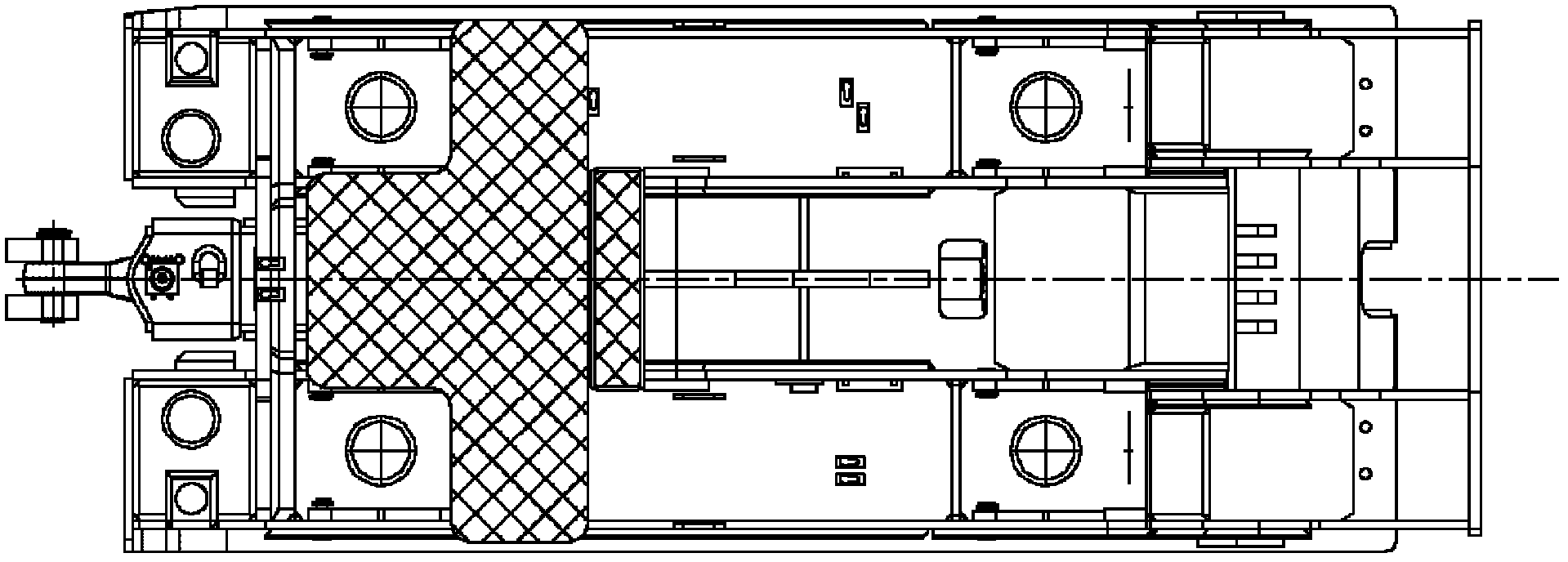

Backstop gangue beam suspension swinging beam type gangue filing hydraulic support frame with side protection plate

ActiveCN102828762ASupportPlay a supporting roleMaterial fill-upMine roof supportsEngineeringCoal mining

The invention relates to underground comprehensive mechanized coal mining work surface support equipment for a coal mine, in particular to a backstop gangue beam suspension swinging beam type gangue filing hydraulic support frame with a side protection plate for goaf filling. The hydraulic support frame comprises a front top beam, a back top beam, a front upright post, a back upright post, an upper connecting rod, a front connecting rod, a back connecting rod and a base, wherein the back top beam is hinged with one end of the front top beam, a backstop gangue beam with a side protection plate is also hinged on the back end of the base, a telescopic swinging beam is hinged on the backstop gangue beam with the side protection plate, the telescopic swinging beam is suspended in the air through a swinging beam jack, in addition, the angle is adjusted, and the side protection plate of the backstop gangue beam with the side protection plate can be opened to two sides or the single side through the lateral pushing of the jack or other external force during the support frame filling, so a sealed separation plate is formed between the support frames, and sundries such as gangue and the like are prevented from entering the front side of the support frames.

Owner:CATERPILLAR ZHENGZHOU

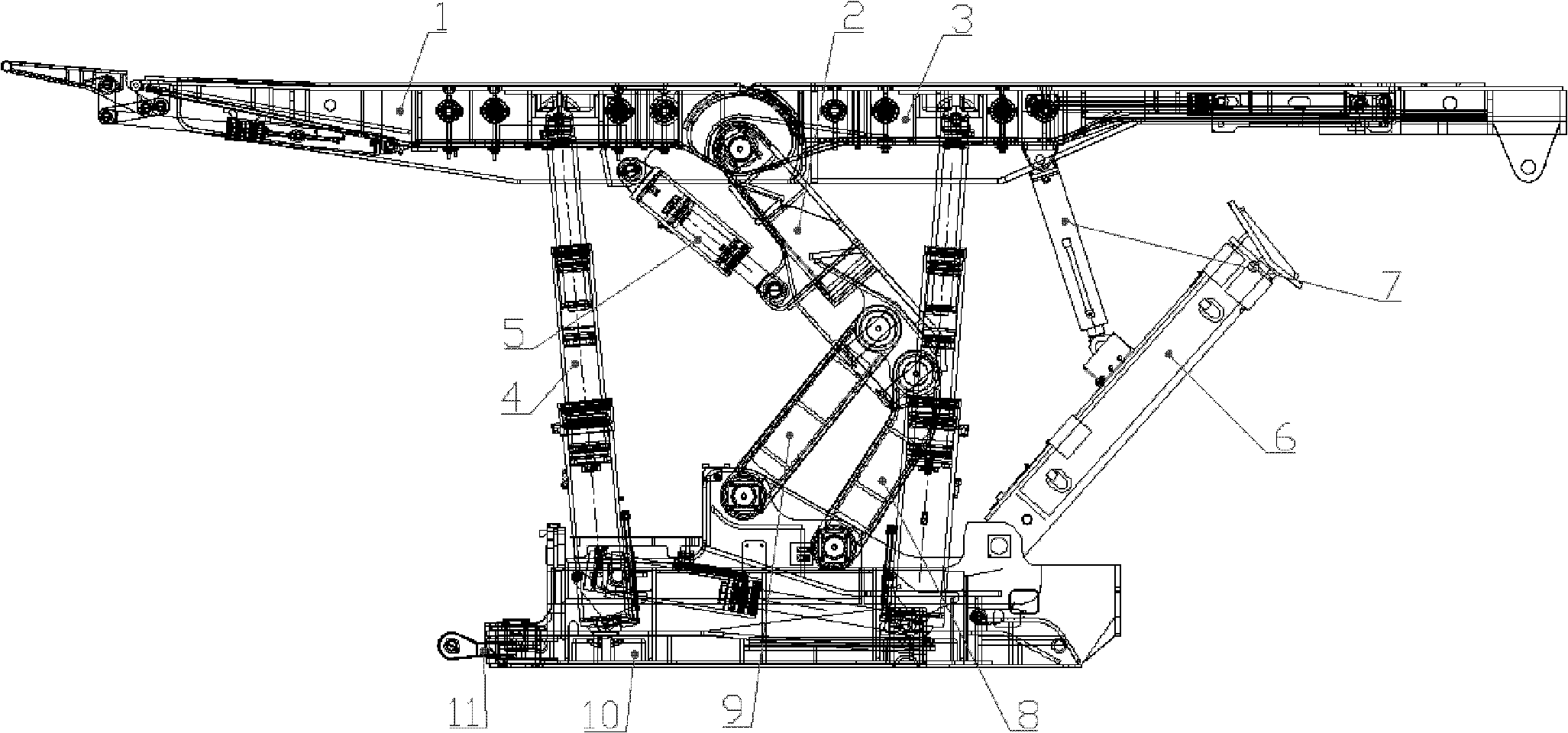

Four-column and double-swing-beam type gangue filling hydraulic support

InactiveCN102587977AEasy to fillGood filling effectMaterial fill-upMine roof supportsEngineeringHinge point

The invention relates to a four-column and double-swing-beam type gangue filling hydraulic support, comprising a front top beam, a Y-shaped upper connecting rod, a rear top beam hinged with the front top beam, columns, a balance jack, a swing beam, a swing beam jack, a rear connecting rod, a front connecting rod, a base, a pushing frame, a pushing jack, an upper swing beam jack and an upper swing beam, wherein the columns are supported between the front top beam and the base and between the rear top beam and the base; the upper end of the Y-shaped upper connecting rod is hinged on a hinged point of the front top beam and the rear top beam; the Y-shaped upper connecting rod, the front connecting rod, the rear connecting rod and the base are hinged in pairs to form a four-connecting-rod structure; the upper part and the lower part of the swing beam jack are hinged with the rear top beam and the swing beam respectively so as to regulate the swing beam; one end of the upper swing beam jack is hinged with a lug at the rear end of the rear top beam, and the other end of the upper swing beam jack is hinged with the upper swing beam. According to the four-column and double-swing-beam type gangue filling hydraulic support, not only a top plate is supported during the coal mining, but also a mined-out area is filled, so that the supporting operation and the filling operation are integrated.

Owner:CATERPILLAR ZHENGZHOU

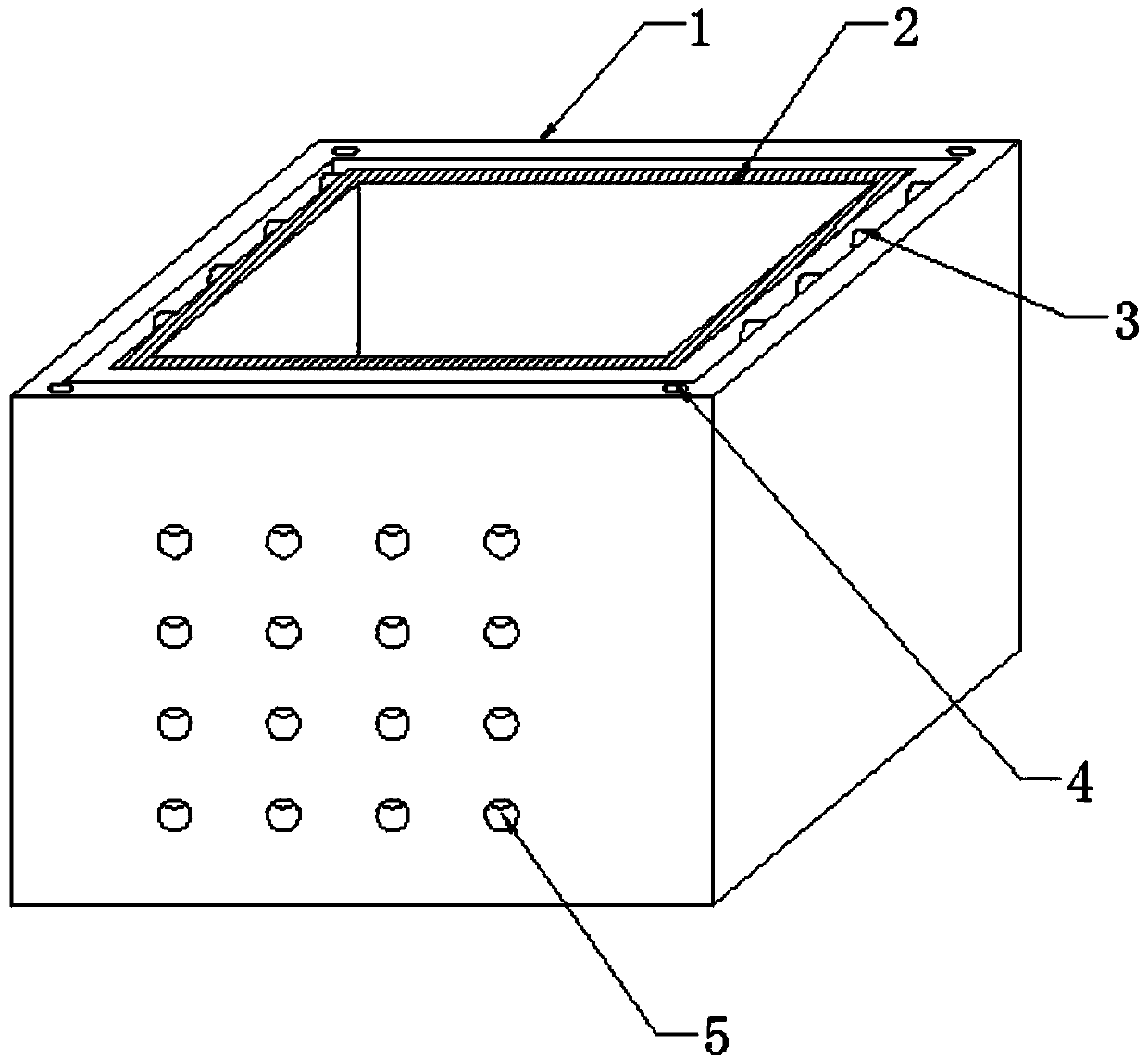

Novel battery storage device

InactiveCN109677558AImprove stabilityGuaranteed temperatureAnti-theft cycle devicesCell component detailsAbsorption columnEngineering

The invention provides a novel battery storage device. An inner frame is assembled inside an outer frame; the outer frame and the inner frame are fixed by a shock absorption column; limiting holes areformed in four right-angle positions of the end face on the upper side of the outer frame; a heat dissipation hole is formed in the end face on the front side of the outer frame; an upper fixing plate is arranged at a position on the upper side of the outer frame; a shock absorption column is arranged on the side face on the upper side of the upper fixing plate; and an outer plate is arranged onthe end face on the upper side of the shock absorption column. A battery arranged in the inner frame is fixed by adding the upper fixing plate and the shock absorption column. According to the design,the battery fixing stability is greatly improved, the design of the heat dissipation hole achieves an effect of dissipating heat emitted by the battery, battery extrusion is realized by airbag expansion, the gap in the battery and the inner frame is further filled, the application convenience of the novel battery storage device disclosed by the invention is further greatly improved, the pressuredetection is realized by a pressure sensor, and the condition that the alarm gives an alarm after the battery is stolen is avoided.

Owner:天津代琛奇科技有限公司

Marine light filling dressing

Marine light filling dressing is formed by mixing and stirring 8-20 meshes quartz sand, general silicon 42.5# cement, expanded perlite, ceramic sand, rubber powder, tartaric acid and an efficient water reducing agent. The raw materials comprise, by weight, 15%-25% of the 8-20 meshes quartz sand, 25%-35% of the general silicon 42.5# cement, 5%-7% of the expanded perlite, 25%-35% of the ceramic sand, 5%-7% of the rubber powder, 2% of the tartaric acid and 2% of the efficient water reducing agent. The marine light filling dressing has the advantages of being light in weight, small in density, good in adiabatic and fire-proof performance and the like.

Owner:DALIAN MINGYANG DECK COVERING

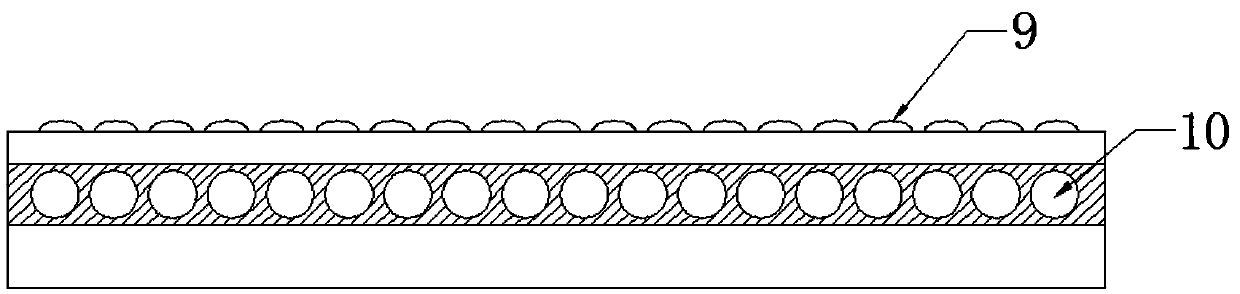

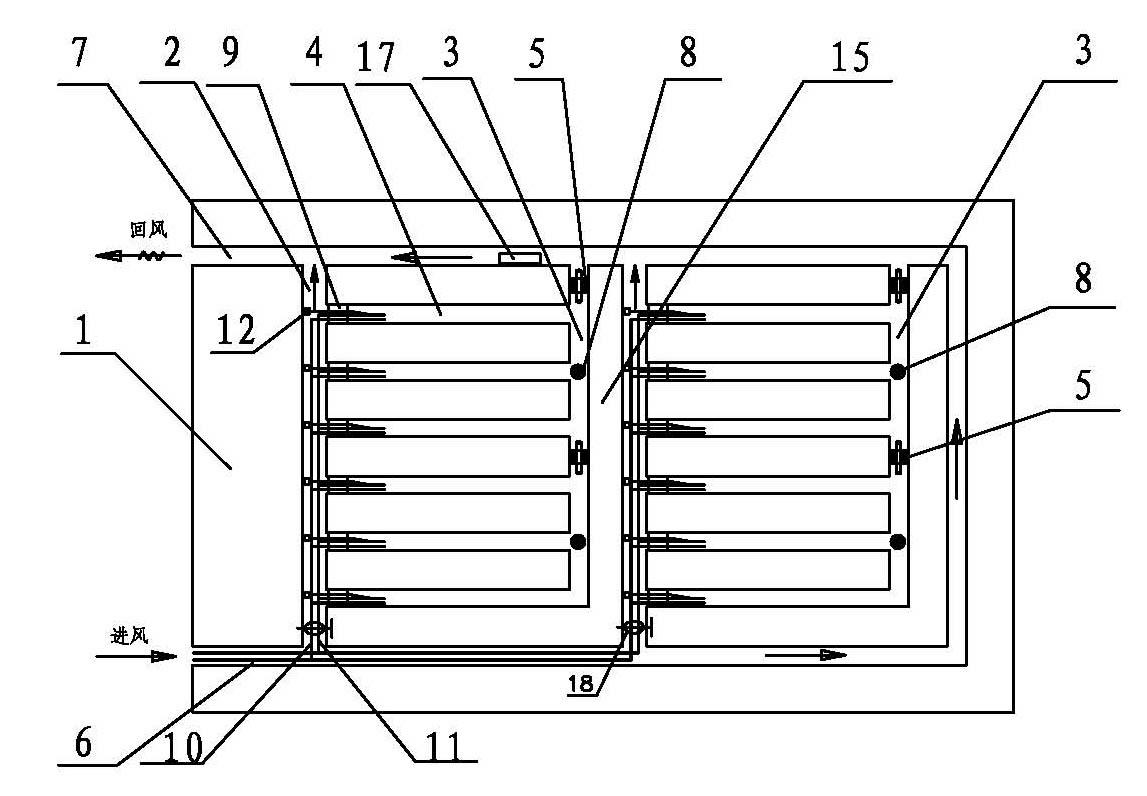

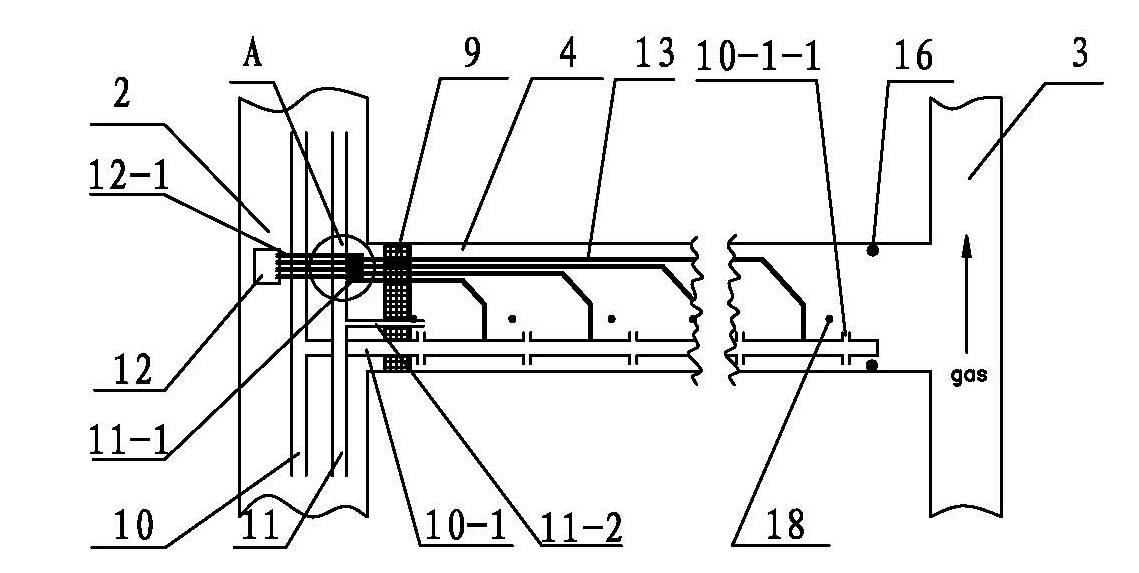

Spraying device for continuously filling carbon fiber battery grids with active substances

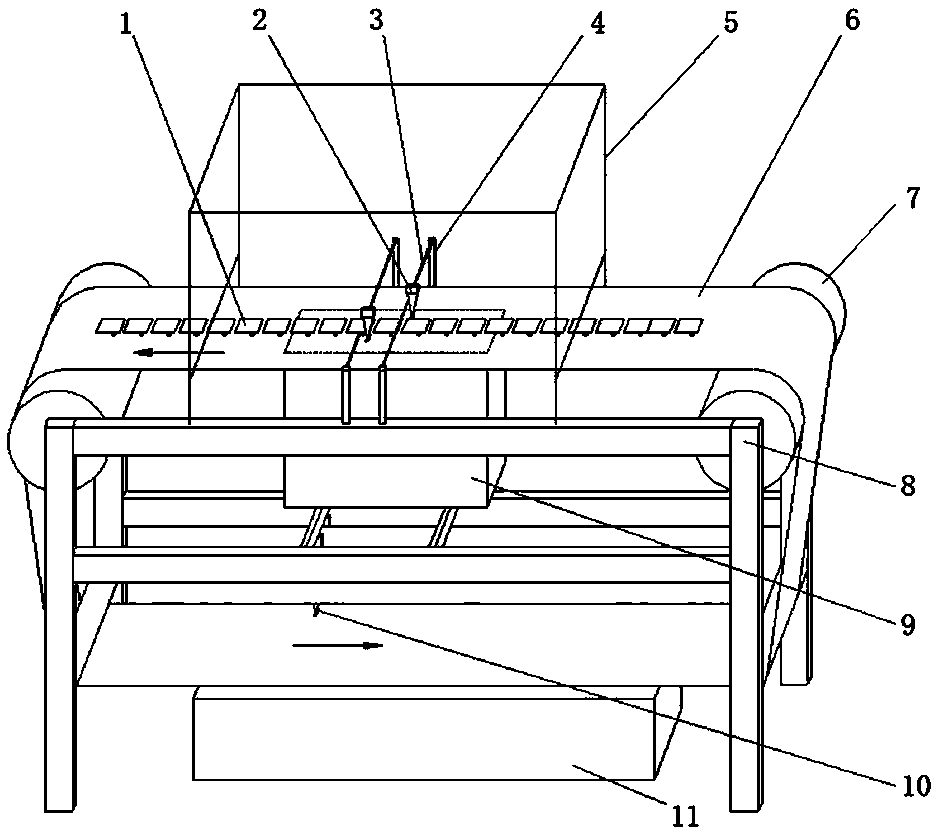

InactiveCN107930911AEvenly filledEasy to operateLead-acid accumulator electrodesElectrode collector coatingContinuous/uninterruptedFiber

The invention provides a spraying device for continuously filling carbon fiber battery grids with active substances. According to the spraying device, a transferring net belt is driven through a transmission motor, through the negative pressure and spraying method, the carbon fiber grids are continuously filled with the active substances, and the spraying device is composed of a control system, atransmission system, a pneumatic system, a negative pressure system, a filtering system spraying gun and the like. The spraying device is formed by assembling all components and can continuously fillthe carbon fiber felt grids with the active substances. Through the spraying device, the carbon fiber felt grids can be continuously and uninterruptedly filled with the active substances, the fillingquantity can be adjusted according to the requirement, operation is easy and convenient, produced carbon fiber polar plates are compactly and evenly filled with the active substances, and the grids are completely filled with the active substances.

Owner:SHUANGDENG GRP

Crack repairing method of concrete wall or terrace

InactiveCN107975249ARepair method is simpleLess likely to cause damageBuilding repairsChemical groutingSealant

The invention relates to a crack repairing method of a concrete wall or a terrace. The method comprises the following steps: a: digging a V-shaped groove in the wall or the terrace; b: cleaning dust of the V-shaped groove; c: brushing a basic level processing agent in the V-shaped groove; d: filling the V-shaped groove with a sealant; e: digging a communicating hole and filling the communicating hole by using a chemical grouting method. The crack repairing method is simple. Additionally, no damage is caused to a wall surface during crack repair. A crack of a crossed hole or of an oblique holeis filled by using a chemical grouting method. Finally, concrete cracks are densely filled with sediments. Therefore, concrete cracks are healed. The repair effect is good.

Owner:俞岳峰

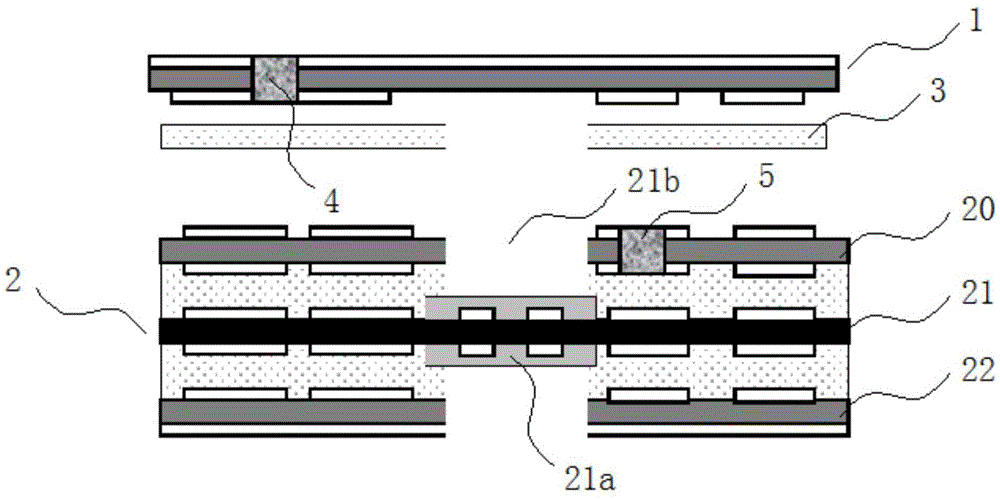

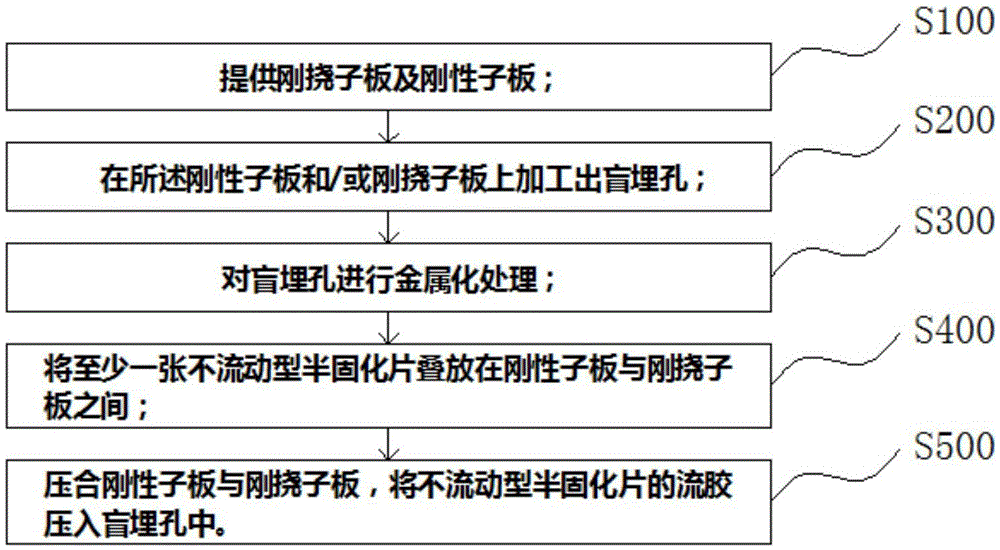

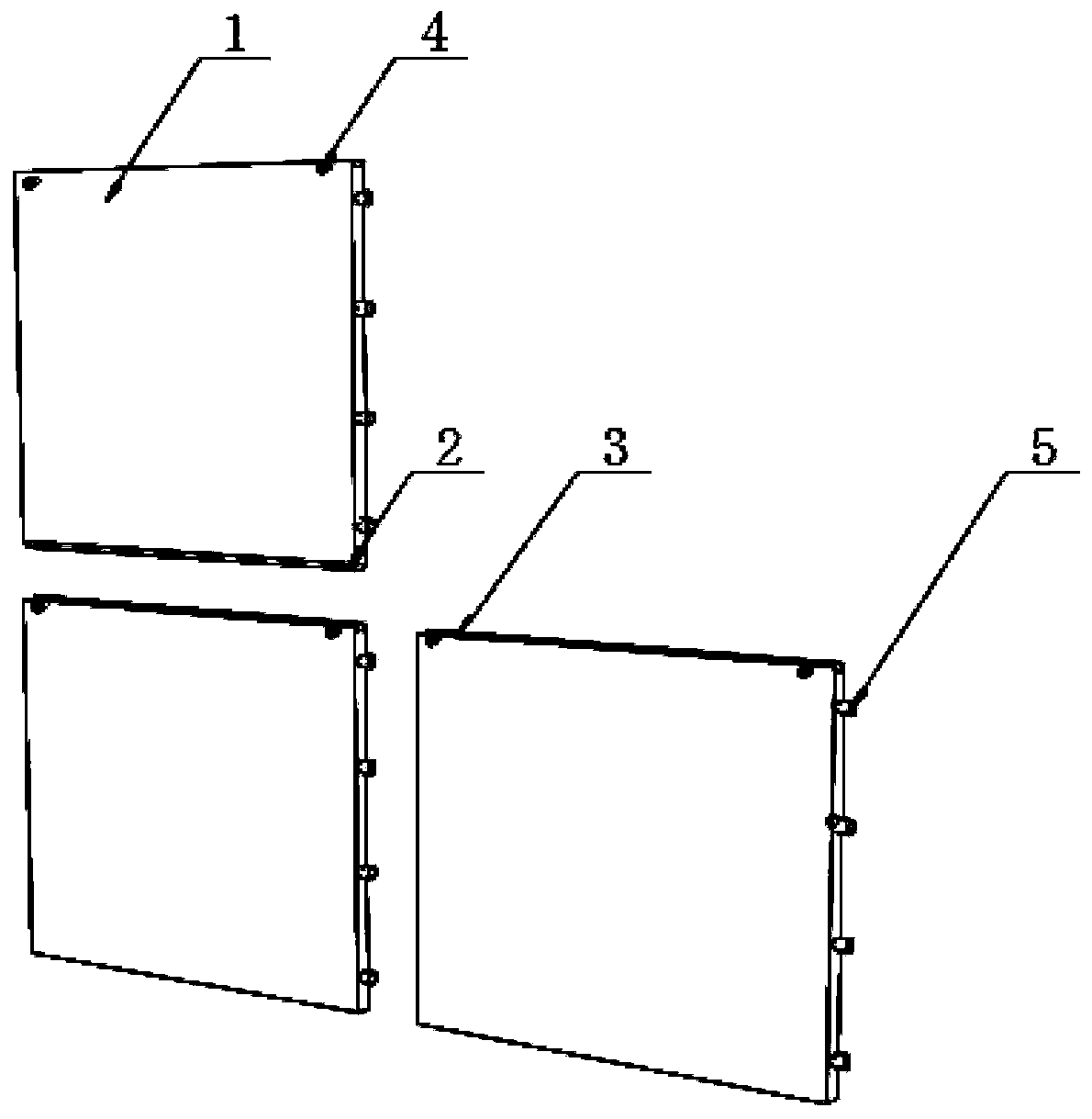

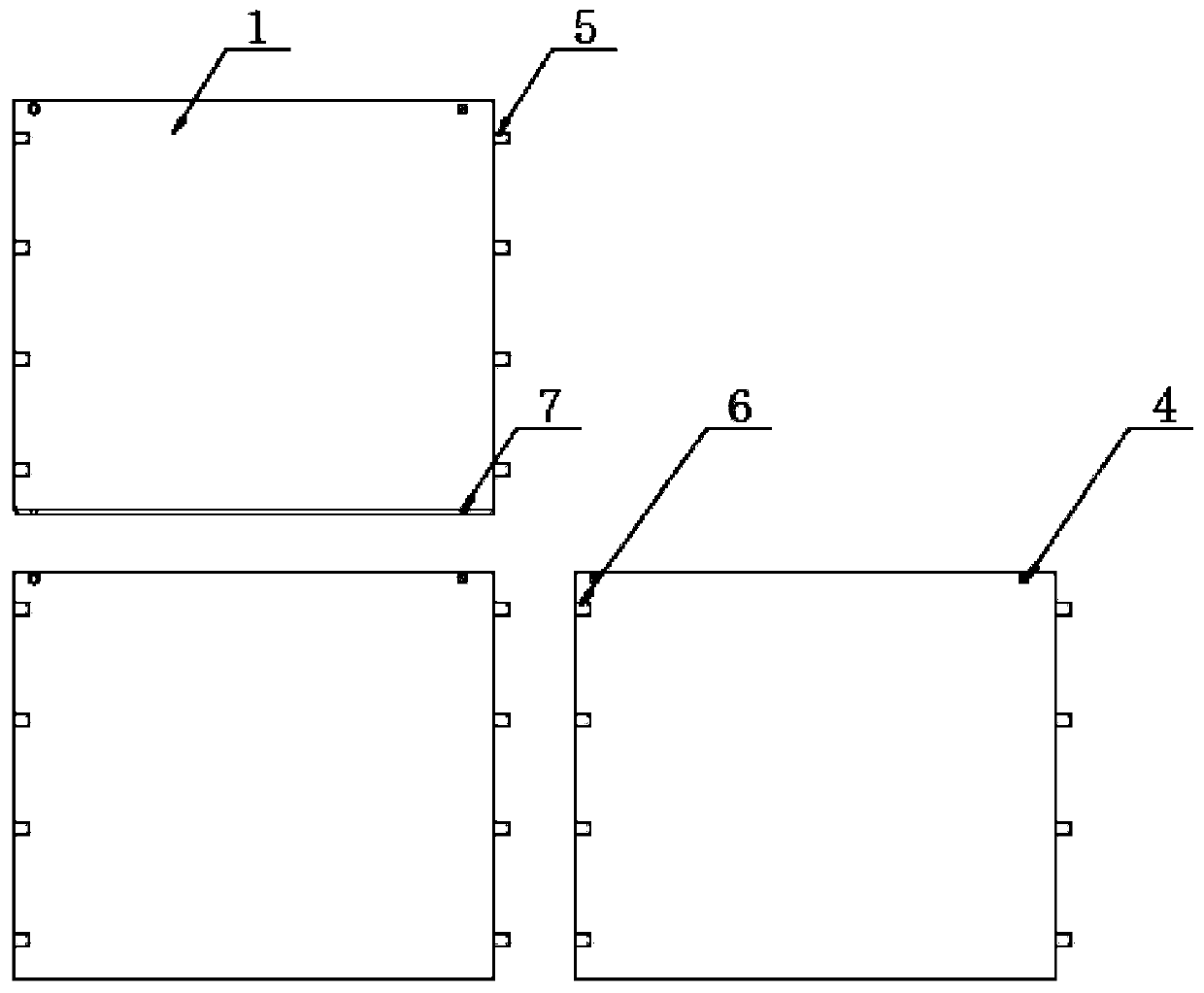

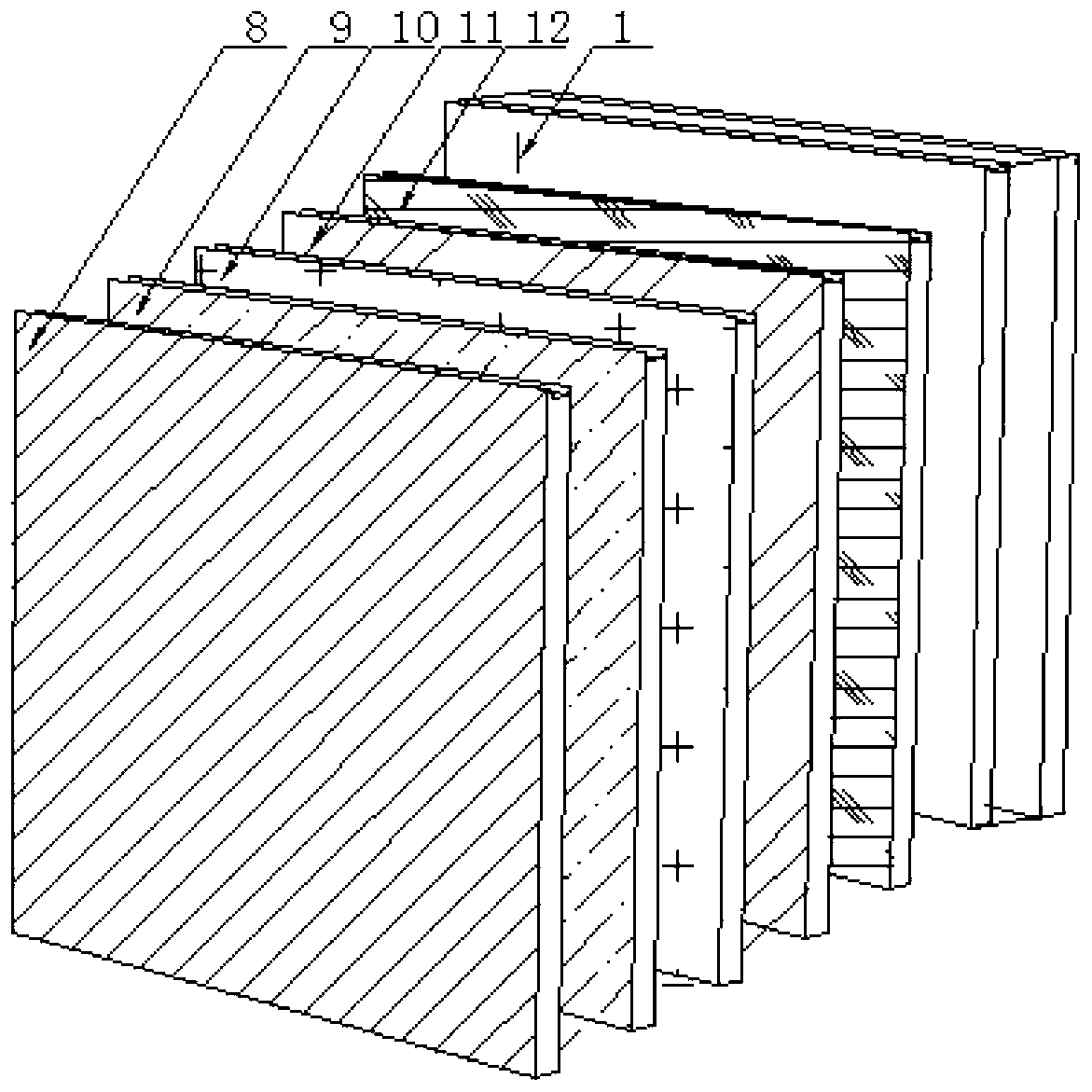

Rigid-flexible combined plate and method for plugging blind buried hole thereof

ActiveCN105657970ASimplify the resin plugging processReduce manufacturing costPrinted circuit aspectsPrinted circuit manufactureEngineering

The invention discloses a rigid-flexible combined plate and a method for plugging a blind buried hole thereof. The rigid-flexible combined plate comprises a rigid sub-plate and a rigid-flexible sub-plate, wherein the rigid sub-plate is fixedly arranged on the rigid-flexible sub-plate; the blind buried hole is formed on the rigid sub-plate and / or the rigid-flexible sub-plate; at least one non-flowing type prepreg is arranged between the rigid sub-plate and the rigid-flexible sub-plate; the blind buried hole is filled with the flowing glue of the non-flowing type prepreg. The method for plugging the blind buried hole of the rigid-flexible combined plate comprises the following steps: supplying the rigid sub-plate and the rigid-flexible sub-plate; forming the blind buried hole on the rigid sub-plate and / or the rigid-flexible sub-plate; performing metallizing treatment on the blind buried hole; stacking at least one non-flowing type prepreg between the rigid sub-plate and the rigid-flexible sub-plate; pressing the rigid sub-plate and the rigid-flexible sub-plate and pressing the flowing glue of the non-flowing type prepreg into the blind buried hole. According to the rigid-flexible combined plate and the method for plugging the blind buried hole thereof, the processing is convenient, the smoothness of the plate is excellent, the special device is saved and the production cost is lowered.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

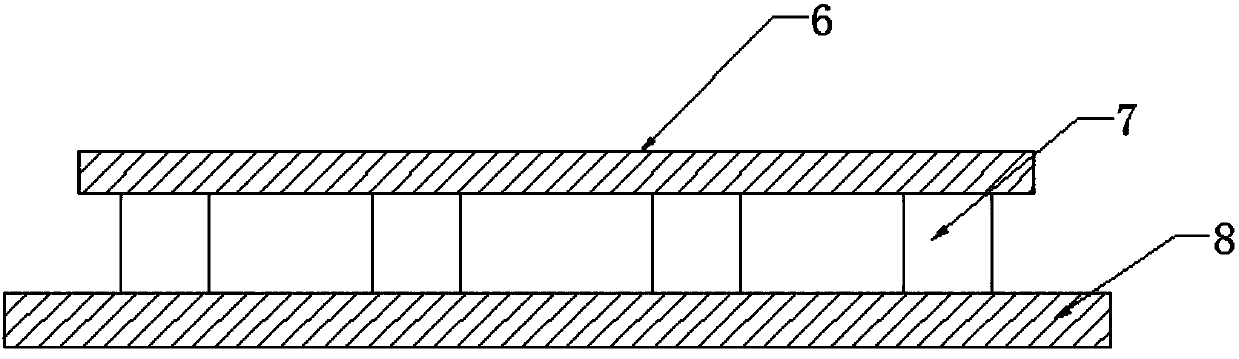

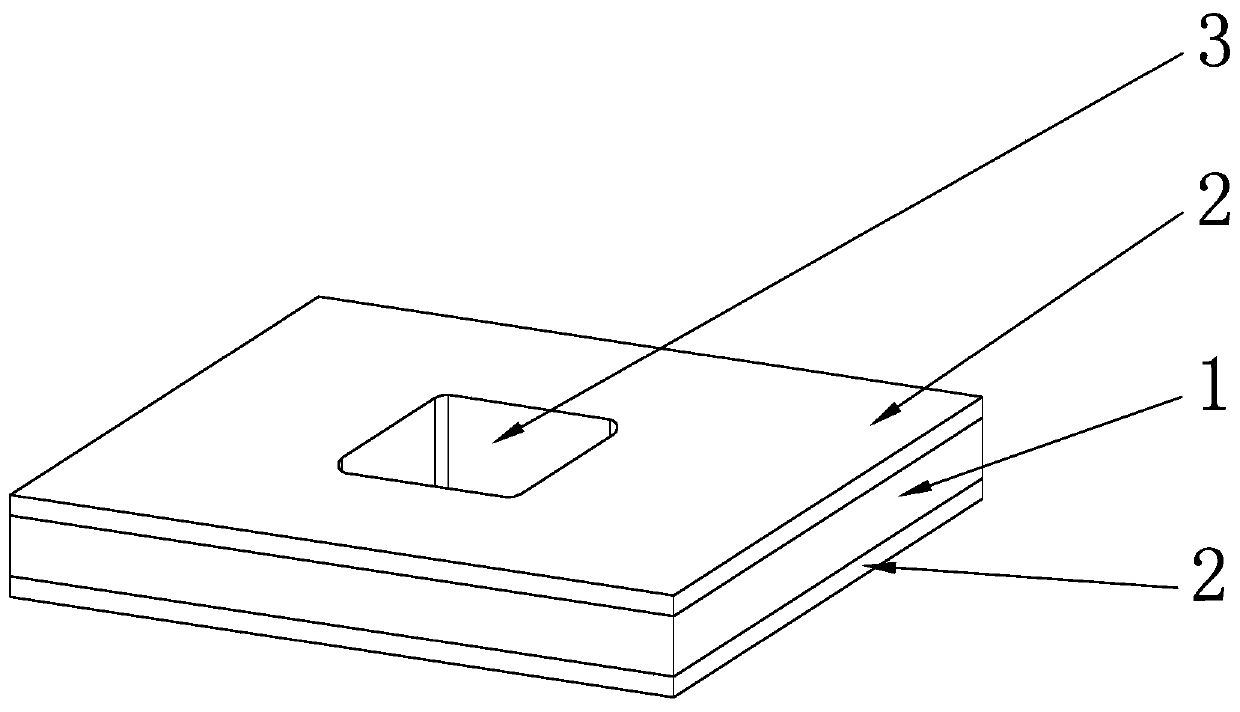

Prefabricated assembled heat insulation wall body

ActiveCN110644632AGuaranteed connection reliabilityAchieve paddingHeat proofingSound proofingEngineeringSlurry

The invention relates to the technical field of a wall body, in particular to a prefabricated assembled heat insulation wall body. Connecting seam outer sealing mechanisms are arranged in connecting positions of two adjacent wall body support main bodies; the connecting seam outer sealing mechanisms consisting of I-shaped tensioning elements and sealing expansion layers can well realize the sealing treatment on connecting positions of the wall body support main bodies; and the sealing performance is improved. A sealing cavity is sealed in an expansion solidification slurry injection mode, andthe sealing expansion layers are formed. Therefore, the filling onto each gap can be effectively realized; the sealing stability is improved; the stable and firm connection on wall body units can be realized; and the connection reliability of the wall body is ensured. The end part of an outer heat insulation protection assembly is of a step structure, the stable and firm connection on the externalheat insulation protection assembly can be effectively ensured; and the problem that the outer heat insulation protection assembly falls off due to inform bonding of the outer heat insulation protection assembly after the long-time use can be solved.

Owner:SOUTHEAST UNIV +1

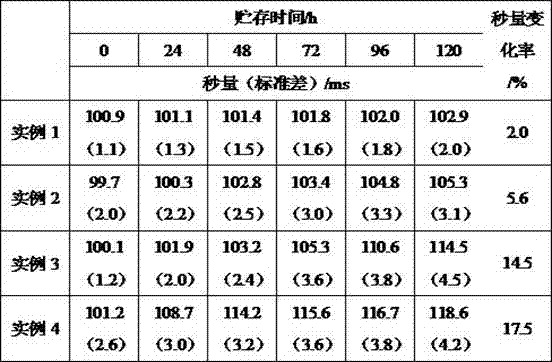

Preparation method of blasting delay composition

InactiveCN107188770AImprove adsorption capacityIncrease touch pointsExplosivesFusesPolyvinyl alcoholTitanium tetraisopropoxide

The invention discloses a preparation method of a blasting delay composition, and belongs to the technical field of preparation of blasting materials. The preparation method comprises the following steps: firstly, corroding silicon powder by utilizing corrosive acid liquid to form porous silicon powder; then modifying the porous silicon powder by utilizing dopamine to obtain modified porous silicon powder; then corroding and mixing by utilizing the acid liquid, and corroding red lead, so as to form porous red lead; modifying by utilizing the dopamine to prepare modified porous red lead; then mixing the modified porous silicon powder and the modified porous red lead with a barium nitrate solution, a polyvinyl alcohol solution and the like; generating barium sulfate sediment in a system by taking sodium sulfate as a precipitant; after ageing, filtering, washing and drying; then treating by utilizing nitrogen gas loaded with titanium isopropoxide and water-containing nitrogen gas in sequence to obtain the blasting delay composition. The blasting delay composition prepared by the preparation method has high delay precision and good storage stability, and a condition that the delay precision is drifted along storage time can be effectively avoided.

Owner:常州武城服饰有限公司

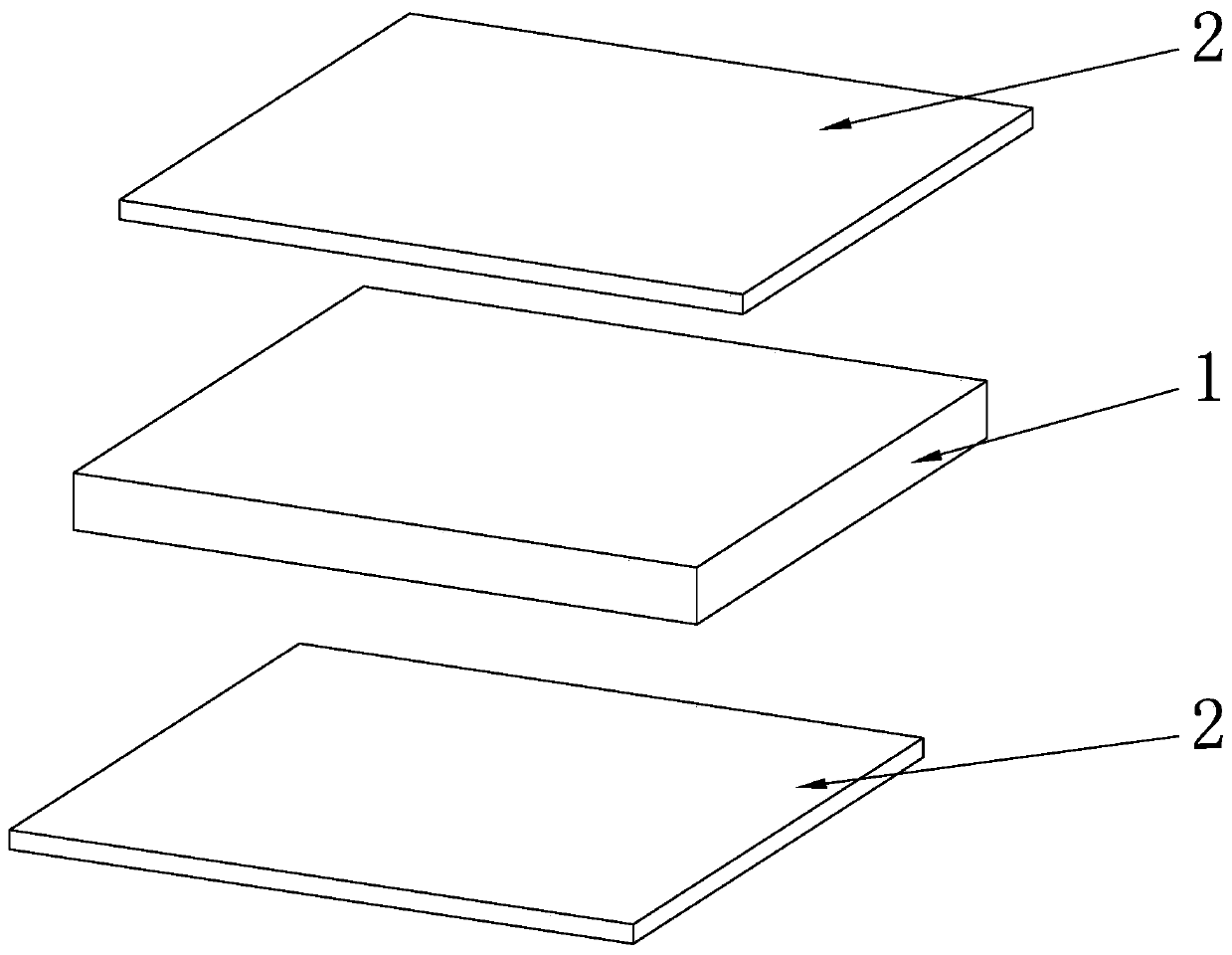

Method for embedding copper block of double-sided circuit board

InactiveCN110996520AEasy to processAchieve paddingPrinted circuit manufactureCircuit thermal arrangementsAdhesive beltCopper foil

The invention relates to the technical field of printed circuit boards, and discloses a method for embedding a copper block of a double-sided circuit board, which comprises the following steps of: preparing a double-sided copper-clad plate; pasting high-temperature adhesive tapes on two sides of the double-sided copper-clad plate in a whole surface manner; milling a through hole in the double-sided copper-clad plate coated with the high-temperature adhesive tape; putting the copper block into the through hole; sequentially placing prepregs and first copper foils on the two outer sides of the double-sided copper-clad plate in which the copper blocks are placed from inside to outside, and carrying out high-temperature pressing; after pressing, tearing off the first copper foil, the prepreg and the high-temperature adhesive tape; and grinding off the residual PP glue on the surfaces of the double-sided copper-clad plate and the copper block. According to the method, for the double-sided circuit board, the gap between the double-sided copper-clad plate and the copper block is filled by utilizing the fluidity of prepregs during high-temperature lamination, so that the risk of medicine liquid hiding due to recession caused by insufficient glue filling is avoided; and through lamination and board grinding, the two sides of the copper block can be ensured to be flush with the two sidesof the double-sided copper-clad board, and subsequent circuit board processing is facilitated.

Owner:珠海杰赛科技有限公司 +1

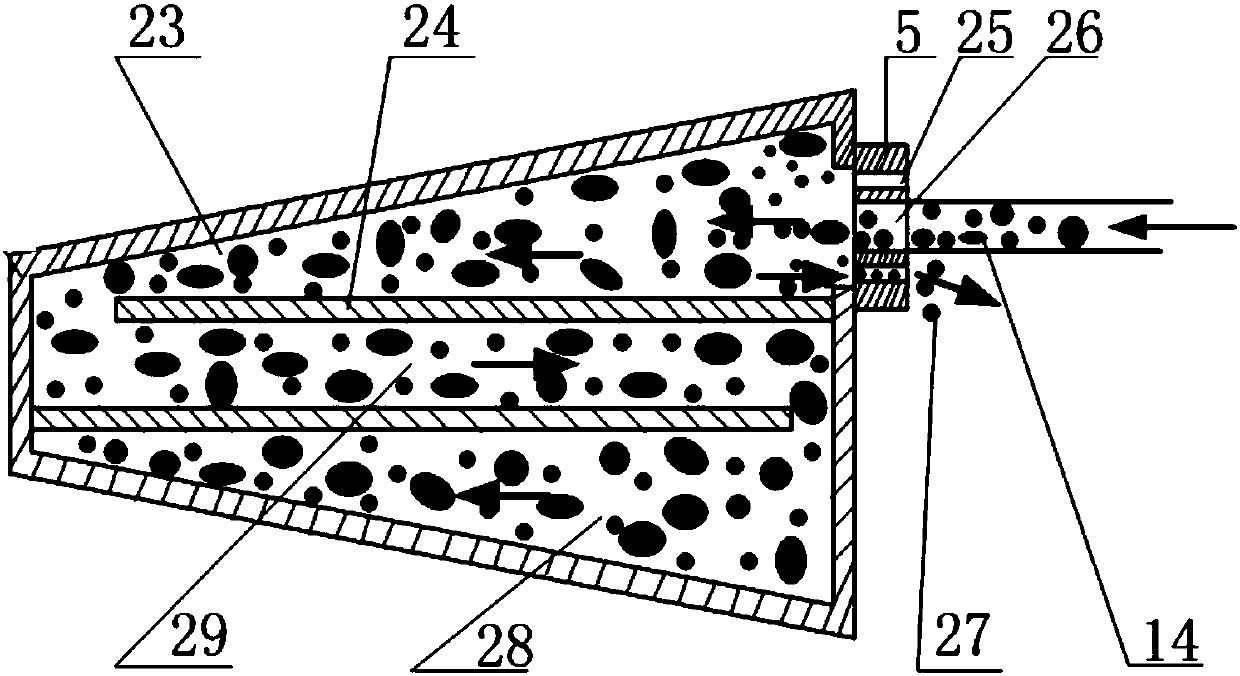

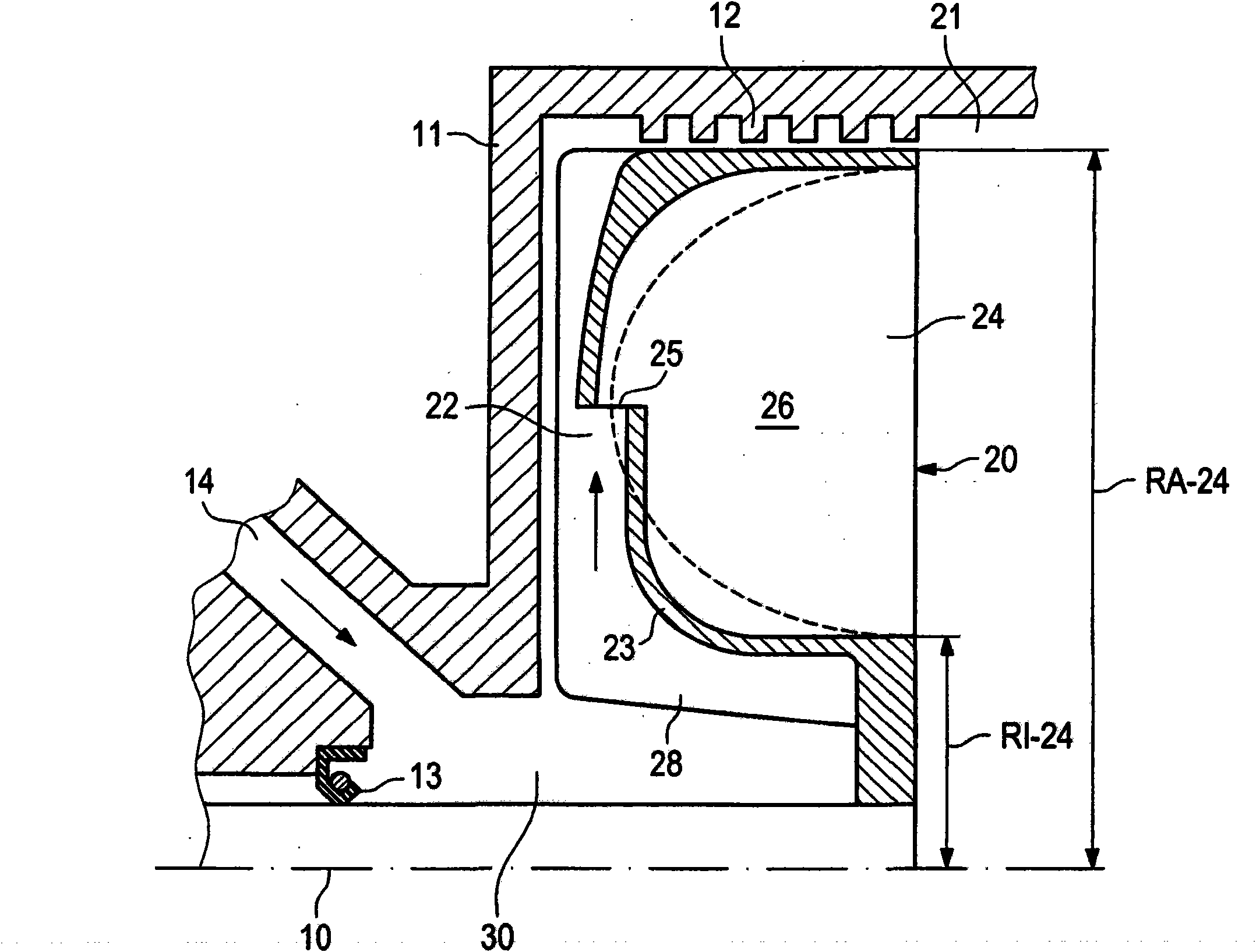

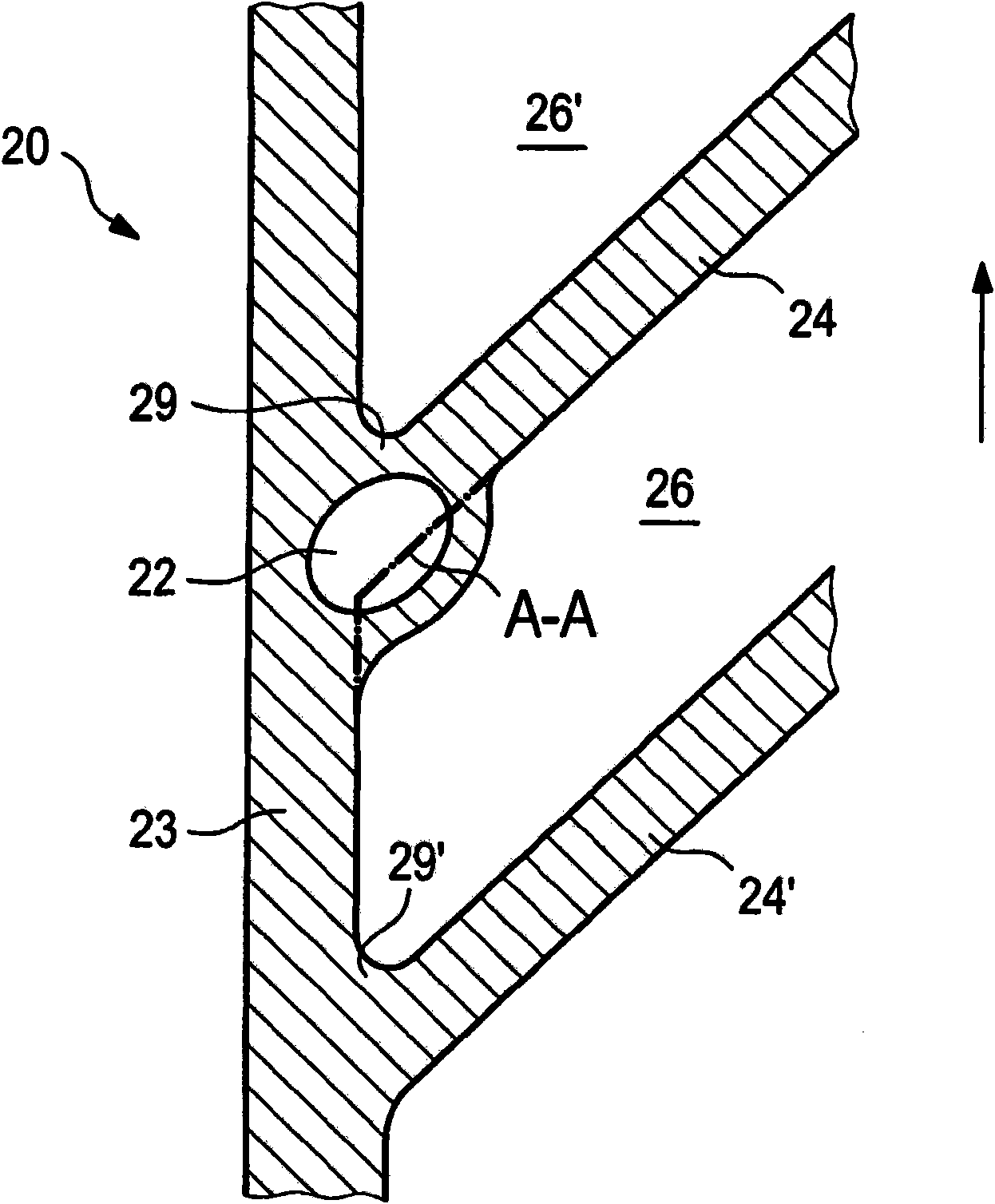

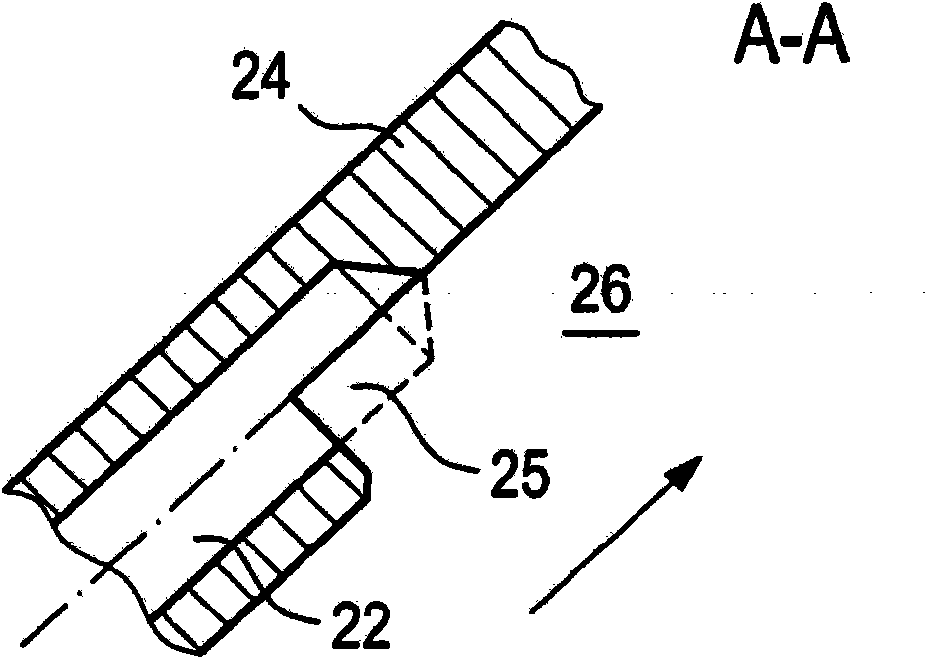

Hydrodynamic machine, in particular hydrodynamic retarder

InactiveCN101903675AFluid cross section widthSuppression of oscillatory excitationLiquid resistance brakesRotary clutchesImpellerInlet channel

A hydrodynamic machine, in particular a hydrodynamic retarder, having a bladed primary wheel (20), which can be rotated via a rotational axle (10) of the hydrodynamic machine, and a bladed secondary wheel which is stationary or can be rotated via the rotational axle of the hydrodynamic machine, wherein the primary wheel and the secondary wheel together form a toroidal working chamber (21) which is filled or can be filled with working medium (30), and the primary wheel has at least one inlet channel (22) for the working medium. The inlet channel extends within the torus wall (23) and / or withina blade (24) of the primary wheel and opens in the region of the centre or radially outside the centre between the outer radius (RA-24) and the inner radius (RI-24) of the blades (24) of the primary wheel (20) at a location in the region of the torus wall in the working chamber.

Owner:VOITH PATENT GMBH

Hollow special-shaped column high-rise fabricated steel structural system

InactiveCN108193775APowerfulRealize infusionStrutsProtective buildings/sheltersHigh riseStructural system

The invention discloses a hollow special-shaped column high-rise fabricated steel structural system which comprises a special-shaped column and mounting grooves and further comprises a first connecting seat composed of a first mounting sleeve, a first receding groove and a first threaded sleeve, and a second connecting seat composed of a second mounting sleeve, a connecting sleeve, a second receding groove and a second threaded sleeve. According to the hollow special-shaped column high-rise fabricated steel structural system, the structure is ingenious, and the function is powerful; firstly, through the stable bridging structure effect, quick assembly is achieved, the overall stability of a steel structure is further greatly improved, and the construction speed is increased; secondly, through sunken design of the special-shaped column, concrete can be poured into the special-shaped column, and effective filling of subsequent concrete pouring is reinforced; and finally, the quakeproof effect and stability of a whole building are improved, and application and popularization in industries are facilitated.

Owner:山东经典重工集团股份有限公司

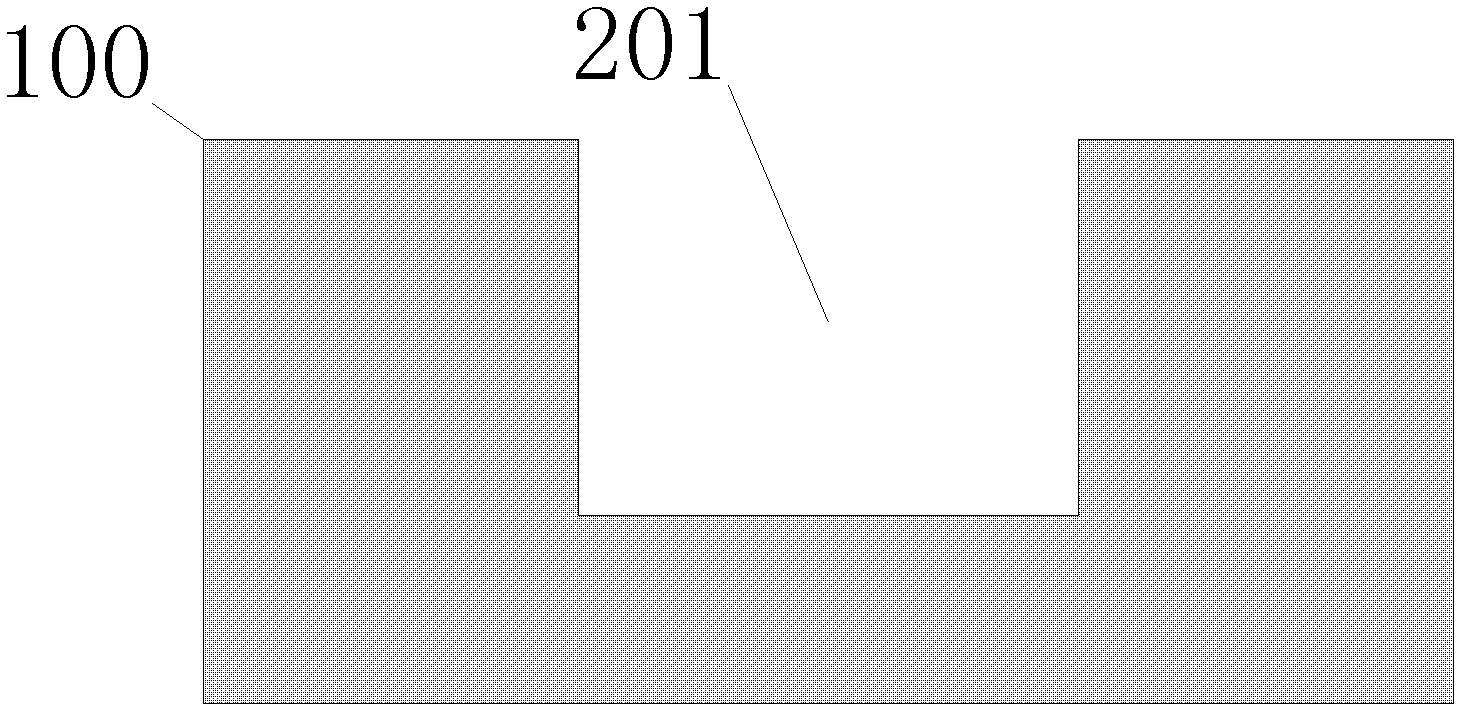

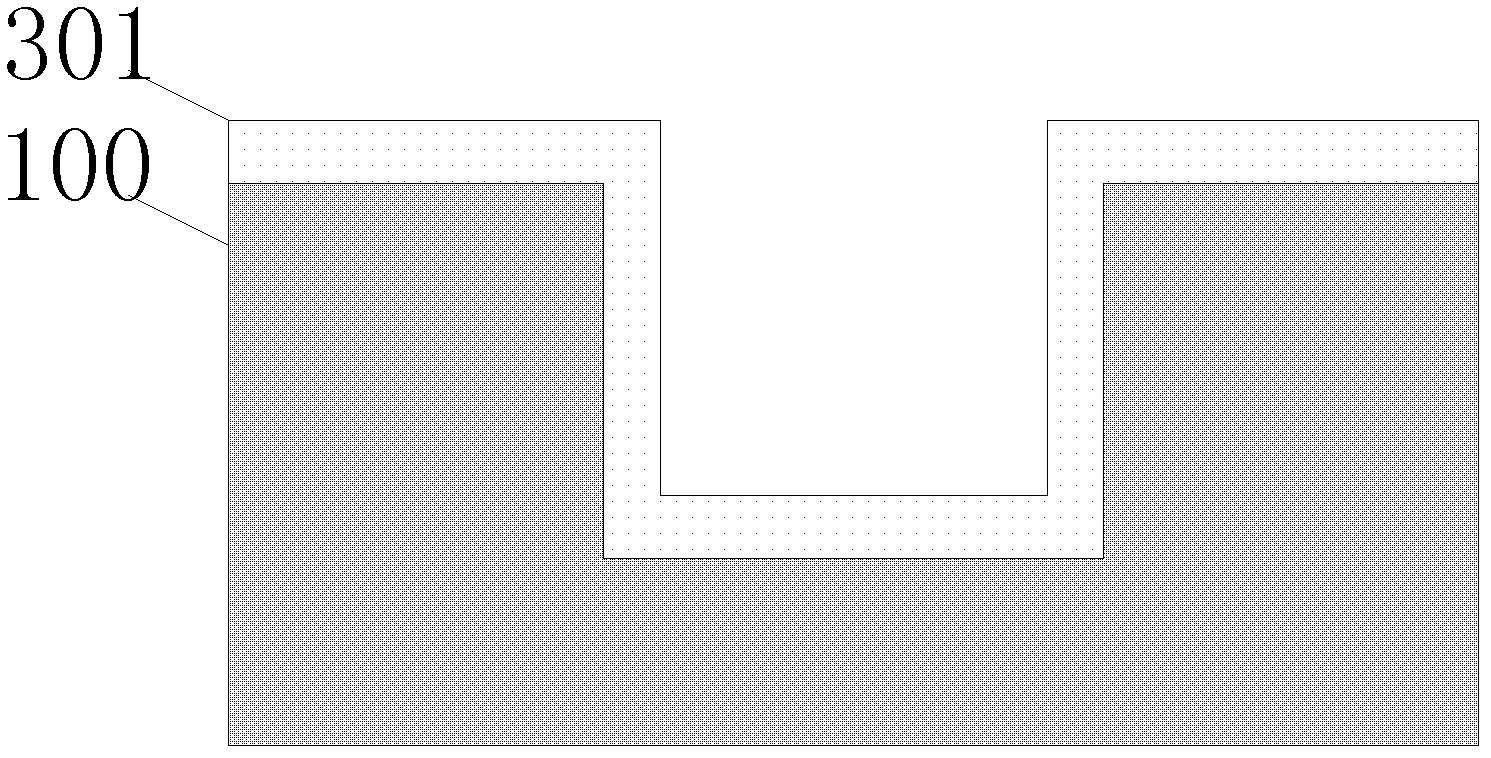

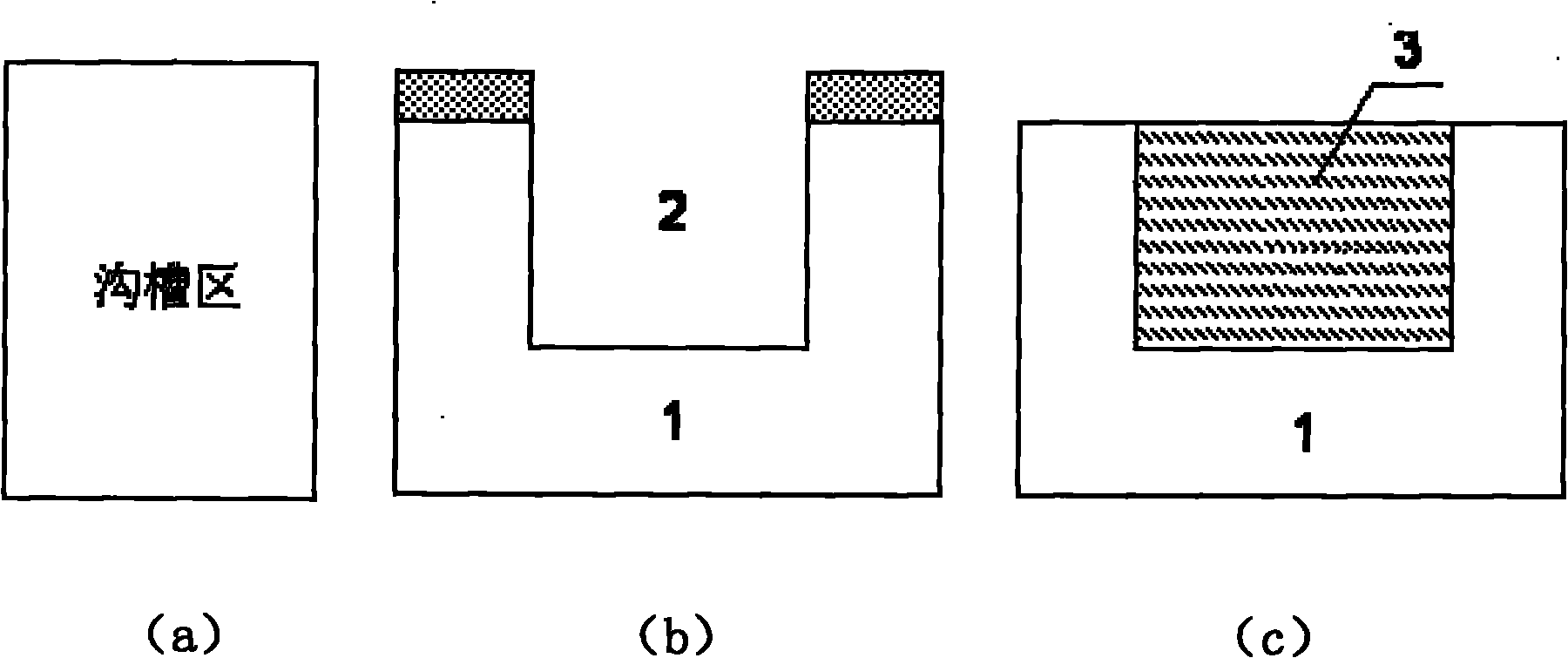

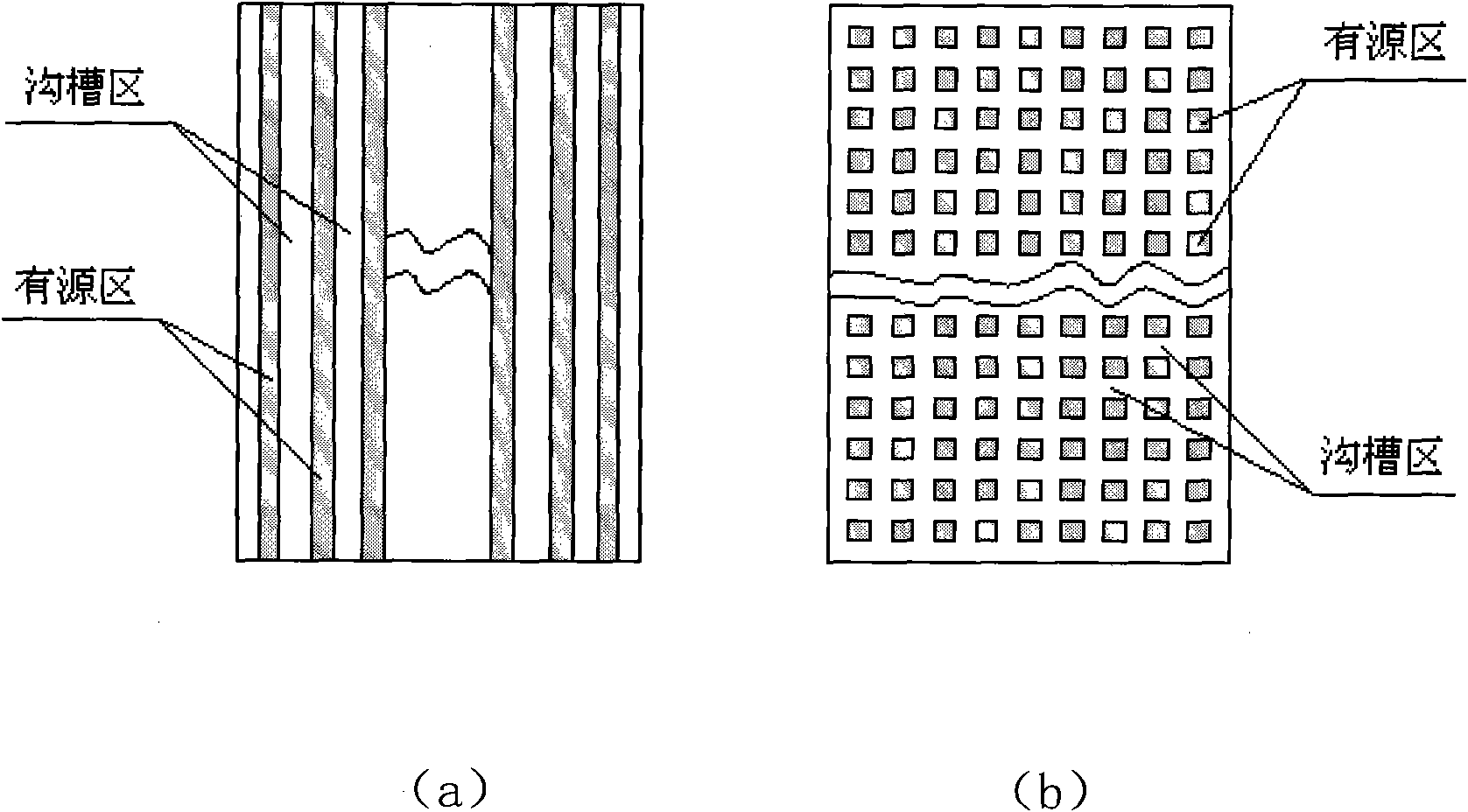

Method for manufacturing wide and deep trenches by medium filling

InactiveCN102054737AMinimize Microloading EffectsGood uniformitySemiconductor/solid-state device manufacturingPhotoresistSilicon nitride

The invention discloses a method for manufacturing wide and deep trenches by medium filling, which comprises the following steps of: sequentially growing a layer of bottom-layer oxide film, a silicon nitride film and a top-layer oxide film on a silicon wafer; coating a photoresist on the top-layer oxide film, and defining a plurality of trenches at an equal interval by photoetching; removing the exposed top-layer oxide film by etching, and then removing the photoresist; etching the silicon nitride film, the bottom-layer oxide film and the silicon wafer by utilizing a pattern of the top-layer oxide film as a mask to obtain the plurality of required trenches; oxidizing all the sidewalls of the plurality of trenches by thermal oxidation to form silicon oxide sidewalls; removing the top-layer oxide film and the silicon nitride film; depositing a required medium film by chemical vapor deposition, and filling the trenches; and removing the medium film on the surface of the silicon wafer by back-etching or chemical mechanical grinding, and removing the oxide film on the surface of the silicon wafer to obtain the wide and deep trenches filled with the medium film. In the method, the filling of the wide and deep trenches is realized by utilizing a proven process in combination with the innovation of the pattern.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Copper and copper bonding method

InactiveCN104134615ANot easy to electricity performanceSteps to Simplify BondingSolid-state devicesSemiconductor/solid-state device manufacturingEpoxyTime range

The invention relates to a copper and copper bonding method. The copper and copper bonding method comprises the following technological steps that first, surface preprocessing is carried out on a substrate and a chip, so that the surface roughness of the substrate is smaller than 0.3nm, no particles with the diameter larger than 1 micron exist on the surface of the substrate, the protruding height of copper solder joints on the substrate ranges from 100 nm to 500 nm, and the surface evenness of the substrate is smaller than 5%; second, the substrate is covered with a layer of covering material in a spin coating mode or a vacuum lamination mode, wherein the covering material is epoxy resin or photodecomposition adhesive film or back-side adhesive film or thermoplastic resin or a light resistance material; third, copper solder spots of the chip are aligned with the copper solder spots of the substrate; fourth, the chip is fixed to the substrate through a soft pressing head in a closed space filled with inert gas, the temperature ranges from 150 DEG C to 250 DEG C, the pressure of the soft pressing head ranges from 50 kN to 100 kN, and the time ranges from 30 minutes to 3 hours; fifth, after curing is carried out, a plurality of chips are stacked on the chip according to the steps. According to the copper and copper bonding method, high-density integration of copper wires super-dense pitches can be achieved, and fixation carried out after bonding is completed at the temperature lower than 200 DEG C.

Owner:NAT CENT FOR ADVANCED PACKAGING

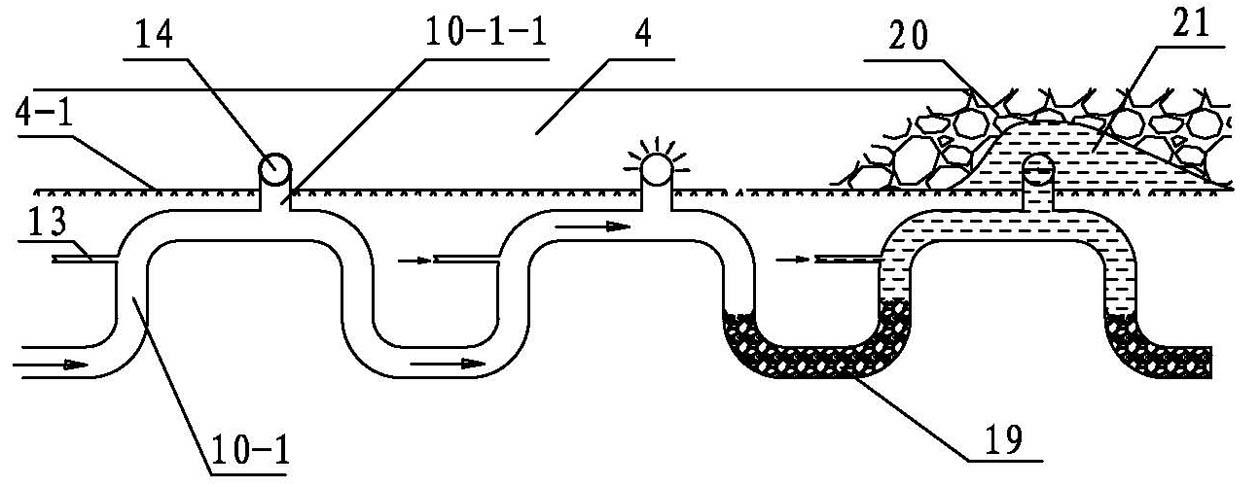

Underground coal gasification system and producing process

InactiveCN101315026BAllow nearby operationMaximize miningConstructionsCoal gasificationThermodynamicsCombustion

The invention relates to an underground coal gasification system and a production process thereof. The system comprises an air course and a gas transmission course which are arranged in a coal seam, a plurality of gasification channels are arranged in the coal seam, the two mutually parallel ends of each gasification channel respectively communicate with the air course and the gas transmission course, and a water drainage closed wall is arranged in the gas transmission course; and the both ends of the air course are respectively connected with an intake airway and a return airway of a mine system. The gasification process comprises the following steps: igniting; judging whether the burning point is required to be moved forward; moving the burning point of the coal seam backwards; plugginga gas passage of a combustion-supporting gas injection branch pipe which is disabled, and filling a burning control area with paste. The coal underground gasification system and the production process have the advantages that the coal seam can be mined to the utmost extent; the leakage of the combustion-supporting gas to the burning control area can be thoroughly cut off when the secure retraction during the coal underground gasification process is realized; the problem that the gasification agent is short-circuited because a passage is formed due to the collapsing of the coal seam floors in the gasification channel and the earlier period gasification area can be solved in the later period of the underground coal gasification, the gas production is secure and reliable, and the gasification rate is high.

Owner:中矿天晟能源科技有限公司

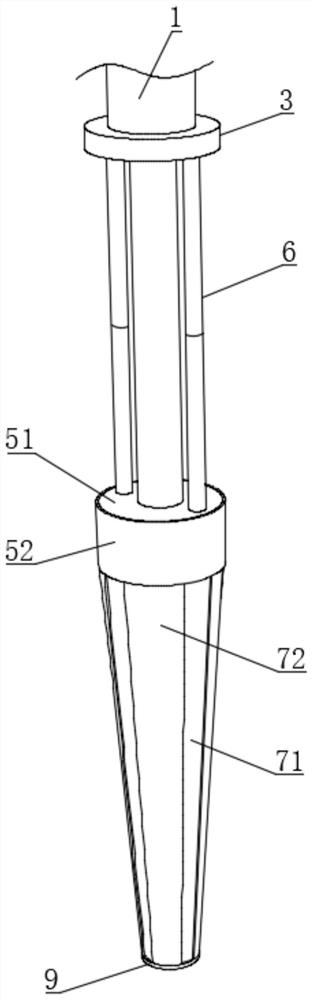

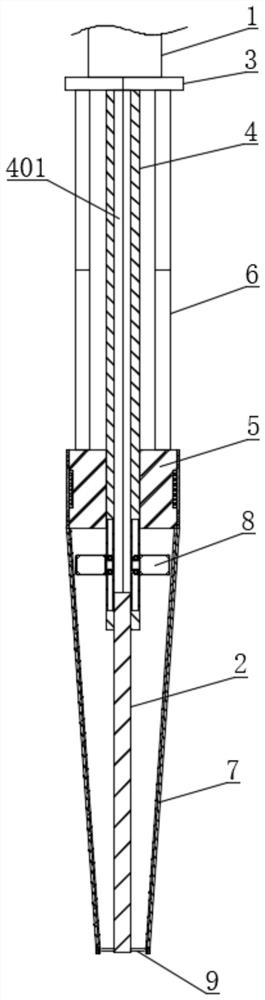

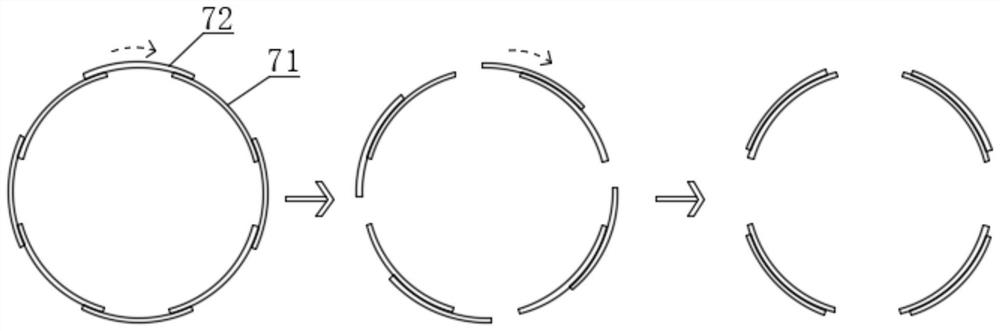

Internal extrusion synchronous backfill type concrete vibrating rod

ActiveCN111910929AReduce internal voidsImprove compactnessBuilding material handlingStructural engineering

The invention discloses an internal extrusion synchronous backfill type concrete vibrating rod, and belongs to the field of concrete vibrating rods. The internal extrusion synchronous backfill type concrete vibrating rod comprises a vibrating rod and a connecting pipe with one end connected to vibrating equipment wherein, a lead is connected between the other end of the connecting pipe and the vibrating rod, and a top tray is fixedly connected to the lower end of the connecting pipe. In the vibrating process, through rotating dislocation of a dislocation flow control barrel, concrete is controlled to enter and exit from the inner part of the dislocation flow control barrel, filling of the concrete in the dislocation flow control barrel is achieved, and in the process of taking out the vibrating rod, a special-shaped elastic squeezer automatically squeezes the concrete in the dislocation flow control barrel, so that the concrete synchronously flows out from the lower end of the dislocation flow control barrel in the process of taking out the vibrating rod and is stuffed into space formed by drawing out the vibrating rod, the situation of internal gaps of the concrete due to drawingout of the vibrating rod is effectively reduced, the compactness of the concrete is greatly improved, and a high-quality concrete molded body is obtained.

Owner:安徽建工集团蚌埠建材有限公司 +1

Cracking-resistant high-strength insulating brick

The invention discloses a cracking-resistant high-strength insulating brick which comprises the following raw materials in parts by weight: 60-100 parts of Portland cement, 10-20 parts of rice husk complex, 30-80 parts of magnesia cement, 2-10 parts of coal cinder, 4-10 parts of sepiolite powder, 1-3 parts of microcrystalline cellulose, 4-9 parts of talcum powder, 1-2 parts of an early strength agent, 1-2 parts of an enhancer, 50-150 parts of water, 1-3 parts of polystyrene foam particles, 1-2 parts of a colloidal agent and 0.2-1 part of a liquid foaming agent. The rice husk complex is prepared according to the following process steps: adding rice husks into a potassium hydroxide solution, raising the temperature, stirring, filtering, performing vacuum drying, adding graphene oxide to be uniformly mixed, carbonizing, uniformly grinding, adding glycerin, sodium polyacrylate and water to stir, adding hydroiodic acid to stir, filtering, washing and drying, thereby obtaining the rice huskcomplex. The cracking-resistant high-strength insulating brick provided by the invention is extremely high in flexibility, difficult to crack, high in strength and excellent in thermal insulation effect.

Owner:安徽润晟建设有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com