Backstop gangue beam suspension swinging beam type gangue filing hydraulic support frame with side protection plate

A technology of hydraulic supports and side guards, which is applied to mine roof supports, fillings, mining equipment, etc., and can solve the problem of gangue and other sundries entering the supports, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

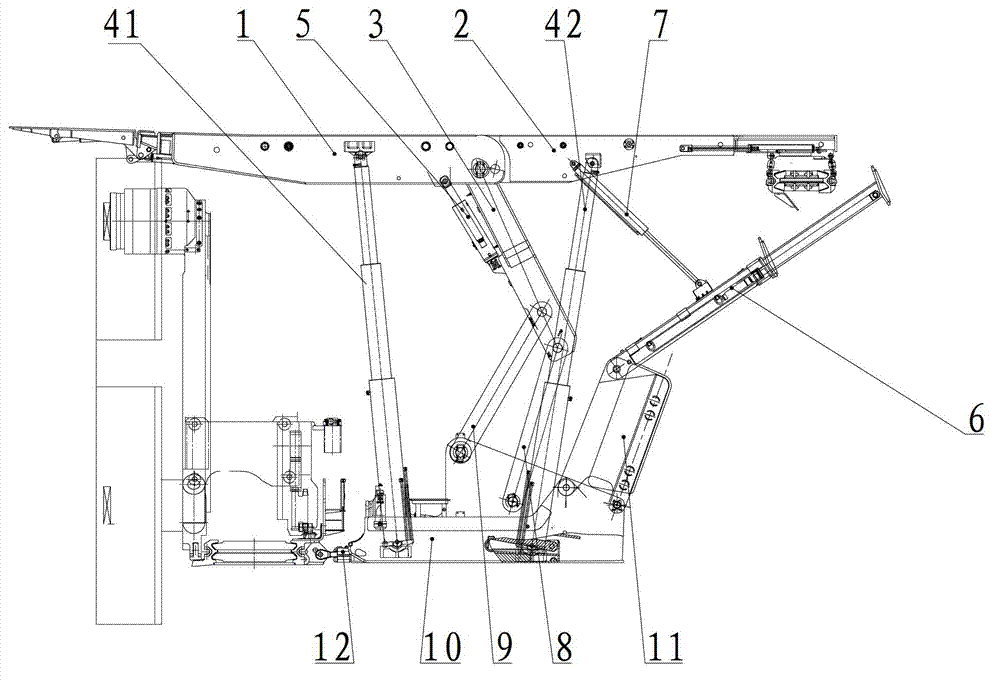

[0021] Such as figure 1 As shown, the embodiment of the present invention provides a rear gangue beam suspension swing beam type gangue filled hydraulic support with side guards, including a front top beam 1, a rear top beam 2 hinged with one end of the front top beam, a front top beam Column 41, rear column 42, upper connecting rod 3, front connecting rod 9, rear connecting rod 8, base 10, pushing frame and pushing jack 12; where upper connecting rod 3 is hinged at the joint between front top beam 1 and rear top beam 2 A three-point-in-one structure is formed on the point to support the cover type bracket, and the upper link 3 is respectively hinged with one end of the front link 9 and the rear link 8, and the other end of the front link 9 and the rear link 8 is respectively connected with the base 10. Hinged; the two ends of the front column 41 are respectively hinged with the front top beam 1 and the front end of the base 10, and the two ends of the rear column 42 are respe...

Embodiment 2

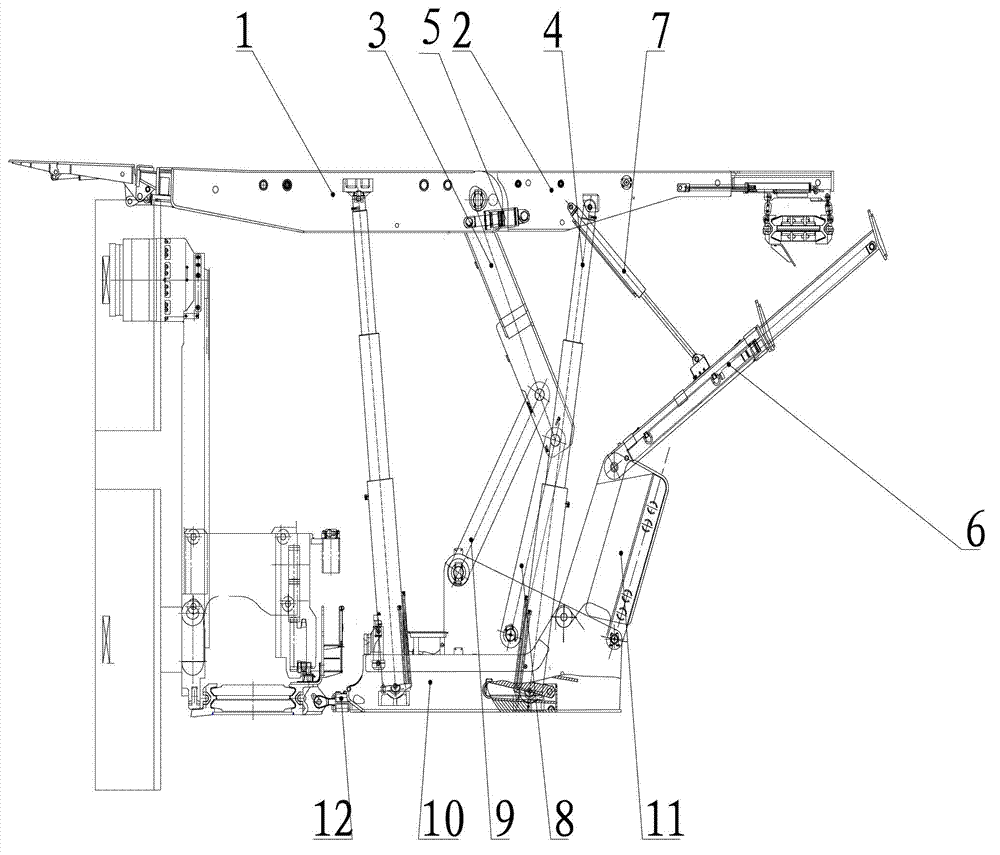

[0026] The difference from Example 1 is that, as figure 2 As shown, the balance jack 5 is arranged between the front top beam 1 and the rear top beam 2 . Other than that, other components and connection methods are the same as those in Embodiment 1, and will not be repeated in this embodiment.

[0027] The working principle of the embodiment of the present invention is as follows:

[0028] The support part of the hydraulic support in the embodiment of the present invention is the same as the support function of the traditional hydraulic support, and the realization process in the filling part is as follows: the pallet on which the filling conveyor is suspended slides in the chute of the rear top beam under the action of the pallet jack To the goaf that needs to be filled, the filling conveyor transports the filler to fill the goaf; the telescopic swing beam hinged on the rear retaining beam with side guards is pushed and pulled by the swing beam jack hinged on the rear top b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com