Novel brush worktable plate

A technology of worktable and brush, which is applied in the direction of manufacturing tools, metal processing equipment, feeding devices, etc., can solve the problems of easy scratch on the surface of the plate and affect the appearance quality of the workpiece, and achieve protection from scratches and light weight , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

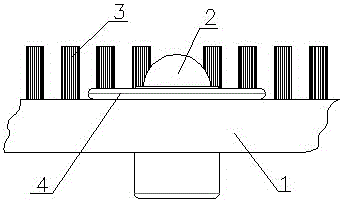

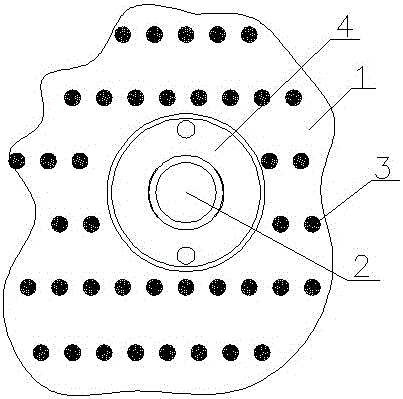

[0015] A new type of brush work table includes a work table 1 installed on a work frame. The upper surface of the work table 1 is provided with a number of ball pits, and movable steel balls 2 are installed in the ball pits. The upper surface of the steel ball 2 protrudes from the worktable 1, and the upper surface of the worktable 1 is also provided with a plurality of brush bundles 3, and the plurality of brush bundles 3 are fixedly placed on the upper surface of the working table 1. In the brush hole, the plurality of bristle brush bundles 3 are evenly distributed around the plurality of movable steel balls 2, and the upper end of the brush bundle 3 protrudes upwards higher than the upper surface of the movable steel ball 2.

[0016] Further, the upper end surface of the movable steel ball 2 is provided with a steel ball restraint plate 4 fixed on the worktable plate 1, and the steel ball restraint plate 4 is provided with a circular hole, and the diameter of the circular hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com