Large three-way joint die forging device for power station equipment and die forging method thereof

A three-way, large-scale technology, used in forging/pressing/hammer devices, driving devices of forging presses, mechanical equipment, etc., can solve the problems that are not suitable for mass production, unqualified die forging products, and heavy machining drilling workload. and other problems, to achieve the effect of improving the efficiency and competitiveness of enterprises, reducing the amount of machining, and shortening the production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

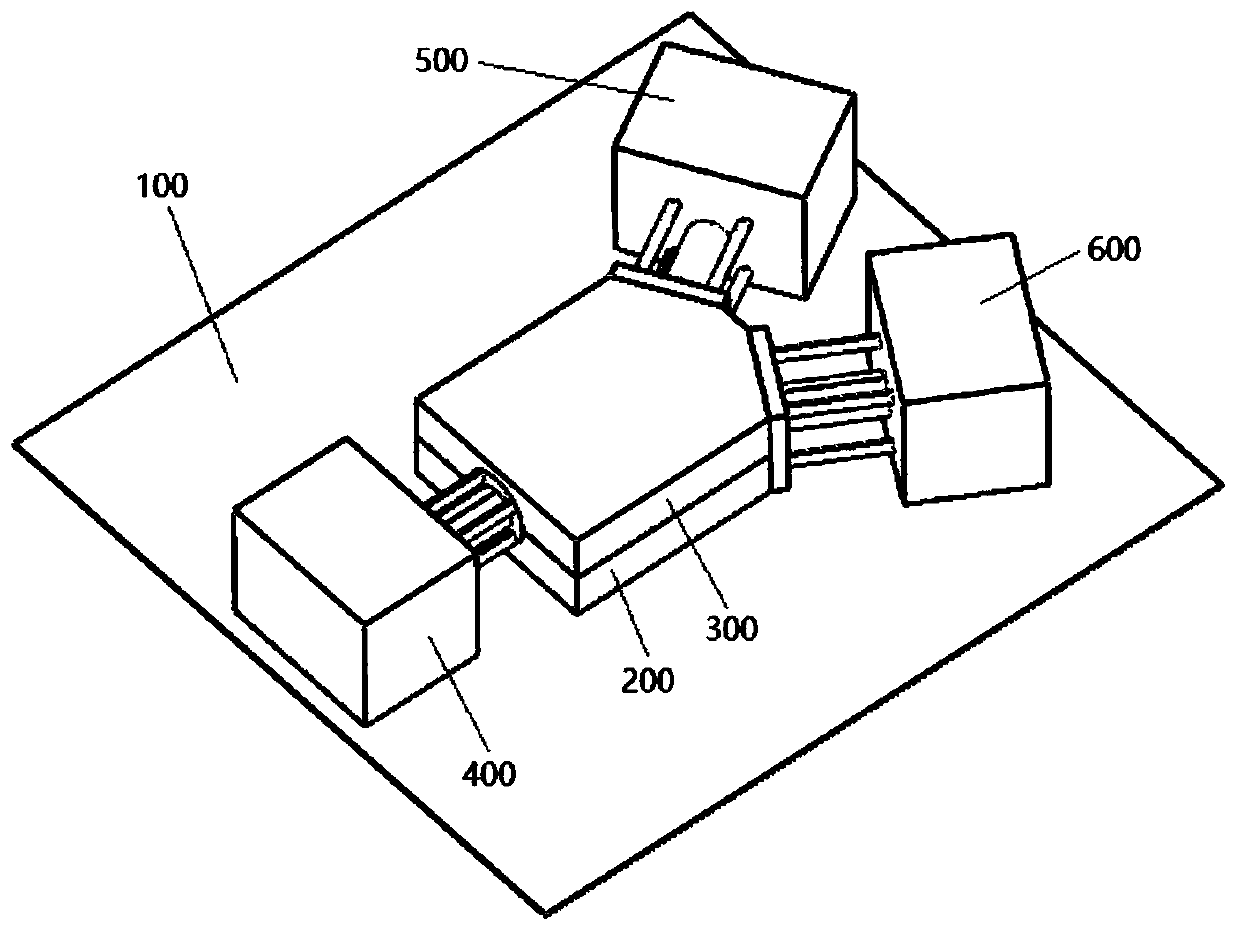

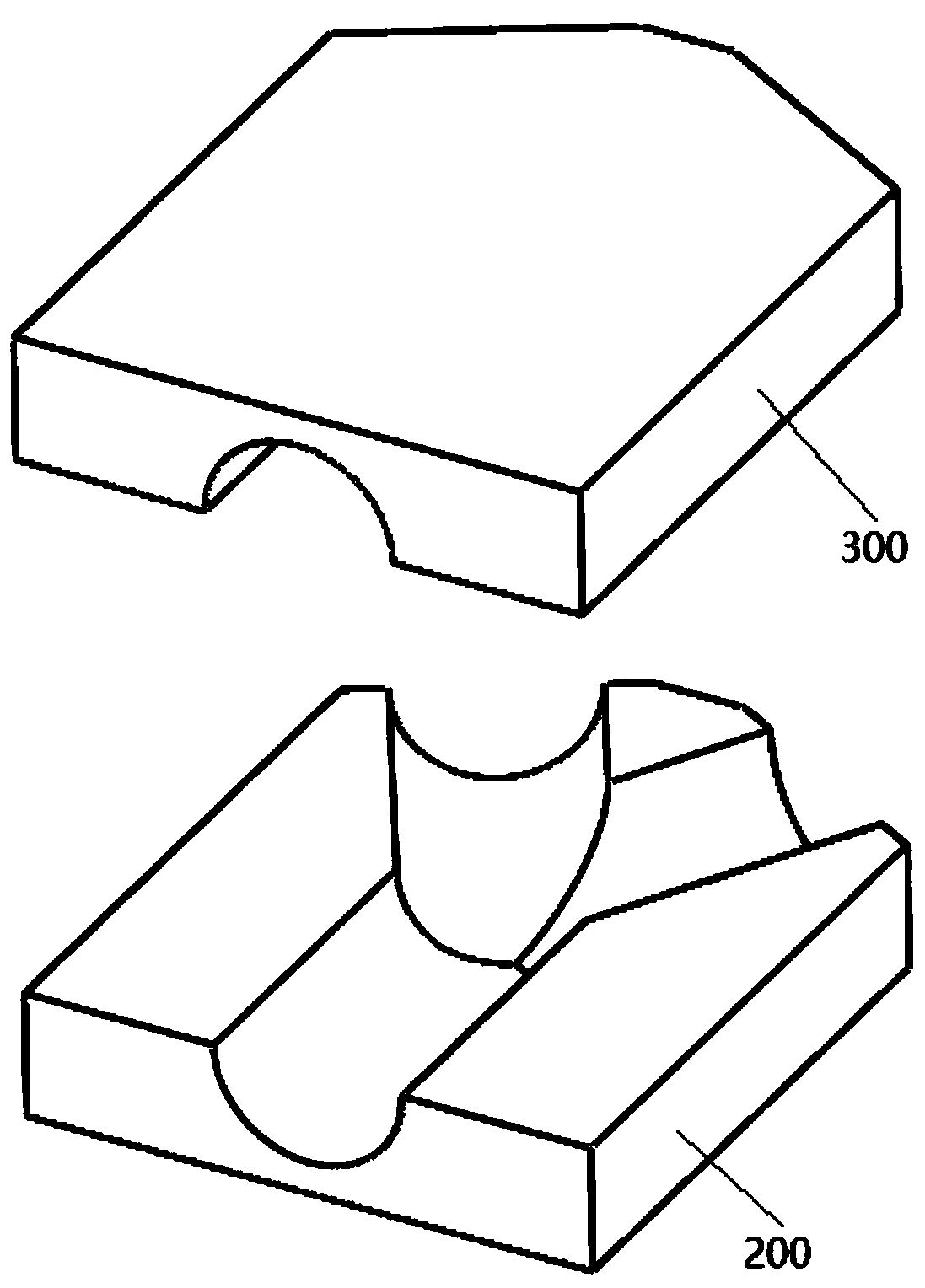

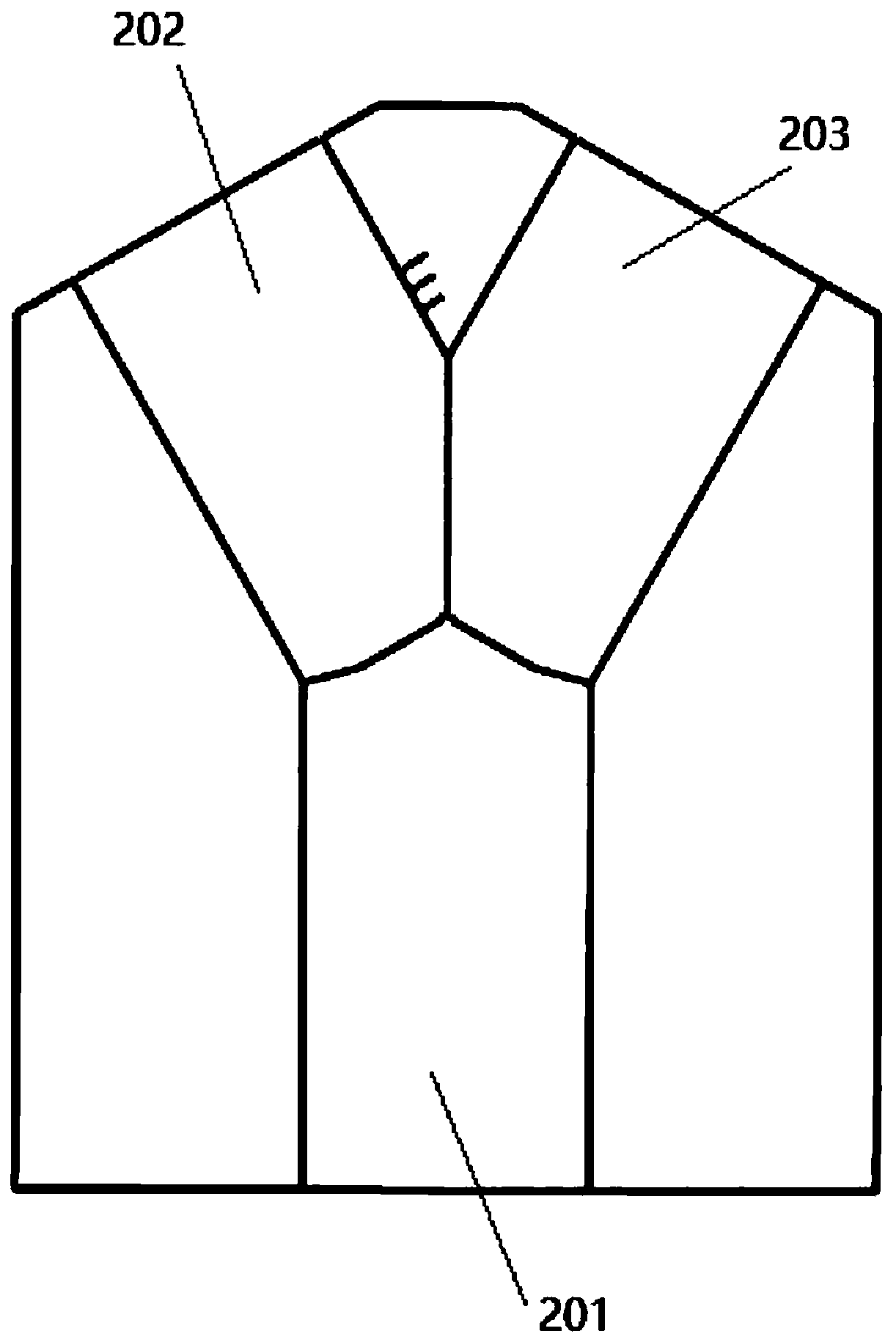

[0039] Embodiment 1: as Figure 1 to Figure 7 As shown, a large-scale three-way die forging device for power station equipment proposed by the present invention includes a bottom plate 100 , a lower die 200 , and an upper die 300 . The lower mold 200 includes a main cavity 201, a first branch cavity 202 and a second branch cavity 203, all of which are semi-cylindrical. The structure of the upper mold 300 corresponds to the lower mold 200, and the lower mold 200 and the upper mold 300 are enclosed After forming a chamber for forming large Y-shaped tees.

[0040] The bottom plate 100 is connected with a main road propulsion device 400, a first branch road blocking device 500, and a second branch road blocking device 600, the first branch road blocking device 500 and the second branch road blocking device 600 have the same structure, and respectively It corresponds to the first branch cavity 202 and the second branch cavity 203 .

[0041] Wherein, the trunk propulsion device 40...

Embodiment 2

[0045] Embodiment 2 is further designed on the basis of Embodiment 1. The blocking plate 503 is provided with a pressure sensor for detecting the pressure on the blocking plate 503, and the pressure sensor can sense the pressure changes at multiple positions of the blocking plate 503 around the plug 504, And the pressure signal can be transmitted to the host computer for processing, and the pressure sensor in the embodiment is the prior art, which will not be repeated here; in addition, in this embodiment, several pressure sensors can be provided and distributed around the plug 504 .

[0046] And the side walls of the first branch cavity 202 and / or the second branch cavity 203 of the lower mold 200 are provided with several scale lines. In this embodiment, the first branch cavity 202 is selected to set three scale lines.

[0047] Due to the different materials of different metal materials, the fluidity of the metal in the molten state is different. Therefore, when the blocking...

Embodiment 3

[0048] Embodiment 3, a die forging method of a large-scale three-way die forging device for power station equipment, comprising the following steps:

[0049] Step 1, preparatory work, the trunk main engine box 401 in the trunk propulsion device 400 operates and drives four trunk hydraulic push rods 402, trunk push plates 403, and punches 404 to withdraw from the main cavity 201; the first Both the branch blocking device 500 and the second branch blocking device 600 drive the corresponding plug 504 to separate from the first branch cavity 202 and the second branch cavity 203 , and remove the upper mold 300 .

[0050] Step 2: Start working, heat the cylindrical metal blank material to be extruded to 1200 degrees Celsius in a heating furnace, and then place it in the main cavity 201 of the lower mold 200 by clamping it.

[0051] Step 3: The upper mold 300 is fastened to the lower mold 200, and the top of the upper mold 300 is pressed by an external press, and the main road host b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com