Laser processing drilling method of workpiece with complex cavity and auxiliary filling system

A laser processing and filling system technology, applied in the field of auxiliary systems, can solve problems such as surface wall damage, and achieve the effect of dense filling, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

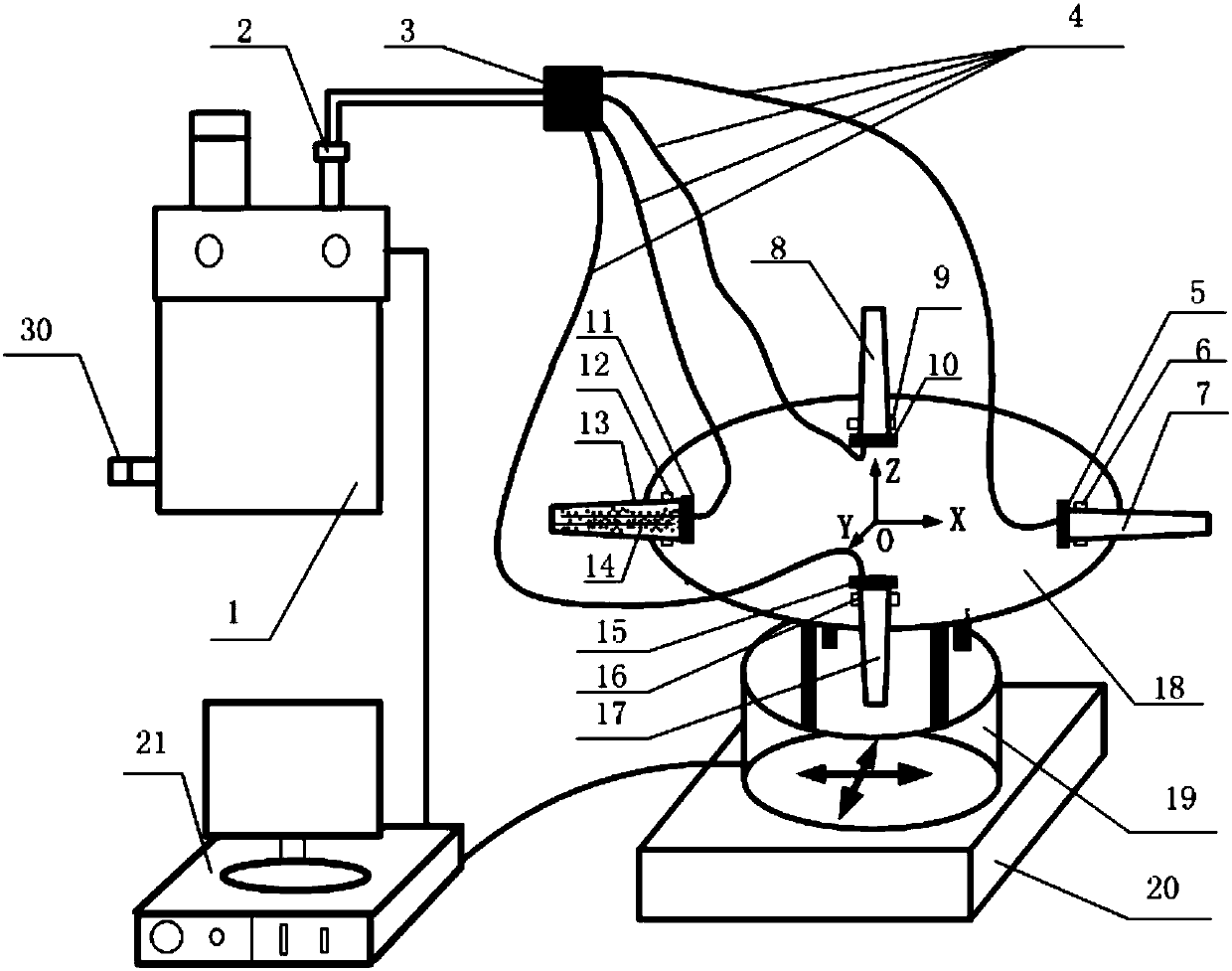

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

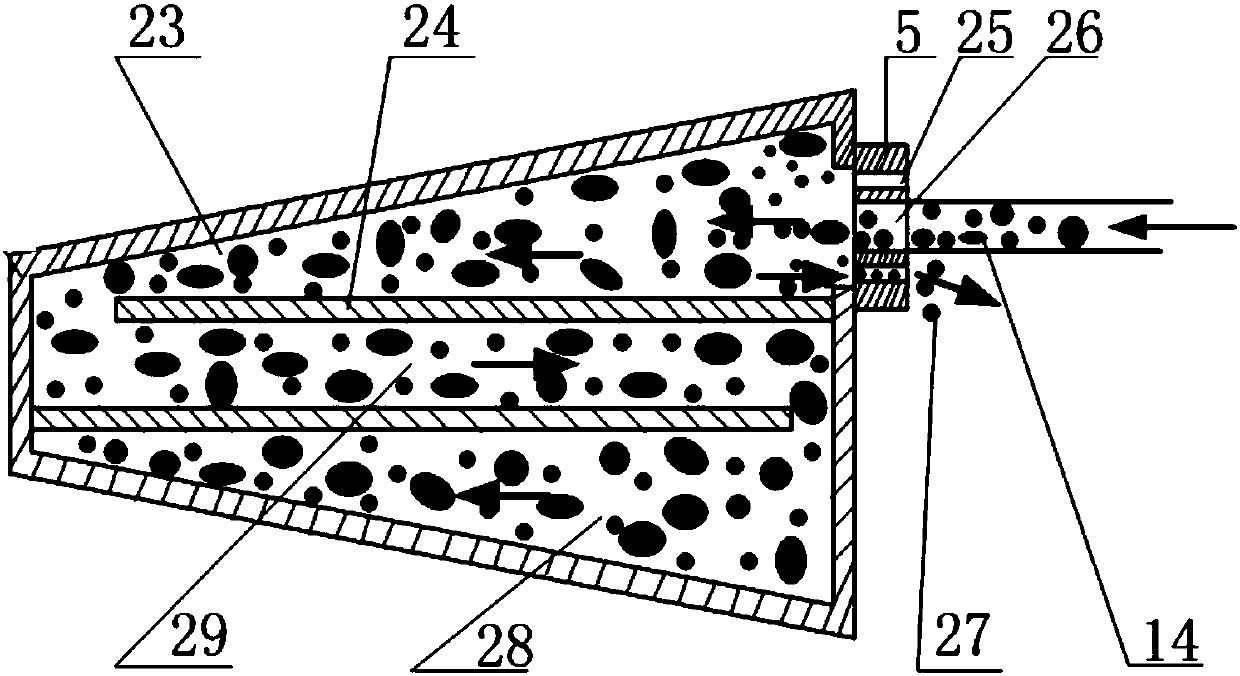

[0036] The present invention proposes a method of using laser to process through-holes and through-groove features in hollow blades and other workpieces with complex cavities, so as to realize dense filling of powder particles without dead ends to prevent damage to the opposite wall of the workpiece processing part during laser processing. .

[0037] In this method, before starting laser processing and hole making, air flow is used to blow particles into the cavity of the workpiece to be processed while vibrating the workpiece to achieve the effect of densely filling the particles in the cavity. After the filling is completed, the laser processing and hole making process is carried out. After the hole is processed, the inner cavity of the workpiece is cleaned with high-pressure airflow from multiple angles, and the workpiece is vibrated at the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com