Spraying device for continuously filling carbon fiber battery grids with active substances

A technology of active material and spraying device, which is applied in the direction of spraying device, spraying manufacturing, lead-acid battery electrodes, etc. It can solve the problems of reduced strength and porosity requirements, simple devices are not suitable for production, etc., and achieve simple and convenient operation and uniform filling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

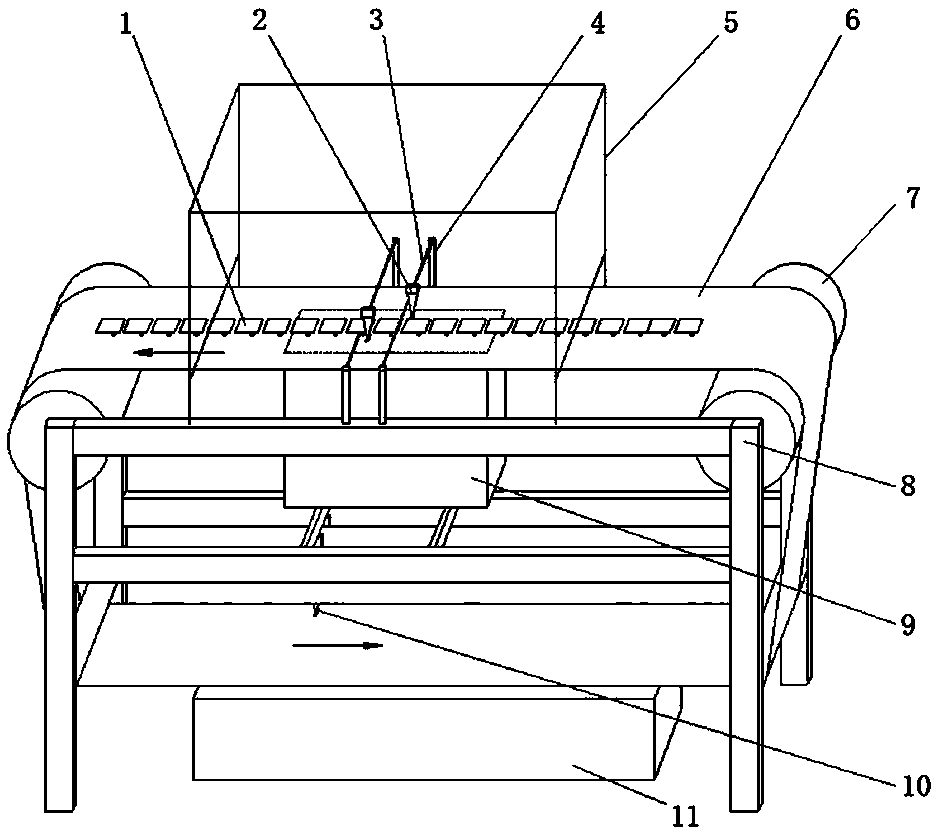

[0030] See figure 1 , the present invention has the control system, transmission system and spray gun 2 that are installed on the equipment girder 8; The control system is PLC; The transmission system includes drive motor, transmission pulley 7 and transmission mesh belt 6; The conveyor pulley 7 rotates; the conveyor belt 6 is tensioned and adjustable and wound on two parallel conveyor pulleys 7; the position of the spray gun 2 corresponding to the pole plate 1 is placed above the conveyor belt 6, and is driven by a motor to slide and set on the spray gun bracket beam 3 Go up and make a reciprocating motion perpendicular to the forward direction of the conveying mesh belt 6. The realization of the reciprocating motion can be realized by cam design or lead screw design or the forward and reverse rotation of the motor; the spray gun bracket beam 3 is installed on the equipment beam 8 through the spray gun bracket 4 ; It also has a pneumatic system and a negative pressure system;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com