Long plant fiber-reinforced polypropylene composite material and preparation method thereof

A technology of plant fibers and composite materials, which is applied in the field of long fiber reinforced polypropylene composite materials and its preparation, can solve the problems of poor mechanical properties of composite materials, consume a lot of manpower and energy, and excellent composite materials, so as to improve impact strength and improve Compatibility, high filling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

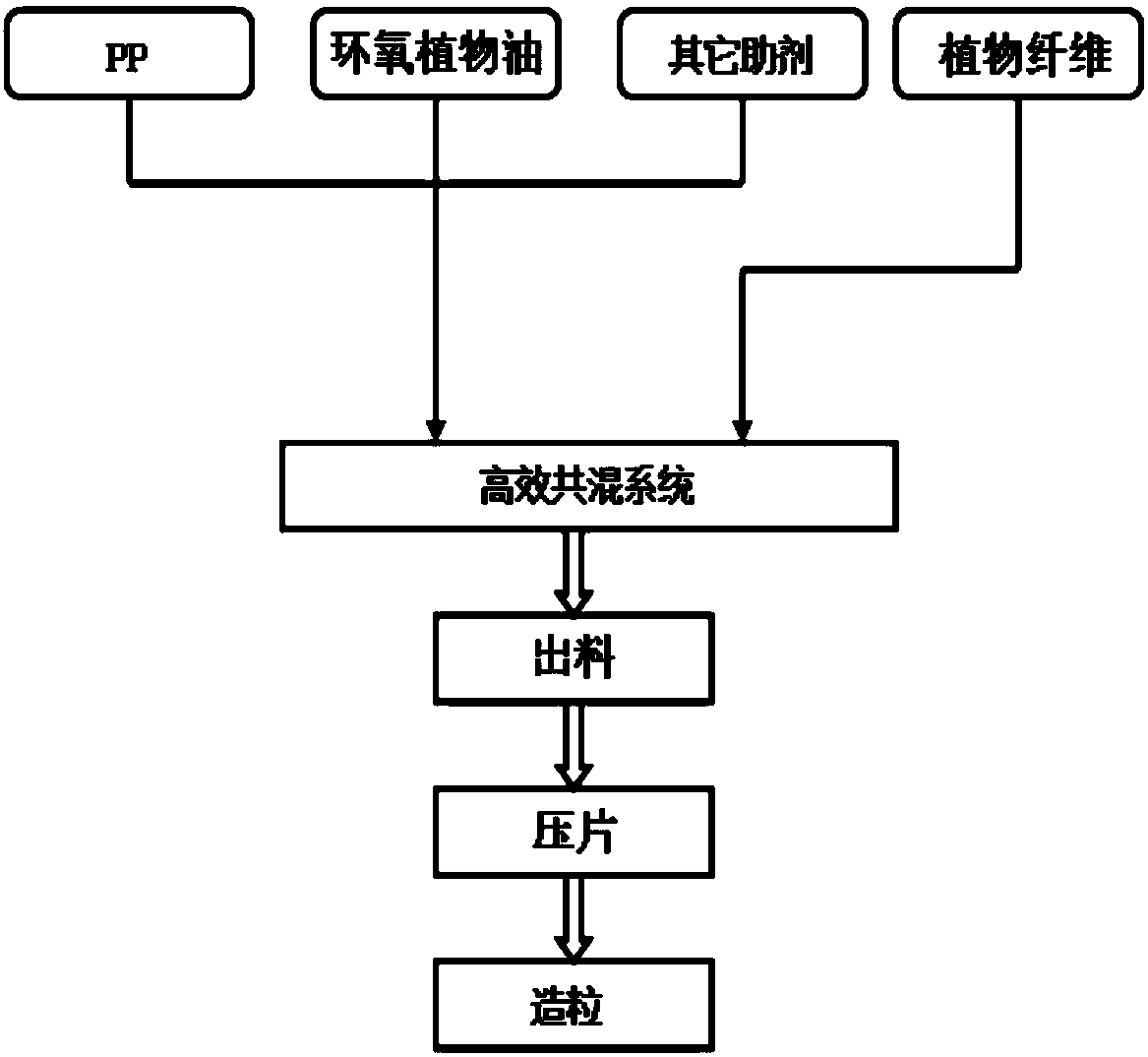

[0041] use as figure 1 Shown processing technology, take by weight 53 parts of polypropylene, 40 parts of jute fiber (average length is 100mm), 4 parts of epoxy tung oil, 2 parts of lubricant (polyethylene wax), antioxidant (antioxidant 1010 and antioxidant 168 according to 1:1 compound) 1 part. Then put the above raw materials into the high-speed blending system through the feeding hopper, close the feeding hopper, adjust the blending speed to 2000rpm, melt and blend for 10s after the temperature of the materials rises to 200°C, then discharge, and melt the blended The mixture is pressed into flakes, and after cooling, it is pulverized and granulated in a pulverizer to obtain a pellet of long plant fiber reinforced polypropylene composite material.

[0042] The obtained pellets were injected into standard test specimens in an injection molding machine, and the mechanical properties were tested with a universal testing machine and a pendulum impact testing machine. The mechan...

Embodiment 2

[0044] use as figure 1 Shown processing technology, take by weight 53 parts of polypropylene, 40 parts of jute fiber (average length is 100mm), 4 parts of epoxy castor oil, 2 parts of lubricant (polyethylene wax), antioxidant (antioxidant Agent 1010 and antioxidant 168 are compounded at 1:1) 1 part. Then put the above raw materials into the high-speed blending system through the feeding hopper, close the feeding hopper, adjust the blending speed to 2000rpm, melt and blend for 10s after the temperature of the materials rises to 200°C, then discharge, and melt the blended The mixture is pressed into flakes, and after cooling, it is pulverized and granulated in a pulverizer to obtain a pellet of long plant fiber reinforced polypropylene composite material.

[0045] The pellets were injected into standard test specimens in an injection molding machine, and the mechanical properties were tested with a universal testing machine and a pendulum impact testing machine. The mechanical ...

Embodiment 3

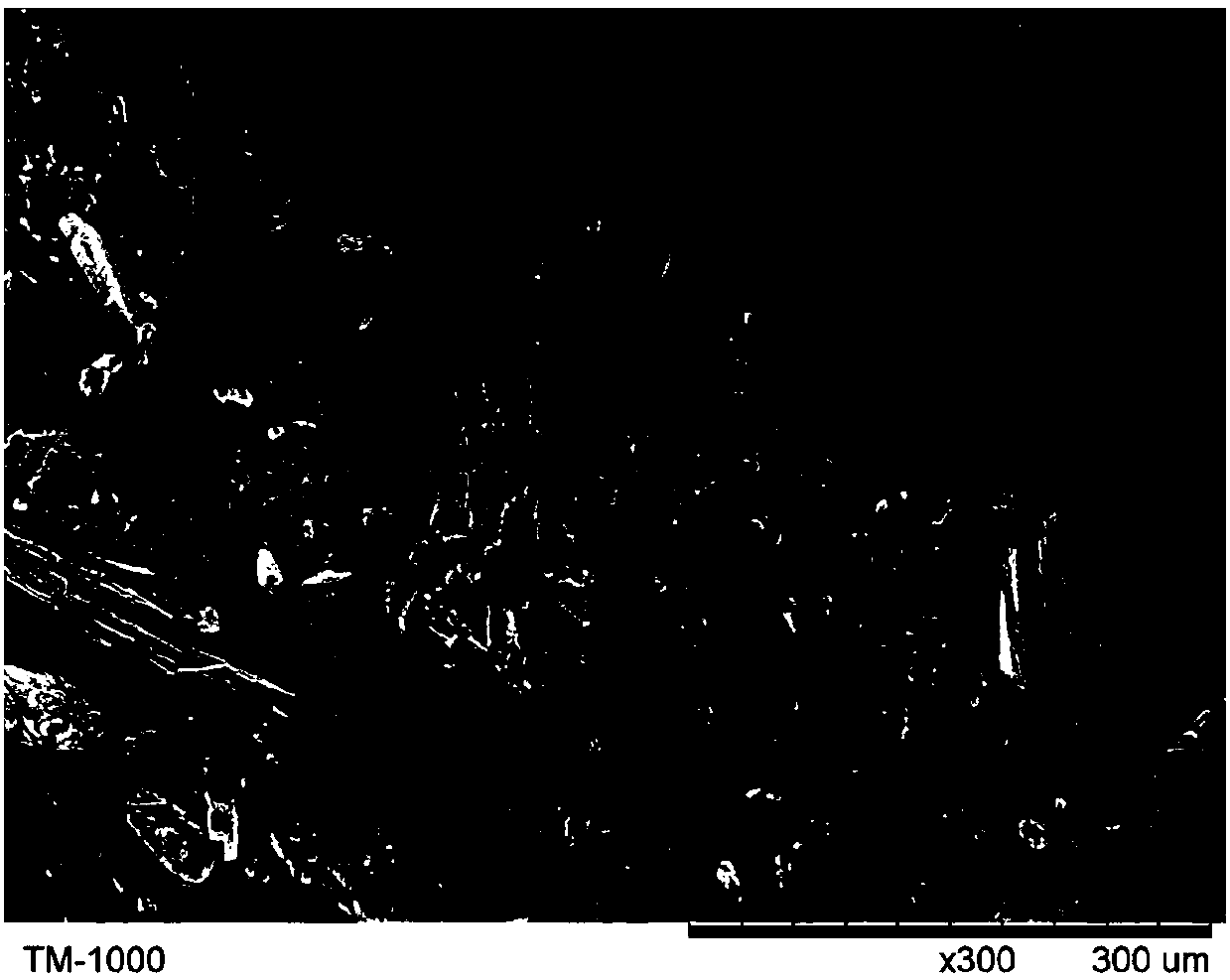

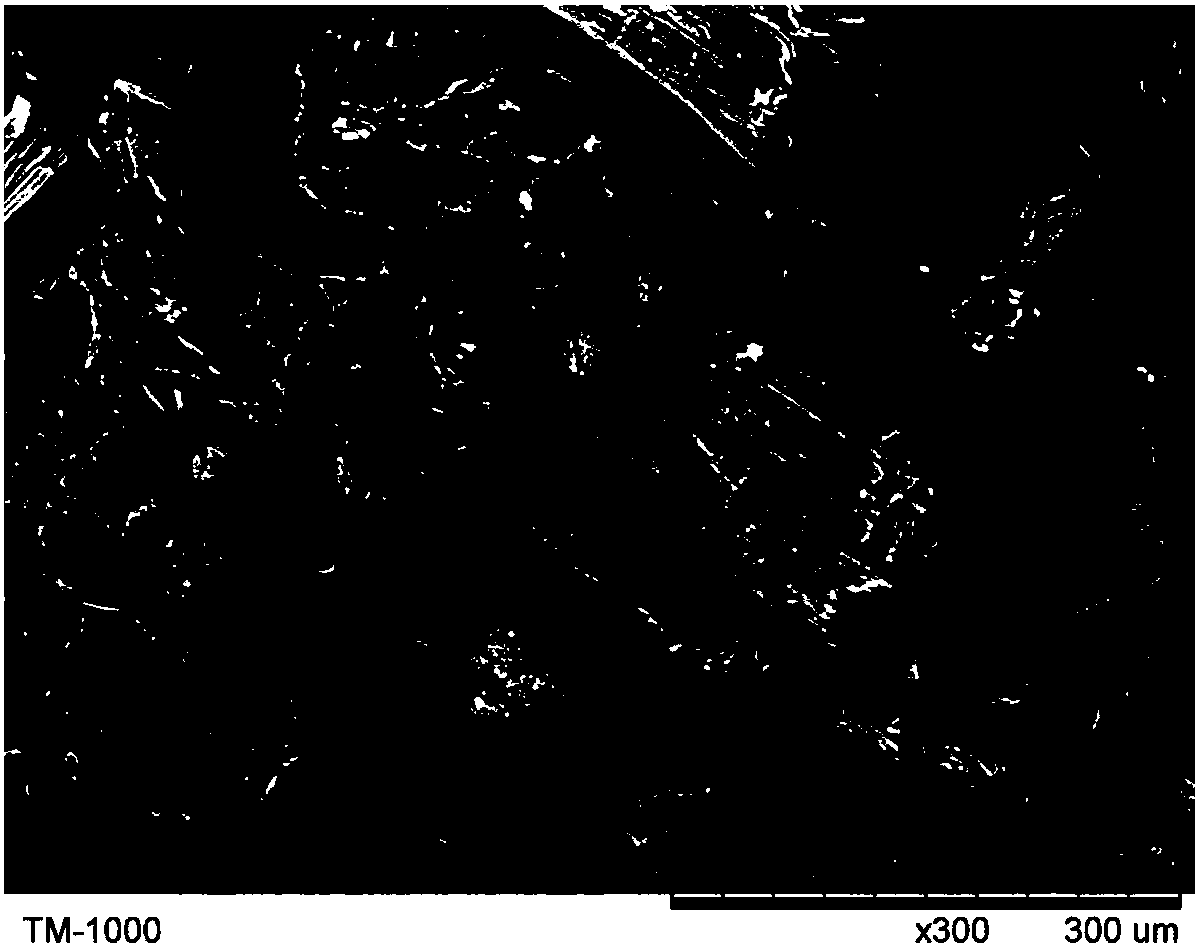

[0047] use as figure 1 Shown processing technology, take by weight 53 parts of polypropylene, 40 parts of jute fiber (average length is 100mm), 4 parts of epoxy cardanol glycidyl ether, 2 parts of lubricant (polyethylene wax), antioxidant (Antioxidant 1010 and Antioxidant 168 are compounded at 1:1) 1 part. Then put the above raw materials into the high-speed blending system through the feeding hopper, close the feeding hopper, adjust the blending speed to 2000rpm, melt and blend for 10s after the temperature of the materials rises to 200°C, then discharge, and melt the blended The mixed material is pressed into flakes, and after cooling, it is pulverized and granulated in a pulverizer to obtain a pellet of a long plant fiber reinforced polypropylene composite material, and its SEM photo is as follows figure 2 shown.

[0048] From figure 2 It can be seen from the figure that after adding epoxy vegetable oil, the jute fiber and the polypropylene plastic matrix are closely c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com