High-rate high-safety long-life lithium iron phosphate battery and preparation method thereof

A technology of lithium iron phosphate battery and lithium iron phosphate, which is applied in the direction of secondary batteries, battery electrodes, battery pack components, etc., can solve the problems of poor electrical conductivity of lithium iron phosphate, fast cycle life attenuation, and slow diffusion of lithium ions, etc., to achieve Improved high-rate performance, reduced diffusion resistance, and the effects of multiple migration channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

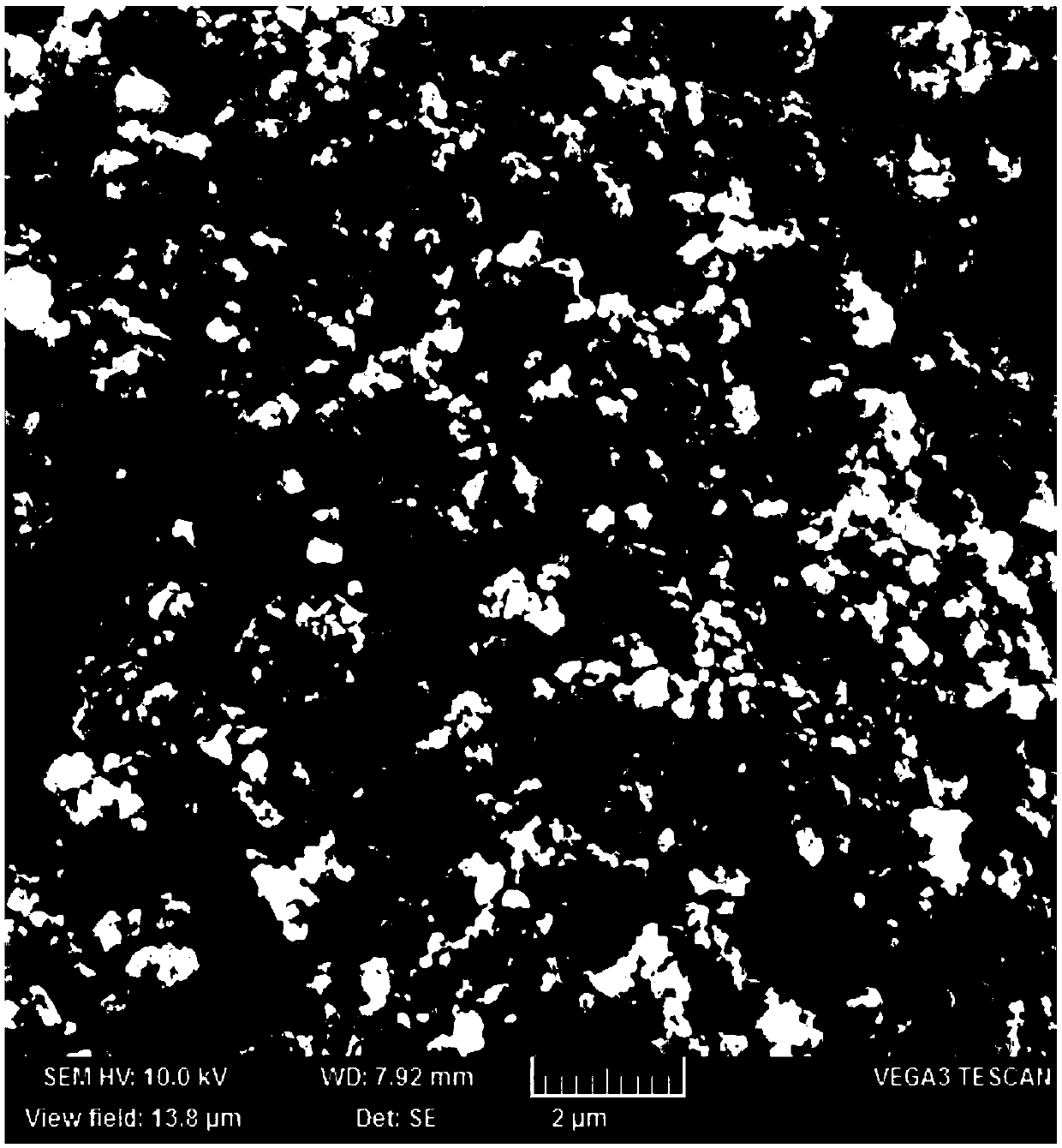

[0051] The preparation method of lithium iron phosphate in the present embodiment comprises the following steps:

[0052] S11, ferric orthophosphate and Fe 3 o 4 Mix according to the mass ratio of 3:1 to form a composite iron source, add it to the ball mill, then add deionized water to mix, and ball mill at a speed of 200r / min for 1h. The amount of ionized water added is ferric orthophosphate and Fe 3 o 4 40 of the total mass;

[0053] S12. Add lithium carbonate and carbon nanotubes to the ball mill in step S11, and continue to add ethanol to mix ball milling for 2 hours. After ball milling, the slurry particle size D50 is controlled at 1-1.5 μm; wherein, the mass ratio of lithium carbonate, carbon nanotubes, and composite iron source For 20:10:20, the addition of ethanol is lithium carbonate, 20% of the total mass of carbon nanotubes;

[0054] S13. Vacuum dry the slurry in step S12 at 90°C, pre-calcine the dried material at 600°C for 4 hours, and protect the whole proces...

Embodiment 2

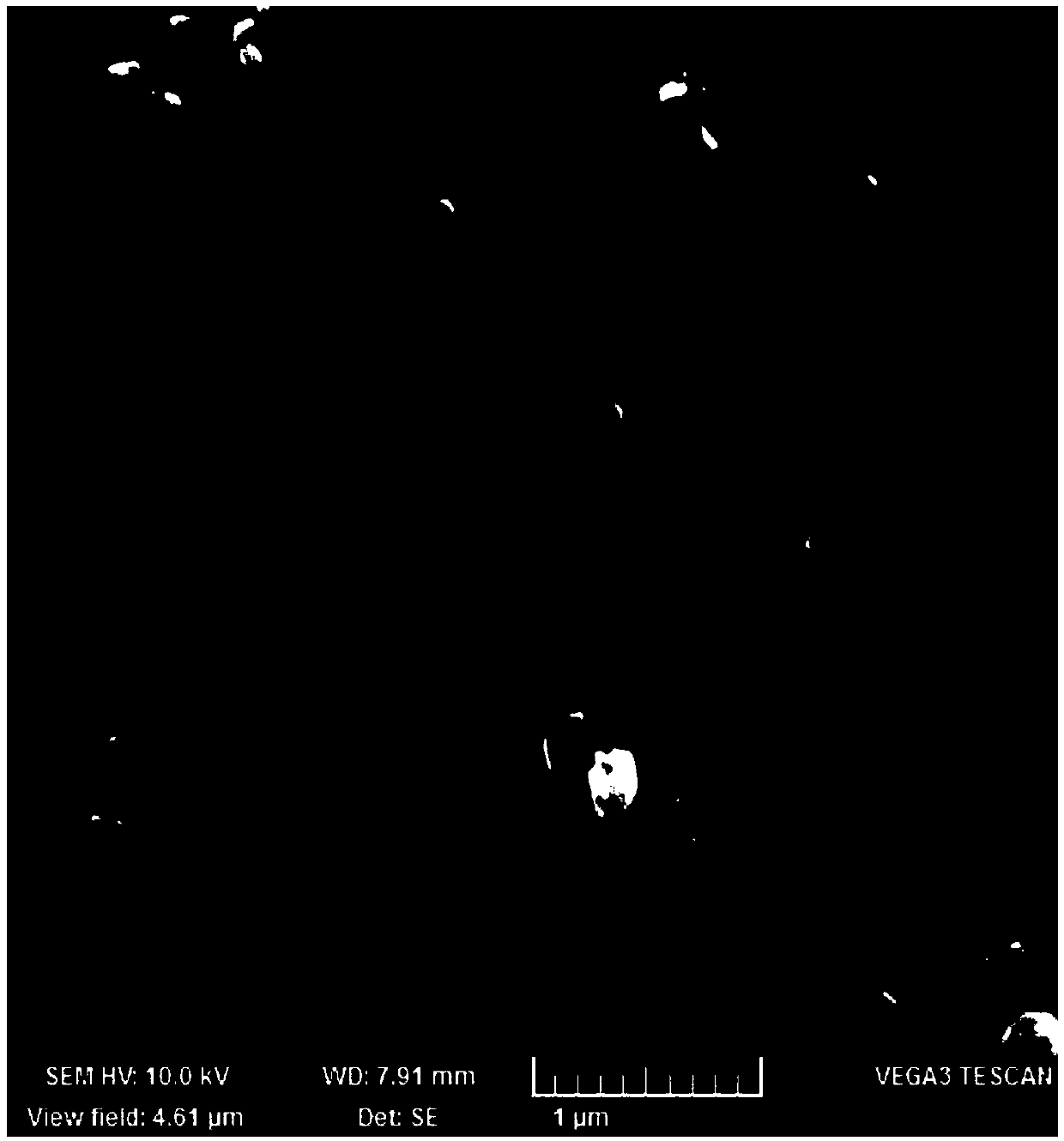

[0073] The preparation method of lithium iron phosphate in the present embodiment comprises the following steps:

[0074] S11, ferric orthophosphate and Fe 3 o 4 Mix according to the mass ratio of 3.5:1 to form a composite iron source, add it to the ball mill, then add deionized water to mix, and ball mill at a speed of 250r / min for 2h, and the particle size D50 of the slurry after ball milling is controlled at 1-1.5μm; among them, deionized water The addition amount is ferric orthophosphate and Fe 3 o 4 45% of the total mass;

[0075] S12. Add lithium carbonate and carbon nanotubes to the ball mill in step S11, and continue to add ethanol to mix ball milling for 3 hours. After ball milling, the slurry particle size D50 is controlled at 1-1.5 μm; wherein, the mass ratio of lithium carbonate, carbon nanotubes, and composite iron source For 21:11:21, the addition of ethanol is lithium carbonate, 25% of the total mass of carbon nanotubes;

[0076] S13. Vacuum-dry the slurry ...

Embodiment 3

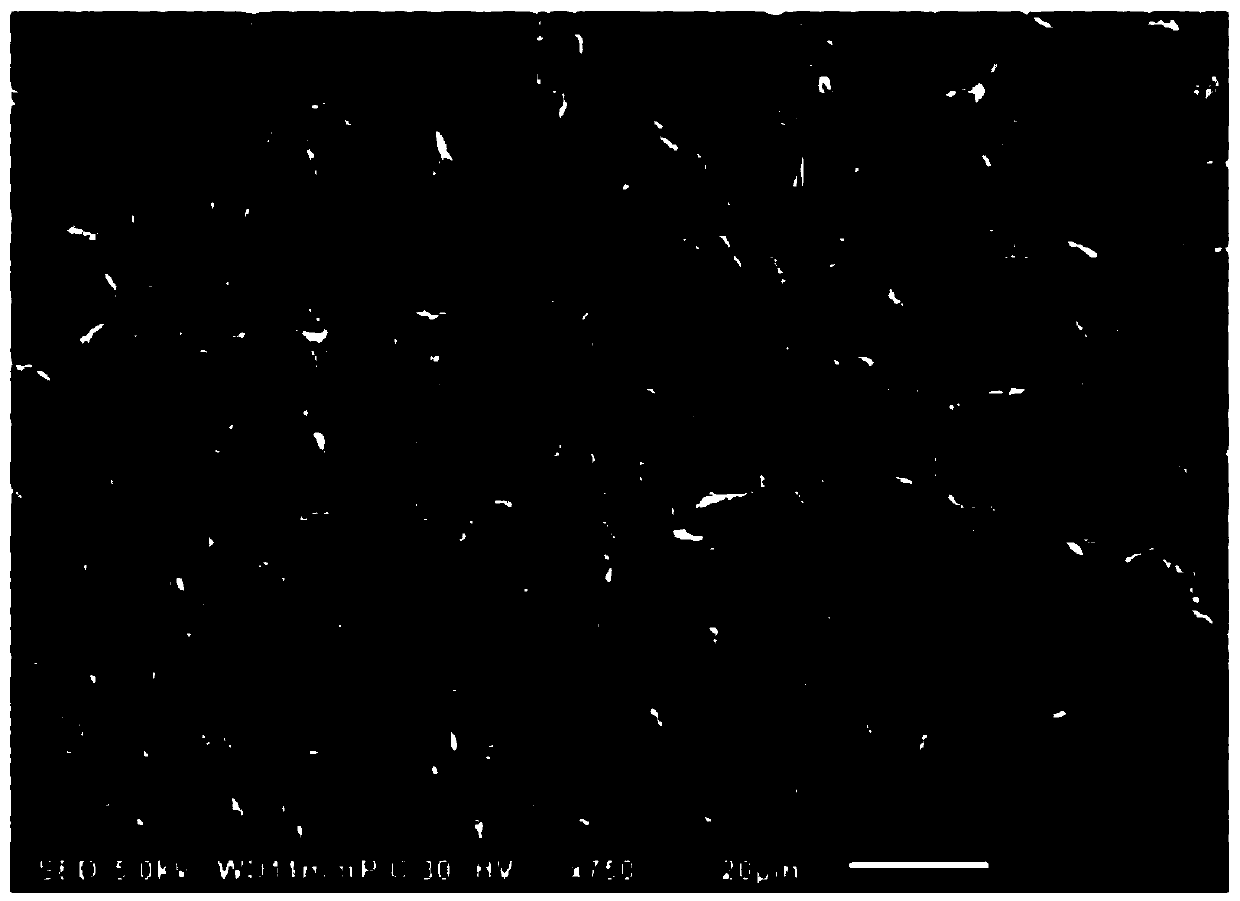

[0095] The preparation method of lithium iron phosphate in the present embodiment comprises the following steps:

[0096] S11, ferric orthophosphate and Fe 3 o 4 Mix according to the mass ratio of 4:1 to form a composite iron source, add it to a ball mill, then add deionized water to mix, and ball mill at a speed of 300r / min for 3 hours, and the particle size D50 of the slurry after ball milling is controlled at 1-1.5μm; among them, deionized water The addition amount is ferric orthophosphate and Fe 3 o 4 50% of the total mass;

[0097] S12. Add lithium carbonate and carbon nanotubes to the ball mill in step S11, and continue to add ethanol to mix ball milling for 4 hours. After ball milling, the slurry particle size D50 is controlled at 1-1.5 μm; wherein, the mass ratio of lithium carbonate, carbon nanotubes, and composite iron source For 22:12:22, the addition of ethanol is lithium carbonate, 30% of the total mass of carbon nanotubes;

[0098] S13. Vacuum-dry the slurry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com