Electrode paste for buried-gate type crystalline silicon solar cell

A solar cell and electrode paste technology, which is applied to conductive materials dispersed in non-conductive inorganic materials, circuits, photovoltaic power generation, etc., can solve the problem of no electrode paste, and achieve the effect of reducing viscosity and surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

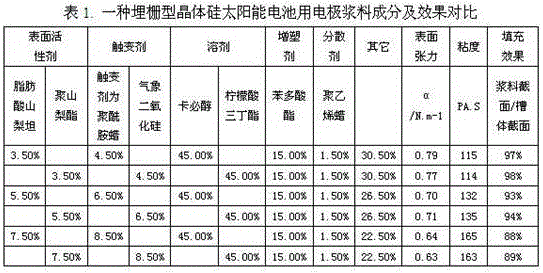

[0014] An electrode paste for a buried gate type crystalline silicon solar cell, the composition and weight percentage of the paste are: 80-92% silver powder, 1-4% glass powder, 0.1-5% additive, 3-3% organic carrier 12%.

[0015] The shape of the silver powder is spherical, and the D50 of the silver powder particles is 0.5-3um.

[0016] Glass powder is a particle, its diameter D50 is 0.3-15μm, and its composition and mole percentage are: 5-60% tellurium oxide, 1-45% bismuth oxide, 1-50% lead oxide and 0.1-10% Zinc oxide, and other metal oxide components containing tungsten, cadmium, and lithium, the sum of the mole percentages of each component is 100%.

[0017] The additive is at least one of thixotropic agent, viscosity regulator, surfactant, stabilizer, dispersant, thickener, wetting and dispersing agent, plasticizer and defoamer.

[0018] The organic carrier is a mixture of organic resin and organic solvent, wherein the organic resin is polybutylmethacrylate, ethyl cellu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com