Method for embedding copper block of double-sided circuit board

A technology of double-sided circuit board and manufacturing method, which is applied in the direction of printed circuit manufacturing, printed circuit, circuit heating device, etc., and can solve the problem of corrosion of substrate and copper block, large slot size of embedded copper block, and slot resin that cannot meet the requirements of glue filling And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] see Figure 1-Figure 8 , a kind of manufacturing method of double-sided circuit board embedding copper block of the present invention, comprises the following steps:

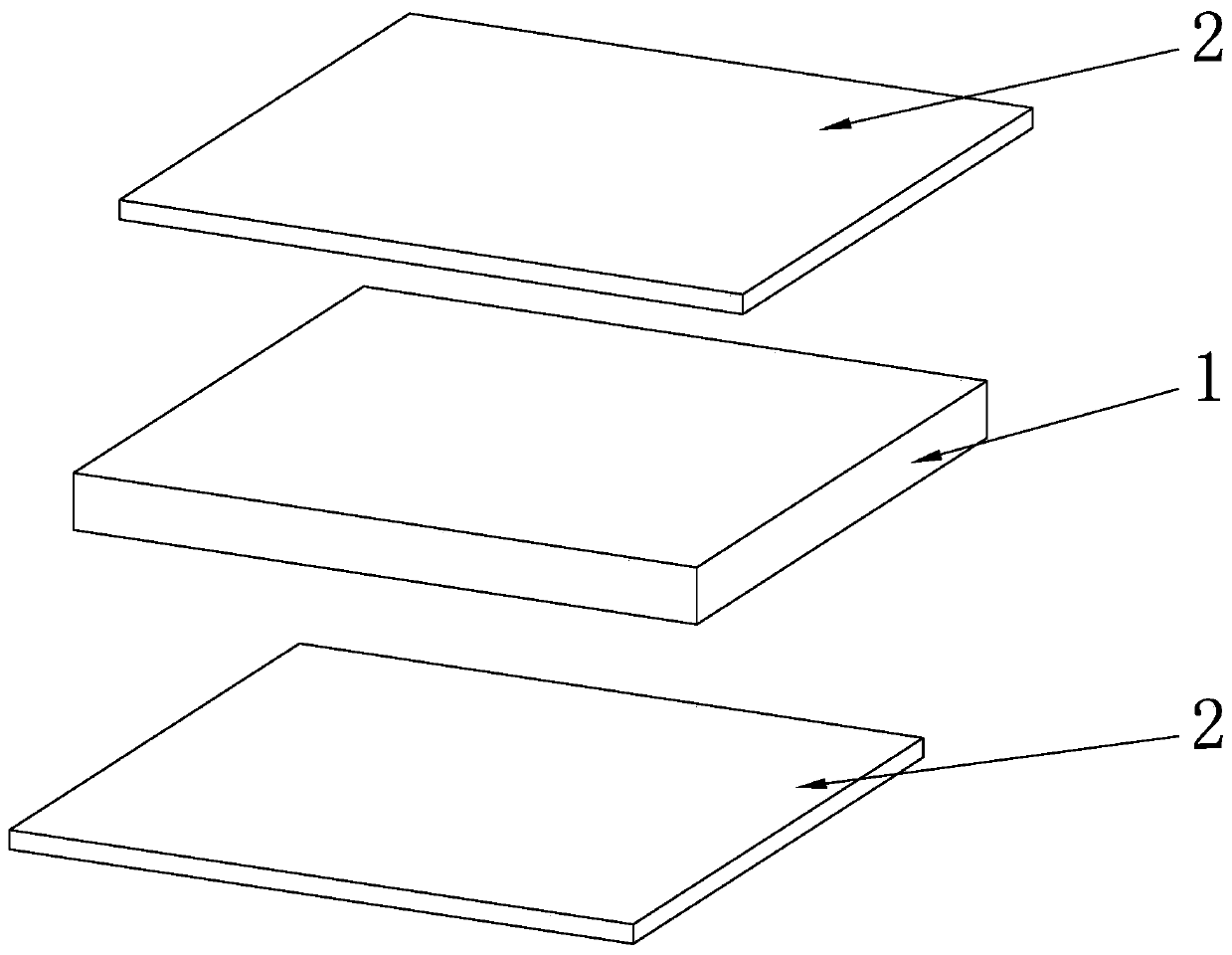

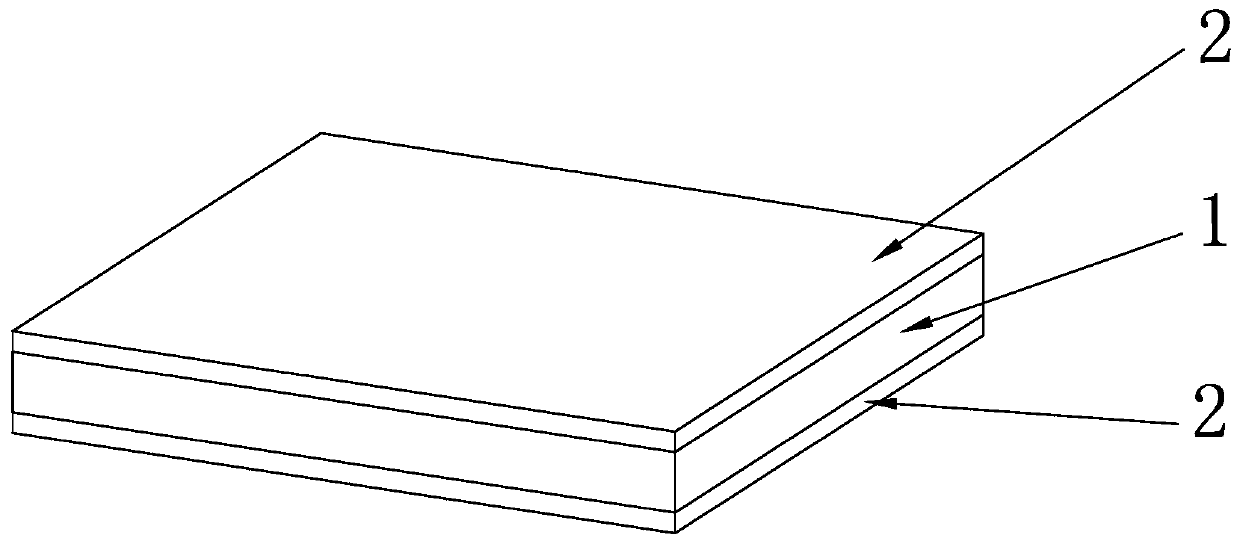

[0026] S01. Prepare a double-sided copper-clad laminate 1; the double-sided copper-clad laminate 1 includes a middle substrate 11 and a second copper foil 12 pressed on both sides of the substrate 11, and the thickness ratio of the second copper foil 12 in this step is The thickness of the second copper foil 12 after step S07 is 5um-8um, so as to avoid the risk of exposing the base material 11 caused by the grinding plate in step S07.

[0027] S02. On both sides of the double-sided copper-clad laminate 1, a high-temperature adhesive tape 2 is pasted on the entire surface; specifically, the high-temperature adhesive tape 2 is a PI high-temperature adhesive tape.

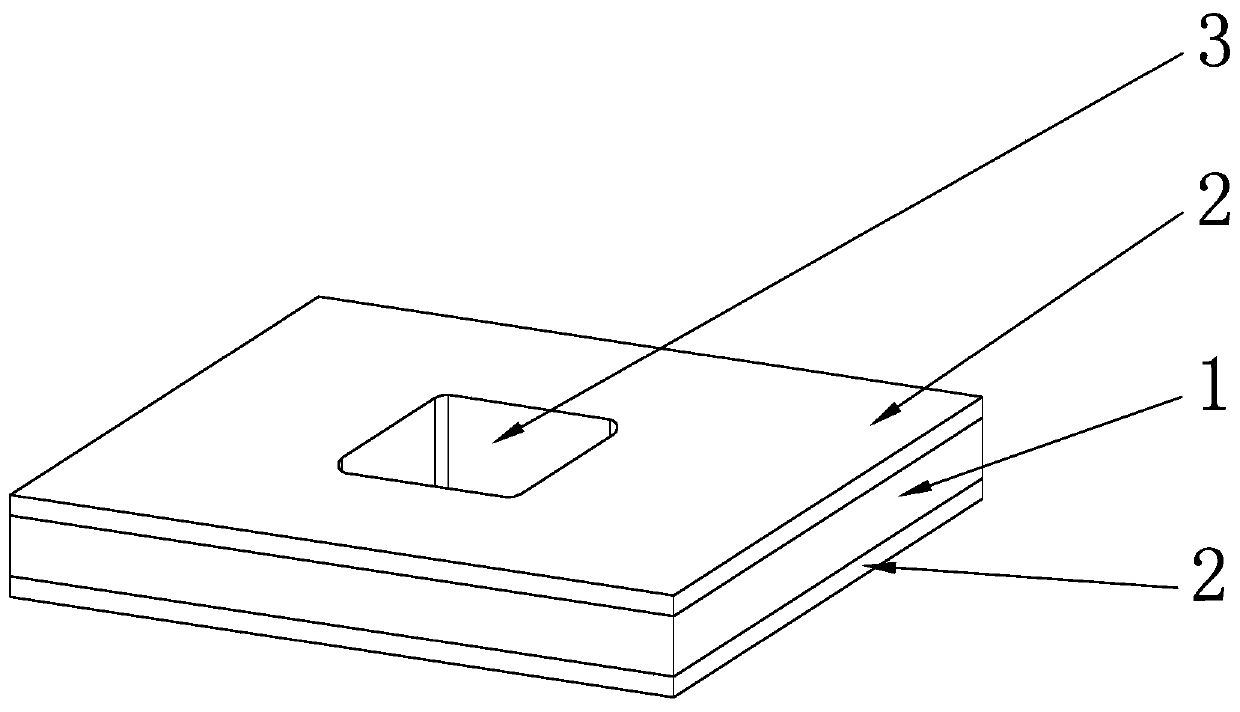

[0028] S03. According to the size of the copper block 4 to be put in, mill the through hole 3 at the predetermined position of the double-sided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com