Hydrodynamic machine, in particular hydrodynamic retarder

A technology of hydraulic reducer and hydraulic machinery, which is applied in the field of hydraulic machinery and can solve problems such as high cost, high input pressure, cost of funds and power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

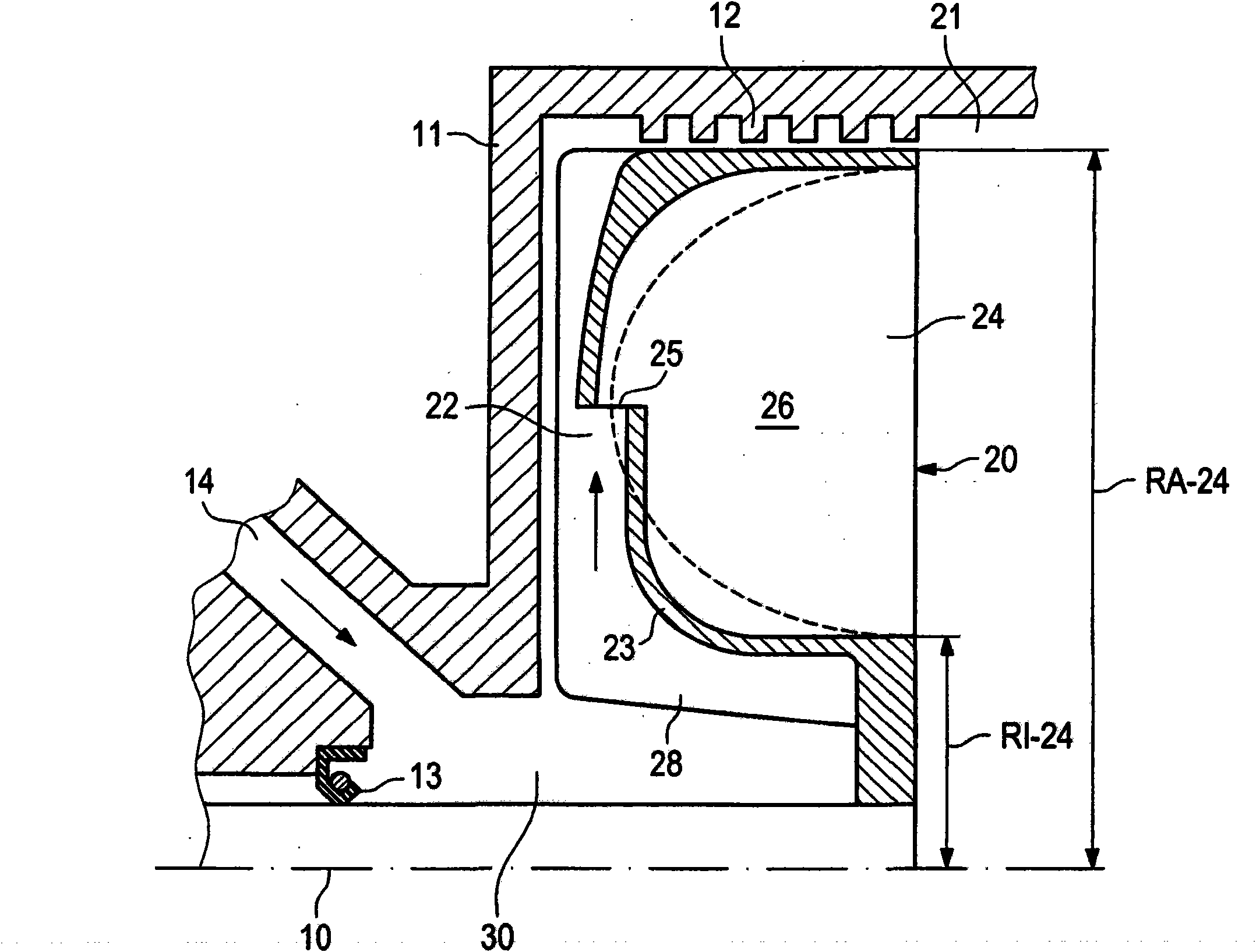

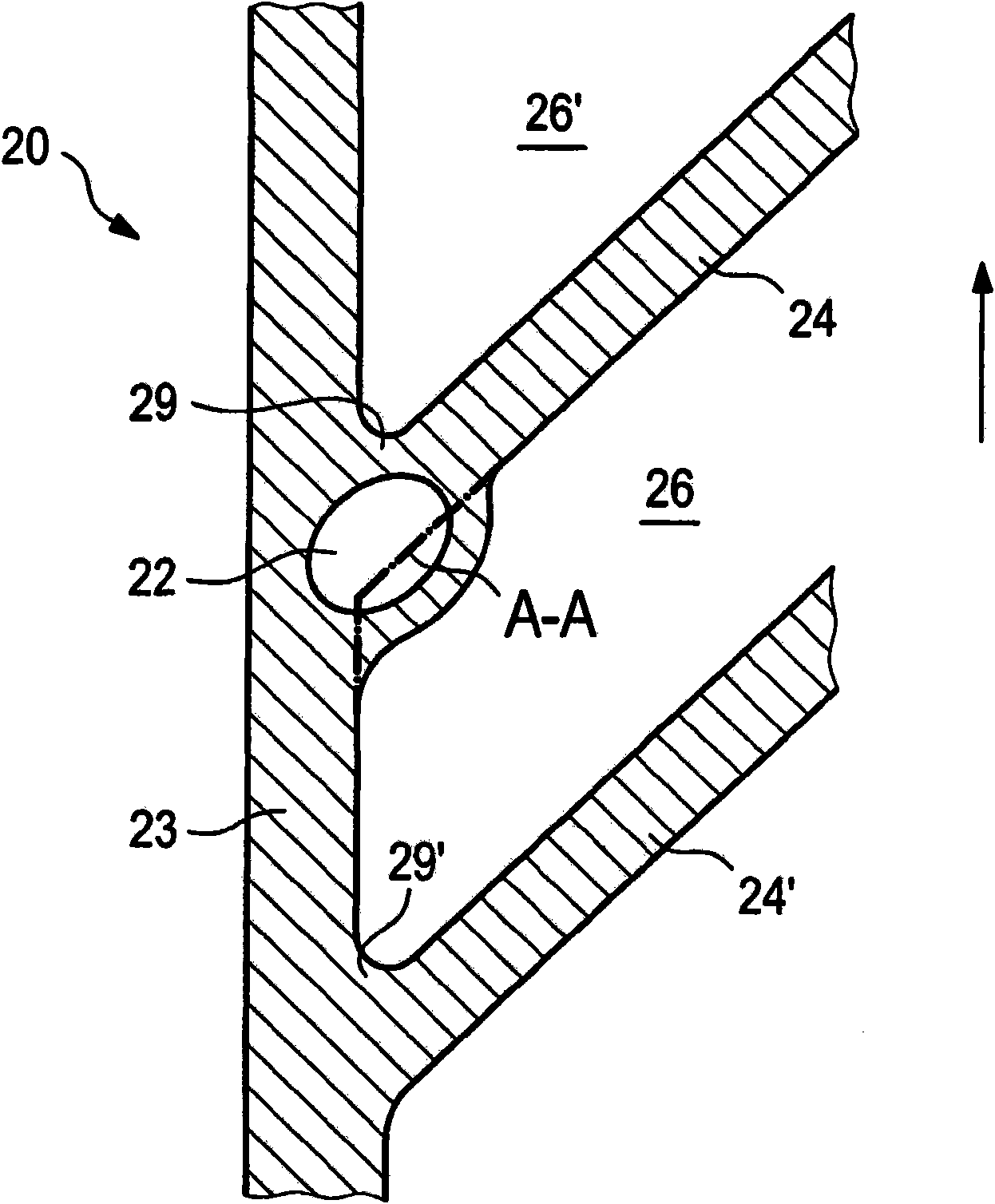

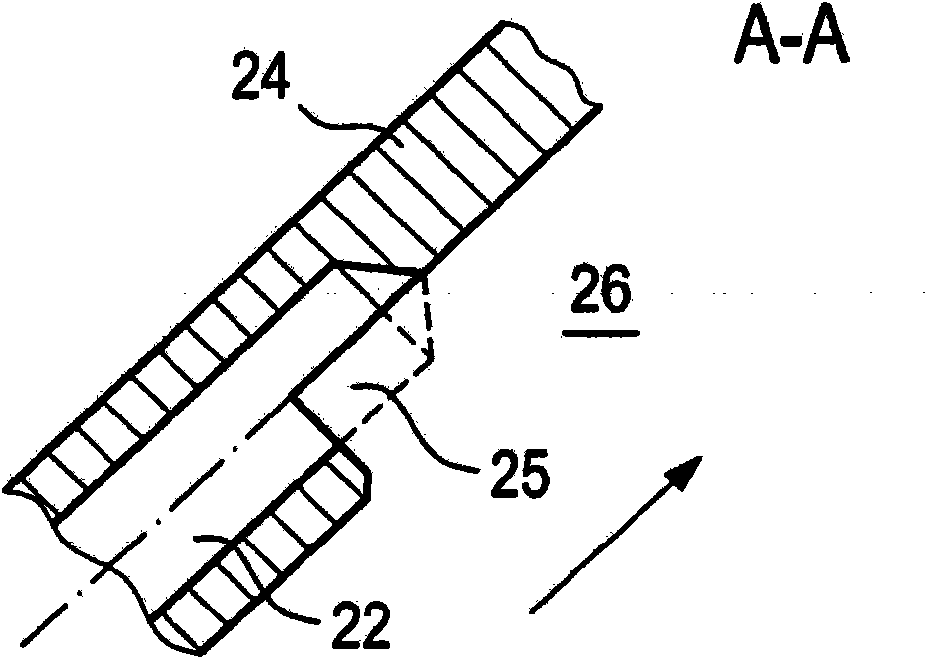

[0026] figure 1A section of the hydrodynamic machine according to the invention is shown along the axis of rotation 10 , having a primary impeller 20 arranged therein. The primary impeller 20 is accommodated here in a machine housing 11 which is provided with a gap seal 12 on the outside relative to the primary impeller 20 . An axial seal 13 is also mounted between the axis of rotation 10 and the housing 11 . The working medium 30 is injected via the supply line 14 into the chamber thus formed (in the direction of the arrow), and as soon as the chamber rotates, the working medium is sucked into the primary impeller 20 via the inlet channel 22 in the torus-shaped working chamber 21 of the machine. In the torus wall 23 . The feed channel 22 is mounted radially from the inside to the outside in the annular wall 23 so that the conveyance of the working medium 30 is supported centrifugally. The inlet channel 22 opens approximately at half the height between the outer diameter R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com