Rigid-flexible combined plate and method for plugging blind buried hole thereof

A rigid-flex board, blind and buried via technology, applied in the structural connection of printed circuits, printed circuit components, electrical components, etc., can solve problems such as increasing production costs, achieve high flatness, reduce production costs, and reduce board surface. High flatness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention are described in detail below:

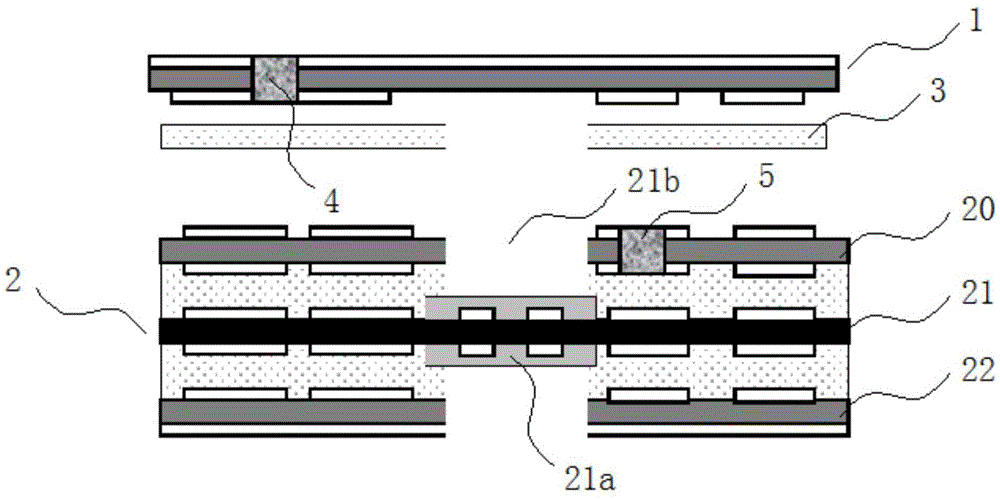

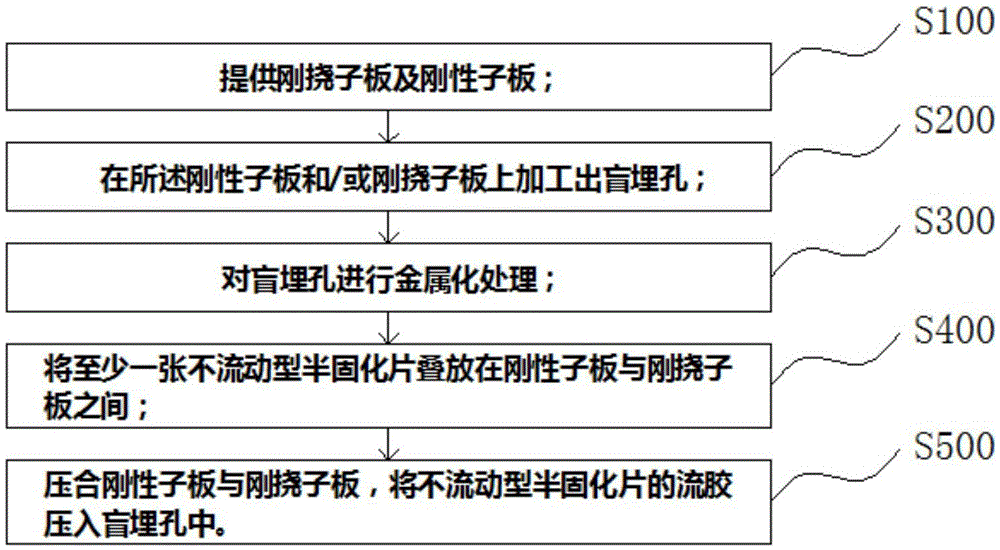

[0034] like figure 1 As shown, the rigid-flex board described in this embodiment includes a rigid sub-board 1 and a rigid-flex sub-board 2, the rigid sub-board 1 is fixed on the rigid-flex sub-board 2, and the rigid sub-board 1 and / or The rigid-flex sub-board 2 is provided with a blind buried hole, and at least one non-flowing prepreg 3 is arranged between the rigid sub-board 1 and the rigid-flexible sub-board 2 , and the blind buried hole passes through the flow of the non-flowing prepreg 3 Gum filling. The above-mentioned rigid-flex board realizes the filling of blind buried holes on the rigid-flex board by arranging at least one non-flowing prepreg 3 between the rigid sub-board 1 and the rigid-flex sub-board 2 , thus simplifying the resin plug holes. process, without special plugging equipment and resin, greatly reducing production costs. Moreover, the rigid-flex bonded board obtained by pressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com