Pipe fitting packaging and fixing support assembly facilitating loading, unloading and transporting

A technology for fixing brackets and components, applied in the direction of transportation and packaging, packaging, external frames, etc., can solve the problems of pipe deformation, increased scrapping, container collision, etc., to achieve the effect of convenient loading and unloading, avoiding scrapping, and avoiding deformation under pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Feature and advantage of the present invention are described in detail as follows in conjunction with accompanying drawing:

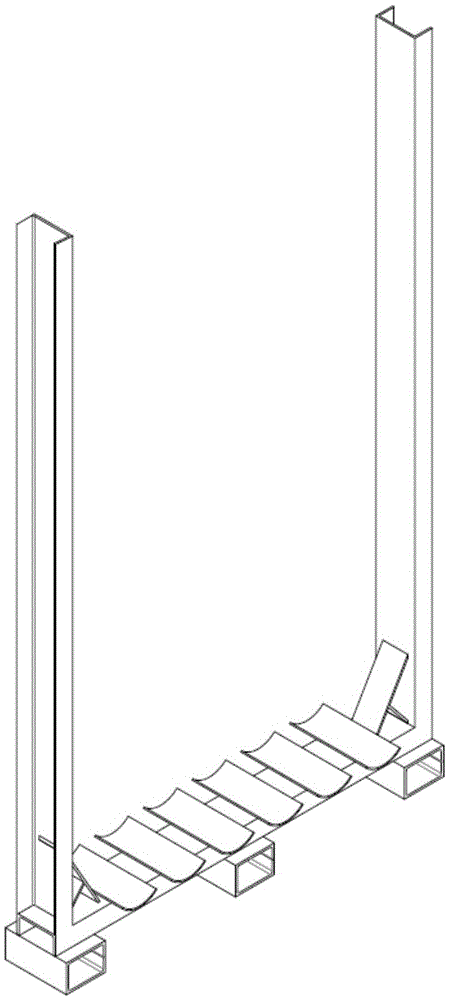

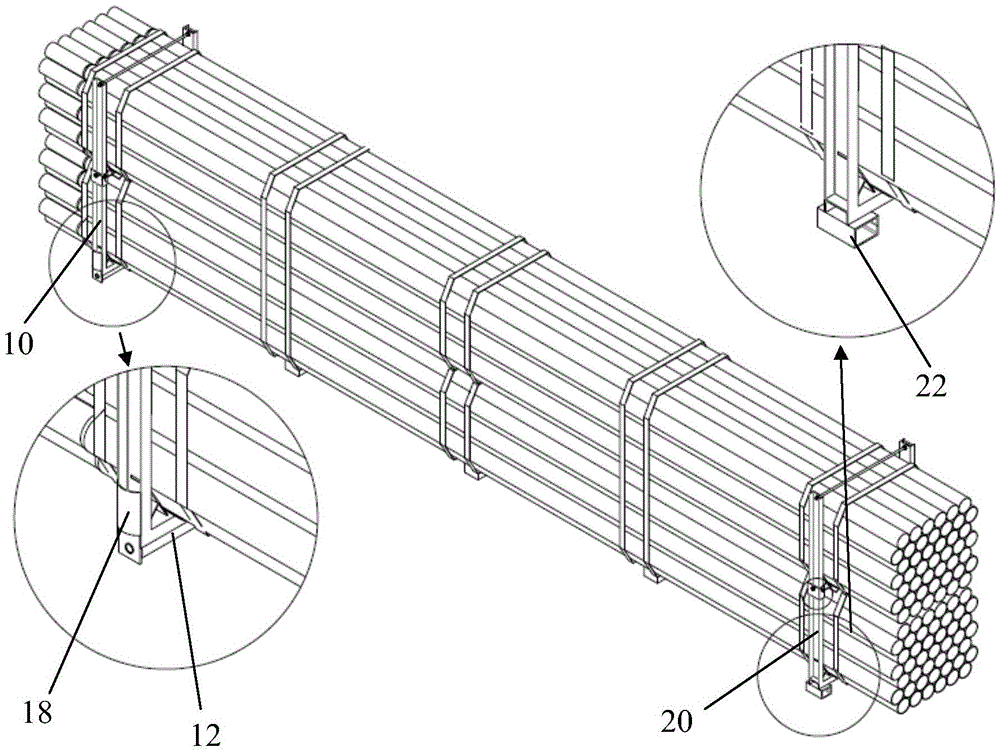

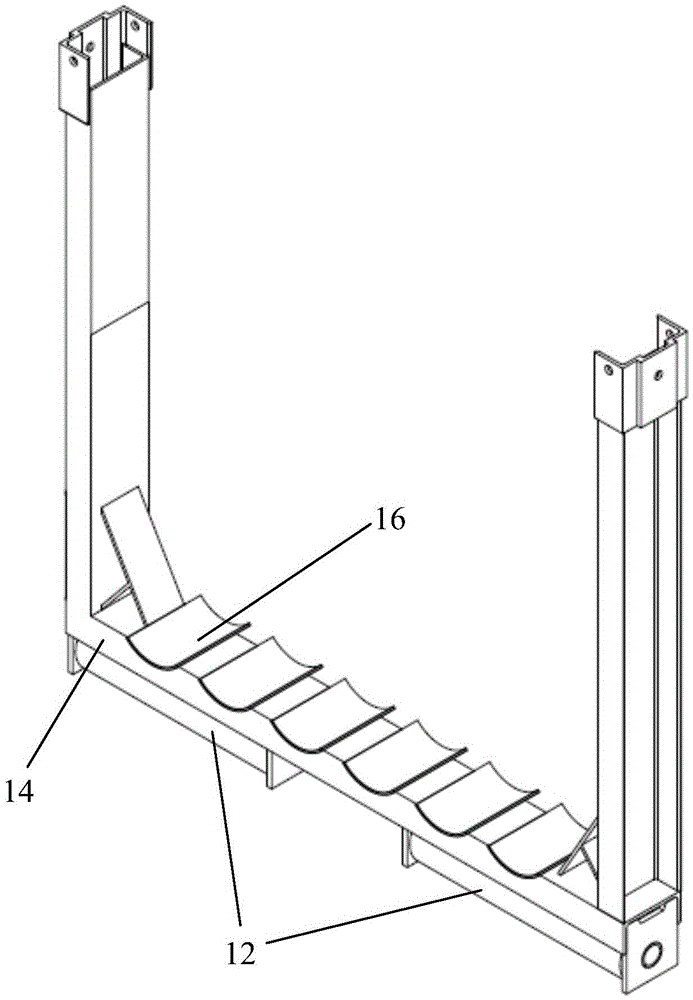

[0017] refer to figure 2 Shown is a schematic diagram of a pipe fitting packaging and fixing bracket assembly that is easy to load, disassemble and transport in the present invention and a packaging assembly of pipe fittings. The packaging and fixing bracket assembly includes a front bracket 10 and a rear bracket 20 in a U-shaped structure, combined with image 3 and Figure 4 , the bottom of the front support 10 is a roller support structure 12, the bottom of the rear support is a planar support structure 22, and the lower support horizontal frames 14 and 24 of the front support and the rear support are provided with a plurality of pipe fittings Placed arc structures 16 and 26.

[0018] When using the pipe fitting packaging fixing bracket assembly of the present invention to pack and load the pipe fittings, first place the pipe fittings one b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com