Heat radiator

A technology of a heat sink and a heat sink set, which is applied in cooling/ventilation/heating transformation, electrical components, electric solid devices, etc., can solve the problems of heat pipe deformation and affect the heat dissipation efficiency of the heat sink, so as to reduce pressure and avoid pressure. Deformation, the effect of ensuring heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

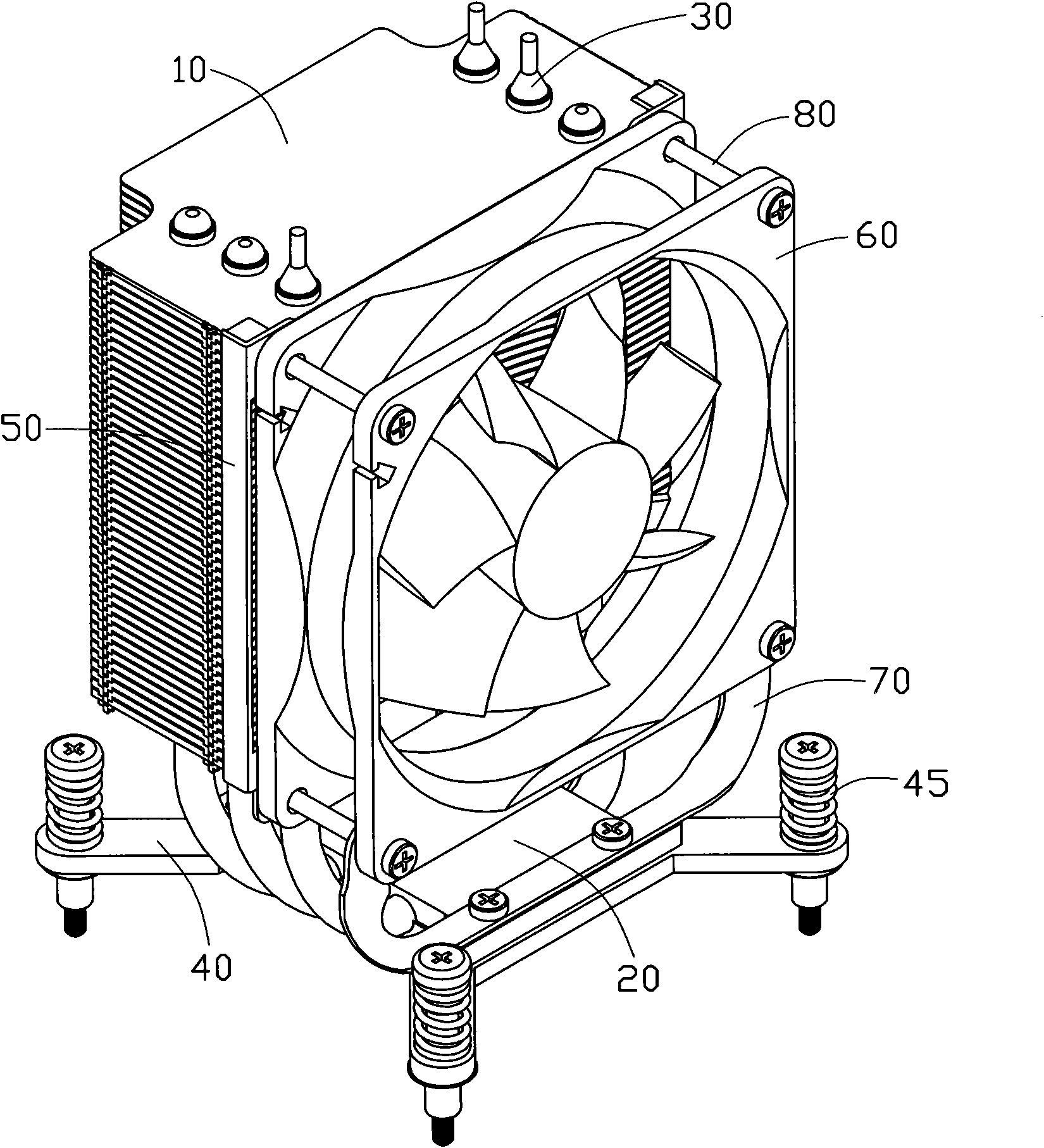

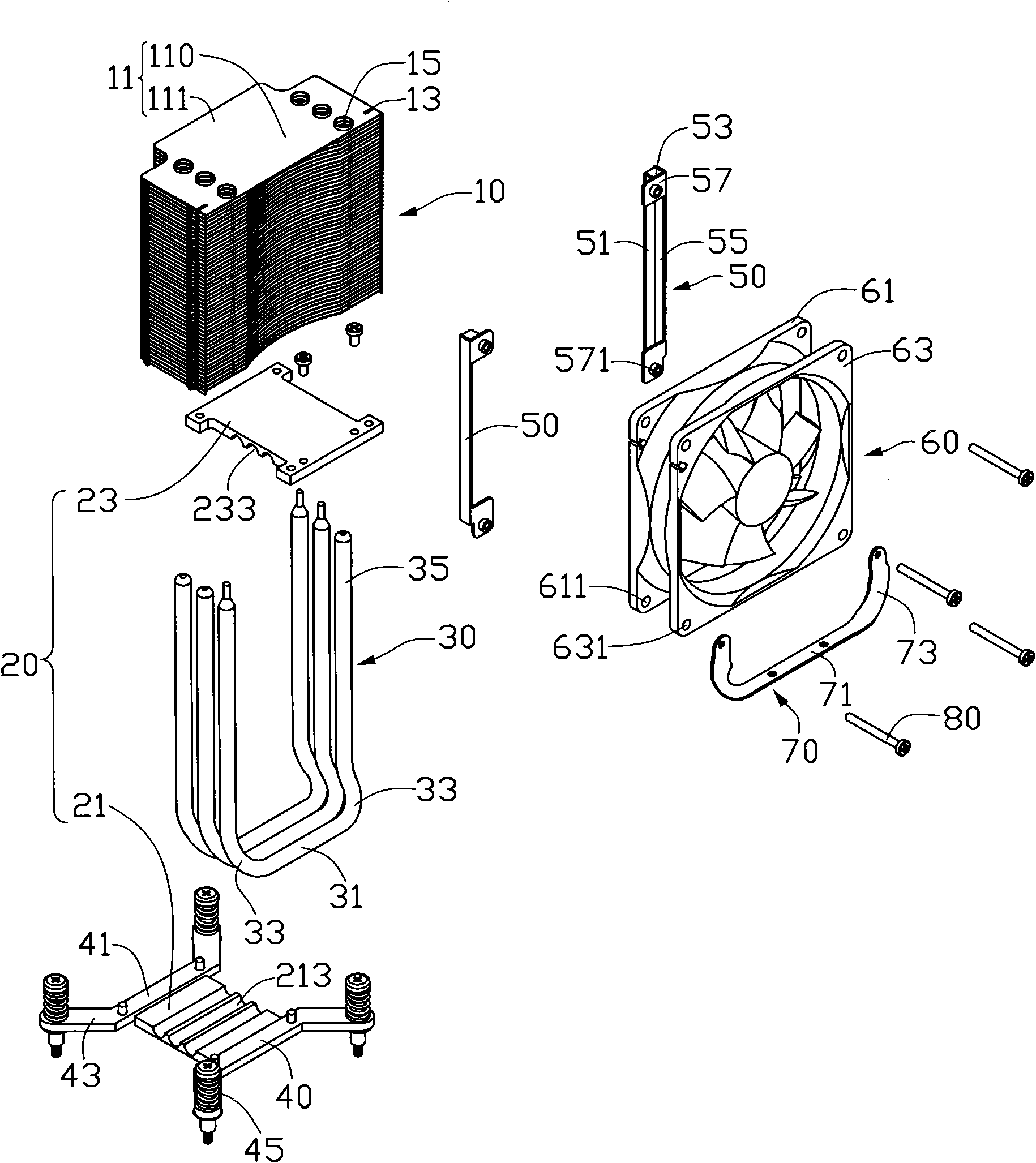

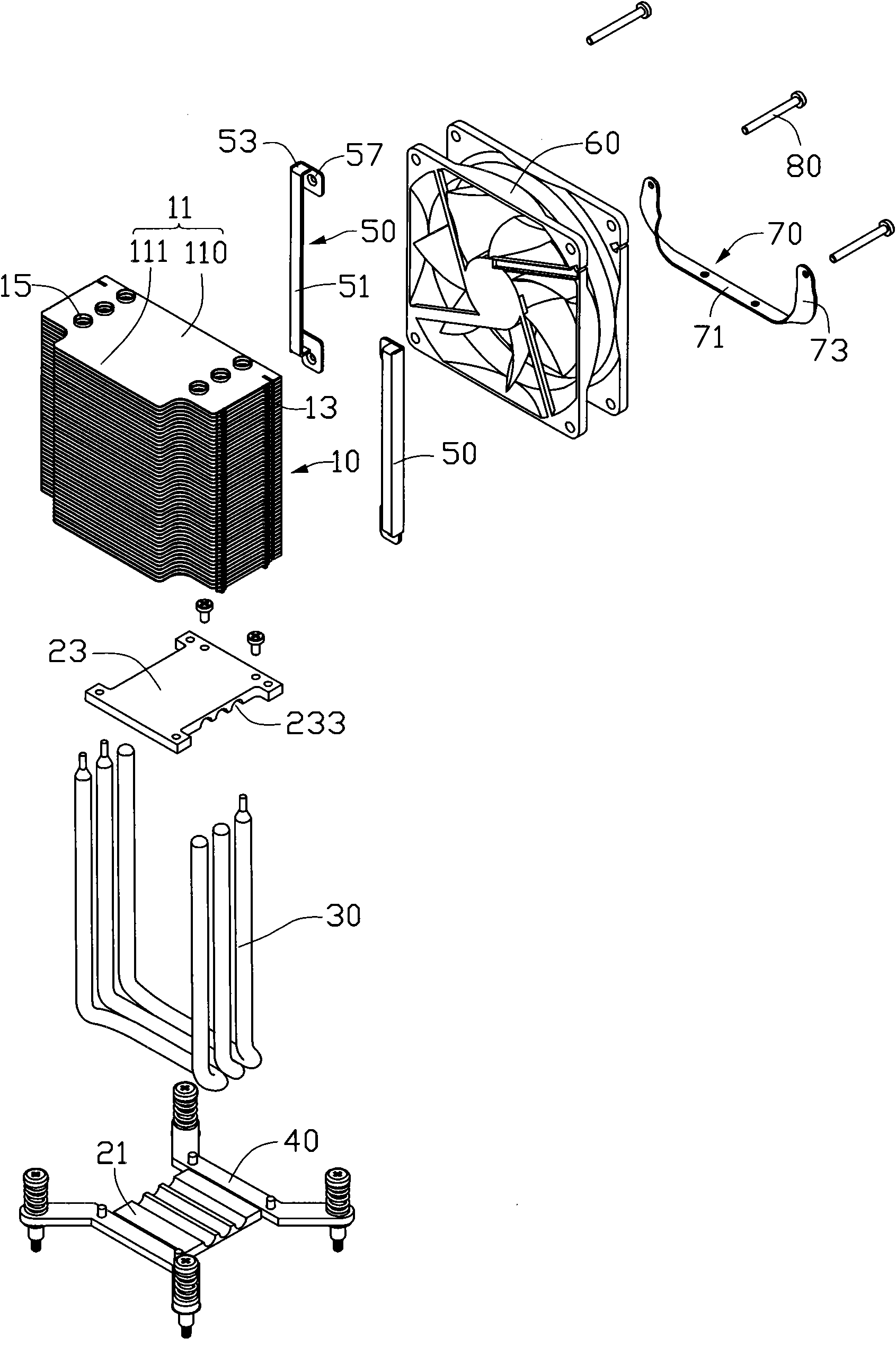

[0011] Such as figure 1 and figure 2 As shown, the heat dissipation device of the present invention is used to dissipate heat from a heat-generating electronic component (not shown) fixed on a circuit board (not shown). The heat dissipation device includes a base plate 20 in contact with the heat-generating electronic component, a heat sink set 10 above the base plate 20, three heat pipes 30 connecting the heat sink set 10 and the base plate 20, and two fans installed on one side of the heat sink set 10. The fixing frame 50 , a fan 60 connected with the fan fixing frame 50 , a supporting frame 70 connecting the fan 60 and the substrate 20 , and two fixing frames 40 fixing the substrate 20 on the circuit board.

[0012] The three heat pipes 30 are arranged at intervals and are all U-shaped. Each heat pipe 30 includes a straight evaporating section 31 , two connecting sections 33 bent and extending from opposite sides of the evaporating section 31 , and two condensing section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com