Rectangular tube bundle heat exchanger adopting swirl plate support and its intensified heat-conduction method

A swirl fin and heat exchanger technology is applied in the field of rectangular tube bundle heat exchangers, which can solve the problems of large consumption of metal materials, easy leakage of plate heat exchangers, and high operating energy consumption, and achieves increased flow speed, reduced length, Overcome the effect of pipe wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

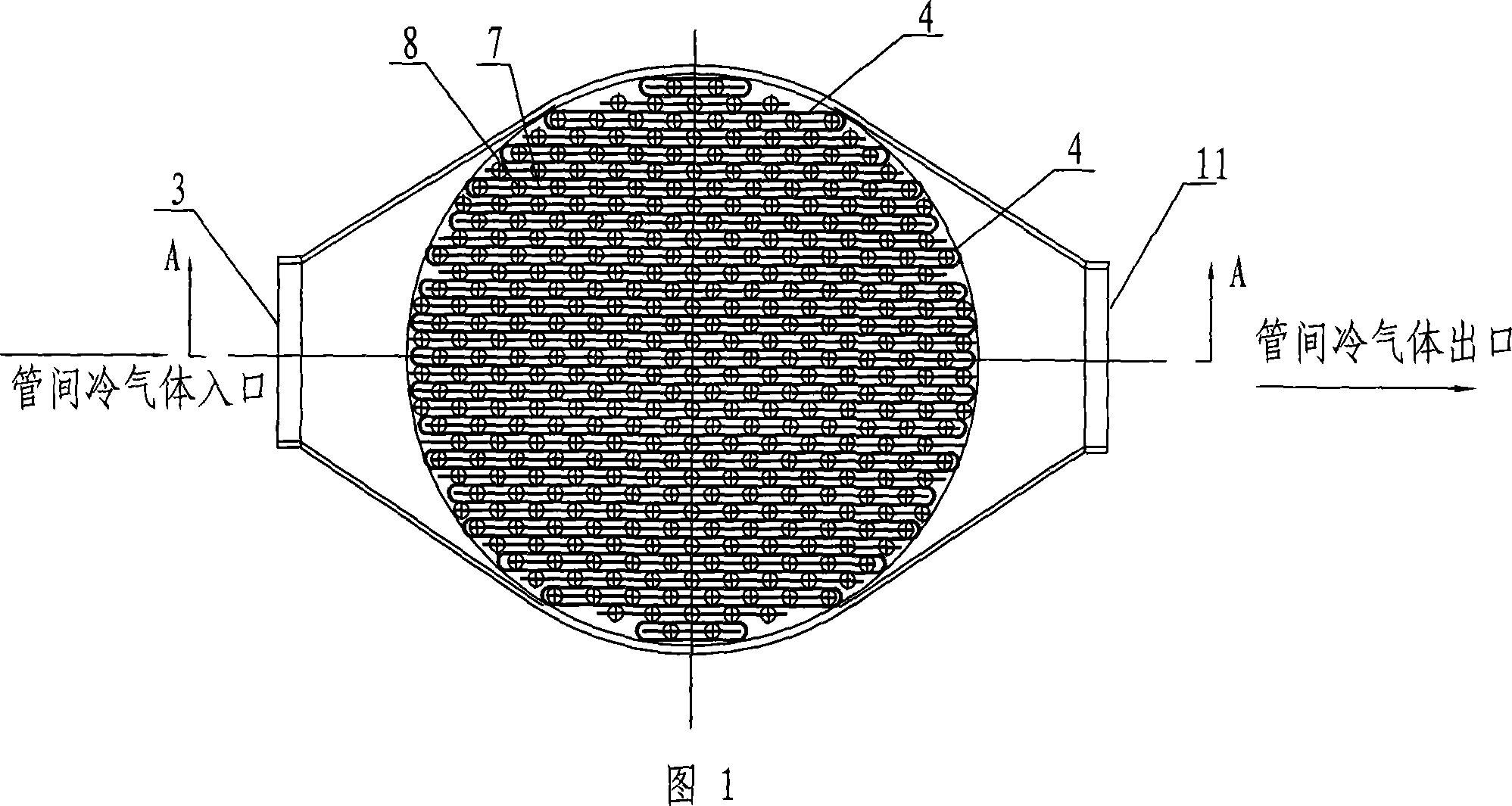

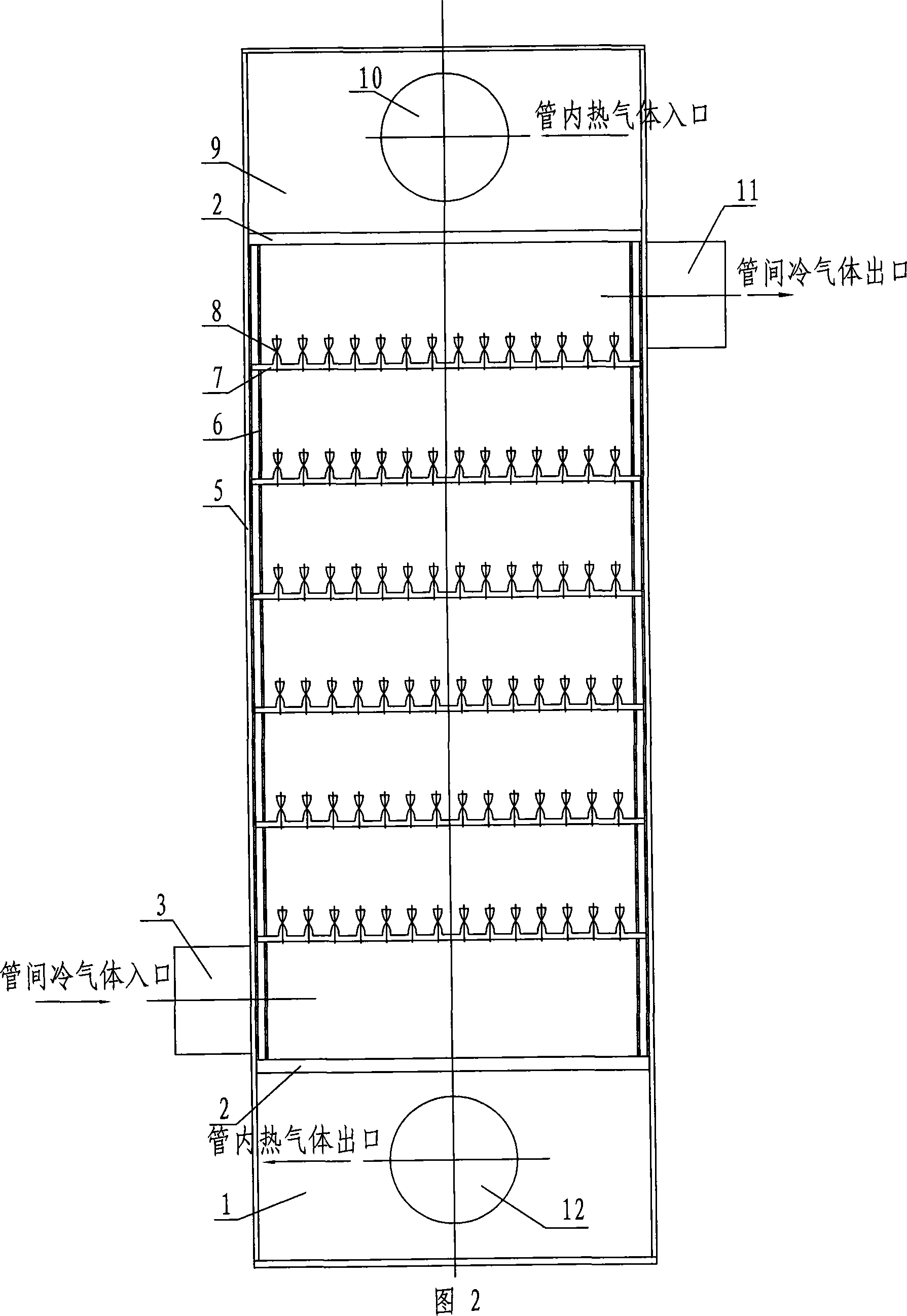

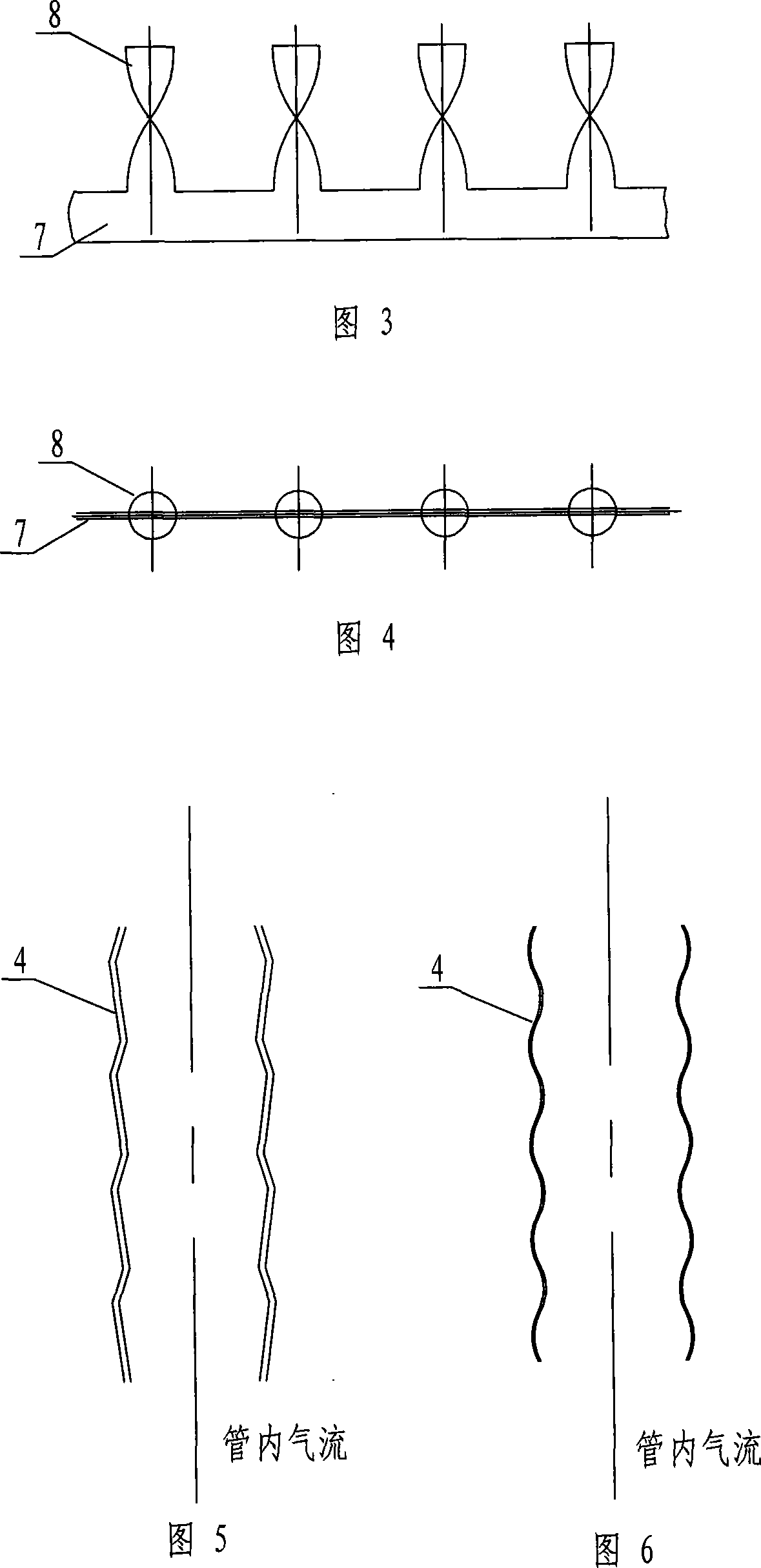

[0023] Figures 1 and 2 show a structural form of a rectangular tube bundle heat exchanger supported by swirl fins in the present invention. As shown in Figures 1 and 2, the rectangular tube bundle heat exchanger supported by swirl fins includes a cylinder 5, several rectangular tube bundles 4 with different widths and parallel to each other placed in the cylinder 5 and along the axis of the cylinder , the tube sheet 2 placed at both ends of the rectangular tube bundle 4, the upper and lower heads 1, 9 connected to the tube sheet 2 at both ends, and the inlet and outlet interfaces 10, 12, 3, 11 between the tube side and the shell side of the heat exchanger, and the inlet and outlet of the tube side The interfaces 10, 12 are connected with the upper and lower heads 1, 9, the inlet and outlet interfaces 3, 11 of the shell side are connected with the cylinder body 5, and the swirl plates 8 are arranged at approximately uniform intervals in the axial and lateral directions in the tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com