A method and device for treating phosphorus-containing wastewater using multi-plate baffle electrocoagulation technology

A technology of technical treatment and electrocoagulation, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. Complete and other problems, to avoid the decline of electrolysis efficiency, avoid electrolysis short flow, reduce the effect of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

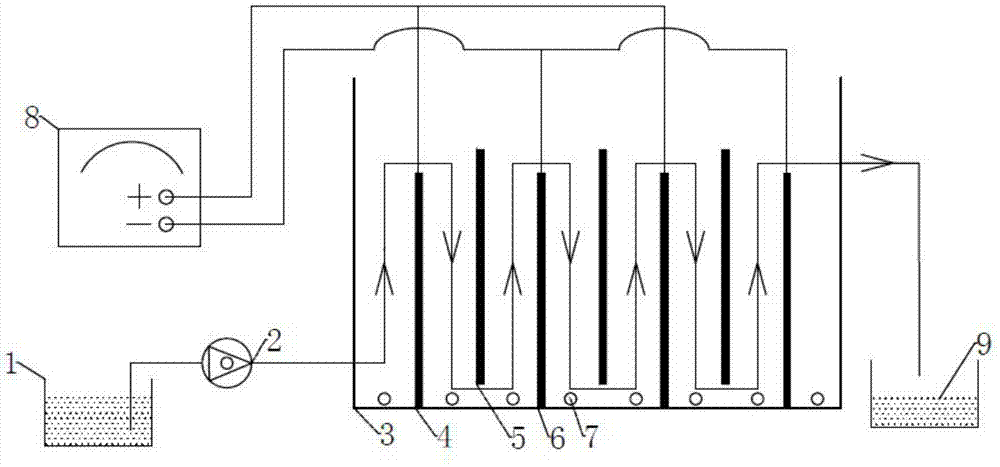

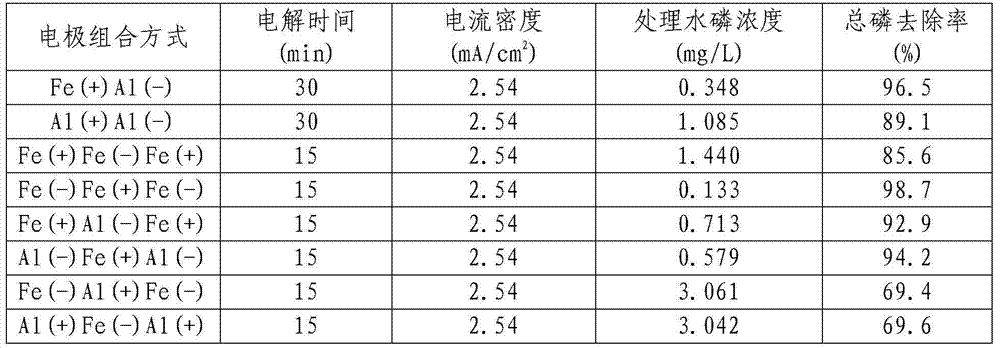

[0022] The multi-plate baffle electrocoagulation treatment process for phosphorus-containing wastewater uses high-molecular organic resin as the electrolytic cell, with a size of 200mmx200mmx200mm and an effective volume of 4L. Iron plate and aluminum plate are used as electrodes, the plate size is 105mmx87mmx2mm, and the effective area is 78.8cm 2 , set 8 kinds of anodes and cathodes and their arrangements, and the distance between the plates is 1.5cm. NaOH solution is used to adjust the pH value of wastewater to 7.0-8.0, the initial total phosphorus concentration is 10.0mg / L, and DC power supply is used for batch electrolytic treatment with a current density of 2.54mA / cm 2 , the aeration rate is 0.25L / (L·min), and the total electrolysis time is 15-30min. After the drained water was allowed to stand for 30 minutes, the total phosphorus concentration of the sample was measured. Table 1 shows the electroflocculation phosphorus removal effect of different cathode and anode pla...

Embodiment 2

[0026] The multi-plate baffle electrocoagulation treatment process for phosphorus-containing wastewater uses high-molecular organic resin as the electrolytic cell, with a size of 200mmx200mmx200mm and an effective volume of 4L. The iron plate is used as the anode and the aluminum plate is used as the cathode. The size of the plate is 105mmx87mmx2mm, and the effective area is 78.8cm 2. The distance between the anode and cathode plates is set to 4 levels, 1cm, 1.5cm, 3cm, 4cm. Use NaOH solution to adjust the pH value of wastewater to 7.0-8.0, the initial total phosphorus concentration is 10.0mg / L, and use DC power supply for batch electrolysis treatment with a current density of 2.54mA / cm 2 , the aeration rate is 0.25L / (L·min), and the electrolysis time is 30min. After the drained water was allowed to stand for 30 minutes, the total phosphorus concentration of the sample was measured. Table 2 shows the phosphorus removal effect of electrocoagulation with different plate spaci...

Embodiment 3

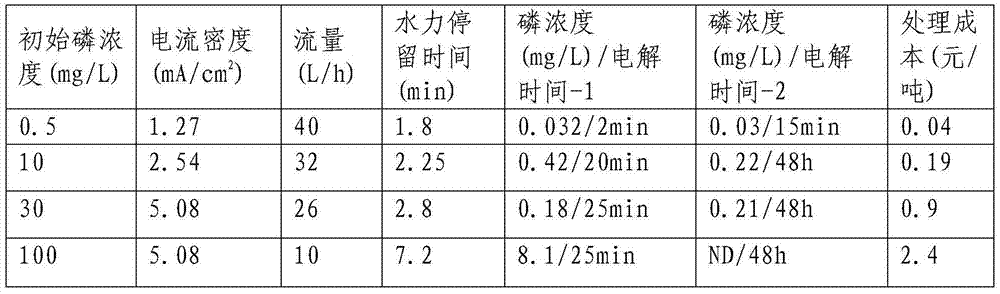

[0030] The multi-plate baffle electrocoagulation treatment process for phosphorus-containing wastewater uses high-molecular organic resin as the electrolytic cell, with a size of 140mmx55mmx185mm and an effective volume of about 1.20L. Set two sets of electrolysis, one set of non-induction, the electrode connection mode is Fe(+)-Fe(-)-Fe(+), the other set is induction electrolysis, the electrode arrangement is Fe(+)-Fe (sensing electrode plate)-Fe(-), the specifications of the plates are 145mmx60mmx2mm, and the effective area of the single plate is 71.5cm 2 , The distance between the positive and negative plates is 1.5cm. Using the baffle electrolysis method, the waste water folds and flows along the plate, the pH value of the waste water is adjusted to 7.0-8.0 by using NaOH solution, the initial total phosphorus concentration is 10.0 mg / L, and the DC power supply is continuously flowed for electrolysis treatment, with a conductivity of 150 μS / cm. The current density is 2.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com