Metal spacer bender bending device

A bending device and spacer technology, applied in the field of insulating glass auxiliary production equipment, can solve the problems of material waste, spacer deformation, deviation exceeding 0.3 mm, etc., to achieve smooth bending parts, avoid compression deformation, and uniform width Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

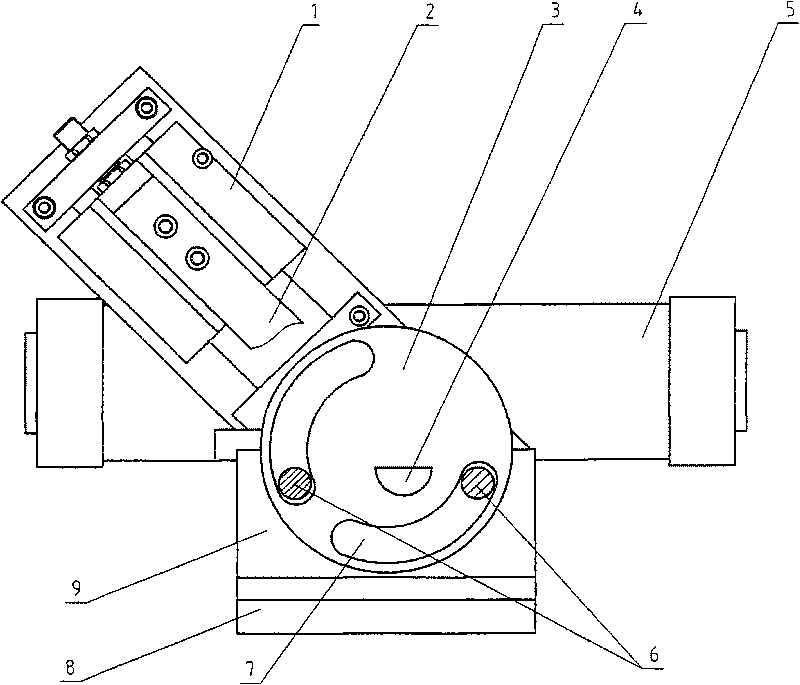

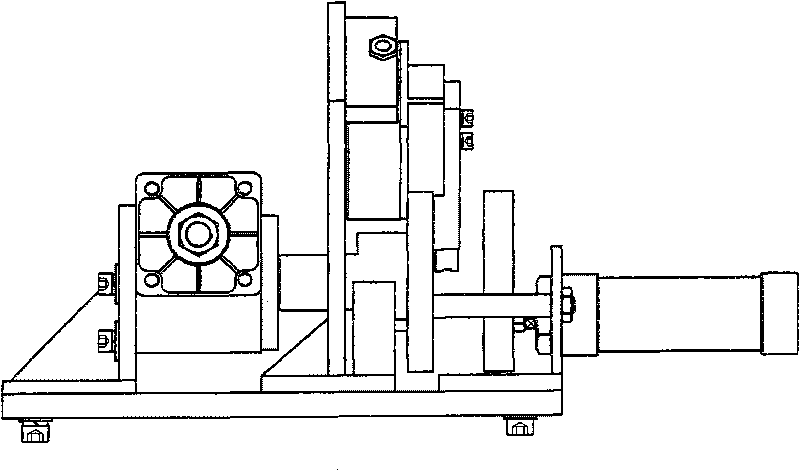

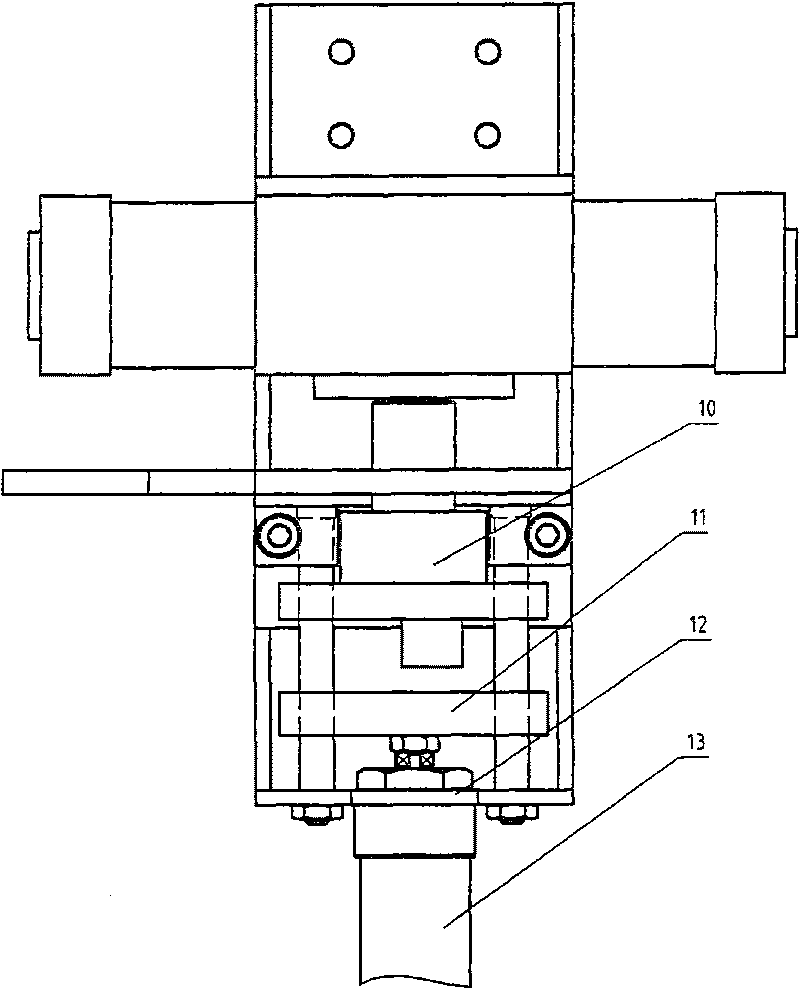

[0014] Figure 4 to Figure 6 Shown is a metal spacer bar bending machine bending device according to a specific embodiment of the present invention, including a known turntable 3, a positioning block 4, a rotary cylinder 5, a fixed block 9, a guide shaft 6, a pressure plate 11, a pressure plate The material cylinder 13 and the base plate 8, the fixed block 9 are used to fix one end of the guide shaft 6, the pressure material cylinder 13 is fixed on the pressure material cylinder seat 12, and a guide shaft 6 is connected between the fixed block 9 and the material pressure cylinder seat 12, Corresponding to the guide shaft 6, the turntable 3 is provided with an arc-shaped groove 7, and a through hole is correspondingly provided on the binder plate 11, and the binder plate 11 can slide along the guide shaft 6; A cantilever guide shaft 14, one end of which is fixed on the binder cylinder seat 12, and the other end is close to the plane of the turntable 3, and the position correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com