Device for detecting air impermeability of component and detecting method thereof

A technology of air tightness detection and parts, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, by measuring the increase and deceleration rate of fluid, and assisting non-electric fluid pressure control, etc., which can solve the problem of insufficient protection of parts installation and the result Inadequate precision, insufficient installation sealing, etc., to achieve the effect of convenient test installation, accurate measurement results, and guaranteed sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

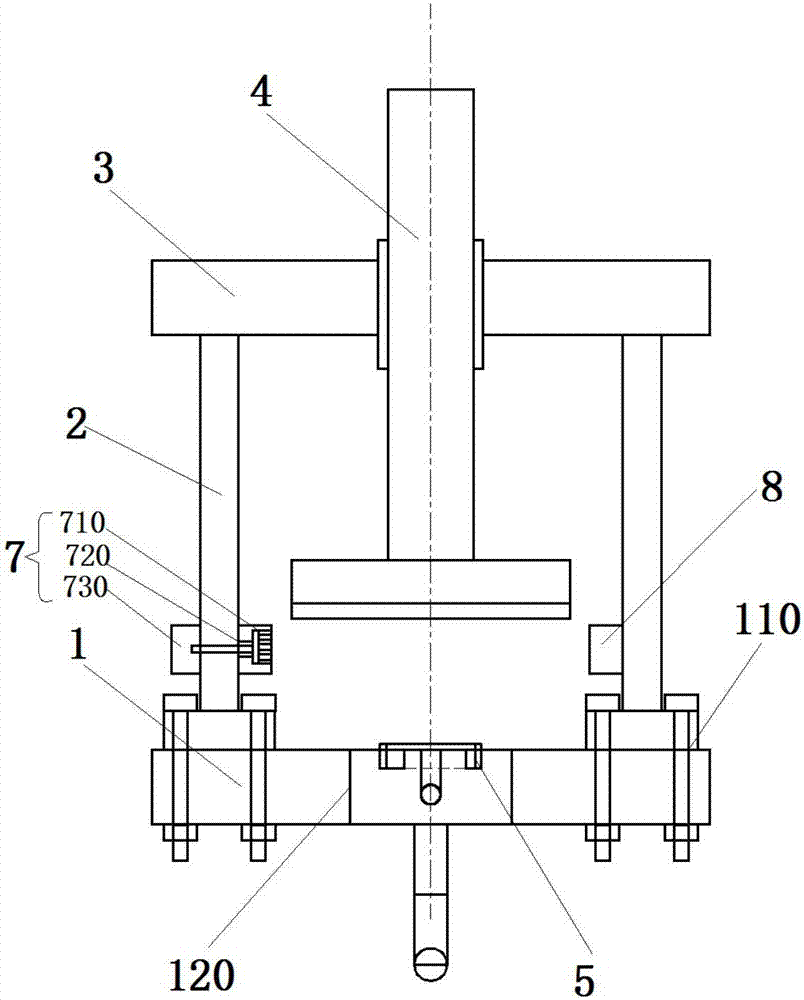

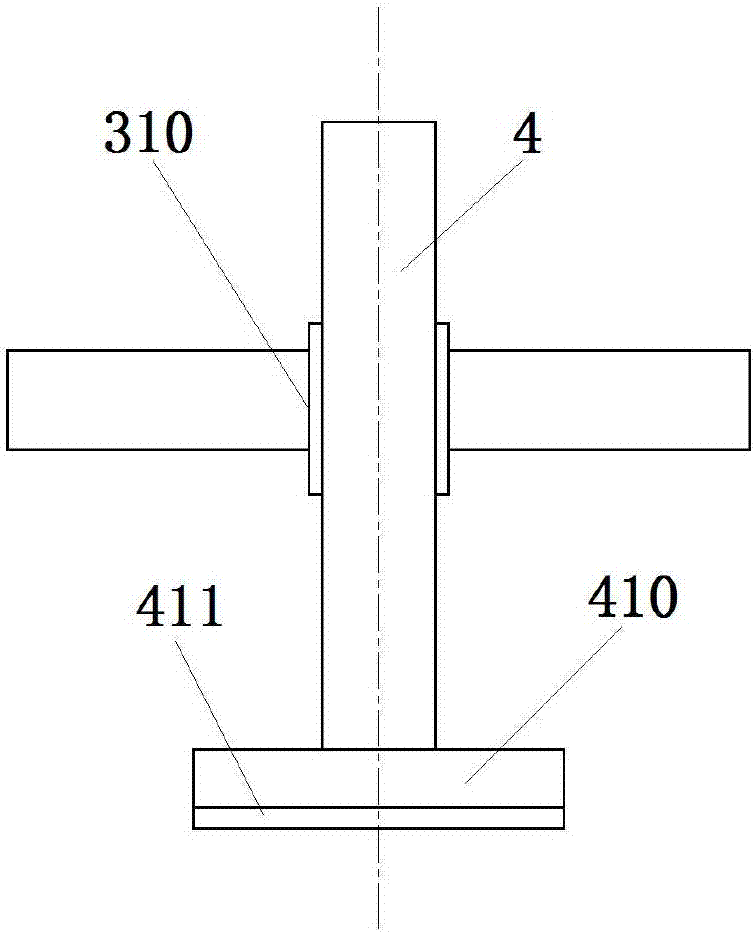

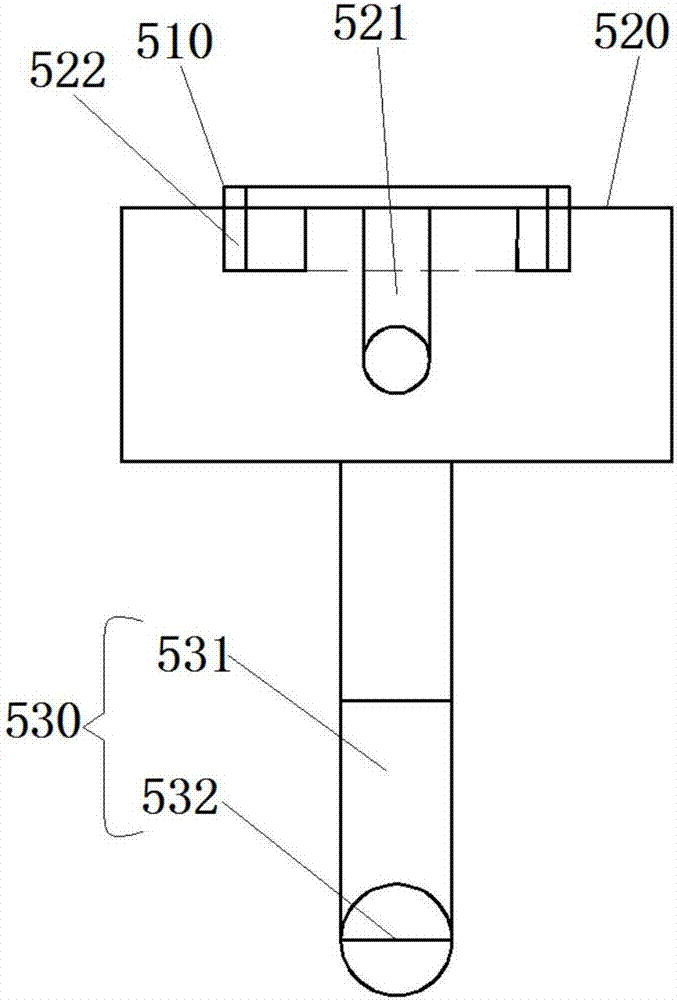

[0029] Please refer to Figure 1-Figure 4 , figure 1 Provide a schematic diagram of the overall structure of a part air tightness detection device for the present invention; figure 2 Provide a schematic diagram of the installation structure of the tooling mechanism for the present invention; image 3 A schematic diagram of the installation structure of the hydraulic action rod is provided for the present invention; Figure 4 A schematic diagram of the framework of the detection system is provided for the present invention.

[0030] Specifically, this embodiment provides a device for detecting air tightness of parts, which includes from bottom to top: a bottom plate 1, a support rod 2, an upper connecting plate 3, a hydraulic operating rod 4, and a tooling mechanism 5; wherein, the bottom plate 1 There are support rod mounting threaded holes 110 symmetrically arranged on both sides of the base plate 1; a through hole 120 is processed at the center of the base plate 1; the l...

Embodiment 2

[0041] Please refer to Figure 5 , Figure 5 The present invention provides a flow chart of a method for detecting the airtightness of parts.

[0042] Specifically, this embodiment provides a method for detecting air tightness of parts, using the device for detecting air tightness of parts described in Embodiment 1, including the following steps:

[0043] Step1, according to the shape of the detected part, select the corresponding mounting slot for the outer contour of the detected workpiece; and adjust the pressure regulating valve of the overpressure protection mechanism;

[0044] Step2, place the workpiece on the installation card slot for detecting the outer contour of the workpiece, press the hydraulic action lever down to compress the workpiece, start the gas compressor, open the two-position two-way manual valve, and the three-position three-way valve to inflate the container , pressure gauge 1 and pressure gauge 2 display the inflation pressure;

[0045] Step3, afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com