Transversely-wiping type windscreen wiper

A wiper and horizontal scraping technology, which is applied in the field of dirt devices, can solve the problems of the wiper blades being unable to move left and right, the phenomenon of rain followed by scraping, and dead angles that cannot be scraped, so as to avoid rain follow and scrape and prolong the aging time , The effect of smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

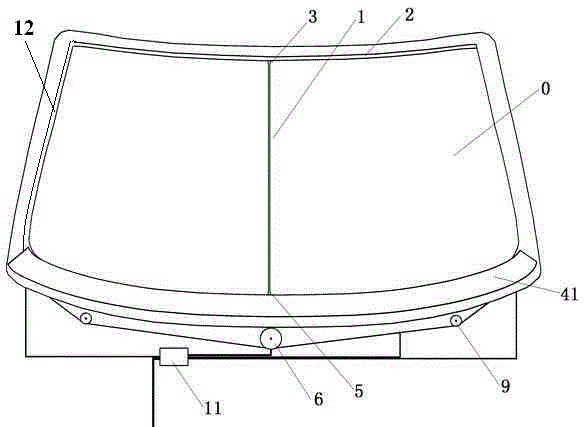

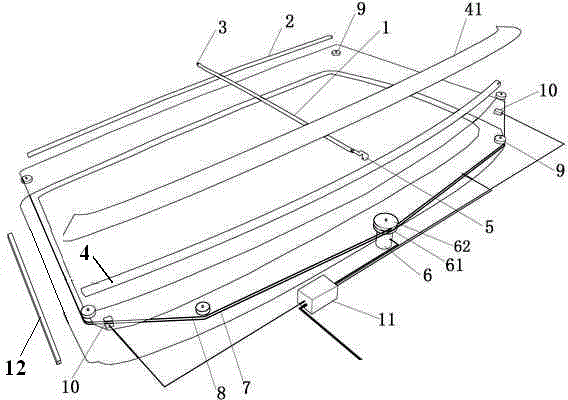

[0030] see figure 2 As shown, the horizontal wiper in this embodiment is mainly composed of a wiper blade 1, an upper slide rail 2, an upper slide block 3, a lower slide rail 4, a lower slide block 5, a motor 6, a guide elastic wheel 9 and a control switch 10 . The upper slide rail 2 is arranged on the upper edge of the windshield 0, and the upper slide rail 2 in this embodiment is a groove-shaped slide rail. The upper slider 3 is arranged on the upper slide rail 2, and can freely slide horizontally along the upper slide rail 2, such as Figure 4 , 5 As shown in . , the first roller 32 is located in the groove of the upper slide rail 2. The sliding rail 4 is arranged on the lower edge of the windshield 0, and the sliding rail 4 in the present embodiment is a groove-shaped sliding rail. The lower block 5 is arranged on the lower rail 4, and can slide freely along the lateral direction of the lower rail 4, such as Figure 4 As shown, the lower slider 5 in this embodiment ...

Embodiment 2

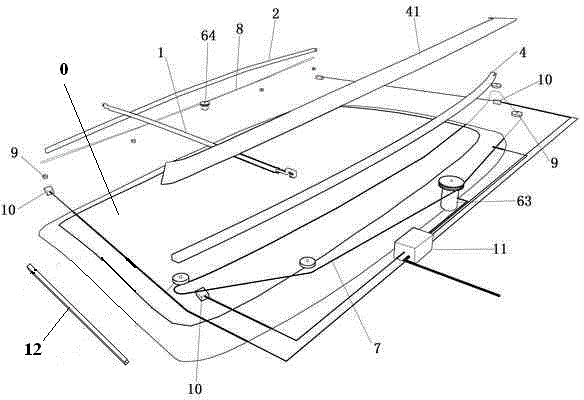

[0034] see image 3 As shown, the difference from Embodiment 1 is that in this embodiment, two motors are used to drive the reciprocating motion of the wiper blade 1, which are the first motor 63 fixedly connected to the lower slider 5 through the first transmission belt 7 and the first motor 63 through the The second transmission belt 8 is fixedly connected to the second motor 64 of the upper slider 3, and simultaneously, the upper slider 3 and the lower slider 5 are respectively provided with control switches for detecting their moving positions. When the upper slider 3 moves to the left end or the right end of the upper slide rail 2, the corresponding control switch for detecting its motion position controls the second motor 64 to rotate in reverse. When the lower slider 5 moves to the left end or the right end of the lower rail 4, the corresponding control switch that detects its motion position controls the first motor 63 to rotate in reverse.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com