Multi-tube intensive flexible efficient automatic tube insertion process

An automatic pipe threading machine and automatic threading technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of easy deformation of copper pipes, high production cost, low production efficiency, etc., to reduce labor demand and production. Cost and effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

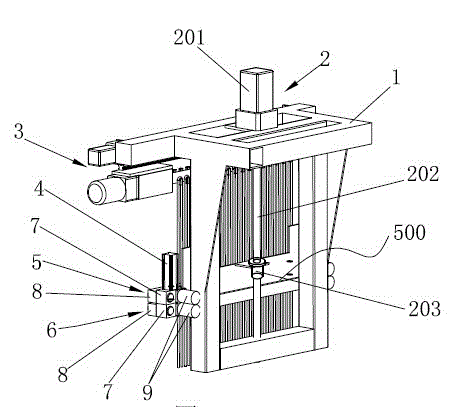

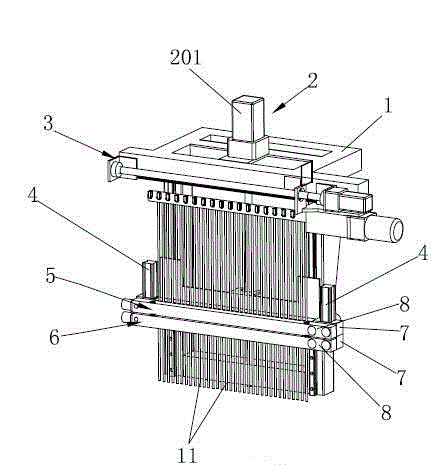

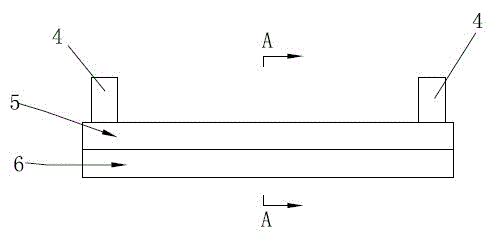

[0028] The present invention adopts automatic pipe threading machine to carry out flexible pipe threading, such as Figure 1~5 As shown, the automatic pipe threading machine includes a frame 1, a long U-shaped copper pipe positioning hanging rod device 3, a pinch device 500, a pinch device driving mechanism 2, a workbench (not shown in the figure), and a pinch device 500 The pinch drive mechanism 2 is driven to move up and down. The pinch drive mechanism 2 includes a servo motor 201 , a ball screw 202 and a lead screw nut 203 . The clamper 500 includes an upper clamper 5 and a lower clamper 6 arranged in parallel, and an up and down movement mechanism 4 is arranged between the upper clamper 5 and the lower clamper 6, and the upper clamper is driven by the up and down movement mechanism 4 5 moves relative to the lower clamp 6. The upper pinch device 5 and the lower pinch device 6 are respectively composed of a pinch rod 7 and a positioning pinch rod 8, and the positioning pinc...

Embodiment 2

[0039] Such as Figure 8 Shown is another expression of the invention. The pinch device 500 is composed of the upper pinch device 13 and the lower pinch device 14 crossing each other vertically to form a matrix grid. The copper pipes 11 are hung in a matrix on the hooks of the long U-shaped copper pipe positioning hanging rod device and precisely positioned. The copper tube 11 is positioned by the device 13 and the lower pinch device 14, so that each grid has only one copper tube (note: the bent long U-shaped copper tube counts as two pieces) and combs from the long U-shaped part of the copper tube , the pincer 500 combs the copper pipe to the vicinity of the copper pipe port, the lower pincer 14 keeps the position and the clamping force unchanged, the air bag of the upper pincer 13 degasses and moves upward for a certain distance, the air bag of the upper pincer 13 Inflate and clamp the copper pipe, the air bag of the lower pinch device 14 is deflated, and the upper pinch de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com