Entire-line non-pressure conveying method for bottle belts

A pressure and bottle belt technology, applied in the direction of conveyor objects, conveyor control devices, transportation and packaging, etc., can solve problems such as bottle deformation, affecting product quality, and no effective technical solutions for this, to prevent The bottle is deformed under pressure and the effect of improving the flexibility of speed control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

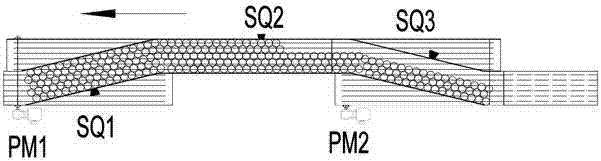

[0011] The present invention aims at the defect that belt conveying is easy to be deformed under pressure in the lightweight production of PET bottles. In order to improve product quality and reduce energy consumption, the present invention develops a whole line of pressure-free conveying method without major changes in the mechanical mechanism. , this conveying method can flexibly adjust the conveying speed, and minimize the bad working conditions of the bottle body being squeezed and deformed.

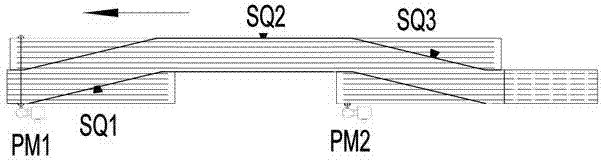

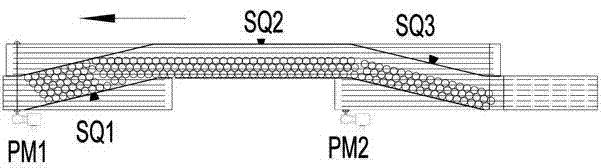

[0012] From the overview of the principle of the technical solution of the present invention: this kind of bottle belt whole line pressure-free conveying method is realized based on the conveying line and its drive controller. Its technical feature is that a sensor SQ1, SQ2, and SQ3 for detecting bottles are respectively set on the bottom of the arched position, the top of the arched position and the top of the arched position on a section of the arched conveyor belt in the conveyor l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com