Fully automatic vibrating cold extrusion plastic forming device and process for medium and small diameter internal threads

A plastic forming and internal thread technology, applied in the direction of tangent device, tangent feed device, manufacturing tools, etc., can solve the problems of low material utilization rate, low mechanical properties of thread teeth, large frictional resistance of thread surface, etc., to achieve material utilization rate High, improved smoothness, high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

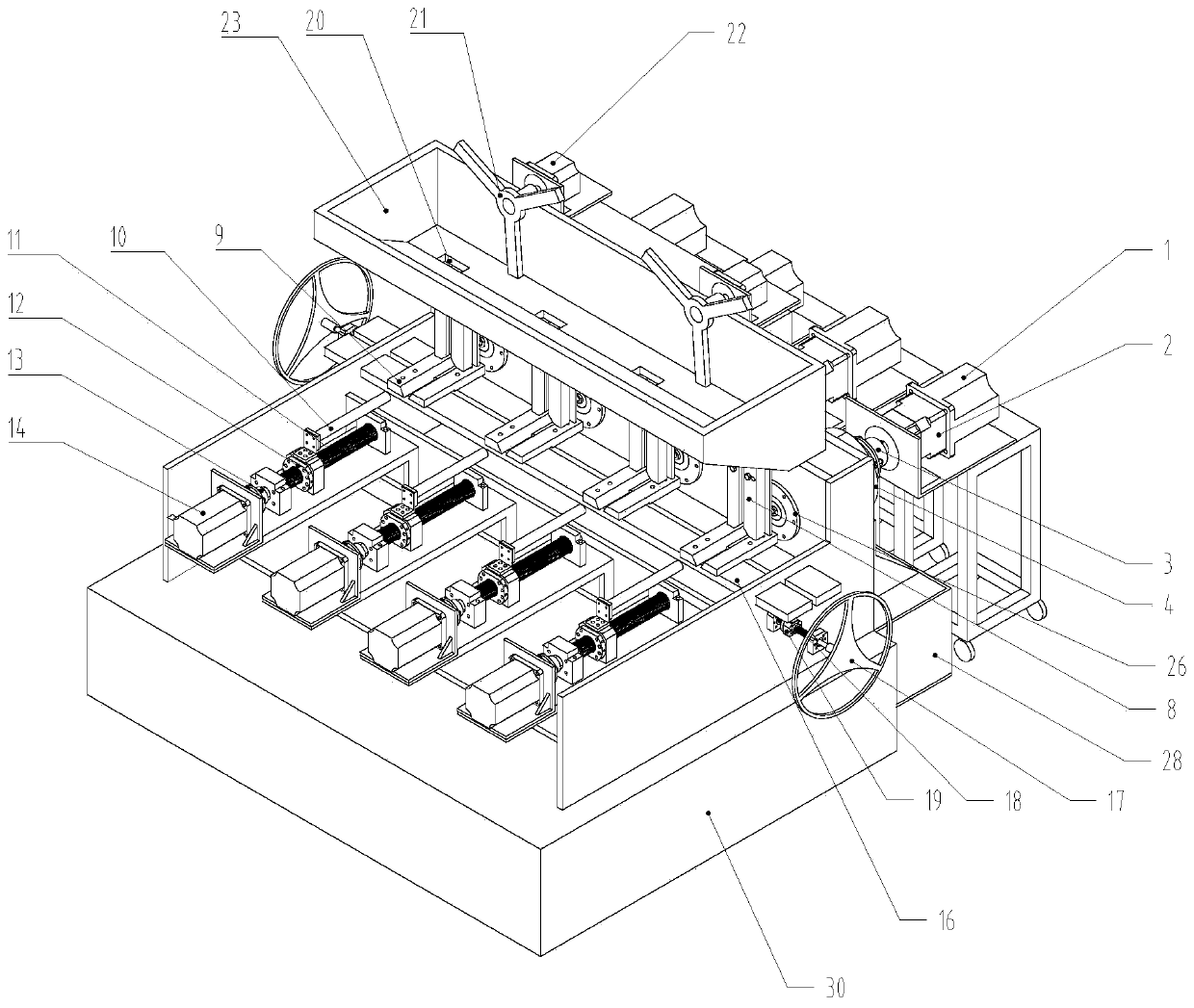

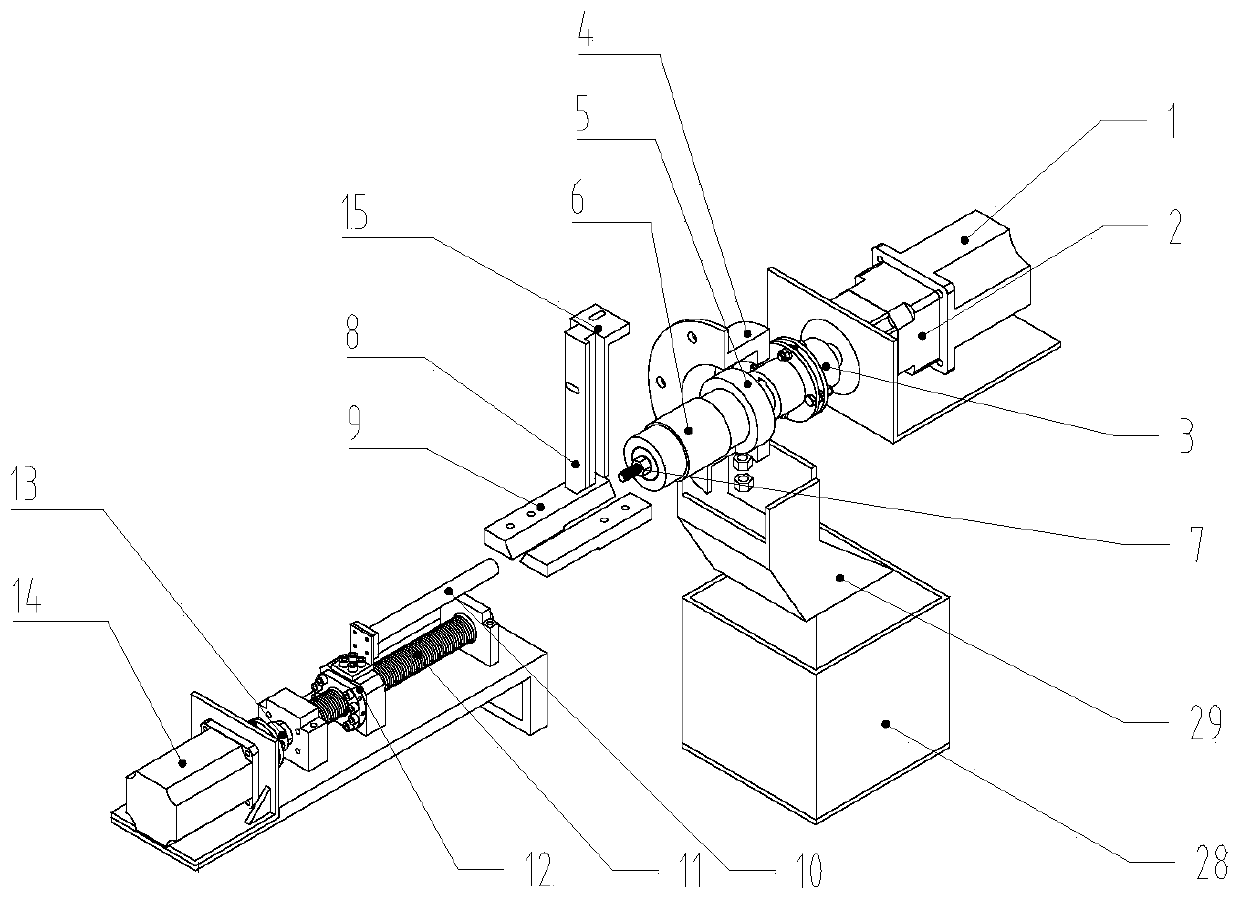

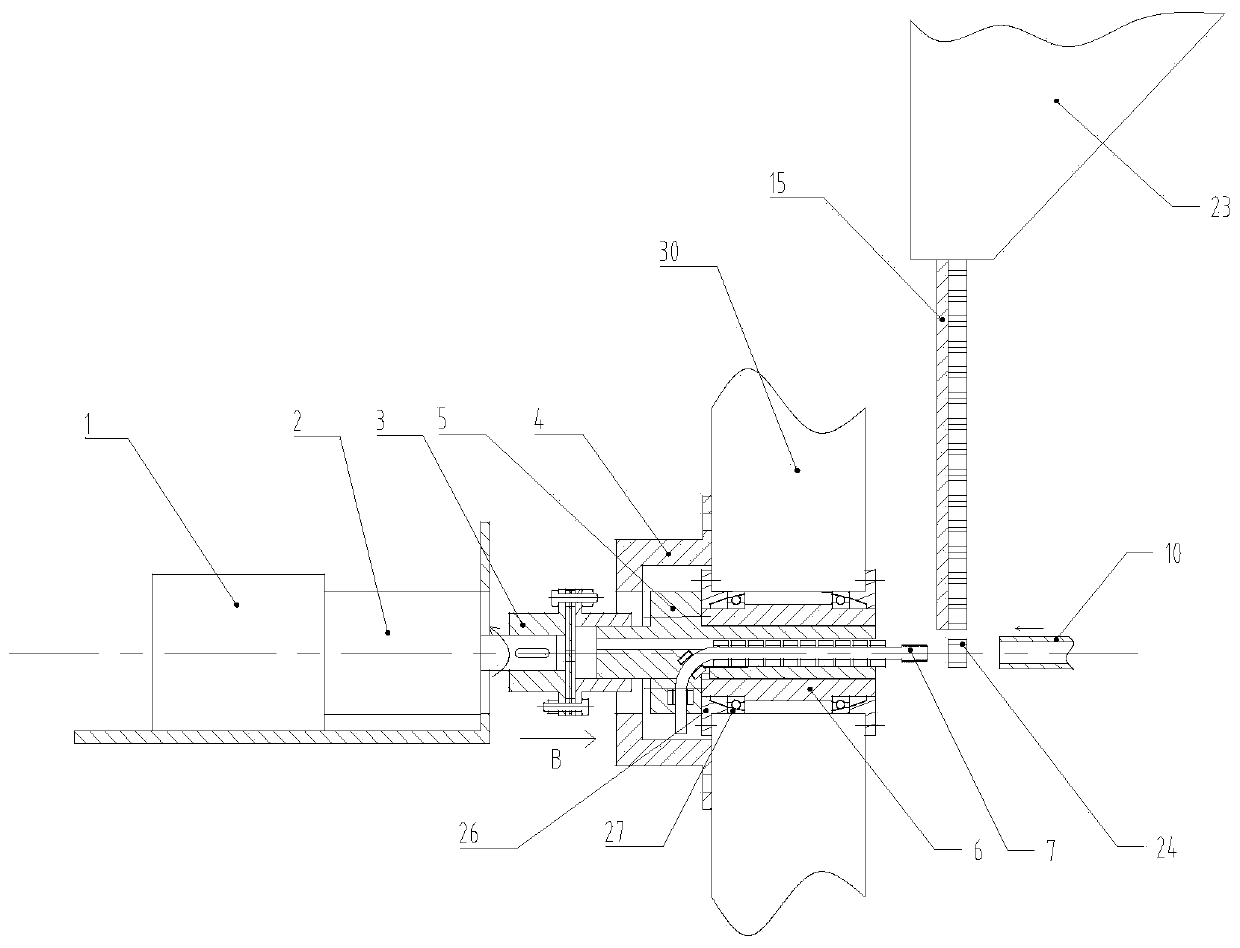

[0027] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , a full-automatic vibrating cold extrusion plastic forming device for small and medium-diameter internal threads, including four extrusion taps 7, each extrusion tap 7 has a 90° bent handle at the end, and the extrusion tap 7 starts from the drive shaft 5 Passing through inside, the drive shaft 5 power input end is provided with a through groove, and the width of the through groove is greater than the maximum dimension of the nut 24 to be processed (such as a hexagonal nut, the maximum dimension of the nut 24 to be processed is the outer circle dimension formed by the outer hexagon of the hexagonal nut), The bent shank of the extrusion tap 7 passes through the slot, and the input end of the drive shaft 5 is connected to the tapping motor 1 through the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com