Organic pretreatment system for food samples

A sample and organic technology, applied in the system field of sample pretreatment, can solve problems such as complex and tedious sample pretreatment, and achieve the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] For further illustrating the present invention, specifically illustrate in conjunction with following examples:

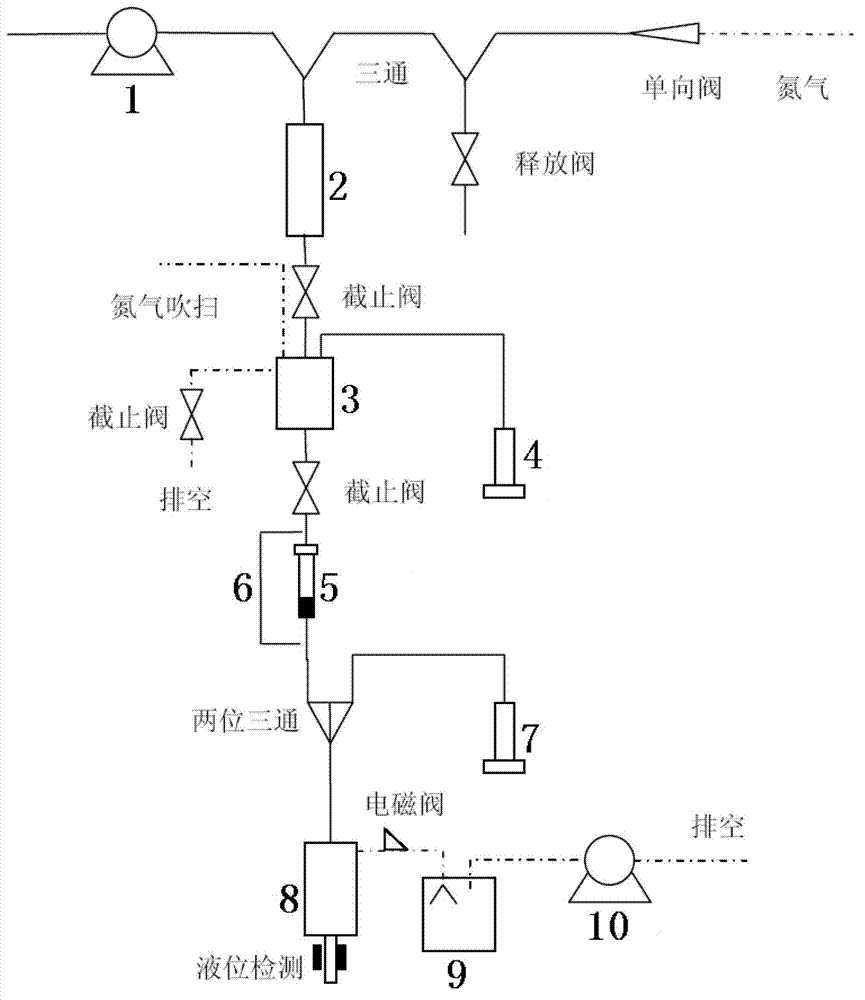

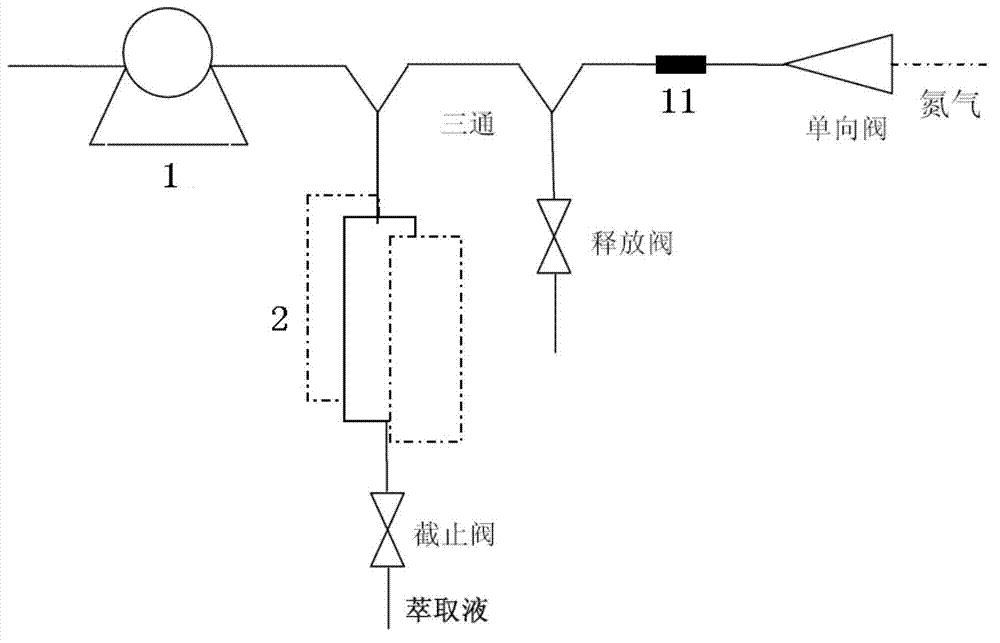

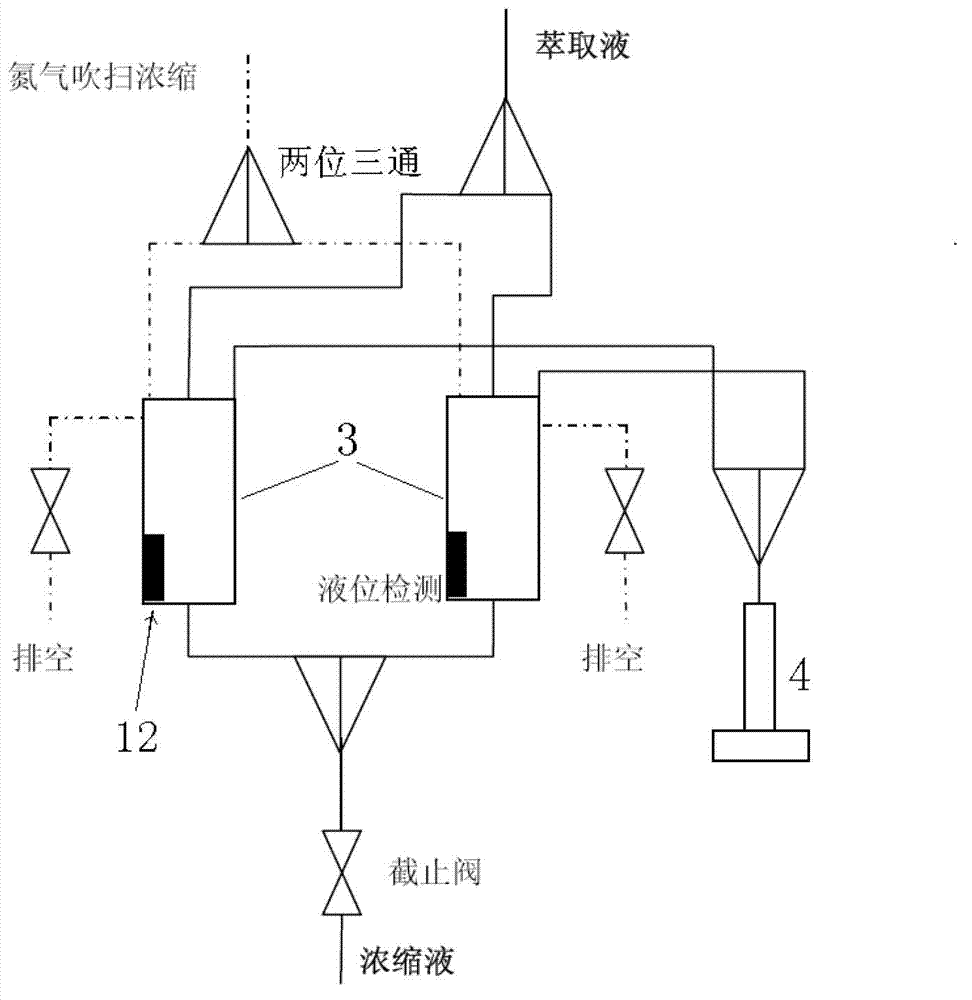

[0019] Such as figure 1 As shown, the present invention is a fully automatic food sample organic pretreatment system with functions of extraction, preconcentration, purification and constant volume, comprising an extraction module, a preconcentration module, a purification module and a constant volume module connected in sequence; the extraction module It includes a high-pressure pump 1, a pressure-resistant extraction and cleaning tank 2, a flow path tee, a one-way valve, a pressure transmitter 11, a release valve and a stop valve; the high-pressure pump 1 is connected to the pressure-resistant extraction and the Cleaning pool 2; the other channel is connected to the release valve and pressure transmitter 11 respectively through a flow tee; the pressure transmitter 11 is connected to the check valve; the pressure-resistant extraction and cleaning pool 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com