A kind of processing method of handle paper cup

A processing method and technology for handle paper, which are applied in the manufacture of papermaking, paper/cardboard containers, rigid/semi-rigid containers, etc., can solve problems such as low efficiency, and achieve convenient operation, stable device structure, good practicability and promotion value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the accompanying drawings.

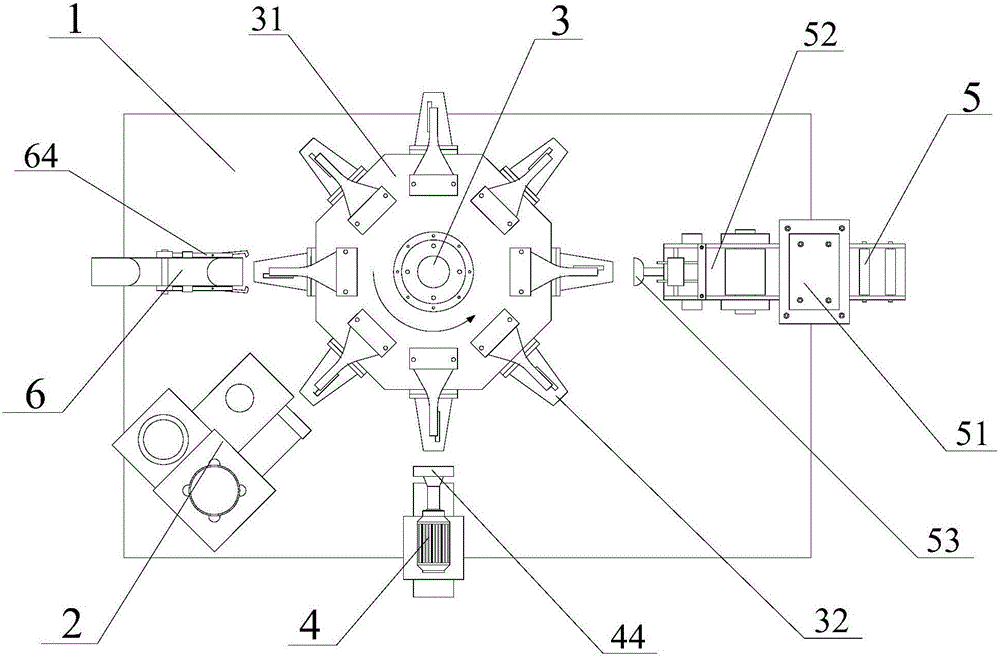

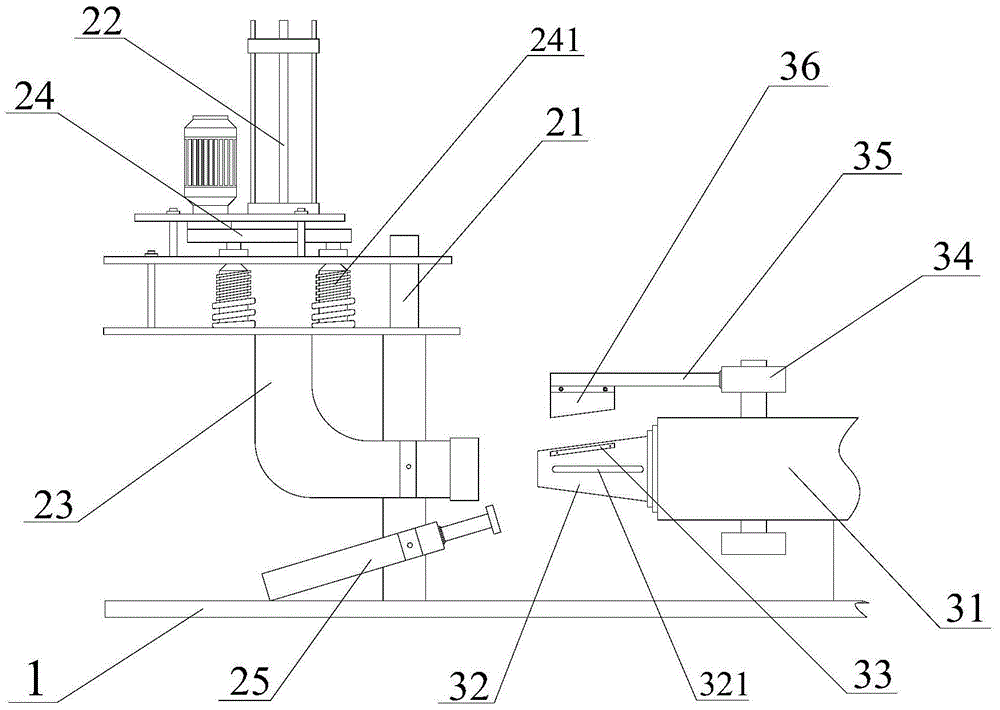

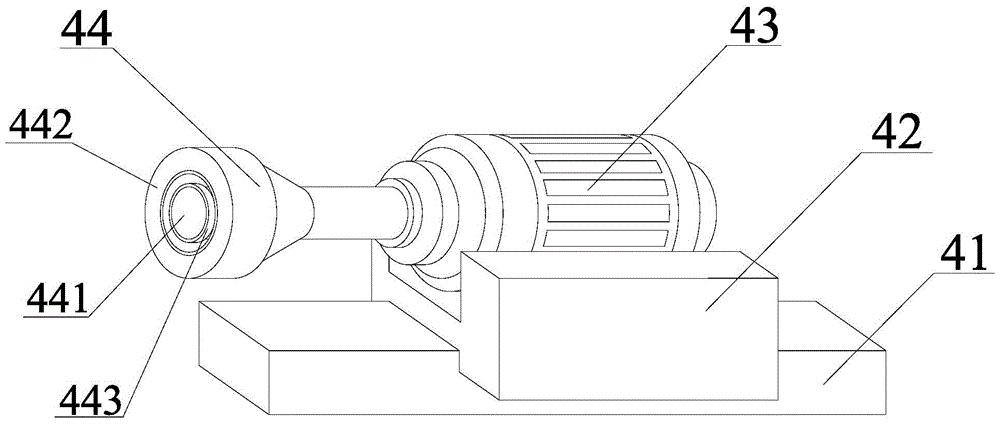

[0030] like Figure 1-5 As shown, a handle paper cup automatic patch processing device includes a frame 1, a paper cup feeding control mechanism 2, a patch control mechanism 3, a paper cup clamping mechanism 4, a handle paper feeding mechanism 5, and a cup receiving control mechanism 6.

[0031] The paper cup feeding control mechanism 2 includes a fixed bracket 21, a paper cup holder 22, a feeding tube 23, a counting control device 24 and a push rod 25. The fixed bracket 21 is vertically fixed on the frame 1, and the paper cup holder 22 Fixed on the fixing bracket 21, the counting control device 24 is installed on the lower end of the paper cup holder 22, and is connected with the feeding end of the feeding pipe 23, the feeding pipe 23 is a cylindrical curved The tube is fixed on the fixing bracket 21, the discharge end of which is facing the patch control mechanism 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com