A multi-station continuous hexagonal hole processing integrated machine

A hexagonal hole, multi-station technology, applied in metal processing machinery parts, metal processing, metal processing equipment and other directions, can solve the problems of low efficiency and high defective rate of finished products, improve processing efficiency, improve processing quality, and facilitate positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

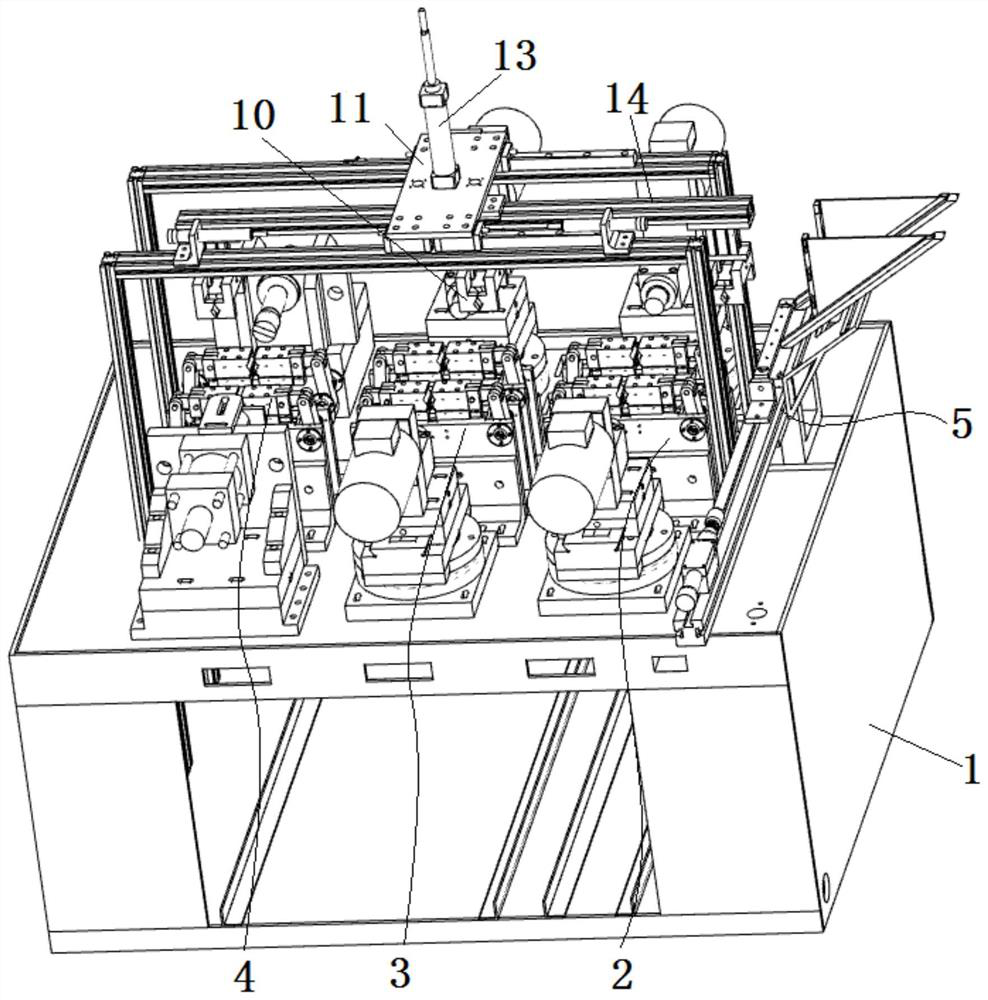

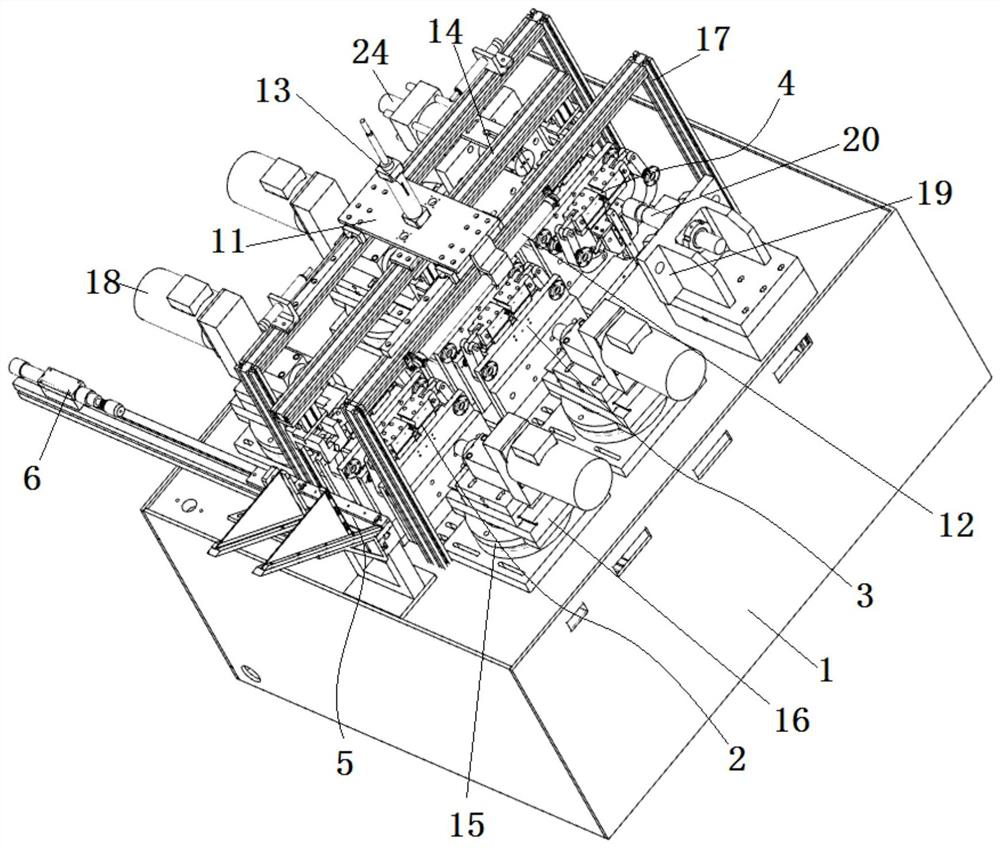

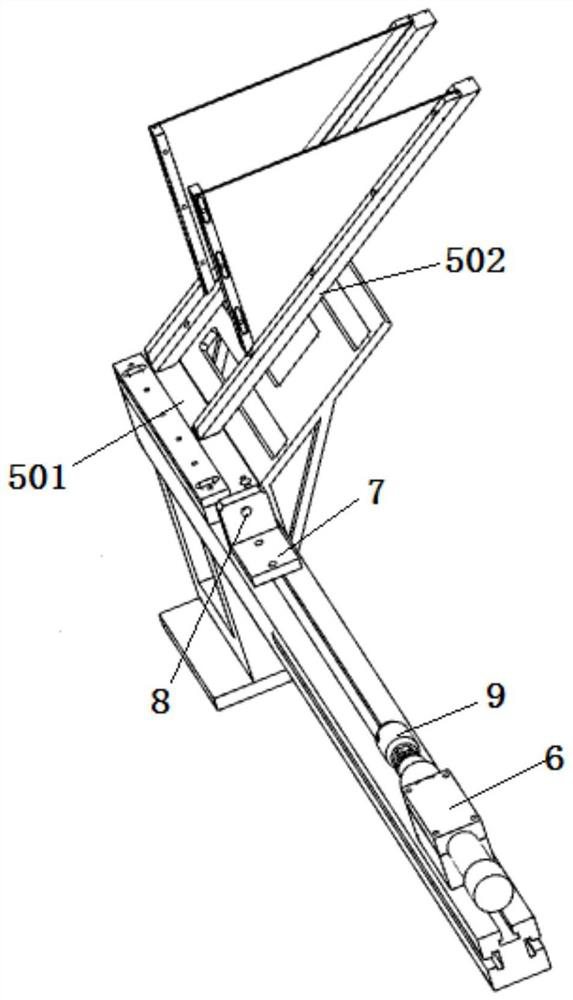

[0020] refer to Figure 1 to Figure 7 Shown: a multi-station continuous hexagonal hole processing integrated machine, including a workbench 1, on which a hole-leading station 2, a punching station 3 and a forming station 4 are arranged side by side in sequence. The station 2 is cooperatively provided with a hole-leading mechanism for processing the workpiece, the punching station 3 is cooperatively provided with a punching mechanism for processing the leading hole on the workpiece into a through hole, and the forming station 4 is cooperatively provided with a hole-piercing mechanism on the workpiece. The through hole is processed into a hole forming mechanism of a hexagonal hole; a feeding station 5 is arranged on one side of the hole introduction station 2, and a pushing mechanism is arranged on the feeding station 5, and the support frame passes through the workbench 1 17 is connected with a mobile clamping mechanism that is slidably arranged above the leading hole station 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com