Large-formwork lifting-type construction method of shear wall and cylinder concrete structure

A concrete structure and construction method technology, which is applied in the direction of formwork/formwork/work frame, house structure support, house structure support, etc., can solve the problems of large amount of labor, etc., and achieve easy disassembly and assembly, convenient fixing of rollers, and uniform concrete Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

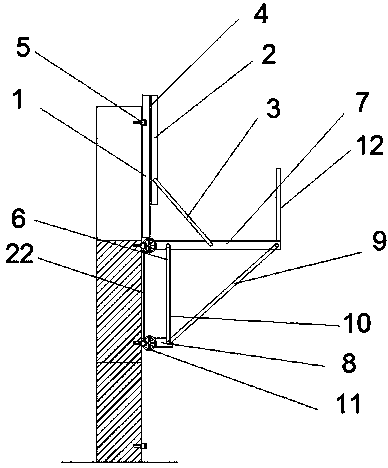

[0027] The invention discloses a large formwork lifting construction method for shear walls and cylindrical concrete structures (such as figure 1 shown), including the following steps:

[0028] 1) arrange and install tower crane;

[0029] 2) Use plywood to make a large formwork panel 1 whose height is the height of the storey, use square wood as the vertical back corrugation 2, and 8# channel steel as the horizontal back corrugation 3, and reinforce it with pull bolts 4;

[0030] 3) After the steel bars of the concrete wall to be poured are installed, install the embedded part 5 for the next wall in the concrete wall to be poured, and remove the large formwork and the panels of its support system, the vertical back corrugation, and the horizontal back corrugation;

[0031] 4) Pour and maintain the concrete. After reaching a certain strength, push the movable tripod platform 6 upward into the embedded parts of the poured wall, and use the embedded parts to fix the movable tria...

Embodiment 2

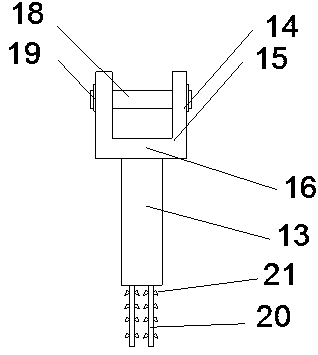

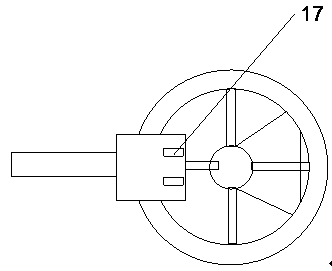

[0033] Embodiment 2: The present invention also discloses a movable triangular platform (such as figure 2 , image 3 shown), the movable triangular platform includes a supporting steel plate 7, a supporting base plate 8, a reinforcing inclined bar 9 and a vertical pole 10, a roller 11 is installed on one end of the supporting steel plate, and a guardrail is installed on the other end of the supporting steel plate 12. One end of the supporting base plate is equipped with a roller, one end of the reinforcing slanting rod is fixedly connected to one end of the supporting steel plate with a guardrail, and the other end of the reinforcing slanting rod is fixedly connected to the end of the supporting base plate away from the roller; one end of the vertical support rod is fixed Connect one end of the supporting base plate away from the roller, and the other end is fixedly connected to the side of the supporting steel plate near the roller. The concrete wall is installed with the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com