Inflation valve element, explosion-proof valve capable of detecting air tightness of box body through rapid inflation and detection method

A technology for explosion-proof valves and inflation valves, which is applied in fluid tightness testing, inflation valves, safety valves, etc. It can solve the problems of poor secondary sealing of inflation holes, low detection efficiency, and slow inflation speed, etc., to avoid Poor secondary seal, high detection efficiency and fast air intake speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

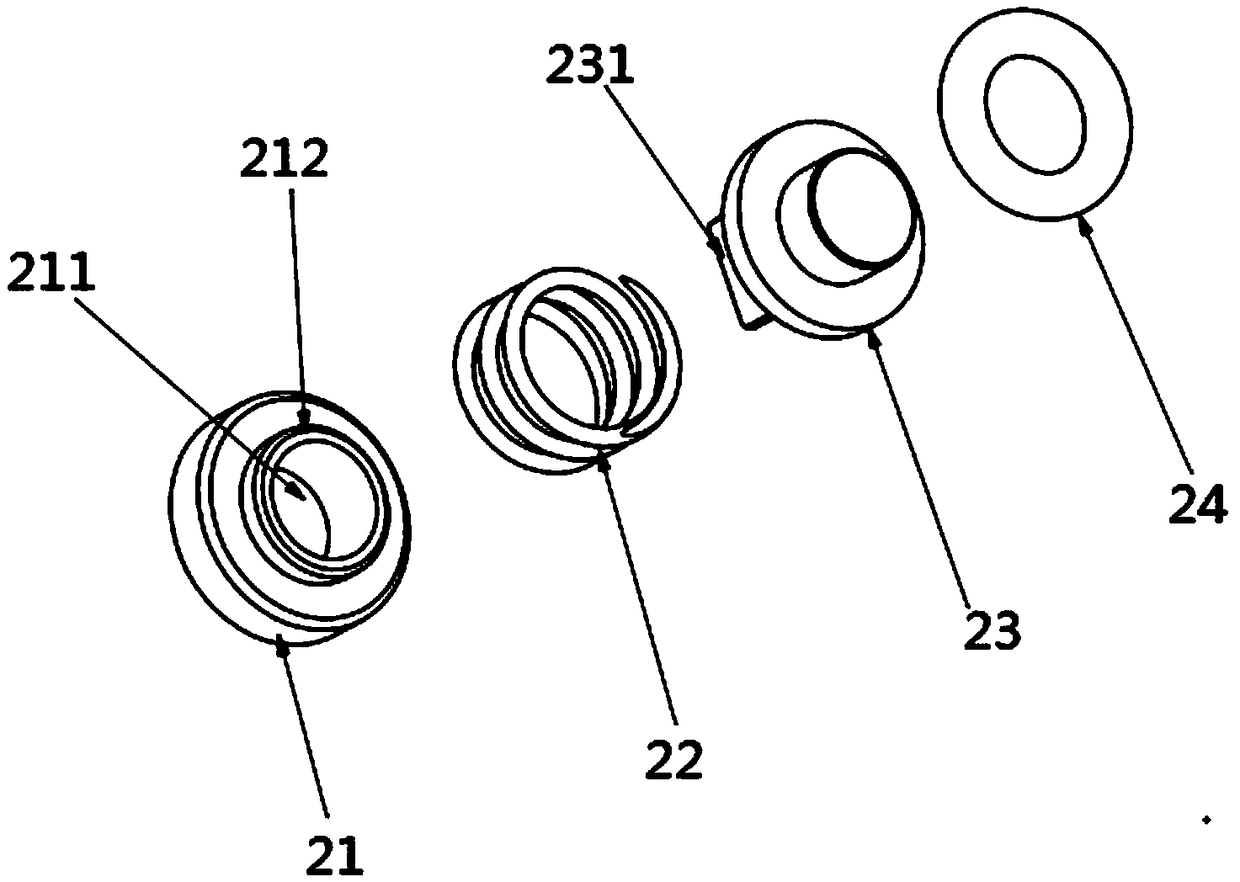

[0036] see image 3 , the invention provides an inflatable valve core, the inflatable valve core includes a fixed part 21, a compression spring 22, an inflatable piston 23, and a rubber seal 24, and one end of the inflatable piston 23 is connected to the fixed part 21 through a compressed spring 22, and the inflated The other end of the piston 23 is connected with a rubber seal 24 .

[0037] In this embodiment, one end of the inflation piston 23 is further provided with a guide post 231 , and the fixing member 21 is provided with a guide hole 211 for radially limiting the guide post 231 .

[0038] In order to prevent the inflating piston 23 from being deflected when inflated, and the seal cannot be reset after inflating, a guide column 231 is provided on the inflating piston 23, and the guiding column 231 can move up and down through the hollow fixing part 21, ensuring the accurate reset of the inflating piston 23 after inflating seal.

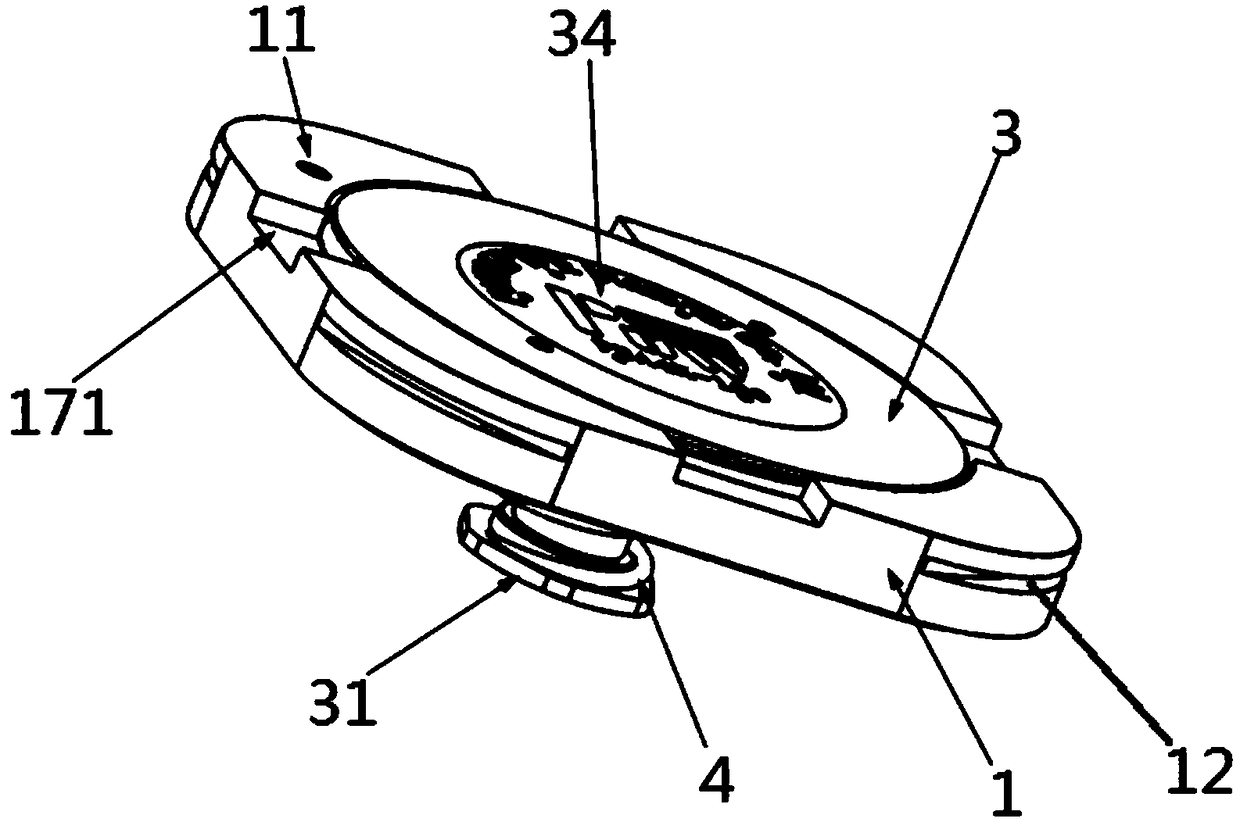

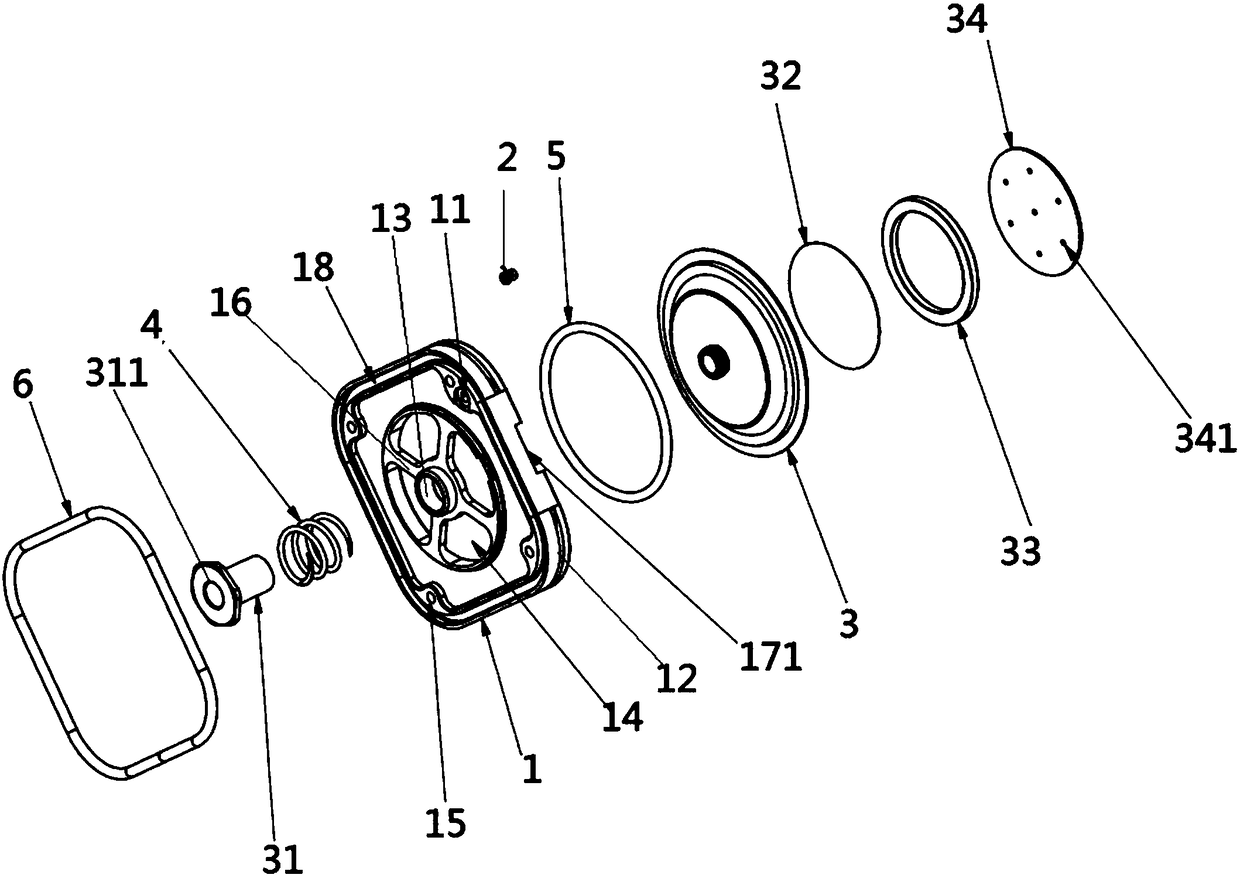

[0039] see Figure 1-4 , the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com