Preparation method of polyvinylidene fluoride mixed matrix membrane with high flux and strong pollution resistance

A polyvinylidene fluoride and mixed matrix membrane technology, applied in the field of membrane separation, can solve problems such as insufficient anti-pollution, and achieve excellent anti-pollution, enhanced anti-pollution, and increased pure water flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment is to prepare zeolite imidazolate framework-8 material (ZIF-8) by solvothermal method, and the specific steps are:

[0033] (1) 0.94g of Zn(NO 3 ) 2 ·6H 2 O is dissolved in 40mLMeOH / DI mixed solution (20mLMeOH and 20mLDI) with magnetic stirring to obtain zinc nitrate solution;

[0034] (2) 2.0762 g of 2-methylimidazole (HmIM) was dissolved in 20 mL of methanol with magnetic stirring to obtain a 2-methylimidazole solution;

[0035] (3) After fully dissolving, pour the zinc nitrate solution in step (1) into the 2-methylimidazole solution in step (2), and magnetically stir for 120 min;

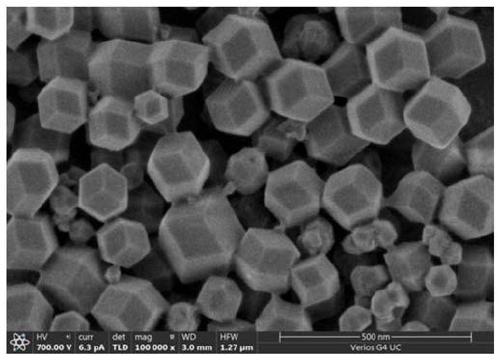

[0036] (4) The mixed solution obtained in step (3) is centrifuged, washed with methanol for 4 times, and then put into a 60° C. oven to dry to obtain ZIF-8 crystals, and the obtained ZIF-8 crystals are characterized to obtain ZIF-8 crystals. Electron microscope photographs, such as figure 1 As shown, from the electron micrographs, a granular ZIF-8 material with good sh...

Embodiment 2

[0039]In this example, the ZIF-8 particles in Example 1 are used to further prepare a polyvinylidene fluoride mixed matrix film, and the specific preparation method is as follows:

[0040] (1) Dissolve ZIF-8, PVP, and PVDF after removing the guest molecules in DMAC, the composition ratio is: PVDF:ZIF-8:PVP=10:0.1:3, stir at 80°C to fully dissolve, Stand for defoaming for 24 hours;

[0041] (2) Scrape the casting solution of step (1) on a glass plate to a film with a thickness of 150 μm;

[0042] (3) Immerse the glass plate with the film solution in step (2) into deionized water at 15°C for phase separation;

[0043] (4) Soak the membrane after phase separation in step (3) in deionized water for 3 to 8 days to remove excess solvent, and then put it into clean deionized water for storage to obtain a polyvinylidene fluoride mixed matrix membrane, which is designated as ZIF-8 / PVDF ultrafiltration membrane.

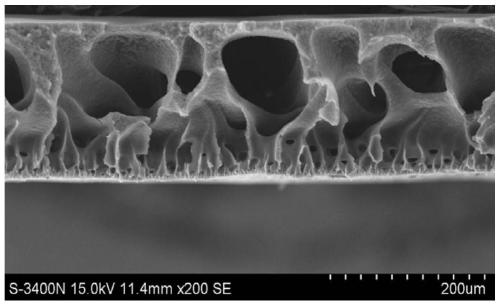

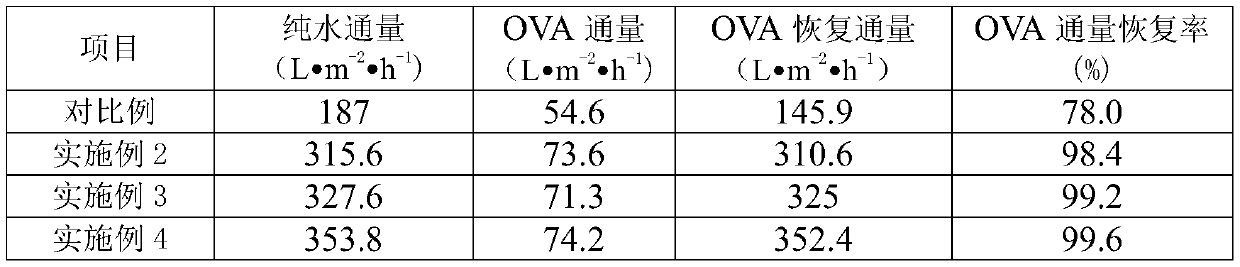

[0044] The structure of the obtained ZIF-8 / PVDF ultrafiltration membr...

Embodiment 3

[0046] In this example, the ZIF-8 particles in Example 1 are used to further prepare a polyvinylidene fluoride mixed matrix film, and the specific preparation method is as follows:

[0047] (1) Dissolve ZIF-8, PVP, and PVDF after removing the guest molecules in DMAC, the composition ratio is: PVDF:ZIF-8:PVP=20:0.3:3, stir at 80°C to fully dissolve, Stand for defoaming for 24 hours;

[0048] (2) Scrape the casting solution of step (1) on a glass plate to a film with a thickness of 180 μm;

[0049] (3) Immerse the glass plate with the membrane solution in step (2) in deionized water at 20°C for phase separation;

[0050] (4) Soak the membrane after phase separation in step (3) in deionized water for 3 to 8 days to remove excess solvent, and then put it into clean deionized water for storage to obtain a polyvinylidene fluoride mixed matrix membrane, which is designated as ZIF-8 / PVDF ultrafiltration membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com