Packaging method for optical film overlap

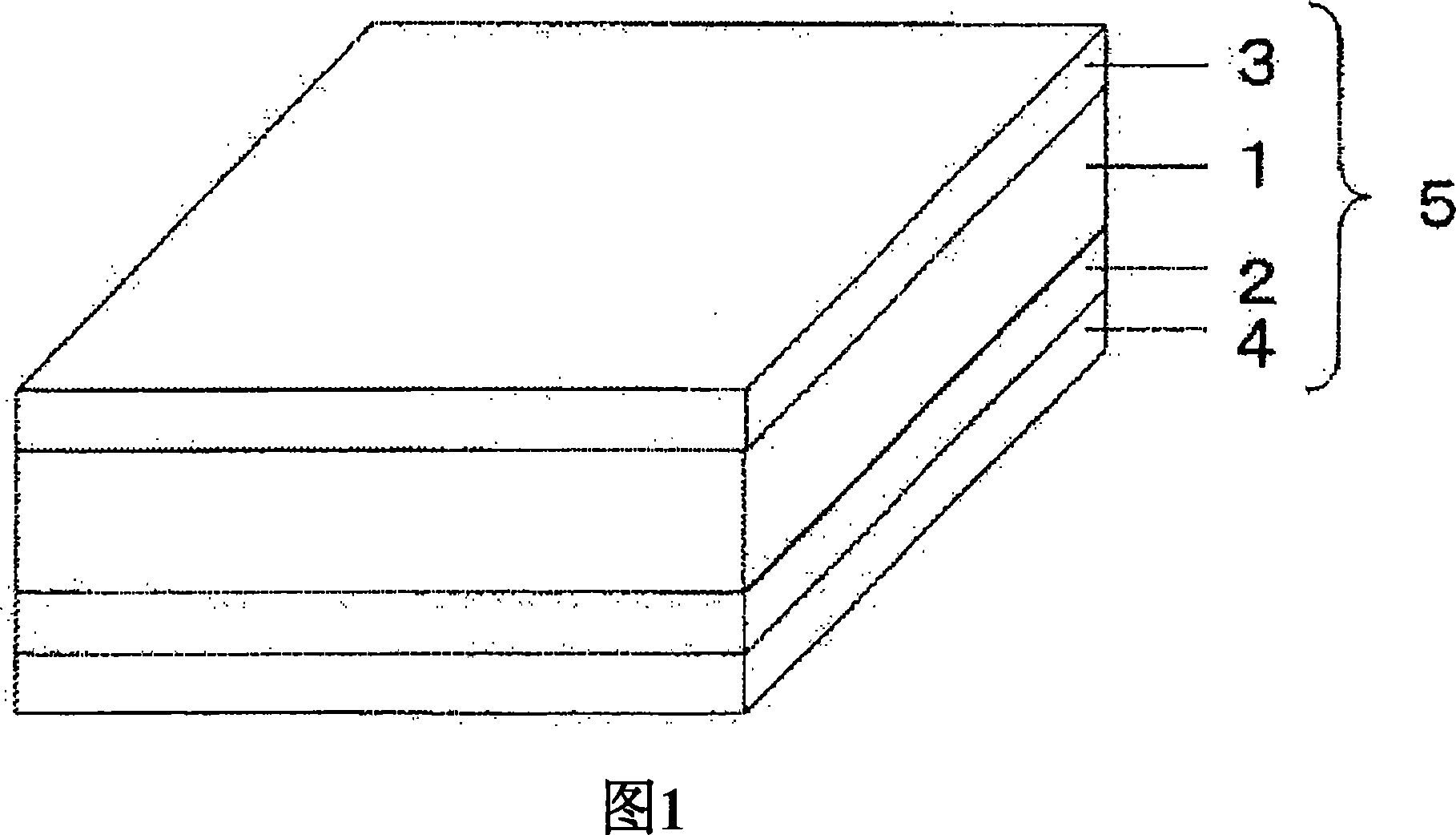

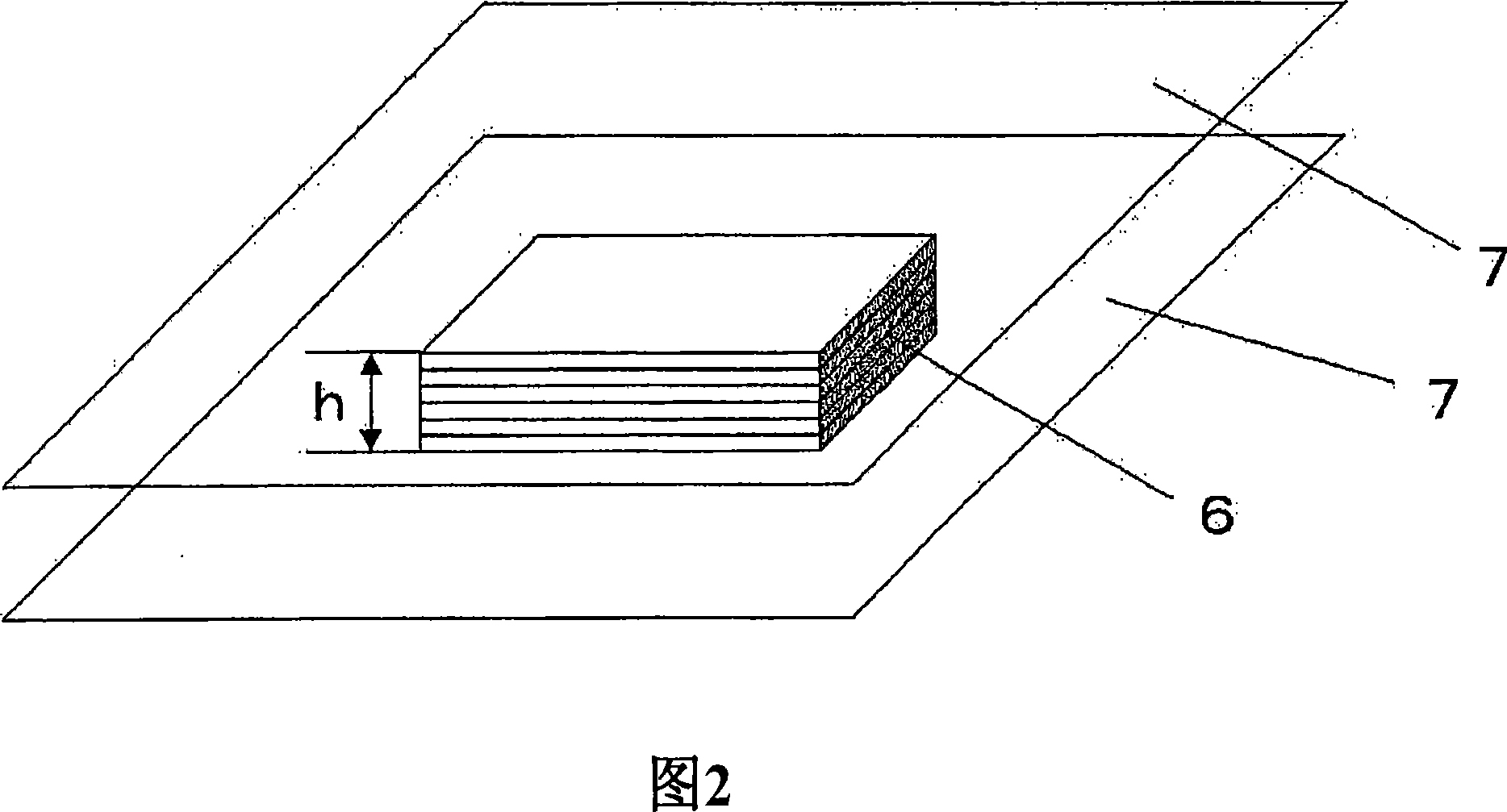

A packaging method and optical film technology, applied in packaging, wrapping paper, transportation packaging, etc., can solve the problems of sticking to the surface of optical film, troublesome and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

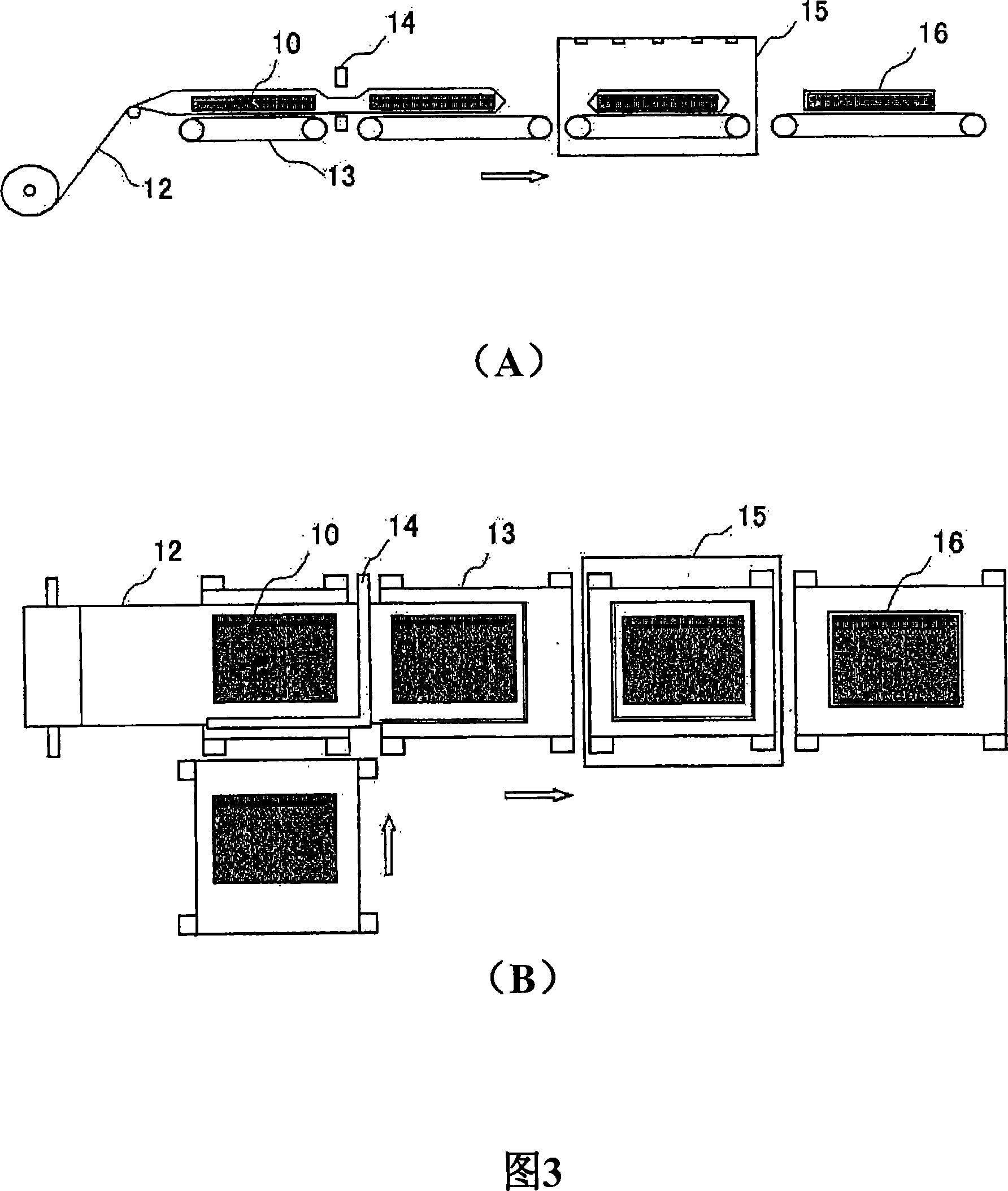

[0076] The optical film laminate was packaged using the same packaging device as shown in FIG. 3 .

[0077] (1) Optical film laminated body: Polarizing film SRF862APG6-S / 81 (manufactured by Sumitomo Chemical Co., Ltd.) was cut into 400 mm long x 300 mm wide, and 20 sheets were stacked.

[0078] (2) Packaging film: polyethylene shrink film (manufactured by Okura Kogyo Co., Ltd.), 15 μm in thickness, and 500 mm in width after being folded in half.

[0079] (3) Protective sheet: length 400mm×width 300mm×thickness 1mm, with a pear skin pattern on the surface.

[0080] (4) Packing machine: L-shaped packing machine (manufactured by Natsunki Koichi Co., Ltd.)

[0081] The optical film laminate was inserted between the packaging films folded in half at a distance of about 7 mm in the longitudinal direction and about 4 mm in the width direction, and the packaging films were heat-sealed to obtain a film packaging body.

[0082] Send it into the hot air stove, with about 1Nm 3 / cm 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com