Special high-air-flow rapid inflation valve for plasma fracture prevention

A plasma and atmospheric volume technology, applied in the fields of high-voltage technology, magnetic confinement fusion, high-pressure vessel technology, and vacuum technology, which can solve the problem that solenoid valves and piezoelectric crystal valves cannot satisfy rupture mitigation at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

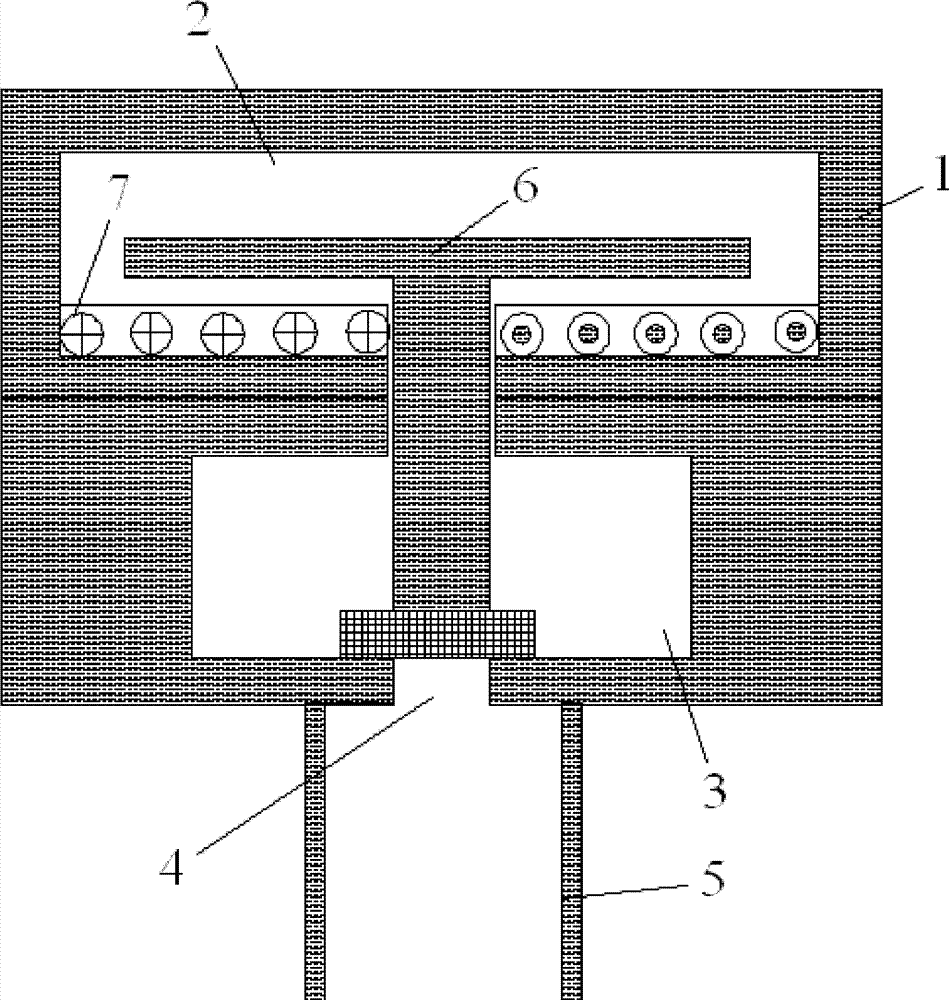

[0019] see figure 1 , a large-volume fast inflation valve dedicated to plasma rupture protection, including a valve body 1, the valve body 1 includes a back pressure chamber 2 and a working gas chamber 3, and the back pressure chamber 2 and the working gas chamber 3 are respectively externally connected High-pressure gas source, the bottom of the working gas chamber 3 is provided with an air outlet 4 and is connected with a pipeline 5 leading to the vacuum chamber of the tokamak device; Extend into the back pressure chamber 2 and the working gas chamber 3 respectively, the lower end of the I-shaped valve core 6 is against the mouth of the gas outlet 4, and the I-shaped valve core 6 is surrounded by a plane spiral coil 7, the plane The two terminals of the helical coil 7 are respectively externally connected to the positive and negative terminals of the charging capacitor.

[0020] The back pressure chamber 2 and the working gas chamber 3 are sealed with a rubber ring; the I-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com